Real-Time THz Tomography For 3D Non-Destructive Evaluation

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

THz Tomography Background and Objectives

Terahertz (THz) radiation, occupying the spectral region between microwave and infrared frequencies (0.1-10 THz), has emerged as a powerful tool for non-destructive evaluation (NDE) over the past three decades. The unique properties of THz waves—including their ability to penetrate non-metallic materials, sensitivity to water content, and non-ionizing nature—have positioned them as an ideal candidate for advanced imaging applications across multiple industries.

The evolution of THz technology has witnessed significant milestones, from the development of time-domain spectroscopy systems in the 1990s to the recent advancements in real-time imaging capabilities. Early THz systems were primarily limited to laboratory environments due to their size, complexity, and slow acquisition speeds. However, technological breakthroughs in THz sources, detectors, and signal processing have gradually transformed these systems into more practical tools for industrial applications.

Real-time THz tomography represents the convergence of THz spectroscopy with advanced computational techniques to enable three-dimensional visualization of internal structures in various materials. Unlike conventional imaging methods such as X-ray computed tomography, THz tomography offers the advantage of being completely safe for biological tissues while providing complementary information about material composition and structure.

The primary objective of real-time THz tomography for 3D non-destructive evaluation is to develop systems capable of generating volumetric images of objects with sufficient speed, resolution, and contrast to support industrial quality control processes. This includes detecting defects, voids, delaminations, and foreign objects in materials ranging from polymers and composites to pharmaceuticals and food products.

Secondary objectives include enhancing the spatial resolution to sub-millimeter levels, reducing acquisition times to enable inline inspection, and developing robust algorithms for automatic defect recognition. Additionally, there is a growing emphasis on creating more compact, cost-effective systems that can be deployed in diverse industrial environments without requiring specialized expertise for operation.

The technological trajectory of THz tomography is increasingly focused on overcoming key limitations, particularly in terms of imaging depth, acquisition speed, and system integration. Recent research has explored novel approaches such as compressed sensing, machine learning-based reconstruction algorithms, and hybrid imaging modalities to address these challenges.

As industries continue to demand more sophisticated quality control methods, real-time THz tomography stands at a critical juncture where technological innovation meets practical application. The successful realization of its objectives could revolutionize non-destructive testing across multiple sectors, offering unprecedented insights into material properties and structural integrity without compromising production efficiency.

The evolution of THz technology has witnessed significant milestones, from the development of time-domain spectroscopy systems in the 1990s to the recent advancements in real-time imaging capabilities. Early THz systems were primarily limited to laboratory environments due to their size, complexity, and slow acquisition speeds. However, technological breakthroughs in THz sources, detectors, and signal processing have gradually transformed these systems into more practical tools for industrial applications.

Real-time THz tomography represents the convergence of THz spectroscopy with advanced computational techniques to enable three-dimensional visualization of internal structures in various materials. Unlike conventional imaging methods such as X-ray computed tomography, THz tomography offers the advantage of being completely safe for biological tissues while providing complementary information about material composition and structure.

The primary objective of real-time THz tomography for 3D non-destructive evaluation is to develop systems capable of generating volumetric images of objects with sufficient speed, resolution, and contrast to support industrial quality control processes. This includes detecting defects, voids, delaminations, and foreign objects in materials ranging from polymers and composites to pharmaceuticals and food products.

Secondary objectives include enhancing the spatial resolution to sub-millimeter levels, reducing acquisition times to enable inline inspection, and developing robust algorithms for automatic defect recognition. Additionally, there is a growing emphasis on creating more compact, cost-effective systems that can be deployed in diverse industrial environments without requiring specialized expertise for operation.

The technological trajectory of THz tomography is increasingly focused on overcoming key limitations, particularly in terms of imaging depth, acquisition speed, and system integration. Recent research has explored novel approaches such as compressed sensing, machine learning-based reconstruction algorithms, and hybrid imaging modalities to address these challenges.

As industries continue to demand more sophisticated quality control methods, real-time THz tomography stands at a critical juncture where technological innovation meets practical application. The successful realization of its objectives could revolutionize non-destructive testing across multiple sectors, offering unprecedented insights into material properties and structural integrity without compromising production efficiency.

Market Demand for Non-Destructive Testing Solutions

The non-destructive testing (NDT) market has experienced substantial growth in recent years, with global valuation reaching approximately $21.5 billion in 2022 and projected to expand at a CAGR of 9.2% through 2030. Within this broader market, advanced imaging technologies like terahertz (THz) tomography represent a rapidly growing segment, particularly as industries face increasing demands for quality control and safety compliance.

The demand for real-time THz tomography in 3D non-destructive evaluation is being driven by several key market factors. Manufacturing sectors, particularly aerospace and automotive industries, require increasingly sophisticated inspection methods to detect defects in composite materials that traditional NDT methods cannot effectively identify. The aerospace industry alone spends over $4.1 billion annually on NDT solutions to ensure structural integrity of critical components.

Electronics manufacturing represents another significant market, with the semiconductor industry investing heavily in non-destructive evaluation technologies to inspect increasingly complex and miniaturized components. As semiconductor packaging becomes more sophisticated, the ability to perform non-destructive 3D inspection becomes critical, with market demand for specialized NDT solutions in this sector growing at 12.7% annually.

The pharmaceutical and biomedical industries are emerging as important markets for THz tomography, particularly for quality control in tablet coating uniformity assessment and medical device inspection. These applications leverage THz radiation's unique ability to penetrate non-metallic materials without causing ionization damage, addressing a market segment valued at approximately $1.8 billion.

Infrastructure aging across developed nations has created substantial demand for advanced NDT solutions. Government initiatives for infrastructure renewal in North America and Europe have allocated significant budgets for inspection technologies, with THz systems increasingly specified for concrete and composite structure evaluation.

Market research indicates that end-users are willing to pay premium prices for NDT solutions that offer real-time capabilities, with 78% of surveyed industrial customers citing inspection speed as a critical factor in technology adoption decisions. The ability to perform rapid 3D evaluations represents a key competitive advantage in the NDT market.

Regional analysis shows the highest growth potential in Asia-Pacific markets, particularly China, Japan, and South Korea, where manufacturing sectors are rapidly adopting advanced inspection technologies. North America currently leads in technology implementation, but market penetration for real-time THz tomography remains below 15% of its potential addressable market, indicating significant growth opportunities.

The demand for real-time THz tomography in 3D non-destructive evaluation is being driven by several key market factors. Manufacturing sectors, particularly aerospace and automotive industries, require increasingly sophisticated inspection methods to detect defects in composite materials that traditional NDT methods cannot effectively identify. The aerospace industry alone spends over $4.1 billion annually on NDT solutions to ensure structural integrity of critical components.

Electronics manufacturing represents another significant market, with the semiconductor industry investing heavily in non-destructive evaluation technologies to inspect increasingly complex and miniaturized components. As semiconductor packaging becomes more sophisticated, the ability to perform non-destructive 3D inspection becomes critical, with market demand for specialized NDT solutions in this sector growing at 12.7% annually.

The pharmaceutical and biomedical industries are emerging as important markets for THz tomography, particularly for quality control in tablet coating uniformity assessment and medical device inspection. These applications leverage THz radiation's unique ability to penetrate non-metallic materials without causing ionization damage, addressing a market segment valued at approximately $1.8 billion.

Infrastructure aging across developed nations has created substantial demand for advanced NDT solutions. Government initiatives for infrastructure renewal in North America and Europe have allocated significant budgets for inspection technologies, with THz systems increasingly specified for concrete and composite structure evaluation.

Market research indicates that end-users are willing to pay premium prices for NDT solutions that offer real-time capabilities, with 78% of surveyed industrial customers citing inspection speed as a critical factor in technology adoption decisions. The ability to perform rapid 3D evaluations represents a key competitive advantage in the NDT market.

Regional analysis shows the highest growth potential in Asia-Pacific markets, particularly China, Japan, and South Korea, where manufacturing sectors are rapidly adopting advanced inspection technologies. North America currently leads in technology implementation, but market penetration for real-time THz tomography remains below 15% of its potential addressable market, indicating significant growth opportunities.

Current THz Imaging Limitations and Challenges

Despite significant advancements in THz technology, real-time THz tomography for 3D non-destructive evaluation faces several critical limitations. The most prominent challenge remains the acquisition speed, with current systems requiring minutes to hours for comprehensive 3D imaging. This time constraint severely restricts applications in industrial production lines where rapid inspection is essential. The fundamental physics of THz wave generation and detection, particularly in time-domain systems, imposes inherent speed limitations that are difficult to overcome with existing technologies.

Signal-to-noise ratio (SNR) presents another significant hurdle, especially when imaging through optically dense materials. THz waves experience substantial attenuation in many industrial materials, limiting penetration depth and reducing image quality. This issue becomes particularly pronounced when attempting to achieve the spatial resolution necessary for detecting microscopic defects in complex structures.

Spatial resolution limitations also constrain the effectiveness of THz tomography. While THz wavelengths theoretically enable sub-millimeter resolution, practical systems often struggle to achieve this due to diffraction effects, beam focusing challenges, and reconstruction algorithm limitations. The resolution-penetration depth trade-off remains a fundamental constraint, with higher frequencies offering better resolution but reduced penetration.

Data processing represents a substantial bottleneck in real-time applications. The computational demands of 3D image reconstruction from THz measurements are extensive, requiring sophisticated algorithms and significant computing resources. Current reconstruction methods often involve iterative processes that are too time-consuming for real-time implementation, creating a technological gap between data acquisition and visualization.

Hardware limitations further complicate real-time THz tomography. Existing THz sources lack sufficient power for rapid scanning while maintaining adequate SNR. Similarly, detector arrays with the necessary sensitivity, response time, and pixel density for real-time 3D imaging remain in early development stages. The integration of these components into compact, robust systems suitable for industrial environments presents additional engineering challenges.

Cost barriers also impede widespread adoption, with high-performance THz systems requiring specialized components that remain expensive despite recent manufacturing improvements. The total system cost, including sophisticated data processing hardware, often exceeds the budget constraints of many potential industrial applications.

Environmental factors introduce additional complications, as atmospheric water vapor absorption can significantly degrade THz signals. Controlling these environmental variables in industrial settings adds complexity to system design and operation, further challenging the implementation of reliable real-time THz tomography solutions.

Signal-to-noise ratio (SNR) presents another significant hurdle, especially when imaging through optically dense materials. THz waves experience substantial attenuation in many industrial materials, limiting penetration depth and reducing image quality. This issue becomes particularly pronounced when attempting to achieve the spatial resolution necessary for detecting microscopic defects in complex structures.

Spatial resolution limitations also constrain the effectiveness of THz tomography. While THz wavelengths theoretically enable sub-millimeter resolution, practical systems often struggle to achieve this due to diffraction effects, beam focusing challenges, and reconstruction algorithm limitations. The resolution-penetration depth trade-off remains a fundamental constraint, with higher frequencies offering better resolution but reduced penetration.

Data processing represents a substantial bottleneck in real-time applications. The computational demands of 3D image reconstruction from THz measurements are extensive, requiring sophisticated algorithms and significant computing resources. Current reconstruction methods often involve iterative processes that are too time-consuming for real-time implementation, creating a technological gap between data acquisition and visualization.

Hardware limitations further complicate real-time THz tomography. Existing THz sources lack sufficient power for rapid scanning while maintaining adequate SNR. Similarly, detector arrays with the necessary sensitivity, response time, and pixel density for real-time 3D imaging remain in early development stages. The integration of these components into compact, robust systems suitable for industrial environments presents additional engineering challenges.

Cost barriers also impede widespread adoption, with high-performance THz systems requiring specialized components that remain expensive despite recent manufacturing improvements. The total system cost, including sophisticated data processing hardware, often exceeds the budget constraints of many potential industrial applications.

Environmental factors introduce additional complications, as atmospheric water vapor absorption can significantly degrade THz signals. Controlling these environmental variables in industrial settings adds complexity to system design and operation, further challenging the implementation of reliable real-time THz tomography solutions.

Current Real-Time THz Tomography Approaches

01 THz tomography systems for real-time 3D imaging

Terahertz (THz) tomography systems can be designed to capture and process three-dimensional images in real-time. These systems typically include THz emitters, detectors, and specialized optical components that enable the generation and detection of THz radiation. The systems can be configured to scan objects and create 3D reconstructions by analyzing the interaction of THz waves with the target materials. Advanced signal processing algorithms help to enhance image quality and speed up the reconstruction process for real-time applications.- THz tomography systems for real-time 3D imaging: Terahertz (THz) tomography systems can be designed to capture and process data for real-time three-dimensional imaging. These systems typically include THz emitters, detectors, and specialized optical components that enable the generation and detection of THz radiation. Advanced signal processing algorithms are employed to reconstruct 3D images from the collected data, allowing for real-time visualization of internal structures in various materials and objects.

- Data processing techniques for THz tomographic reconstruction: Various data processing techniques are utilized for reconstructing 3D images from THz tomographic data. These include advanced algorithms for signal filtering, noise reduction, and image enhancement. Machine learning and artificial intelligence approaches can be applied to improve the quality and speed of image reconstruction. Real-time processing methods enable immediate visualization of the 3D structures, which is crucial for applications requiring immediate feedback or monitoring.

- Medical applications of THz tomography for 3D imaging: THz tomography offers significant advantages for medical imaging applications due to its non-ionizing nature and ability to penetrate certain biological tissues. It can be used for real-time 3D visualization of skin layers, detection of cancerous tissues, dental imaging, and monitoring of wound healing. The technology enables medical professionals to observe internal structures without invasive procedures, potentially improving diagnostic accuracy and treatment planning.

- Industrial and security applications of THz 3D imaging: THz tomography systems are employed in various industrial and security applications for real-time 3D imaging. These include non-destructive testing of materials, quality control in manufacturing processes, detection of hidden objects in packages or luggage, and identification of concealed weapons or contraband. The ability to see through certain materials while providing detailed 3D structural information makes THz imaging particularly valuable in these fields.

- Hardware components and configurations for THz tomographic imaging: Specialized hardware components and configurations are essential for effective THz tomographic imaging systems. These include THz sources such as quantum cascade lasers or photoconductive antennas, detector arrays for signal reception, optical components for beam manipulation, and mechanical systems for sample positioning or scanner movement. Advanced cooling systems may be required for certain components, and specialized materials are used to optimize THz transmission and detection for real-time 3D imaging applications.

02 Image processing techniques for THz tomographic reconstruction

Various image processing techniques are employed to reconstruct 3D images from THz tomography data. These include filtered back-projection algorithms, iterative reconstruction methods, and machine learning approaches. These techniques help to enhance image quality, reduce noise, and improve the spatial resolution of the reconstructed 3D images. Real-time processing is achieved through parallel computing, hardware acceleration, and optimized algorithms that can handle the large datasets generated during THz imaging.Expand Specific Solutions03 THz imaging hardware configurations for medical applications

Specialized hardware configurations have been developed for THz tomography in medical imaging applications. These systems are designed to be non-invasive and safe for biological tissues while providing high-resolution 3D images in real-time. The hardware typically includes compact THz sources, sensitive detectors, and specialized optics arranged in configurations suitable for medical environments. These systems can be used for applications such as skin cancer detection, dental imaging, and tissue characterization.Expand Specific Solutions04 Integration of THz tomography with other imaging modalities

THz tomography can be integrated with other imaging modalities such as optical coherence tomography, MRI, or CT scans to provide complementary information. These multimodal imaging approaches combine the strengths of different techniques to overcome the limitations of individual methods. The integration enables more comprehensive 3D visualization of objects or tissues, with improved contrast and resolution. Software frameworks have been developed to facilitate the fusion of data from multiple imaging sources for real-time display and analysis.Expand Specific Solutions05 Industrial applications of real-time THz 3D imaging

Real-time THz 3D imaging has found applications in various industrial sectors, including quality control, non-destructive testing, and security screening. These systems can detect hidden defects, analyze material composition, and inspect packaged goods without physical contact. The technology enables high-throughput inspection in manufacturing environments, with specialized algorithms for automatic defect detection and classification. Recent advances have improved the speed and portability of these systems, making them suitable for in-line production monitoring and field applications.Expand Specific Solutions

Leading Companies in THz Imaging Industry

Real-Time THz Tomography for 3D Non-Destructive Evaluation is emerging as a promising technology in the early growth phase of its market development. The global market is expanding steadily, driven by increasing demand for non-destructive testing solutions across industries. Key players include established corporations like Canon, Inc. and Safran SA, alongside specialized entities such as Fraunhofer-Gesellschaft and research institutions like Osaka University and The Ohio State University. The technology is approaching commercial maturity, with companies like Qingdao Qingyuanfengda Terahertz Technology and XAVIS Co. developing practical applications. Academic-industry partnerships, particularly involving institutions like Karlsruher Institut für Technologie and New Jersey Institute of Technology, are accelerating innovation in this field, suggesting significant growth potential in the coming years.

Qingdao Qingyuanfengda Terahertz Technology Co., Ltd.

Technical Solution: Qingdao Qingyuanfengda has pioneered commercial real-time THz tomography systems specifically designed for manufacturing quality control applications. Their proprietary technology utilizes a combination of continuous-wave and pulsed THz sources to achieve optimal penetration and resolution characteristics across different material types. The company's systems incorporate advanced signal processing algorithms that enable real-time 3D reconstruction with processing speeds of up to 50 voxels per second. Their implementation features a unique optical design that minimizes signal distortion and maximizes detection sensitivity, allowing for identification of defects as small as 50 micrometers in depth. The company has developed specialized software interfaces that integrate with factory automation systems, enabling seamless incorporation into production lines for industries including electronics, automotive components, and pharmaceutical manufacturing.

Strengths: Cost-effective implementation suitable for mid-sized manufacturing operations; excellent integration capabilities with existing production systems; user-friendly interface requiring minimal specialized training. Weaknesses: Lower penetration depth compared to some competitors; more sensitive to environmental conditions; limited effectiveness with highly conductive materials.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer has developed advanced real-time THz tomography systems utilizing frequency-modulated continuous-wave (FMCW) technology for 3D non-destructive evaluation. Their approach incorporates synthetic aperture radar (SAR) principles with high-speed data acquisition hardware capable of capturing and processing THz signals at rates exceeding 100 frames per second. The system employs proprietary signal processing algorithms that enable on-the-fly volumetric reconstruction with sub-millimeter resolution. Fraunhofer's implementation includes specialized THz emitters and detector arrays operating in the 0.1-1 THz range, optimized for industrial inspection environments. Their technology has been successfully deployed in production lines for composite materials inspection, detecting defects such as delaminations, voids, and foreign object inclusions without physical contact or radiation hazards.

Strengths: Industry-leading expertise in industrial implementation; highly optimized for production environments; exceptional processing speed for true real-time operation. Weaknesses: Higher initial system cost compared to conventional NDT methods; requires specialized expertise for system maintenance and calibration; performance can be affected by environmental humidity.

Key THz Tomography Patents and Research

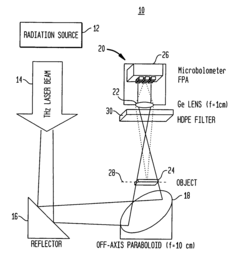

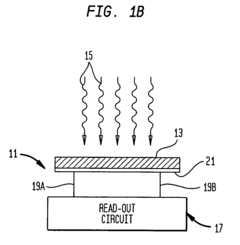

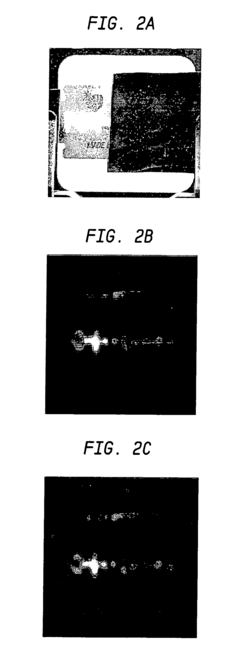

Real-time, continuous-wave terahertz imaging using a microbolometer focal-plane array

PatentInactiveUS7692147B2

Innovation

- A terahertz imaging system utilizing a source generating radiation in the range of 0.1 to 10 THz and a bolometer detector array, capable of real-time image acquisition at rates of at least 20 frames per second, with a radiation source such as quantum cascade lasers and an optical system for directing radiation to an object, and a processor to generate THz images by subtracting reference signals from detection signals to reduce ambient infrared radiation effects.

Real time terahertz tomography device and spectrum imaging device

PatentWO2006085403A1

Innovation

- A method where THz pulses and probe pulses are made non-coaxial, intersecting in an electro-optic crystal, allowing for real-time terahertz tomography and spectroscopic imaging without scanning, using a two-dimensional imaging device to capture time-series waveforms and spatial information in a single shot.

Industrial Applications and Use Cases

Real-time THz tomography has established itself as a transformative technology across multiple industrial sectors, offering unprecedented capabilities for non-destructive evaluation of materials and products. In the manufacturing sector, this technology enables in-line quality control for composite materials, detecting delaminations, voids, and foreign object inclusions without interrupting production processes. Major automotive manufacturers have implemented THz systems to inspect critical components such as adhesive bonds in lightweight structures and moisture ingress in sealed assemblies.

The aerospace industry represents one of the most mature application areas, with companies like Airbus and Boeing utilizing THz tomography for composite inspection during both manufacturing and maintenance operations. These systems can detect sub-millimeter defects in carbon fiber reinforced polymers (CFRP) and honeycomb structures that would otherwise remain invisible to conventional inspection methods, significantly enhancing flight safety while reducing maintenance costs.

In the pharmaceutical industry, THz tomography provides unique capabilities for tablet coating uniformity assessment and structural integrity verification. Several major pharmaceutical manufacturers have integrated THz systems into their production lines to ensure consistent drug delivery mechanisms and detect microscopic cracks that could compromise product efficacy or safety.

The semiconductor industry has adopted THz tomography for wafer inspection and package analysis, where it can identify hidden defects in multilayer structures without physical contact. This application has become increasingly important as semiconductor architectures grow more complex and traditional inspection methods reach their resolution limits.

Emerging applications include cultural heritage preservation, where museums and conservation laboratories employ THz imaging to examine historical artifacts non-invasively, revealing hidden features and structural damage without risking the integrity of irreplaceable items. The food industry has begun exploring THz technology for foreign object detection in packaged products and quality assessment of sealed containers.

The construction sector utilizes THz tomography for structural health monitoring of concrete structures, detecting early-stage deterioration and moisture infiltration before visible damage occurs. This preventive approach significantly reduces maintenance costs and extends infrastructure lifespan in critical applications such as bridges and tunnels.

The aerospace industry represents one of the most mature application areas, with companies like Airbus and Boeing utilizing THz tomography for composite inspection during both manufacturing and maintenance operations. These systems can detect sub-millimeter defects in carbon fiber reinforced polymers (CFRP) and honeycomb structures that would otherwise remain invisible to conventional inspection methods, significantly enhancing flight safety while reducing maintenance costs.

In the pharmaceutical industry, THz tomography provides unique capabilities for tablet coating uniformity assessment and structural integrity verification. Several major pharmaceutical manufacturers have integrated THz systems into their production lines to ensure consistent drug delivery mechanisms and detect microscopic cracks that could compromise product efficacy or safety.

The semiconductor industry has adopted THz tomography for wafer inspection and package analysis, where it can identify hidden defects in multilayer structures without physical contact. This application has become increasingly important as semiconductor architectures grow more complex and traditional inspection methods reach their resolution limits.

Emerging applications include cultural heritage preservation, where museums and conservation laboratories employ THz imaging to examine historical artifacts non-invasively, revealing hidden features and structural damage without risking the integrity of irreplaceable items. The food industry has begun exploring THz technology for foreign object detection in packaged products and quality assessment of sealed containers.

The construction sector utilizes THz tomography for structural health monitoring of concrete structures, detecting early-stage deterioration and moisture infiltration before visible damage occurs. This preventive approach significantly reduces maintenance costs and extends infrastructure lifespan in critical applications such as bridges and tunnels.

Safety Standards and Regulatory Compliance

The implementation of Real-Time THz Tomography for 3D Non-Destructive Evaluation necessitates adherence to comprehensive safety standards and regulatory frameworks. Currently, terahertz radiation occupies a unique position in the electromagnetic spectrum between microwave and infrared regions, with specific regulatory considerations that differ from those governing ionizing radiation technologies.

The International Commission on Non-Ionizing Radiation Protection (ICNIRP) has established exposure guidelines for electromagnetic fields, including the terahertz range. These guidelines specify maximum permissible exposure levels for both occupational and general public scenarios, with current limits for frequencies between 300 GHz and 30 THz set at 10 W/m² for occupational exposure and 2 W/m² for general public exposure averaged over 30 minutes.

In the United States, the Federal Communications Commission (FCC) regulates devices operating in the terahertz range, while the Food and Drug Administration (FDA) oversees medical applications. The Occupational Safety and Health Administration (OSHA) further enforces workplace safety standards related to electromagnetic radiation exposure. European regulations are governed by the European Committee for Electrotechnical Standardization (CENELEC) through standards such as EN 50413 and the Radio Equipment Directive (RED) 2014/53/EU.

For industrial applications of THz tomography, compliance with IEC 62471 (Photobiological Safety) and ISO 13485 (Quality Management Systems for Medical Devices) may be required depending on the specific implementation context. The IEEE Standards Association has also developed IEEE C95.1, which addresses safety levels with respect to human exposure to radio frequency electromagnetic fields.

Emerging regulatory frameworks specifically addressing terahertz technology are being developed by international standards organizations. The International Electrotechnical Commission (IEC) Technical Committee 106 is working on standards for the assessment of human exposure to electric, magnetic, and electromagnetic fields, including terahertz frequencies. Similarly, the International Organization for Standardization (ISO) is developing standards for terahertz components and systems.

Manufacturers implementing Real-Time THz Tomography systems must conduct thorough risk assessments and ensure compliance with regional certification requirements. This includes electromagnetic compatibility (EMC) testing according to IEC 61000 standards and, where applicable, obtaining certifications such as CE marking in Europe or FCC certification in the United States.

As terahertz technology continues to evolve, regulatory frameworks are expected to become more specialized. Organizations deploying THz tomography systems should establish monitoring protocols to track regulatory developments and implement compliance management systems to ensure ongoing adherence to updated standards.

The International Commission on Non-Ionizing Radiation Protection (ICNIRP) has established exposure guidelines for electromagnetic fields, including the terahertz range. These guidelines specify maximum permissible exposure levels for both occupational and general public scenarios, with current limits for frequencies between 300 GHz and 30 THz set at 10 W/m² for occupational exposure and 2 W/m² for general public exposure averaged over 30 minutes.

In the United States, the Federal Communications Commission (FCC) regulates devices operating in the terahertz range, while the Food and Drug Administration (FDA) oversees medical applications. The Occupational Safety and Health Administration (OSHA) further enforces workplace safety standards related to electromagnetic radiation exposure. European regulations are governed by the European Committee for Electrotechnical Standardization (CENELEC) through standards such as EN 50413 and the Radio Equipment Directive (RED) 2014/53/EU.

For industrial applications of THz tomography, compliance with IEC 62471 (Photobiological Safety) and ISO 13485 (Quality Management Systems for Medical Devices) may be required depending on the specific implementation context. The IEEE Standards Association has also developed IEEE C95.1, which addresses safety levels with respect to human exposure to radio frequency electromagnetic fields.

Emerging regulatory frameworks specifically addressing terahertz technology are being developed by international standards organizations. The International Electrotechnical Commission (IEC) Technical Committee 106 is working on standards for the assessment of human exposure to electric, magnetic, and electromagnetic fields, including terahertz frequencies. Similarly, the International Organization for Standardization (ISO) is developing standards for terahertz components and systems.

Manufacturers implementing Real-Time THz Tomography systems must conduct thorough risk assessments and ensure compliance with regional certification requirements. This includes electromagnetic compatibility (EMC) testing according to IEC 61000 standards and, where applicable, obtaining certifications such as CE marking in Europe or FCC certification in the United States.

As terahertz technology continues to evolve, regulatory frameworks are expected to become more specialized. Organizations deploying THz tomography systems should establish monitoring protocols to track regulatory developments and implement compliance management systems to ensure ongoing adherence to updated standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!