Process Parameters For Uniform Dry-Press Coating

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Dry-Press Coating Technology Background and Objectives

Dry-press coating technology has evolved significantly over the past several decades, emerging as a critical process in various manufacturing sectors including pharmaceuticals, ceramics, electronics, and advanced materials. Initially developed in the 1960s as an alternative to traditional wet coating methods, this technology has gained prominence due to its environmental advantages, cost efficiency, and precise control capabilities.

The fundamental principle of dry-press coating involves the application of powdered materials onto substrates through mechanical compression, eliminating the need for solvents or liquid carriers. This approach represents a paradigm shift from conventional coating methodologies, offering substantial reductions in processing time and energy consumption while minimizing environmental impact.

Historical development of dry-press coating technology has progressed through several distinct phases. Early implementations faced challenges with coating uniformity and adhesion strength. The 1980s witnessed significant advancements in press design and powder formulation, while the 1990s brought computerized control systems that enhanced precision and repeatability. Recent decades have seen integration with nanotechnology and smart materials, expanding application possibilities.

Current global interest in dry-press coating stems from increasing regulatory pressure on volatile organic compound (VOC) emissions, growing demand for sustainable manufacturing processes, and the need for more precise coating control in advanced applications. Industries are actively seeking methods to achieve uniform coatings with minimal material waste and energy consumption.

The primary technical objectives in this field center on achieving consistent coating uniformity across various substrate geometries and dimensions. This includes developing precise parameter control mechanisms for pressure distribution, dwell time optimization, and powder flow characteristics. Additional goals involve enhancing adhesion strength between coating and substrate without compromising material properties, and increasing production throughput while maintaining quality standards.

Looking forward, the technology trajectory aims toward fully automated systems with real-time monitoring and adaptive control capabilities. This evolution will likely incorporate artificial intelligence for process optimization and predictive maintenance. The integration of Industry 4.0 principles represents a significant opportunity to address current limitations in process reliability and scalability.

Understanding the complex interplay of process parameters—including compression force, dwell time, powder characteristics, and environmental conditions—is essential for advancing this technology toward its full potential. These parameters collectively determine coating uniformity, which remains the central challenge and opportunity in dry-press coating applications.

The fundamental principle of dry-press coating involves the application of powdered materials onto substrates through mechanical compression, eliminating the need for solvents or liquid carriers. This approach represents a paradigm shift from conventional coating methodologies, offering substantial reductions in processing time and energy consumption while minimizing environmental impact.

Historical development of dry-press coating technology has progressed through several distinct phases. Early implementations faced challenges with coating uniformity and adhesion strength. The 1980s witnessed significant advancements in press design and powder formulation, while the 1990s brought computerized control systems that enhanced precision and repeatability. Recent decades have seen integration with nanotechnology and smart materials, expanding application possibilities.

Current global interest in dry-press coating stems from increasing regulatory pressure on volatile organic compound (VOC) emissions, growing demand for sustainable manufacturing processes, and the need for more precise coating control in advanced applications. Industries are actively seeking methods to achieve uniform coatings with minimal material waste and energy consumption.

The primary technical objectives in this field center on achieving consistent coating uniformity across various substrate geometries and dimensions. This includes developing precise parameter control mechanisms for pressure distribution, dwell time optimization, and powder flow characteristics. Additional goals involve enhancing adhesion strength between coating and substrate without compromising material properties, and increasing production throughput while maintaining quality standards.

Looking forward, the technology trajectory aims toward fully automated systems with real-time monitoring and adaptive control capabilities. This evolution will likely incorporate artificial intelligence for process optimization and predictive maintenance. The integration of Industry 4.0 principles represents a significant opportunity to address current limitations in process reliability and scalability.

Understanding the complex interplay of process parameters—including compression force, dwell time, powder characteristics, and environmental conditions—is essential for advancing this technology toward its full potential. These parameters collectively determine coating uniformity, which remains the central challenge and opportunity in dry-press coating applications.

Market Analysis for Uniform Dry-Press Coating Applications

The global market for uniform dry-press coating technologies has experienced significant growth in recent years, driven primarily by increasing demand for high-quality surface finishes across multiple industries. The current market size is estimated at 4.2 billion USD with a compound annual growth rate of 6.7% projected through 2028, according to industry analysis reports from coating technology sectors.

Manufacturing industries, particularly automotive and aerospace, represent the largest market segment, accounting for approximately 38% of the total market share. These sectors demand precise coating uniformity to meet stringent quality and performance standards. The electronics industry follows closely at 27% market share, where uniform dry-press coating technologies are essential for creating consistent protective layers on sensitive components.

Consumer goods and construction materials collectively represent another substantial market segment at 22%, with applications ranging from household appliances to architectural finishes. The remaining market share is distributed across various industries including medical devices, renewable energy components, and specialized industrial equipment.

Geographically, Asia-Pacific dominates the market with 42% share, driven by robust manufacturing sectors in China, Japan, and South Korea. North America and Europe follow with 28% and 23% respectively, where advanced manufacturing and stringent quality requirements fuel adoption of sophisticated coating technologies.

Market analysis indicates several key drivers propelling growth in this sector. First, increasing emphasis on product longevity and performance across industries has elevated the importance of uniform coating applications. Second, environmental regulations limiting solvent-based coating processes have accelerated the shift toward dry-press technologies that produce minimal waste and emissions.

Customer demand patterns show growing preference for coating solutions that offer multi-functional benefits beyond basic protection, such as antimicrobial properties, self-cleaning capabilities, and enhanced aesthetic qualities. This trend is particularly evident in consumer-facing industries where product differentiation through superior finishes provides competitive advantage.

The market also exhibits sensitivity to raw material costs, particularly specialty powders and binding agents essential to dry-press coating processes. Recent supply chain disruptions have highlighted vulnerabilities in this area, prompting manufacturers to seek more resilient sourcing strategies and alternative formulations.

Industry forecasts suggest emerging applications in renewable energy components and advanced electronics will represent the fastest-growing market segments, with projected growth rates exceeding 9% annually through 2028. These applications demand exceptionally uniform coatings to ensure consistent performance in challenging operational environments.

Manufacturing industries, particularly automotive and aerospace, represent the largest market segment, accounting for approximately 38% of the total market share. These sectors demand precise coating uniformity to meet stringent quality and performance standards. The electronics industry follows closely at 27% market share, where uniform dry-press coating technologies are essential for creating consistent protective layers on sensitive components.

Consumer goods and construction materials collectively represent another substantial market segment at 22%, with applications ranging from household appliances to architectural finishes. The remaining market share is distributed across various industries including medical devices, renewable energy components, and specialized industrial equipment.

Geographically, Asia-Pacific dominates the market with 42% share, driven by robust manufacturing sectors in China, Japan, and South Korea. North America and Europe follow with 28% and 23% respectively, where advanced manufacturing and stringent quality requirements fuel adoption of sophisticated coating technologies.

Market analysis indicates several key drivers propelling growth in this sector. First, increasing emphasis on product longevity and performance across industries has elevated the importance of uniform coating applications. Second, environmental regulations limiting solvent-based coating processes have accelerated the shift toward dry-press technologies that produce minimal waste and emissions.

Customer demand patterns show growing preference for coating solutions that offer multi-functional benefits beyond basic protection, such as antimicrobial properties, self-cleaning capabilities, and enhanced aesthetic qualities. This trend is particularly evident in consumer-facing industries where product differentiation through superior finishes provides competitive advantage.

The market also exhibits sensitivity to raw material costs, particularly specialty powders and binding agents essential to dry-press coating processes. Recent supply chain disruptions have highlighted vulnerabilities in this area, prompting manufacturers to seek more resilient sourcing strategies and alternative formulations.

Industry forecasts suggest emerging applications in renewable energy components and advanced electronics will represent the fastest-growing market segments, with projected growth rates exceeding 9% annually through 2028. These applications demand exceptionally uniform coatings to ensure consistent performance in challenging operational environments.

Current Technical Challenges in Dry-Press Coating Uniformity

Despite significant advancements in dry-press coating technology, achieving uniform coating remains a persistent challenge in industrial applications. The primary technical hurdle involves maintaining consistent material distribution across substrates during the pressing process. Current manufacturing systems struggle with pressure gradient issues, where uneven force distribution leads to thickness variations and structural inconsistencies in the final coating.

Material flow behavior during compression presents another significant obstacle. The rheological properties of coating materials often change unpredictably under pressure, creating zones of varying density. This phenomenon is particularly problematic when working with composite materials or those containing particles of different sizes, as segregation can occur during the pressing phase, compromising the homogeneity of the final coating.

Temperature control during the dry-press process represents a critical challenge that directly impacts coating uniformity. Even minor temperature fluctuations can alter material viscosity and flow characteristics, resulting in inconsistent coating properties. Current heating systems lack the precision required to maintain optimal temperature profiles throughout large-scale production runs, especially when dealing with thermally sensitive materials.

Die design limitations further complicate uniform coating achievement. Conventional die geometries often create dead zones where material accumulation or depletion occurs, leading to thickness variations. The interface between the die wall and the coating material introduces friction effects that vary across the pressing surface, contributing to non-uniform material distribution during compression.

Scale-up challenges persist when transitioning from laboratory to industrial production. Parameters that yield excellent uniformity in small-scale operations often fail to translate directly to larger production environments. This scaling discrepancy stems from complex interactions between process variables that become more pronounced at industrial scales, including heat transfer inefficiencies and pressure distribution anomalies across larger surface areas.

Monitoring and control systems currently employed in dry-press coating operations lack real-time feedback capabilities necessary for dynamic process adjustments. Most systems rely on post-production quality control rather than in-process monitoring, limiting the ability to make immediate corrections when uniformity deviations occur. The absence of reliable in-situ measurement technologies for coating thickness and density distribution represents a significant technological gap.

Material preparation inconsistencies prior to the pressing stage also contribute to uniformity problems. Variations in particle size distribution, moisture content, and additive dispersion in the pre-press mixture directly translate to non-uniform coatings. Current mixing and preparation technologies struggle to achieve the level of homogeneity required for consistently uniform dry-press coatings, particularly when processing complex formulations with multiple components.

Material flow behavior during compression presents another significant obstacle. The rheological properties of coating materials often change unpredictably under pressure, creating zones of varying density. This phenomenon is particularly problematic when working with composite materials or those containing particles of different sizes, as segregation can occur during the pressing phase, compromising the homogeneity of the final coating.

Temperature control during the dry-press process represents a critical challenge that directly impacts coating uniformity. Even minor temperature fluctuations can alter material viscosity and flow characteristics, resulting in inconsistent coating properties. Current heating systems lack the precision required to maintain optimal temperature profiles throughout large-scale production runs, especially when dealing with thermally sensitive materials.

Die design limitations further complicate uniform coating achievement. Conventional die geometries often create dead zones where material accumulation or depletion occurs, leading to thickness variations. The interface between the die wall and the coating material introduces friction effects that vary across the pressing surface, contributing to non-uniform material distribution during compression.

Scale-up challenges persist when transitioning from laboratory to industrial production. Parameters that yield excellent uniformity in small-scale operations often fail to translate directly to larger production environments. This scaling discrepancy stems from complex interactions between process variables that become more pronounced at industrial scales, including heat transfer inefficiencies and pressure distribution anomalies across larger surface areas.

Monitoring and control systems currently employed in dry-press coating operations lack real-time feedback capabilities necessary for dynamic process adjustments. Most systems rely on post-production quality control rather than in-process monitoring, limiting the ability to make immediate corrections when uniformity deviations occur. The absence of reliable in-situ measurement technologies for coating thickness and density distribution represents a significant technological gap.

Material preparation inconsistencies prior to the pressing stage also contribute to uniformity problems. Variations in particle size distribution, moisture content, and additive dispersion in the pre-press mixture directly translate to non-uniform coatings. Current mixing and preparation technologies struggle to achieve the level of homogeneity required for consistently uniform dry-press coatings, particularly when processing complex formulations with multiple components.

Current Process Parameter Optimization Approaches

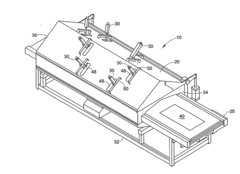

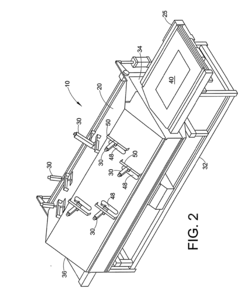

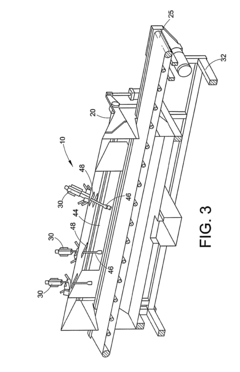

01 Dry-press coating equipment design

Specialized equipment designs for dry-press coating processes can significantly improve coating uniformity. These designs include optimized press mechanisms, automated distribution systems, and precision control interfaces that ensure even application of coating materials. Advanced equipment features such as pressure regulation systems and uniform material feeding mechanisms help maintain consistent coating thickness across the substrate surface.- Dry-press coating equipment design: Specialized equipment designs can significantly improve coating uniformity in dry-press processes. These designs include optimized press chambers, automated distribution systems, and precision control mechanisms that ensure even application of coating materials. Advanced equipment may incorporate sensors and feedback systems to monitor and adjust coating parameters in real-time, resulting in more consistent coating thickness and quality across the substrate surface.

- Powder formulation for uniform coating: The composition and physical properties of coating powders significantly impact coating uniformity. Optimized particle size distribution, flow characteristics, and additives can enhance powder distribution during dry-press coating. Formulations may include flow agents, anti-static compounds, and binding agents that prevent agglomeration and promote even deposition. Carefully engineered powder formulations ensure consistent coating thickness and adhesion across the substrate.

- Process parameter optimization: Critical process parameters such as pressure, temperature, dwell time, and application rate must be optimized to achieve uniform dry-press coatings. Systematic approaches to parameter optimization include statistical design of experiments and process modeling. Maintaining precise control over these parameters throughout the coating process helps prevent defects such as uneven thickness, pinholes, or poor adhesion, resulting in consistent coating quality.

- Surface preparation techniques: Proper substrate preparation is essential for achieving uniform dry-press coatings. Techniques include cleaning, degreasing, surface activation, and application of primer layers. These preparation steps ensure optimal adhesion and even distribution of coating materials. Surface roughness control and contamination removal are particularly important factors that influence the final coating uniformity and quality.

- Quality control and monitoring systems: Advanced monitoring and quality control systems are crucial for maintaining coating uniformity in dry-press processes. These systems may include optical inspection, thickness measurement, adhesion testing, and surface analysis techniques. Real-time monitoring allows for immediate process adjustments to maintain coating uniformity, while comprehensive quality control protocols ensure consistent results across production batches.

02 Powder formulation for uniform coating

The composition and physical properties of coating powders directly impact coating uniformity in dry-press processes. Optimized particle size distribution, flow characteristics, and additives that prevent agglomeration are essential for achieving even coatings. Formulations may include flow agents, anti-static compounds, and binding agents that promote uniform distribution during the pressing process and enhance adhesion to the substrate.Expand Specific Solutions03 Process parameter optimization

Controlling process parameters such as pressure, temperature, dwell time, and application rate is critical for achieving uniform dry-press coatings. Systematic optimization of these parameters based on substrate characteristics and coating material properties ensures consistent results. Advanced process control systems that monitor and adjust parameters in real-time can compensate for variations in environmental conditions or material properties.Expand Specific Solutions04 Surface preparation techniques

Proper preparation of substrate surfaces before dry-press coating application significantly improves coating uniformity. Techniques include cleaning, roughening, or applying primer layers to enhance adhesion and promote even distribution of coating materials. Surface treatments that modify surface energy or create controlled topography can prevent coating defects such as pinholes, edge effects, or uneven thickness.Expand Specific Solutions05 Quality control and monitoring systems

Implementation of advanced quality control systems for monitoring coating uniformity during and after the dry-press process ensures consistent product quality. These systems may include optical inspection technologies, thickness measurement devices, and statistical process control methods. Real-time monitoring allows for immediate adjustments to process parameters when deviations in coating uniformity are detected, reducing waste and improving overall product consistency.Expand Specific Solutions

Key Industry Players in Dry-Press Coating Technology

The dry-press coating technology market is currently in a growth phase, characterized by increasing demand for uniform coating solutions across various industries. The global market size for advanced coating technologies is estimated at $15-20 billion, with dry-press coating representing an emerging segment. Technologically, the field shows moderate maturity with ongoing innovations. Leading players include 3M Innovative Properties with established intellectual property portfolios, FUJIFILM Corp. bringing expertise from imaging solutions, and Avery Dennison contributing significant advancements in pressure-sensitive materials. Regional players like Shanghai Radix Vacuum Metallising and Changzhou Zhongying Science & Technology are expanding capabilities in specialized applications. Academic institutions such as Central South University and Nanjing Forestry University are contributing research innovations, indicating a collaborative ecosystem between industry and academia driving technical refinements in uniform dry-press coating processes.

3M Innovative Properties Co.

Technical Solution: 3M has developed advanced dry-press coating technologies that utilize uniform pressure distribution systems to ensure consistent coating thickness across substrates. Their process parameters focus on optimizing particle size distribution (typically 5-20 μm), controlling moisture content (0.5-2% by weight), and precise temperature regulation (150-200°C) during compression. 3M's approach incorporates specialized binding agents that activate under specific pressure conditions (200-400 MPa) to create uniform coatings without liquid carriers. The company has implemented automated pressure feedback systems that adjust in real-time to material variations, ensuring coating uniformity within ±2% thickness variation across large surface areas. Their dry-press coating technology also incorporates pre-treatment processes that modify substrate surface energy to enhance coating adhesion without requiring wet application methods.

Strengths: Superior coating uniformity with minimal thickness variation; environmentally friendly process that eliminates VOC emissions associated with wet coating methods; excellent scalability for industrial applications. Weaknesses: Higher initial equipment investment compared to traditional coating methods; limited application for certain specialty materials requiring liquid-phase processing; more complex process parameter optimization required for new substrate materials.

Oerlikon Metco AG

Technical Solution: Oerlikon Metco has pioneered thermal spray dry-press coating technology that utilizes precisely controlled powder feedstock parameters for uniform coating deposition. Their process employs specialized powder preparation techniques including spheroidization (producing particles with 99% sphericity) and narrow particle size distribution (typically 20-53 μm) to ensure consistent flow characteristics. The company's thermal spray systems operate with precisely controlled atmospheric conditions (oxygen levels below 100 ppm) and substrate preheating (200-400°C) to optimize coating adhesion. Their proprietary powder feeding systems maintain consistent feed rates (±1% variation) while controlling carrier gas pressure (2-4 bar) and velocity. Oerlikon's process parameters include precise control of spray distance (150-300 mm), torch movement patterns (optimized for specific geometries), and cooling rates to minimize residual stresses in the coating. The company has developed specialized parameter sets for various substrate materials, ensuring optimal adhesion strength exceeding 80 MPa for most metal-ceramic combinations.

Strengths: Exceptional coating adhesion strength and durability; ability to apply functional coatings with specific thermal, electrical, or wear-resistant properties; highly reproducible results with sophisticated process monitoring. Weaknesses: Higher energy consumption compared to some alternative coating methods; requires specialized equipment and technical expertise; limited application for heat-sensitive substrate materials.

Critical Patents and Research on Uniform Coating Achievement

Uniform temperature thermally conductive coating and manufacturing method thereof including materials such as graphene, adhesion-enhancing resin, scratch-resistant and chemical-resistant resin, wetting and wear-resistant resin, slow drying agent, defoaming agent, molding agent, wetting agent, pure water and other ingredients

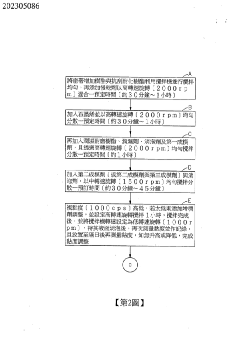

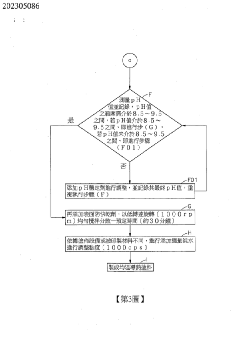

PatentActiveTW202305086A

Innovation

- The integration of graphene into a thermally conductive coating formulation that provides uniform temperature distribution properties.

- A specific sequential mixing process that ensures proper dispersion of components, particularly the controlled addition and mixing of graphene with various functional resins.

- Adaptable formulation with optional components (thickeners, pH stabilizers, drying prevention agents) that can be adjusted based on viscosity requirements for different substrate materials.

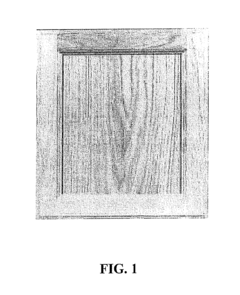

Process for Applying a Thin-film Radiation-cured Coating on a Three-dimensional Substrate

PatentInactiveUS20060029730A1

Innovation

- A process and system for applying a uniform thin film of 100 percent solids coatings using high precision spray guns and controlled temperature and pressure conditions, which eliminates the need for organic solvents and water-based delivery systems, ensuring improved knitting and transfer efficiency on three-dimensional surfaces.

Material Science Considerations for Optimal Coating Performance

The selection of appropriate materials for dry-press coating applications requires careful consideration of multiple physicochemical properties that directly influence coating uniformity and performance. Particle size distribution represents a critical factor, as it determines packing efficiency and surface coverage. Optimal distributions typically feature a controlled blend of fine and coarse particles, with D50 values between 10-30 μm for most industrial applications, enabling sufficient interparticle contact while minimizing void formation.

Surface chemistry characteristics of coating materials significantly impact adhesion mechanisms and coating integrity. Materials with appropriate functional groups that can form chemical or physical bonds with the substrate demonstrate superior adhesion properties. For ceramic-based coatings, silane coupling agents have proven effective in enhancing interfacial bonding, while polymer-based systems benefit from materials containing polar functional groups that promote secondary bonding interactions.

Rheological behavior under compression presents another crucial consideration, particularly in dry-press processes where materials undergo significant pressure. Ideal coating materials exhibit controlled deformation characteristics, maintaining structural integrity while achieving desired densification. Materials with elastic-plastic deformation profiles typically outperform those with purely elastic or brittle behavior, as they accommodate stress without catastrophic failure during compression.

Thermal expansion compatibility between coating materials and substrates must be carefully matched to prevent delamination or cracking during thermal processing stages. The coefficient of thermal expansion (CTE) differential should generally remain below 2×10^-6/°C to minimize interfacial stress development during heating and cooling cycles.

Moisture sensitivity represents a significant challenge in dry-press coating operations. Hygroscopic materials can absorb atmospheric moisture, leading to agglomeration and processing inconsistencies. Hydrophobic surface treatments or the incorporation of moisture-resistant additives (typically 0.5-2% by weight) can effectively mitigate these issues without compromising coating performance.

Advanced material science approaches, including nanostructured materials and composite formulations, offer enhanced performance characteristics. Nanoparticle-reinforced coatings demonstrate improved mechanical properties and reduced porosity, while hierarchically structured materials provide optimized surface properties. Recent developments in self-healing coating materials show promising results for applications requiring extended service life under challenging environmental conditions.

Surface chemistry characteristics of coating materials significantly impact adhesion mechanisms and coating integrity. Materials with appropriate functional groups that can form chemical or physical bonds with the substrate demonstrate superior adhesion properties. For ceramic-based coatings, silane coupling agents have proven effective in enhancing interfacial bonding, while polymer-based systems benefit from materials containing polar functional groups that promote secondary bonding interactions.

Rheological behavior under compression presents another crucial consideration, particularly in dry-press processes where materials undergo significant pressure. Ideal coating materials exhibit controlled deformation characteristics, maintaining structural integrity while achieving desired densification. Materials with elastic-plastic deformation profiles typically outperform those with purely elastic or brittle behavior, as they accommodate stress without catastrophic failure during compression.

Thermal expansion compatibility between coating materials and substrates must be carefully matched to prevent delamination or cracking during thermal processing stages. The coefficient of thermal expansion (CTE) differential should generally remain below 2×10^-6/°C to minimize interfacial stress development during heating and cooling cycles.

Moisture sensitivity represents a significant challenge in dry-press coating operations. Hygroscopic materials can absorb atmospheric moisture, leading to agglomeration and processing inconsistencies. Hydrophobic surface treatments or the incorporation of moisture-resistant additives (typically 0.5-2% by weight) can effectively mitigate these issues without compromising coating performance.

Advanced material science approaches, including nanostructured materials and composite formulations, offer enhanced performance characteristics. Nanoparticle-reinforced coatings demonstrate improved mechanical properties and reduced porosity, while hierarchically structured materials provide optimized surface properties. Recent developments in self-healing coating materials show promising results for applications requiring extended service life under challenging environmental conditions.

Quality Control and Testing Methods for Coating Uniformity

Quality control and testing methods are essential components in ensuring uniform dry-press coating processes. Manufacturers employ various inspection techniques to verify coating uniformity, with thickness measurement being the primary parameter. Optical microscopy enables visual examination of cross-sections, providing qualitative assessment of coating distribution and identifying potential defects such as pinholes or cracks. For more precise quantitative analysis, scanning electron microscopy (SEM) offers high-resolution imaging of coating microstructure and thickness variations.

Non-destructive testing methods have gained prominence in production environments. X-ray fluorescence (XRF) spectroscopy measures coating thickness without damaging samples, allowing for rapid in-line quality control. Similarly, ultrasonic testing detects coating thickness variations by analyzing sound wave reflections, particularly valuable for thicker coatings where optical methods may be limited.

Statistical process control (SPC) frameworks provide systematic approaches to monitoring coating uniformity. Key performance indicators include thickness standard deviation, coefficient of variation, and defect rates. Control charts track these metrics over time, enabling early detection of process drift before it results in out-of-specification products.

Automated vision systems equipped with machine learning algorithms have revolutionized inspection capabilities. These systems can detect subtle variations in coating appearance, texture, and uniformity at production speeds. The integration of these systems with manufacturing execution systems (MES) allows for real-time process adjustments based on inspection results.

Surface characterization techniques provide additional insights into coating quality. Profilometry measures surface roughness parameters such as Ra and Rz values, which correlate with coating uniformity. Contact angle measurements assess the wettability of coated surfaces, indicating consistency in surface energy distribution.

Accelerated aging tests evaluate long-term coating performance under simulated environmental conditions. These tests include thermal cycling, humidity exposure, and UV radiation to predict coating durability and adhesion stability over time. Standardized testing protocols from organizations like ASTM and ISO ensure consistency in quality assessment methodologies across the industry.

Emerging technologies in quality control include terahertz imaging for non-contact inspection of multi-layer coatings and hyperspectral imaging for chemical composition mapping across coated surfaces. These advanced techniques provide deeper insights into coating uniformity beyond traditional thickness measurements, addressing the increasing complexity of modern coating formulations and performance requirements.

Non-destructive testing methods have gained prominence in production environments. X-ray fluorescence (XRF) spectroscopy measures coating thickness without damaging samples, allowing for rapid in-line quality control. Similarly, ultrasonic testing detects coating thickness variations by analyzing sound wave reflections, particularly valuable for thicker coatings where optical methods may be limited.

Statistical process control (SPC) frameworks provide systematic approaches to monitoring coating uniformity. Key performance indicators include thickness standard deviation, coefficient of variation, and defect rates. Control charts track these metrics over time, enabling early detection of process drift before it results in out-of-specification products.

Automated vision systems equipped with machine learning algorithms have revolutionized inspection capabilities. These systems can detect subtle variations in coating appearance, texture, and uniformity at production speeds. The integration of these systems with manufacturing execution systems (MES) allows for real-time process adjustments based on inspection results.

Surface characterization techniques provide additional insights into coating quality. Profilometry measures surface roughness parameters such as Ra and Rz values, which correlate with coating uniformity. Contact angle measurements assess the wettability of coated surfaces, indicating consistency in surface energy distribution.

Accelerated aging tests evaluate long-term coating performance under simulated environmental conditions. These tests include thermal cycling, humidity exposure, and UV radiation to predict coating durability and adhesion stability over time. Standardized testing protocols from organizations like ASTM and ISO ensure consistency in quality assessment methodologies across the industry.

Emerging technologies in quality control include terahertz imaging for non-contact inspection of multi-layer coatings and hyperspectral imaging for chemical composition mapping across coated surfaces. These advanced techniques provide deeper insights into coating uniformity beyond traditional thickness measurements, addressing the increasing complexity of modern coating formulations and performance requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!