PMMA Solutions for Low-Emission Transportation

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMMA in Transportation: Background and Objectives

Polymethyl methacrylate (PMMA), commonly known as acrylic or plexiglass, has emerged as a crucial material in the transportation industry's pursuit of low-emission solutions. The evolution of PMMA in transportation can be traced back to the mid-20th century when it was first introduced as a lightweight alternative to glass in aircraft windows. Since then, its applications have expanded significantly, driven by the growing demand for fuel-efficient and environmentally friendly vehicles.

The primary objective of incorporating PMMA in transportation is to reduce vehicle weight, thereby improving fuel efficiency and reducing emissions. As global environmental regulations become increasingly stringent, automotive manufacturers are under pressure to develop vehicles with lower carbon footprints. PMMA, with its excellent optical properties, durability, and lightweight nature, offers a compelling solution to this challenge.

In recent years, the focus on PMMA in transportation has shifted from mere weight reduction to a more holistic approach. Researchers and engineers are now exploring ways to enhance PMMA's properties to meet the specific demands of modern transportation. This includes improving its impact resistance, thermal stability, and weatherability to ensure its suitability for a wide range of automotive applications.

The current technological landscape surrounding PMMA in transportation is characterized by continuous innovation. Advancements in polymer science have led to the development of new PMMA formulations with enhanced properties, such as increased scratch resistance and improved UV stability. These innovations are expanding the potential applications of PMMA beyond traditional uses, enabling its integration into more critical components of vehicles.

As the automotive industry transitions towards electric and autonomous vehicles, the role of PMMA is expected to evolve further. The material's transparency and formability make it an ideal candidate for integrating sensors, displays, and other electronic components essential for next-generation vehicles. This trend aligns with the broader objective of creating smarter, safer, and more energy-efficient transportation systems.

The development of PMMA solutions for low-emission transportation is not without challenges. Researchers are working to address issues such as the material's relatively low heat resistance and susceptibility to certain chemicals. Overcoming these limitations is crucial for expanding PMMA's use in more demanding automotive applications and ensuring its long-term viability as a sustainable material in transportation.

Looking ahead, the objectives for PMMA in transportation extend beyond mere material improvements. There is a growing emphasis on developing circular economy solutions, focusing on the recyclability and end-of-life management of PMMA components. This aligns with the broader sustainability goals of the transportation industry and represents a key area for future research and development.

The primary objective of incorporating PMMA in transportation is to reduce vehicle weight, thereby improving fuel efficiency and reducing emissions. As global environmental regulations become increasingly stringent, automotive manufacturers are under pressure to develop vehicles with lower carbon footprints. PMMA, with its excellent optical properties, durability, and lightweight nature, offers a compelling solution to this challenge.

In recent years, the focus on PMMA in transportation has shifted from mere weight reduction to a more holistic approach. Researchers and engineers are now exploring ways to enhance PMMA's properties to meet the specific demands of modern transportation. This includes improving its impact resistance, thermal stability, and weatherability to ensure its suitability for a wide range of automotive applications.

The current technological landscape surrounding PMMA in transportation is characterized by continuous innovation. Advancements in polymer science have led to the development of new PMMA formulations with enhanced properties, such as increased scratch resistance and improved UV stability. These innovations are expanding the potential applications of PMMA beyond traditional uses, enabling its integration into more critical components of vehicles.

As the automotive industry transitions towards electric and autonomous vehicles, the role of PMMA is expected to evolve further. The material's transparency and formability make it an ideal candidate for integrating sensors, displays, and other electronic components essential for next-generation vehicles. This trend aligns with the broader objective of creating smarter, safer, and more energy-efficient transportation systems.

The development of PMMA solutions for low-emission transportation is not without challenges. Researchers are working to address issues such as the material's relatively low heat resistance and susceptibility to certain chemicals. Overcoming these limitations is crucial for expanding PMMA's use in more demanding automotive applications and ensuring its long-term viability as a sustainable material in transportation.

Looking ahead, the objectives for PMMA in transportation extend beyond mere material improvements. There is a growing emphasis on developing circular economy solutions, focusing on the recyclability and end-of-life management of PMMA components. This aligns with the broader sustainability goals of the transportation industry and represents a key area for future research and development.

Market Analysis for Low-Emission Vehicle Materials

The market for low-emission vehicle materials, particularly PMMA (Polymethyl Methacrylate) solutions, is experiencing significant growth driven by the global push towards sustainable transportation. As governments worldwide implement stricter emissions regulations, automakers are increasingly turning to lightweight materials to improve fuel efficiency and reduce carbon footprints. PMMA, known for its high strength-to-weight ratio and excellent optical properties, has emerged as a key player in this market.

The demand for PMMA in the automotive sector is primarily fueled by its application in lightweight glazing, interior components, and exterior parts. The global market for automotive PMMA is projected to grow steadily over the next decade, with a compound annual growth rate (CAGR) exceeding the overall automotive materials market. This growth is attributed to the material's versatility, durability, and potential for reducing vehicle weight without compromising safety or aesthetics.

In terms of regional distribution, Asia-Pacific leads the market for automotive PMMA, followed by Europe and North America. The dominance of the Asia-Pacific region is largely due to the rapid growth of the automotive industry in countries like China and India, coupled with increasing environmental regulations. Europe's strong position is driven by stringent emission standards and a focus on electric vehicle production, where lightweight materials play a crucial role.

The market landscape is characterized by a mix of established chemical companies and specialized automotive material suppliers. Key players are investing heavily in research and development to enhance PMMA's properties and expand its applications in low-emission vehicles. Innovations focus on improving impact resistance, weatherability, and recyclability of PMMA products, aligning with the automotive industry's sustainability goals.

Consumer trends are also shaping the market, with a growing preference for vehicles that offer both environmental benefits and advanced features. PMMA's ability to integrate with smart technologies, such as heads-up displays and advanced lighting systems, positions it favorably in the evolving automotive market. This trend is expected to drive further adoption of PMMA in premium and electric vehicle segments.

However, the market faces challenges, including competition from other lightweight materials such as polycarbonate and the need for cost-effective production methods. The volatility of raw material prices and the impact of global supply chain disruptions also pose potential risks to market growth. Despite these challenges, the overall outlook for PMMA in low-emission transportation remains positive, supported by ongoing technological advancements and the automotive industry's commitment to sustainability.

The demand for PMMA in the automotive sector is primarily fueled by its application in lightweight glazing, interior components, and exterior parts. The global market for automotive PMMA is projected to grow steadily over the next decade, with a compound annual growth rate (CAGR) exceeding the overall automotive materials market. This growth is attributed to the material's versatility, durability, and potential for reducing vehicle weight without compromising safety or aesthetics.

In terms of regional distribution, Asia-Pacific leads the market for automotive PMMA, followed by Europe and North America. The dominance of the Asia-Pacific region is largely due to the rapid growth of the automotive industry in countries like China and India, coupled with increasing environmental regulations. Europe's strong position is driven by stringent emission standards and a focus on electric vehicle production, where lightweight materials play a crucial role.

The market landscape is characterized by a mix of established chemical companies and specialized automotive material suppliers. Key players are investing heavily in research and development to enhance PMMA's properties and expand its applications in low-emission vehicles. Innovations focus on improving impact resistance, weatherability, and recyclability of PMMA products, aligning with the automotive industry's sustainability goals.

Consumer trends are also shaping the market, with a growing preference for vehicles that offer both environmental benefits and advanced features. PMMA's ability to integrate with smart technologies, such as heads-up displays and advanced lighting systems, positions it favorably in the evolving automotive market. This trend is expected to drive further adoption of PMMA in premium and electric vehicle segments.

However, the market faces challenges, including competition from other lightweight materials such as polycarbonate and the need for cost-effective production methods. The volatility of raw material prices and the impact of global supply chain disruptions also pose potential risks to market growth. Despite these challenges, the overall outlook for PMMA in low-emission transportation remains positive, supported by ongoing technological advancements and the automotive industry's commitment to sustainability.

Current PMMA Applications and Challenges in Vehicles

Polymethyl methacrylate (PMMA), commonly known as acrylic or plexiglass, has found extensive applications in the automotive industry due to its unique properties. In vehicles, PMMA is primarily used for lighting components, instrument panels, and various interior and exterior trim elements. Its lightweight nature, optical clarity, and weather resistance make it an ideal material for headlights, taillights, and indicator lamps, enhancing both aesthetics and functionality.

However, the use of PMMA in vehicles faces several challenges. One of the primary concerns is its relatively low heat resistance compared to other engineering plastics. This limitation can lead to deformation or degradation of PMMA components in high-temperature environments, such as those near engine compartments or in regions with extreme climates. Additionally, PMMA's susceptibility to scratching and chemical attack from certain automotive fluids poses durability issues, particularly for exterior applications.

Another significant challenge is the material's impact resistance. While PMMA offers good impact strength compared to glass, it falls short when compared to other engineering plastics like polycarbonate. This limitation necessitates careful design considerations, especially for safety-critical components. Furthermore, the processing of PMMA for complex automotive parts can be challenging, requiring specialized molding techniques and equipment to achieve desired shapes and surface finishes.

In the context of low-emission transportation, PMMA's role becomes more critical. Its lightweight properties contribute to overall vehicle weight reduction, which directly impacts fuel efficiency and emissions. However, the automotive industry's shift towards electric and hybrid vehicles presents new challenges for PMMA applications. These include the need for enhanced thermal management solutions and integration with advanced electronic systems.

The recyclability of PMMA is another area of focus in the automotive sector's sustainability efforts. While PMMA is recyclable, the process is not as straightforward as with some other plastics, particularly when it comes to separating and purifying PMMA components from multi-material automotive parts. This challenge aligns with the broader industry trend towards circular economy principles and the need for more easily recyclable materials in vehicle design.

As the automotive industry continues to evolve, addressing these challenges while leveraging PMMA's benefits becomes crucial. Innovations in PMMA formulations, such as heat-stabilized grades and scratch-resistant coatings, are being developed to overcome some of these limitations. Additionally, advancements in processing technologies and design methodologies are enabling more efficient use of PMMA in complex automotive applications, further solidifying its position as a key material in modern vehicle manufacturing.

However, the use of PMMA in vehicles faces several challenges. One of the primary concerns is its relatively low heat resistance compared to other engineering plastics. This limitation can lead to deformation or degradation of PMMA components in high-temperature environments, such as those near engine compartments or in regions with extreme climates. Additionally, PMMA's susceptibility to scratching and chemical attack from certain automotive fluids poses durability issues, particularly for exterior applications.

Another significant challenge is the material's impact resistance. While PMMA offers good impact strength compared to glass, it falls short when compared to other engineering plastics like polycarbonate. This limitation necessitates careful design considerations, especially for safety-critical components. Furthermore, the processing of PMMA for complex automotive parts can be challenging, requiring specialized molding techniques and equipment to achieve desired shapes and surface finishes.

In the context of low-emission transportation, PMMA's role becomes more critical. Its lightweight properties contribute to overall vehicle weight reduction, which directly impacts fuel efficiency and emissions. However, the automotive industry's shift towards electric and hybrid vehicles presents new challenges for PMMA applications. These include the need for enhanced thermal management solutions and integration with advanced electronic systems.

The recyclability of PMMA is another area of focus in the automotive sector's sustainability efforts. While PMMA is recyclable, the process is not as straightforward as with some other plastics, particularly when it comes to separating and purifying PMMA components from multi-material automotive parts. This challenge aligns with the broader industry trend towards circular economy principles and the need for more easily recyclable materials in vehicle design.

As the automotive industry continues to evolve, addressing these challenges while leveraging PMMA's benefits becomes crucial. Innovations in PMMA formulations, such as heat-stabilized grades and scratch-resistant coatings, are being developed to overcome some of these limitations. Additionally, advancements in processing technologies and design methodologies are enabling more efficient use of PMMA in complex automotive applications, further solidifying its position as a key material in modern vehicle manufacturing.

Existing PMMA Solutions for Emission Reduction

01 PMMA emission reduction in manufacturing processes

Various techniques are employed to reduce PMMA emissions during manufacturing processes. These include optimizing polymerization conditions, implementing closed-loop systems, and using advanced filtration technologies. Such methods help minimize the release of volatile organic compounds and particulate matter associated with PMMA production.- PMMA emission reduction in manufacturing processes: Various methods are employed to reduce PMMA emissions during manufacturing processes. These include optimizing production parameters, implementing closed-loop systems, and using advanced filtration technologies. Such approaches aim to minimize the release of volatile organic compounds and particulate matter associated with PMMA production.

- PMMA recycling and waste management: Techniques for recycling PMMA and managing its waste are developed to reduce environmental impact. These include mechanical recycling, chemical depolymerization, and thermal treatment methods. Efficient recycling processes help minimize PMMA emissions by reducing the need for new production and preventing improper disposal.

- PMMA emission control in 3D printing applications: Strategies are implemented to control PMMA emissions in 3D printing applications. These include the use of enclosed printing environments, improved ventilation systems, and the development of low-emission PMMA-based filaments. Such measures aim to reduce exposure to potentially harmful particles and vapors during the 3D printing process.

- PMMA-based coatings with reduced emissions: Development of PMMA-based coatings with reduced emissions focuses on formulation improvements and application techniques. This includes the use of water-based systems, high-solid content formulations, and UV-curable PMMA coatings. These innovations aim to lower volatile organic compound emissions while maintaining desired coating properties.

- Monitoring and analysis of PMMA emissions: Advanced methods for monitoring and analyzing PMMA emissions are developed to assess environmental impact and ensure compliance with regulations. These include real-time monitoring systems, improved sampling techniques, and sophisticated analytical instruments. Such tools enable better understanding and control of PMMA emissions across various industries and applications.

02 PMMA recycling and waste management

Innovative approaches for recycling PMMA and managing its waste are developed to reduce environmental impact. These include chemical depolymerization, mechanical recycling, and thermal recovery methods. Efficient recycling processes help minimize PMMA emissions by reducing the need for new production and preventing improper disposal.Expand Specific Solutions03 Low-emission PMMA formulations

Research focuses on developing PMMA formulations with reduced emissions. This involves modifying the polymer structure, incorporating additives, or using alternative monomers to create PMMA variants that release fewer volatile organic compounds during processing and use. These formulations aim to maintain desirable properties while minimizing environmental impact.Expand Specific Solutions04 PMMA emission monitoring and control systems

Advanced monitoring and control systems are implemented to detect, measure, and mitigate PMMA emissions in industrial settings. These systems utilize sensors, real-time data analysis, and automated control mechanisms to ensure compliance with environmental regulations and minimize the release of harmful substances associated with PMMA production and processing.Expand Specific Solutions05 PMMA alternatives for emission-sensitive applications

Development of alternative materials to replace PMMA in applications where emissions are a critical concern. These alternatives may include other polymers, composites, or hybrid materials that offer similar optical and mechanical properties to PMMA but with reduced volatile organic compound emissions. The focus is on maintaining performance while improving environmental compatibility.Expand Specific Solutions

Key Players in PMMA and Automotive Materials

The PMMA solutions for low-emission transportation market is in a growth phase, driven by increasing demand for lightweight and sustainable materials in the automotive and transportation sectors. The market size is expanding as more manufacturers adopt PMMA-based components to reduce vehicle weight and improve fuel efficiency. Technologically, PMMA solutions are maturing, with companies like Kingfa Sci. & Tech., Toray Industries, and Wanhua Chemical Group leading innovation. These firms are developing advanced PMMA formulations with enhanced properties for specific transportation applications. The competitive landscape is characterized by a mix of established chemical companies and specialized materials manufacturers, with ongoing research collaborations between industry and academic institutions like Fudan University to further advance PMMA technologies for low-emission transportation.

Toray Industries, Inc.

Technical Solution: Toray Industries has developed advanced PMMA solutions for low-emission transportation, focusing on lightweight materials to improve fuel efficiency. Their PMMA-based composites are engineered to reduce vehicle weight by up to 50% compared to traditional materials[1]. The company has also introduced nano-engineered PMMA that enhances thermal stability and impact resistance, making it suitable for electric vehicle battery enclosures[3]. Toray's PMMA films with UV-blocking properties are used in automotive glazing, reducing heat transmission and improving energy efficiency in vehicle climate control systems[5].

Strengths: Extensive R&D capabilities, diverse product portfolio, and strong presence in automotive sector. Weaknesses: Higher production costs compared to traditional materials, potential scalability challenges for some advanced solutions.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical has developed a range of PMMA-based solutions for low-emission transportation, including high-performance PMMA resins with enhanced heat resistance and impact strength. Their PMMA grades are specifically designed for automotive applications, offering up to 30% weight reduction compared to glass alternatives[2]. Wanhua has also introduced PMMA-based composite materials that incorporate recycled content, addressing sustainability concerns in the automotive industry[4]. The company's recent innovation includes PMMA with improved weatherability and UV resistance, extending the lifespan of exterior automotive components[6].

Strengths: Strong manufacturing capabilities, focus on sustainable solutions, and competitive pricing. Weaknesses: Relatively newer entrant in automotive PMMA market, potential limitations in global distribution network.

Innovative PMMA Formulations for Lightweight Vehicles

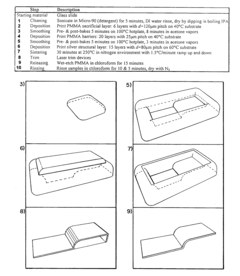

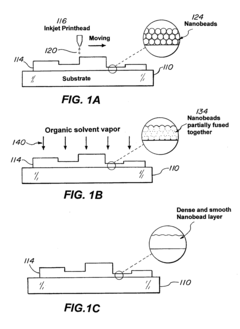

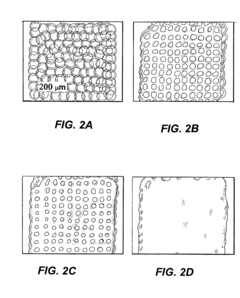

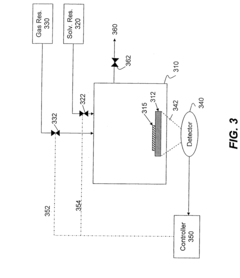

Method and apparatus for forming structures of polymer nanobeads

PatentActiveUS20110206839A1

Innovation

- A post-treatment process involving exposure to a solvent system that lowers the glass transition temperature of PMMA, allowing the polymer nanobeads to reflow and fuse at room temperature, creating a smooth and optically transparent film with improved surface morphology without altering the footprint, using an apparatus with a solvent reservoir and gas system to control the treatment.

Moulding compositions of polymethylmethacrylate with high heat resistance

PatentInactiveEP0534236A3

Innovation

- Copolymers composed of 50-94.49% methyl methacrylate, 0-70% cyclohexyl methacrylate, 0.5-5% C₁-C₄ or C₅-C₈ cycloalkyl acrylate, 5-30% fumaric acid esters, 0-20% additional comonomers, and 0.01-2% transfer regulators are developed to enhance heat resistance and reduce water absorption while maintaining transparency and weather resistance.

Environmental Regulations Impact on PMMA Use

Environmental regulations have become increasingly stringent in recent years, significantly impacting the use of PMMA (Polymethyl Methacrylate) in the transportation sector. These regulations aim to reduce emissions and promote sustainability, driving manufacturers to seek innovative solutions for low-emission transportation.

The European Union's Euro 6 and upcoming Euro 7 standards have set strict limits on vehicle emissions, particularly focusing on reducing carbon dioxide (CO2), nitrogen oxides (NOx), and particulate matter. This has led to a growing demand for lightweight materials in vehicle manufacturing, where PMMA plays a crucial role. As a lightweight alternative to glass, PMMA contributes to overall vehicle weight reduction, thereby improving fuel efficiency and reducing emissions.

In the United States, the Corporate Average Fuel Economy (CAFE) standards have been pushing automakers to improve fuel efficiency across their fleets. This has further accelerated the adoption of lightweight materials like PMMA in vehicle design. The material's versatility and ability to be molded into complex shapes make it an attractive option for aerodynamic improvements, which are essential for meeting these stringent fuel economy standards.

The global push towards electric vehicles (EVs) has also influenced PMMA usage in transportation. As governments worldwide implement policies to phase out internal combustion engines, the demand for materials suitable for EV manufacturing has surged. PMMA's properties, such as its high strength-to-weight ratio and excellent optical clarity, make it ideal for EV components like lightweight windows, headlamp lenses, and interior displays.

However, environmental regulations also present challenges for PMMA use. End-of-life vehicle directives, such as the EU's ELV Directive, require increased recyclability and recoverability of vehicle components. This has prompted research into improving PMMA recycling processes and developing more sustainable production methods. Manufacturers are now exploring bio-based PMMA alternatives and closed-loop recycling systems to address these regulatory requirements.

The impact of environmental regulations on PMMA use extends beyond automotive applications. In the aerospace industry, initiatives like the International Civil Aviation Organization's Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA) are driving the adoption of lightweight materials, including PMMA, to reduce aircraft emissions. Similarly, in the marine sector, the International Maritime Organization's regulations on ship energy efficiency have increased interest in PMMA for lightweight vessel components.

As environmental regulations continue to evolve, the PMMA industry must adapt and innovate. This includes developing new grades of PMMA with enhanced properties, improving manufacturing processes to reduce environmental impact, and investing in recycling technologies. The future of PMMA in low-emission transportation will likely involve a balance between leveraging its beneficial properties and addressing sustainability concerns to meet increasingly stringent environmental standards.

The European Union's Euro 6 and upcoming Euro 7 standards have set strict limits on vehicle emissions, particularly focusing on reducing carbon dioxide (CO2), nitrogen oxides (NOx), and particulate matter. This has led to a growing demand for lightweight materials in vehicle manufacturing, where PMMA plays a crucial role. As a lightweight alternative to glass, PMMA contributes to overall vehicle weight reduction, thereby improving fuel efficiency and reducing emissions.

In the United States, the Corporate Average Fuel Economy (CAFE) standards have been pushing automakers to improve fuel efficiency across their fleets. This has further accelerated the adoption of lightweight materials like PMMA in vehicle design. The material's versatility and ability to be molded into complex shapes make it an attractive option for aerodynamic improvements, which are essential for meeting these stringent fuel economy standards.

The global push towards electric vehicles (EVs) has also influenced PMMA usage in transportation. As governments worldwide implement policies to phase out internal combustion engines, the demand for materials suitable for EV manufacturing has surged. PMMA's properties, such as its high strength-to-weight ratio and excellent optical clarity, make it ideal for EV components like lightweight windows, headlamp lenses, and interior displays.

However, environmental regulations also present challenges for PMMA use. End-of-life vehicle directives, such as the EU's ELV Directive, require increased recyclability and recoverability of vehicle components. This has prompted research into improving PMMA recycling processes and developing more sustainable production methods. Manufacturers are now exploring bio-based PMMA alternatives and closed-loop recycling systems to address these regulatory requirements.

The impact of environmental regulations on PMMA use extends beyond automotive applications. In the aerospace industry, initiatives like the International Civil Aviation Organization's Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA) are driving the adoption of lightweight materials, including PMMA, to reduce aircraft emissions. Similarly, in the marine sector, the International Maritime Organization's regulations on ship energy efficiency have increased interest in PMMA for lightweight vessel components.

As environmental regulations continue to evolve, the PMMA industry must adapt and innovate. This includes developing new grades of PMMA with enhanced properties, improving manufacturing processes to reduce environmental impact, and investing in recycling technologies. The future of PMMA in low-emission transportation will likely involve a balance between leveraging its beneficial properties and addressing sustainability concerns to meet increasingly stringent environmental standards.

Life Cycle Assessment of PMMA in Transportation

Life Cycle Assessment (LCA) of PMMA in transportation is a crucial tool for evaluating the environmental impact of this material throughout its entire lifecycle, from raw material extraction to end-of-life disposal. In the context of low-emission transportation solutions, PMMA (Polymethyl methacrylate) offers significant potential due to its lightweight properties and durability.

The LCA process for PMMA in transportation typically begins with the extraction and processing of raw materials, primarily methyl methacrylate monomer. This stage accounts for a substantial portion of the material's environmental footprint, including energy consumption and greenhouse gas emissions. The production phase of PMMA involves polymerization processes, which also contribute to the overall environmental impact.

During the use phase, PMMA's lightweight nature plays a crucial role in reducing vehicle weight, thereby improving fuel efficiency and lowering emissions. This aspect is particularly significant in the automotive and aerospace industries, where weight reduction is a key strategy for achieving low-emission transportation goals. The durability and weather resistance of PMMA also contribute to extended product lifespans, reducing the need for frequent replacements and associated environmental impacts.

End-of-life considerations for PMMA in transportation applications are increasingly important. While PMMA is recyclable, the current recycling rates in the transportation sector remain relatively low. Improving recycling infrastructure and processes for PMMA could significantly reduce its overall environmental impact. Alternatively, energy recovery through incineration is another end-of-life option, though it comes with its own set of environmental considerations.

Comparative LCAs have shown that PMMA often outperforms traditional materials like glass in transportation applications, particularly when considering the entire lifecycle. The reduced weight of PMMA components leads to lower fuel consumption and emissions during the use phase, which can offset higher production-related impacts. However, these benefits are highly dependent on factors such as vehicle type, usage patterns, and end-of-life scenarios.

Recent advancements in PMMA production techniques, such as improved catalysts and more efficient polymerization processes, have the potential to further reduce the material's environmental footprint. Additionally, ongoing research into bio-based PMMA alternatives could lead to even more sustainable options for low-emission transportation solutions in the future.

In conclusion, the Life Cycle Assessment of PMMA in transportation reveals a complex interplay of environmental impacts and benefits. While challenges remain, particularly in end-of-life management, PMMA's contribution to lightweight, low-emission transportation solutions is significant. Continued research and development in production processes, recycling technologies, and bio-based alternatives will be key to maximizing the environmental benefits of PMMA in the transportation sector.

The LCA process for PMMA in transportation typically begins with the extraction and processing of raw materials, primarily methyl methacrylate monomer. This stage accounts for a substantial portion of the material's environmental footprint, including energy consumption and greenhouse gas emissions. The production phase of PMMA involves polymerization processes, which also contribute to the overall environmental impact.

During the use phase, PMMA's lightweight nature plays a crucial role in reducing vehicle weight, thereby improving fuel efficiency and lowering emissions. This aspect is particularly significant in the automotive and aerospace industries, where weight reduction is a key strategy for achieving low-emission transportation goals. The durability and weather resistance of PMMA also contribute to extended product lifespans, reducing the need for frequent replacements and associated environmental impacts.

End-of-life considerations for PMMA in transportation applications are increasingly important. While PMMA is recyclable, the current recycling rates in the transportation sector remain relatively low. Improving recycling infrastructure and processes for PMMA could significantly reduce its overall environmental impact. Alternatively, energy recovery through incineration is another end-of-life option, though it comes with its own set of environmental considerations.

Comparative LCAs have shown that PMMA often outperforms traditional materials like glass in transportation applications, particularly when considering the entire lifecycle. The reduced weight of PMMA components leads to lower fuel consumption and emissions during the use phase, which can offset higher production-related impacts. However, these benefits are highly dependent on factors such as vehicle type, usage patterns, and end-of-life scenarios.

Recent advancements in PMMA production techniques, such as improved catalysts and more efficient polymerization processes, have the potential to further reduce the material's environmental footprint. Additionally, ongoing research into bio-based PMMA alternatives could lead to even more sustainable options for low-emission transportation solutions in the future.

In conclusion, the Life Cycle Assessment of PMMA in transportation reveals a complex interplay of environmental impacts and benefits. While challenges remain, particularly in end-of-life management, PMMA's contribution to lightweight, low-emission transportation solutions is significant. Continued research and development in production processes, recycling technologies, and bio-based alternatives will be key to maximizing the environmental benefits of PMMA in the transportation sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!