How to Improve PMMA Processing Efficiency in Manufacturing?

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMMA Processing Background and Objectives

Poly(methyl methacrylate) (PMMA), commonly known as acrylic or plexiglass, has been a cornerstone in manufacturing since its development in the 1930s. This versatile thermoplastic has found applications across various industries due to its exceptional optical clarity, weather resistance, and mechanical properties. The evolution of PMMA processing techniques has been driven by the increasing demand for high-quality, cost-effective products in sectors such as automotive, construction, electronics, and medical devices.

The journey of PMMA processing began with simple molding techniques and has progressed to sophisticated methods like injection molding, extrusion, and thermoforming. Each advancement in processing technology has aimed to enhance efficiency, reduce waste, and improve the final product quality. The current focus in PMMA manufacturing is on developing methods that not only increase production speed but also maintain or enhance the material's desirable properties.

Recent years have seen a shift towards more sustainable and energy-efficient processing methods for PMMA. This trend is partly driven by environmental concerns and the need to reduce manufacturing costs in an increasingly competitive global market. Innovations in processing technology are now geared towards minimizing material waste, reducing energy consumption, and exploring recycling possibilities without compromising the end-product quality.

The primary objective in improving PMMA processing efficiency is to optimize the entire manufacturing cycle, from raw material preparation to final product finishing. This involves enhancing melt processing techniques, refining mold designs, and implementing advanced cooling strategies. Additionally, there is a growing emphasis on integrating automation and digital technologies to streamline production processes and ensure consistent quality.

Another critical goal is to develop processing methods that can handle the increasing complexity of PMMA-based products. As industries demand more intricate designs and multi-functional components, PMMA processing techniques must evolve to meet these challenges while maintaining high throughput and cost-effectiveness. This includes exploring new additives and blending techniques to enhance processability without sacrificing the material's inherent properties.

The pursuit of improved PMMA processing efficiency is not just about speed and cost reduction; it also encompasses the broader objectives of sustainability and circular economy principles. Research is ongoing to develop processing methods that facilitate easier recycling and reuse of PMMA products, aligning with global efforts to reduce plastic waste and promote more sustainable manufacturing practices.

The journey of PMMA processing began with simple molding techniques and has progressed to sophisticated methods like injection molding, extrusion, and thermoforming. Each advancement in processing technology has aimed to enhance efficiency, reduce waste, and improve the final product quality. The current focus in PMMA manufacturing is on developing methods that not only increase production speed but also maintain or enhance the material's desirable properties.

Recent years have seen a shift towards more sustainable and energy-efficient processing methods for PMMA. This trend is partly driven by environmental concerns and the need to reduce manufacturing costs in an increasingly competitive global market. Innovations in processing technology are now geared towards minimizing material waste, reducing energy consumption, and exploring recycling possibilities without compromising the end-product quality.

The primary objective in improving PMMA processing efficiency is to optimize the entire manufacturing cycle, from raw material preparation to final product finishing. This involves enhancing melt processing techniques, refining mold designs, and implementing advanced cooling strategies. Additionally, there is a growing emphasis on integrating automation and digital technologies to streamline production processes and ensure consistent quality.

Another critical goal is to develop processing methods that can handle the increasing complexity of PMMA-based products. As industries demand more intricate designs and multi-functional components, PMMA processing techniques must evolve to meet these challenges while maintaining high throughput and cost-effectiveness. This includes exploring new additives and blending techniques to enhance processability without sacrificing the material's inherent properties.

The pursuit of improved PMMA processing efficiency is not just about speed and cost reduction; it also encompasses the broader objectives of sustainability and circular economy principles. Research is ongoing to develop processing methods that facilitate easier recycling and reuse of PMMA products, aligning with global efforts to reduce plastic waste and promote more sustainable manufacturing practices.

Market Analysis for PMMA Products

The global market for Poly(methyl methacrylate) (PMMA) products has been experiencing steady growth, driven by increasing demand across various industries. PMMA, also known as acrylic or plexiglass, is valued for its optical clarity, weather resistance, and versatility in manufacturing processes. The automotive sector represents a significant market for PMMA products, particularly in the production of lightweight components and advanced lighting systems. As vehicle manufacturers strive for improved fuel efficiency and enhanced design aesthetics, the demand for PMMA in automotive applications continues to rise.

In the construction industry, PMMA finds extensive use in glazing applications, offering an alternative to traditional glass due to its superior impact resistance and thermal insulation properties. The growing trend towards energy-efficient buildings has further boosted the adoption of PMMA in construction projects. Additionally, the electronics and display industry heavily relies on PMMA for the production of screens, light guides, and optical components, contributing significantly to market growth.

The healthcare sector presents another crucial market for PMMA products. The material's biocompatibility and optical properties make it ideal for medical devices, dental implants, and diagnostic equipment. As healthcare technologies advance and the global population ages, the demand for PMMA in medical applications is expected to increase substantially.

Emerging applications in 3D printing and additive manufacturing have opened new avenues for PMMA market expansion. The material's compatibility with various 3D printing technologies has led to its increased use in prototyping, custom manufacturing, and small-scale production runs across multiple industries.

Geographically, Asia-Pacific dominates the PMMA market, with China and India being the major contributors to regional growth. The rapid industrialization, urbanization, and increasing disposable income in these countries drive the demand for PMMA products across various end-use industries. North America and Europe follow as mature markets, with steady demand primarily from the automotive, construction, and healthcare sectors.

Despite the positive market outlook, challenges such as volatile raw material prices and environmental concerns regarding plastic waste management pose potential obstacles to market growth. However, ongoing research and development efforts focused on improving PMMA's recyclability and developing bio-based alternatives are expected to address these challenges and create new opportunities in the market.

In the construction industry, PMMA finds extensive use in glazing applications, offering an alternative to traditional glass due to its superior impact resistance and thermal insulation properties. The growing trend towards energy-efficient buildings has further boosted the adoption of PMMA in construction projects. Additionally, the electronics and display industry heavily relies on PMMA for the production of screens, light guides, and optical components, contributing significantly to market growth.

The healthcare sector presents another crucial market for PMMA products. The material's biocompatibility and optical properties make it ideal for medical devices, dental implants, and diagnostic equipment. As healthcare technologies advance and the global population ages, the demand for PMMA in medical applications is expected to increase substantially.

Emerging applications in 3D printing and additive manufacturing have opened new avenues for PMMA market expansion. The material's compatibility with various 3D printing technologies has led to its increased use in prototyping, custom manufacturing, and small-scale production runs across multiple industries.

Geographically, Asia-Pacific dominates the PMMA market, with China and India being the major contributors to regional growth. The rapid industrialization, urbanization, and increasing disposable income in these countries drive the demand for PMMA products across various end-use industries. North America and Europe follow as mature markets, with steady demand primarily from the automotive, construction, and healthcare sectors.

Despite the positive market outlook, challenges such as volatile raw material prices and environmental concerns regarding plastic waste management pose potential obstacles to market growth. However, ongoing research and development efforts focused on improving PMMA's recyclability and developing bio-based alternatives are expected to address these challenges and create new opportunities in the market.

Current PMMA Processing Challenges

PMMA (Polymethyl Methacrylate) processing in manufacturing faces several significant challenges that impact efficiency and overall production quality. One of the primary issues is the material's sensitivity to temperature fluctuations during processing. PMMA requires precise temperature control throughout the manufacturing process, from melting to molding and cooling. Even slight deviations can lead to defects in the final product, such as warping, bubbles, or inconsistent surface finish.

Another challenge is the relatively high melt viscosity of PMMA compared to other thermoplastics. This characteristic makes it more difficult to process, particularly in injection molding applications. The high viscosity can result in longer cycle times, increased energy consumption, and potential issues with mold filling, especially for complex or thin-walled parts.

PMMA's hygroscopic nature presents an additional hurdle in processing efficiency. The material readily absorbs moisture from the environment, which can lead to quality issues if not properly addressed. Inadequate drying before processing can cause surface defects, reduced mechanical properties, and even degradation of the polymer chains. This necessitates additional pre-processing steps and careful material handling, potentially slowing down production cycles.

The material's tendency to produce static charges during processing is another concern. This can lead to problems with part ejection from molds, dust attraction, and difficulties in secondary operations such as painting or printing. Addressing these static-related issues often requires additional equipment or process modifications, impacting overall efficiency.

PMMA's relatively high shrinkage rate compared to some other plastics poses challenges in achieving tight tolerances and dimensional stability. This characteristic can necessitate more complex mold designs, longer cooling times, and potentially multiple iterations to achieve desired specifications, all of which can decrease processing efficiency.

The material's susceptibility to stress cracking under certain conditions is a further processing challenge. This can occur due to exposure to certain chemicals, improper cooling rates, or residual stresses from the molding process. Mitigating this risk often requires careful process control and potentially longer cycle times to ensure proper stress relief.

Lastly, the recycling and reprocessing of PMMA scrap present efficiency challenges. While PMMA is recyclable, the process of grinding, re-melting, and reprocessing can affect the material's properties, potentially leading to quality inconsistencies in the final product. Balancing the use of recycled material with virgin PMMA to maintain product quality while improving sustainability is an ongoing challenge in PMMA processing.

Another challenge is the relatively high melt viscosity of PMMA compared to other thermoplastics. This characteristic makes it more difficult to process, particularly in injection molding applications. The high viscosity can result in longer cycle times, increased energy consumption, and potential issues with mold filling, especially for complex or thin-walled parts.

PMMA's hygroscopic nature presents an additional hurdle in processing efficiency. The material readily absorbs moisture from the environment, which can lead to quality issues if not properly addressed. Inadequate drying before processing can cause surface defects, reduced mechanical properties, and even degradation of the polymer chains. This necessitates additional pre-processing steps and careful material handling, potentially slowing down production cycles.

The material's tendency to produce static charges during processing is another concern. This can lead to problems with part ejection from molds, dust attraction, and difficulties in secondary operations such as painting or printing. Addressing these static-related issues often requires additional equipment or process modifications, impacting overall efficiency.

PMMA's relatively high shrinkage rate compared to some other plastics poses challenges in achieving tight tolerances and dimensional stability. This characteristic can necessitate more complex mold designs, longer cooling times, and potentially multiple iterations to achieve desired specifications, all of which can decrease processing efficiency.

The material's susceptibility to stress cracking under certain conditions is a further processing challenge. This can occur due to exposure to certain chemicals, improper cooling rates, or residual stresses from the molding process. Mitigating this risk often requires careful process control and potentially longer cycle times to ensure proper stress relief.

Lastly, the recycling and reprocessing of PMMA scrap present efficiency challenges. While PMMA is recyclable, the process of grinding, re-melting, and reprocessing can affect the material's properties, potentially leading to quality inconsistencies in the final product. Balancing the use of recycled material with virgin PMMA to maintain product quality while improving sustainability is an ongoing challenge in PMMA processing.

Existing PMMA Processing Solutions

01 Optimization of PMMA processing parameters

Improving PMMA processing efficiency through optimization of various parameters such as temperature, pressure, and molding time. This approach focuses on fine-tuning the processing conditions to achieve better quality and faster production of PMMA products.- Improved extrusion and molding techniques: Advanced extrusion and molding techniques can significantly enhance PMMA processing efficiency. These methods include optimized screw designs, precise temperature control, and improved die configurations. Such techniques result in better melt homogeneity, reduced cycle times, and improved surface quality of PMMA products.

- Incorporation of additives and modifiers: The addition of specific additives and modifiers can improve the processing efficiency of PMMA. These may include lubricants, plasticizers, or impact modifiers that enhance flow properties, reduce melt viscosity, or improve impact resistance. Careful selection and optimization of these additives can lead to faster processing speeds and improved product quality.

- Optimization of polymerization process: Enhancing the polymerization process of PMMA can lead to improved processing efficiency. This may involve adjusting reaction conditions, using advanced catalysts, or implementing continuous polymerization techniques. Optimized polymerization can result in more consistent molecular weight distribution and better control over the final properties of the PMMA resin.

- Advanced thermal management systems: Implementing sophisticated thermal management systems can significantly improve PMMA processing efficiency. This includes precise heating and cooling control during extrusion or injection molding, as well as optimized annealing processes. Effective thermal management can reduce internal stresses, improve dimensional stability, and allow for faster cycle times.

- Process monitoring and automation: Integrating advanced process monitoring and automation technologies can enhance PMMA processing efficiency. This may include real-time monitoring of process parameters, adaptive control systems, and machine learning algorithms for process optimization. Such technologies can lead to more consistent product quality, reduced waste, and improved overall production efficiency.

02 Use of additives to enhance PMMA processing

Incorporating specific additives into PMMA to improve its processing characteristics. These additives can enhance flow properties, reduce cycle times, or improve the overall quality of the final product, thereby increasing processing efficiency.Expand Specific Solutions03 Advanced equipment and machinery for PMMA processing

Utilizing innovative processing equipment and machinery specifically designed for PMMA. This includes advanced injection molding machines, extrusion systems, or other specialized equipment that can significantly improve processing speed and efficiency.Expand Specific Solutions04 Novel PMMA blends and composites for improved processing

Developing new PMMA blends or composites that offer enhanced processing characteristics. These materials are designed to have improved flow properties, faster curing times, or better overall processability compared to standard PMMA.Expand Specific Solutions05 Process monitoring and control systems for PMMA manufacturing

Implementing advanced monitoring and control systems in PMMA processing. These systems can provide real-time data on processing conditions, allowing for immediate adjustments and optimizations to improve efficiency and product quality.Expand Specific Solutions

Key Players in PMMA Industry

The competition landscape for improving PMMA processing efficiency in manufacturing is characterized by a mature market with established players and ongoing innovation. The industry is in a growth phase, driven by increasing demand for high-performance plastics across various sectors. The global PMMA market size is projected to reach several billion dollars by 2025, indicating significant opportunities. Technologically, companies like Röhm GmbH, Trinseo Europe GmbH, and Mitsubishi Rayon Co Ltd are at the forefront, leveraging their extensive experience in PMMA production. Academic institutions such as Fudan University and Sichuan University are contributing to advancements through research collaborations. Emerging players like Suzhou Double Elephant Optical Materials Co. Ltd. are also making strides in developing innovative processing techniques.

Röhm GmbH

Technical Solution: Röhm GmbH has developed advanced PMMA processing techniques to improve manufacturing efficiency. They utilize a continuous bulk polymerization process that allows for higher throughput and reduced energy consumption[1]. The company has also implemented innovative extrusion technologies, such as multi-layer co-extrusion, which enables the production of PMMA sheets with enhanced properties in a single step[2]. Additionally, Röhm has invested in automation and digitalization of their production lines, incorporating real-time process monitoring and adaptive control systems to optimize PMMA processing parameters and minimize waste[3].

Strengths: Industry-leading expertise in PMMA production, advanced process technologies, and strong R&D capabilities. Weaknesses: High capital investment required for cutting-edge equipment and potential dependency on specific raw material suppliers.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has made significant strides in improving PMMA processing efficiency. The company has developed a large-scale continuous bulk polymerization process that increases production capacity while reducing energy consumption[10]. Sinopec has also implemented advanced catalyst systems that allow for better control of molecular weight distribution, resulting in PMMA grades with improved processability and reduced cycle times[11]. Furthermore, the company has invested in state-of-the-art extrusion and molding equipment, incorporating process simulation and optimization software to fine-tune processing parameters and maximize efficiency[12].

Strengths: Large-scale production capabilities, vertical integration with raw material supply, and strong domestic market presence. Weaknesses: Potential challenges in meeting stringent international quality standards and limited brand recognition in global specialty plastics markets.

Innovative PMMA Processing Techniques

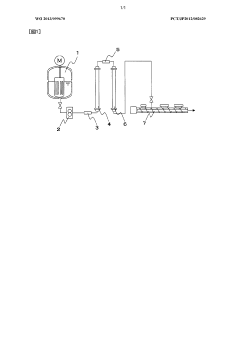

Method for manufacturing methacrylic polymer

PatentWO2013099670A1

Innovation

- A method involving continuous bulk polymerization using a complete mixing reactor and plug flow reactor, with specific conditions for adding radical polymerization initiators and controlling temperatures and half-lives to stabilize the polymerization process, ensuring high productivity and thermal decomposition resistance.

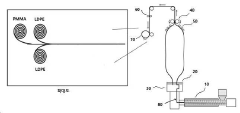

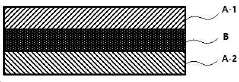

Manufacturing method of polymethylmethacrylate blown film

PatentInactiveKR1020230035894A

Innovation

- A method involving co-extrusion of polyethylene (PE) resin with polymethyl methacrylate (PMMA) resin, forming a multilayer film with PE layers on both sides of the PMMA film, followed by biaxial stretching to enhance physical properties.

Environmental Impact of PMMA Processing

The environmental impact of PMMA processing is a critical consideration in the quest to improve manufacturing efficiency. PMMA, or polymethyl methacrylate, is widely used in various industries due to its versatility and optical properties. However, its production and processing can have significant environmental implications that need to be addressed.

One of the primary environmental concerns associated with PMMA processing is energy consumption. The manufacturing process, particularly during polymerization and molding stages, requires substantial energy input. This high energy demand contributes to increased carbon emissions and overall environmental footprint. Improving energy efficiency in PMMA processing is crucial for reducing its environmental impact and aligning with global sustainability goals.

Waste generation is another significant environmental issue in PMMA manufacturing. The production process can result in material waste, including off-cuts, rejected parts, and process scraps. These waste materials, if not properly managed, can lead to increased landfill usage and potential soil and water contamination. Implementing effective recycling and waste reduction strategies is essential for minimizing the environmental burden of PMMA processing.

Chemical emissions during PMMA processing pose additional environmental challenges. Volatile organic compounds (VOCs) and other potentially harmful substances may be released during various stages of production, including polymerization and molding. These emissions can contribute to air pollution and pose health risks to workers and surrounding communities. Adopting cleaner production technologies and improving ventilation systems are crucial steps in mitigating these environmental and health concerns.

Water usage and potential water pollution are also important environmental aspects of PMMA processing. The manufacturing process may require significant amounts of water for cooling and cleaning purposes. Proper water management, including recycling and treatment of wastewater, is necessary to reduce the strain on local water resources and prevent contamination of water bodies.

The lifecycle impact of PMMA products is an additional environmental consideration. While PMMA is durable and long-lasting, its end-of-life disposal can be problematic. Improving the recyclability of PMMA products and developing more efficient recycling processes are essential for reducing the long-term environmental impact of these materials.

Addressing these environmental challenges in PMMA processing not only contributes to sustainability goals but can also lead to improved manufacturing efficiency. By focusing on energy-efficient processes, waste reduction, and cleaner production methods, manufacturers can simultaneously reduce their environmental footprint and operational costs. This alignment of environmental and economic objectives is crucial for the long-term sustainability of PMMA manufacturing in an increasingly eco-conscious global market.

One of the primary environmental concerns associated with PMMA processing is energy consumption. The manufacturing process, particularly during polymerization and molding stages, requires substantial energy input. This high energy demand contributes to increased carbon emissions and overall environmental footprint. Improving energy efficiency in PMMA processing is crucial for reducing its environmental impact and aligning with global sustainability goals.

Waste generation is another significant environmental issue in PMMA manufacturing. The production process can result in material waste, including off-cuts, rejected parts, and process scraps. These waste materials, if not properly managed, can lead to increased landfill usage and potential soil and water contamination. Implementing effective recycling and waste reduction strategies is essential for minimizing the environmental burden of PMMA processing.

Chemical emissions during PMMA processing pose additional environmental challenges. Volatile organic compounds (VOCs) and other potentially harmful substances may be released during various stages of production, including polymerization and molding. These emissions can contribute to air pollution and pose health risks to workers and surrounding communities. Adopting cleaner production technologies and improving ventilation systems are crucial steps in mitigating these environmental and health concerns.

Water usage and potential water pollution are also important environmental aspects of PMMA processing. The manufacturing process may require significant amounts of water for cooling and cleaning purposes. Proper water management, including recycling and treatment of wastewater, is necessary to reduce the strain on local water resources and prevent contamination of water bodies.

The lifecycle impact of PMMA products is an additional environmental consideration. While PMMA is durable and long-lasting, its end-of-life disposal can be problematic. Improving the recyclability of PMMA products and developing more efficient recycling processes are essential for reducing the long-term environmental impact of these materials.

Addressing these environmental challenges in PMMA processing not only contributes to sustainability goals but can also lead to improved manufacturing efficiency. By focusing on energy-efficient processes, waste reduction, and cleaner production methods, manufacturers can simultaneously reduce their environmental footprint and operational costs. This alignment of environmental and economic objectives is crucial for the long-term sustainability of PMMA manufacturing in an increasingly eco-conscious global market.

Quality Control in PMMA Manufacturing

Quality control plays a crucial role in PMMA manufacturing, ensuring the production of high-quality materials that meet industry standards and customer specifications. Effective quality control measures are essential for improving PMMA processing efficiency and reducing waste, ultimately leading to cost savings and increased productivity.

One of the primary aspects of quality control in PMMA manufacturing is the monitoring of raw materials. This involves rigorous testing of incoming monomers, initiators, and additives to ensure they meet the required specifications. Advanced analytical techniques, such as gas chromatography and spectroscopy, are employed to detect impurities and verify the composition of raw materials.

Process control is another critical component of quality assurance in PMMA production. This includes continuous monitoring of key parameters such as temperature, pressure, and reaction time during polymerization. Real-time data collection and analysis enable operators to make timely adjustments to maintain optimal processing conditions, thereby enhancing efficiency and product consistency.

In-line testing and inspection methods are increasingly being implemented to assess the properties of PMMA throughout the manufacturing process. These may include rheological measurements to evaluate melt flow characteristics, optical tests to check for clarity and color consistency, and mechanical property assessments to ensure the material meets strength and durability requirements.

Statistical process control (SPC) techniques are widely used in PMMA manufacturing to identify and reduce variability in production. By analyzing trends and patterns in quality data, manufacturers can detect potential issues early and implement corrective actions before they lead to significant problems or production inefficiencies.

Advanced quality control systems often incorporate automated inspection technologies, such as machine vision systems and laser scanning devices. These tools can rapidly detect surface defects, dimensional inconsistencies, and other quality issues in PMMA sheets or molded parts, allowing for immediate corrective action and minimizing the production of off-spec material.

Traceability is an important aspect of quality control in PMMA manufacturing. Implementing robust lot tracking systems enables manufacturers to trace materials throughout the production process and supply chain. This capability is crucial for identifying the root cause of quality issues and facilitating targeted recalls if necessary.

Continuous improvement initiatives, such as Six Sigma and Lean Manufacturing, are frequently applied in PMMA production facilities to enhance quality control processes. These methodologies focus on reducing defects, minimizing variability, and streamlining operations to achieve higher levels of efficiency and product quality.

One of the primary aspects of quality control in PMMA manufacturing is the monitoring of raw materials. This involves rigorous testing of incoming monomers, initiators, and additives to ensure they meet the required specifications. Advanced analytical techniques, such as gas chromatography and spectroscopy, are employed to detect impurities and verify the composition of raw materials.

Process control is another critical component of quality assurance in PMMA production. This includes continuous monitoring of key parameters such as temperature, pressure, and reaction time during polymerization. Real-time data collection and analysis enable operators to make timely adjustments to maintain optimal processing conditions, thereby enhancing efficiency and product consistency.

In-line testing and inspection methods are increasingly being implemented to assess the properties of PMMA throughout the manufacturing process. These may include rheological measurements to evaluate melt flow characteristics, optical tests to check for clarity and color consistency, and mechanical property assessments to ensure the material meets strength and durability requirements.

Statistical process control (SPC) techniques are widely used in PMMA manufacturing to identify and reduce variability in production. By analyzing trends and patterns in quality data, manufacturers can detect potential issues early and implement corrective actions before they lead to significant problems or production inefficiencies.

Advanced quality control systems often incorporate automated inspection technologies, such as machine vision systems and laser scanning devices. These tools can rapidly detect surface defects, dimensional inconsistencies, and other quality issues in PMMA sheets or molded parts, allowing for immediate corrective action and minimizing the production of off-spec material.

Traceability is an important aspect of quality control in PMMA manufacturing. Implementing robust lot tracking systems enables manufacturers to trace materials throughout the production process and supply chain. This capability is crucial for identifying the root cause of quality issues and facilitating targeted recalls if necessary.

Continuous improvement initiatives, such as Six Sigma and Lean Manufacturing, are frequently applied in PMMA production facilities to enhance quality control processes. These methodologies focus on reducing defects, minimizing variability, and streamlining operations to achieve higher levels of efficiency and product quality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!