Terahertz Non-Destructive Testing Of Coatings And Adhesive Bonds

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Terahertz NDT Background and Objectives

Terahertz (THz) technology has emerged as a promising tool for non-destructive testing (NDT) over the past three decades, with significant advancements occurring since the early 1990s. This electromagnetic radiation, occupying the frequency range between 0.1 and 10 THz, bridges the gap between microwaves and infrared light, offering unique capabilities for material inspection that were previously unattainable with conventional NDT methods.

The evolution of THz technology has been marked by several key milestones, including the development of reliable THz sources and detectors, time-domain spectroscopy systems, and imaging techniques. Early applications were primarily limited to laboratory settings due to equipment constraints, but recent technological breakthroughs have enabled more compact, portable, and cost-effective THz systems suitable for industrial applications.

In the context of coatings and adhesive bonds inspection, THz NDT offers distinctive advantages due to its non-ionizing nature, ability to penetrate non-metallic materials, and sensitivity to material composition and structural defects. Traditional inspection methods such as ultrasonic testing, X-ray radiography, and infrared thermography each present limitations when examining multi-layered structures, detecting interfacial defects, or providing spectroscopic information about material properties.

The primary objective of THz NDT research for coatings and adhesive bonds is to develop reliable, efficient, and industrially viable inspection methodologies that can detect and characterize defects such as delaminations, voids, disbonds, and thickness variations without damaging the inspected components. This includes enhancing signal processing algorithms, improving spatial resolution, increasing scanning speeds, and developing specialized probes for complex geometries.

Another critical goal is establishing standardized testing protocols and acceptance criteria for THz inspection of coatings and adhesive bonds across various industries, including aerospace, automotive, electronics, and construction. This standardization is essential for widespread industrial adoption and integration into quality control processes.

Furthermore, research aims to expand the application scope of THz NDT by addressing current limitations such as limited penetration depth in high-water-content materials, challenges in inspecting highly curved surfaces, and difficulties in distinguishing between closely spaced defects. Overcoming these challenges requires interdisciplinary approaches combining physics, materials science, signal processing, and machine learning.

The technological trajectory suggests that THz NDT will continue to evolve toward more automated, real-time inspection capabilities with enhanced defect detection sensitivity and classification accuracy, potentially revolutionizing quality assurance processes for coatings and adhesive bonds in critical applications where reliability and safety are paramount.

The evolution of THz technology has been marked by several key milestones, including the development of reliable THz sources and detectors, time-domain spectroscopy systems, and imaging techniques. Early applications were primarily limited to laboratory settings due to equipment constraints, but recent technological breakthroughs have enabled more compact, portable, and cost-effective THz systems suitable for industrial applications.

In the context of coatings and adhesive bonds inspection, THz NDT offers distinctive advantages due to its non-ionizing nature, ability to penetrate non-metallic materials, and sensitivity to material composition and structural defects. Traditional inspection methods such as ultrasonic testing, X-ray radiography, and infrared thermography each present limitations when examining multi-layered structures, detecting interfacial defects, or providing spectroscopic information about material properties.

The primary objective of THz NDT research for coatings and adhesive bonds is to develop reliable, efficient, and industrially viable inspection methodologies that can detect and characterize defects such as delaminations, voids, disbonds, and thickness variations without damaging the inspected components. This includes enhancing signal processing algorithms, improving spatial resolution, increasing scanning speeds, and developing specialized probes for complex geometries.

Another critical goal is establishing standardized testing protocols and acceptance criteria for THz inspection of coatings and adhesive bonds across various industries, including aerospace, automotive, electronics, and construction. This standardization is essential for widespread industrial adoption and integration into quality control processes.

Furthermore, research aims to expand the application scope of THz NDT by addressing current limitations such as limited penetration depth in high-water-content materials, challenges in inspecting highly curved surfaces, and difficulties in distinguishing between closely spaced defects. Overcoming these challenges requires interdisciplinary approaches combining physics, materials science, signal processing, and machine learning.

The technological trajectory suggests that THz NDT will continue to evolve toward more automated, real-time inspection capabilities with enhanced defect detection sensitivity and classification accuracy, potentially revolutionizing quality assurance processes for coatings and adhesive bonds in critical applications where reliability and safety are paramount.

Market Demand for Coating Inspection Solutions

The global market for coating inspection solutions has witnessed substantial growth in recent years, driven by increasing quality control requirements across multiple industries. The coating inspection market was valued at approximately $5.4 billion in 2022 and is projected to reach $8.2 billion by 2028, representing a compound annual growth rate of 7.2%. This growth trajectory underscores the critical importance of reliable inspection technologies in ensuring product integrity and longevity.

Aerospace and automotive sectors represent the largest market segments, collectively accounting for over 40% of the total demand. In these industries, coating failures can lead to catastrophic consequences, making advanced inspection solutions essential rather than optional. The aerospace industry alone spends nearly $1.2 billion annually on coating inspection technologies to ensure compliance with stringent safety regulations.

Electronics manufacturing has emerged as the fastest-growing segment, with a growth rate exceeding 9% annually. As electronic components become increasingly miniaturized and complex, traditional inspection methods prove inadequate, creating significant market opportunities for advanced technologies like terahertz non-destructive testing.

Geographically, North America and Europe dominate the market with a combined share of 58%, primarily due to their established industrial bases and stringent regulatory frameworks. However, the Asia-Pacific region is experiencing the most rapid growth at 8.5% annually, driven by expanding manufacturing capabilities in China, South Korea, and India.

Customer requirements are evolving toward more comprehensive inspection solutions. End-users increasingly demand technologies that can simultaneously evaluate multiple coating parameters including thickness, adhesion strength, uniformity, and subsurface defects. According to industry surveys, 76% of manufacturing companies express dissatisfaction with current inspection methods' ability to detect early-stage delamination and adhesive bond failures.

The market shows strong preference for non-destructive testing methods, with 82% of new technology investments directed toward solutions that preserve sample integrity. This trend particularly benefits terahertz technology, which offers non-contact, non-ionizing inspection capabilities with superior penetration characteristics compared to conventional methods.

Cost considerations remain significant, with 64% of potential adopters citing high implementation costs as the primary barrier to adoption of advanced inspection technologies. This creates market demand for more cost-effective solutions that can deliver comparable or superior performance to existing technologies while reducing the total cost of ownership.

Aerospace and automotive sectors represent the largest market segments, collectively accounting for over 40% of the total demand. In these industries, coating failures can lead to catastrophic consequences, making advanced inspection solutions essential rather than optional. The aerospace industry alone spends nearly $1.2 billion annually on coating inspection technologies to ensure compliance with stringent safety regulations.

Electronics manufacturing has emerged as the fastest-growing segment, with a growth rate exceeding 9% annually. As electronic components become increasingly miniaturized and complex, traditional inspection methods prove inadequate, creating significant market opportunities for advanced technologies like terahertz non-destructive testing.

Geographically, North America and Europe dominate the market with a combined share of 58%, primarily due to their established industrial bases and stringent regulatory frameworks. However, the Asia-Pacific region is experiencing the most rapid growth at 8.5% annually, driven by expanding manufacturing capabilities in China, South Korea, and India.

Customer requirements are evolving toward more comprehensive inspection solutions. End-users increasingly demand technologies that can simultaneously evaluate multiple coating parameters including thickness, adhesion strength, uniformity, and subsurface defects. According to industry surveys, 76% of manufacturing companies express dissatisfaction with current inspection methods' ability to detect early-stage delamination and adhesive bond failures.

The market shows strong preference for non-destructive testing methods, with 82% of new technology investments directed toward solutions that preserve sample integrity. This trend particularly benefits terahertz technology, which offers non-contact, non-ionizing inspection capabilities with superior penetration characteristics compared to conventional methods.

Cost considerations remain significant, with 64% of potential adopters citing high implementation costs as the primary barrier to adoption of advanced inspection technologies. This creates market demand for more cost-effective solutions that can deliver comparable or superior performance to existing technologies while reducing the total cost of ownership.

Current Terahertz NDT Capabilities and Limitations

Terahertz non-destructive testing (THz NDT) has emerged as a promising technique for evaluating coatings and adhesive bonds due to its unique capabilities. Current THz NDT systems can penetrate non-metallic materials and detect subsurface defects without causing damage to the tested components. The technology operates in the frequency range of 0.1 to 10 THz, filling the gap between microwave and infrared regions of the electromagnetic spectrum.

In coating inspection applications, THz NDT demonstrates remarkable capabilities for thickness measurement with precision reaching 10-20 micrometers in optimal conditions. This level of accuracy enables quality control of thin coatings in various industries including automotive, aerospace, and electronics manufacturing. The technology can effectively distinguish between multiple coating layers and identify delamination, voids, or inclusions within these layers.

For adhesive bond evaluation, current THz systems can detect disbonds, weak bonds, and kissing bonds that may be invisible to conventional NDT methods. The technology is particularly valuable for composite materials where traditional ultrasonic testing faces challenges due to acoustic impedance mismatches. THz imaging can reveal bond line thickness variations and adhesive distribution anomalies that directly impact structural integrity.

Despite these advantages, THz NDT faces significant limitations in industrial applications. The primary constraint is penetration depth, which is typically limited to a few millimeters in most materials, restricting its application to relatively thin structures. This limitation becomes more pronounced in materials with high water content or electrical conductivity, which strongly attenuate THz waves.

Resolution capabilities present another challenge, with current systems achieving spatial resolution in the range of 200-500 micrometers. While sufficient for many applications, this resolution falls short when inspecting microstructural features or defects below this threshold. The trade-off between penetration depth and resolution remains a fundamental challenge in THz technology development.

Data acquisition speed represents a significant bottleneck for widespread industrial adoption. Current THz imaging systems require several minutes to scan even modest surface areas, making real-time inspection of large components impractical. This limitation restricts the technology's application in high-volume manufacturing environments where rapid inspection is essential.

Environmental factors also impact THz NDT performance. Ambient humidity significantly affects measurement accuracy due to water vapor absorption of THz radiation at specific frequencies. Temperature variations can alter material properties and consequently affect THz wave propagation and reflection characteristics, necessitating careful calibration procedures.

Cost considerations remain a barrier to widespread adoption, with high-performance THz systems requiring substantial investment in specialized components such as femtosecond lasers or sophisticated detector arrays. The complexity of data interpretation also demands specialized expertise, further increasing the total cost of ownership for industrial users.

In coating inspection applications, THz NDT demonstrates remarkable capabilities for thickness measurement with precision reaching 10-20 micrometers in optimal conditions. This level of accuracy enables quality control of thin coatings in various industries including automotive, aerospace, and electronics manufacturing. The technology can effectively distinguish between multiple coating layers and identify delamination, voids, or inclusions within these layers.

For adhesive bond evaluation, current THz systems can detect disbonds, weak bonds, and kissing bonds that may be invisible to conventional NDT methods. The technology is particularly valuable for composite materials where traditional ultrasonic testing faces challenges due to acoustic impedance mismatches. THz imaging can reveal bond line thickness variations and adhesive distribution anomalies that directly impact structural integrity.

Despite these advantages, THz NDT faces significant limitations in industrial applications. The primary constraint is penetration depth, which is typically limited to a few millimeters in most materials, restricting its application to relatively thin structures. This limitation becomes more pronounced in materials with high water content or electrical conductivity, which strongly attenuate THz waves.

Resolution capabilities present another challenge, with current systems achieving spatial resolution in the range of 200-500 micrometers. While sufficient for many applications, this resolution falls short when inspecting microstructural features or defects below this threshold. The trade-off between penetration depth and resolution remains a fundamental challenge in THz technology development.

Data acquisition speed represents a significant bottleneck for widespread industrial adoption. Current THz imaging systems require several minutes to scan even modest surface areas, making real-time inspection of large components impractical. This limitation restricts the technology's application in high-volume manufacturing environments where rapid inspection is essential.

Environmental factors also impact THz NDT performance. Ambient humidity significantly affects measurement accuracy due to water vapor absorption of THz radiation at specific frequencies. Temperature variations can alter material properties and consequently affect THz wave propagation and reflection characteristics, necessitating careful calibration procedures.

Cost considerations remain a barrier to widespread adoption, with high-performance THz systems requiring substantial investment in specialized components such as femtosecond lasers or sophisticated detector arrays. The complexity of data interpretation also demands specialized expertise, further increasing the total cost of ownership for industrial users.

Existing Terahertz Inspection Methodologies

01 Terahertz imaging systems for non-destructive testing

Terahertz imaging systems provide a non-invasive method for inspecting internal structures of materials without causing damage. These systems utilize terahertz radiation to penetrate various materials and create detailed images of their internal composition. The technology enables detection of defects, voids, and inconsistencies in materials that might not be visible through other testing methods. Advanced imaging algorithms enhance the resolution and accuracy of the scans, making them valuable for quality control in manufacturing processes.- Terahertz imaging systems for non-destructive testing: Terahertz imaging systems provide a non-invasive method for inspecting internal structures of materials without causing damage. These systems utilize terahertz radiation to penetrate various materials and create detailed images of their internal composition. The technology allows for the detection of defects, voids, and inconsistencies within materials that might not be visible through other testing methods. Advanced imaging algorithms enhance the resolution and accuracy of these systems, making them valuable tools for quality control in manufacturing processes.

- Material characterization using terahertz spectroscopy: Terahertz spectroscopy enables non-destructive characterization of materials by analyzing their interaction with terahertz radiation. This technique provides information about material composition, thickness, and properties without physical sampling. The spectral response in the terahertz range can reveal unique fingerprints of different materials, allowing for identification and quality assessment. This approach is particularly valuable for analyzing layered structures, coatings, and composite materials where traditional testing methods might be inadequate or destructive.

- Portable terahertz NDT devices for field applications: Portable terahertz devices have been developed for on-site non-destructive testing applications. These compact systems bring the capabilities of terahertz technology to field environments where traditional laboratory equipment cannot be deployed. The portable devices incorporate miniaturized components and power-efficient designs while maintaining sufficient sensitivity for practical applications. These systems enable real-time inspection of structures and components in their operational environment, facilitating maintenance decisions and quality assurance outside of laboratory settings.

- Advanced signal processing for terahertz NDT data analysis: Advanced signal processing techniques enhance the interpretation of terahertz non-destructive testing data. These methods include machine learning algorithms, pattern recognition, and statistical analysis to extract meaningful information from complex terahertz signals. Signal processing approaches help overcome challenges such as noise, scattering effects, and limited penetration depth that can affect terahertz measurements. By applying these techniques, subtle defects and material variations can be detected with greater reliability and precision, improving the overall effectiveness of terahertz-based inspection systems.

- Industry-specific terahertz NDT applications: Terahertz non-destructive testing has been adapted for specific industry applications with customized solutions. In aerospace, terahertz systems inspect composite materials and detect water ingress in honeycomb structures. For pharmaceutical applications, terahertz technology analyzes tablet coating thickness and uniformity. In the semiconductor industry, it examines package integrity and internal connections. Cultural heritage conservation uses terahertz imaging to study artworks non-invasively. These specialized applications demonstrate the versatility of terahertz technology across diverse fields requiring non-destructive evaluation.

02 Material characterization using terahertz spectroscopy

Terahertz spectroscopy offers unique capabilities for material characterization in non-destructive testing applications. This technique analyzes how terahertz waves interact with different materials, providing information about their composition, density, and structural properties. The spectral fingerprints obtained can identify specific materials and detect subtle changes in their properties. This approach is particularly valuable for analyzing composite materials, polymers, and other complex structures where traditional testing methods may be insufficient.Expand Specific Solutions03 Portable terahertz NDT devices for field applications

Portable terahertz devices have been developed to bring non-destructive testing capabilities to field environments. These compact systems allow for on-site inspection of structures and components without the need to transport samples to a laboratory. The devices incorporate miniaturized terahertz sources and detectors, along with battery power systems and ruggedized housings for operation in challenging environments. This mobility extends the application of terahertz NDT to areas such as infrastructure inspection, aerospace maintenance, and cultural heritage preservation.Expand Specific Solutions04 Integration of AI and machine learning with terahertz NDT

Artificial intelligence and machine learning algorithms are being integrated with terahertz non-destructive testing to enhance defect detection and analysis capabilities. These computational approaches can automatically identify patterns in terahertz data that might be missed by human operators, improving the reliability and speed of inspections. Neural networks trained on extensive datasets can classify defects, predict material properties, and optimize testing parameters in real-time. This integration represents a significant advancement in the automation and accuracy of non-destructive evaluation systems.Expand Specific Solutions05 Multi-modal NDT combining terahertz with other techniques

Multi-modal approaches that combine terahertz technology with other non-destructive testing methods provide comprehensive material evaluation capabilities. By integrating terahertz with techniques such as ultrasound, infrared thermography, or X-ray imaging, these systems leverage the complementary strengths of different modalities. This fusion approach enables detection of a wider range of defects across various material types and depths. Advanced data fusion algorithms correlate information from multiple sensors to create more complete and accurate assessments of material integrity and structural health.Expand Specific Solutions

Leading Terahertz NDT Equipment Manufacturers

Terahertz Non-Destructive Testing (NDT) of coatings and adhesive bonds is currently in a growth phase, with the market expanding as industries recognize its potential for quality control and material characterization. The global market for terahertz technologies is projected to reach significant scale as adoption increases across aerospace, automotive, and industrial sectors. Technologically, the field shows varying maturity levels, with companies like Canon, Boeing, and Robert Bosch leading commercial applications, while PPG Industries and DuPont focus on coating-specific implementations. Academic institutions including Technische Universität Braunschweig and Xiamen University are advancing fundamental research, while specialized firms like Luna Innovations and Advantest are developing purpose-built testing equipment. The technology is transitioning from research laboratories to industrial applications, with increasing integration into manufacturing quality control systems.

The Boeing Co.

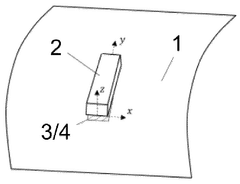

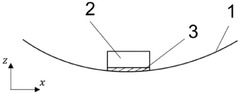

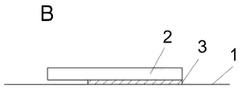

Technical Solution: Boeing has pioneered terahertz non-destructive testing technology specifically optimized for aerospace applications, focusing on composite structures and adhesive bonds critical to aircraft safety. Their proprietary THz imaging system utilizes broadband THz pulses (0.1-3 THz) to penetrate multiple layers of aircraft coatings and detect disbonds, delaminations, and moisture ingress in adhesively bonded structures. Boeing's approach combines fixed-frequency continuous wave (CW) and pulsed THz techniques to maximize both penetration depth and resolution. The system employs advanced signal processing algorithms that can distinguish between different types of defects based on their spectral signatures. Boeing has integrated their THz NDT technology into automated inspection platforms capable of scanning complex curved surfaces of aircraft components. Their solution provides quantitative measurements of bond line thickness variations and can detect contamination layers as thin as 10 μm that could compromise adhesive bond integrity. The technology has been validated through extensive testing on actual aircraft structures and has demonstrated capability to detect defects that conventional ultrasonic and thermographic methods miss.

Strengths: Specifically optimized for aerospace materials and structures; capable of inspecting complex geometries and curved surfaces; provides detailed characterization of adhesive bond quality without damaging the structure. Weaknesses: System requires significant calibration for different material combinations; inspection speed remains slower than some conventional methods for large area scanning; interpretation of results requires specialized training for aerospace applications.

Robert Bosch GmbH

Technical Solution: Bosch has engineered an industrial-grade terahertz non-destructive testing platform specifically designed for high-volume manufacturing environments where coating and adhesive bond quality is critical. Their system employs a combination of continuous wave and pulsed terahertz technologies operating in the 0.3-2 THz range to provide comprehensive inspection capabilities. Bosch's solution features proprietary semiconductor-based THz emitters and detectors that offer exceptional stability and reliability for continuous operation in production settings. The technology incorporates advanced machine learning algorithms that have been trained on thousands of samples to automatically identify and classify various types of coating and adhesive bond defects with high accuracy. Their system is designed with modular architecture that can be integrated directly into production lines for inline quality control, with specialized variants for automotive, electronics, and industrial applications. Bosch's THz NDT technology provides non-contact measurement of multiple coating layers simultaneously with thickness accuracy of ±3 μm and can detect delaminations, voids, and inclusions in adhesive bonds with high spatial resolution. The system includes comprehensive data management capabilities that enable statistical process control and traceability of inspection results.

Strengths: Designed specifically for industrial production environments with high reliability and uptime; seamless integration with manufacturing execution systems; automated defect classification reduces operator dependency. Weaknesses: Higher initial investment compared to conventional inspection methods; requires periodic recalibration for different material combinations; limited flexibility for highly customized or unusual material structures.

Key Terahertz Spectroscopy Innovations

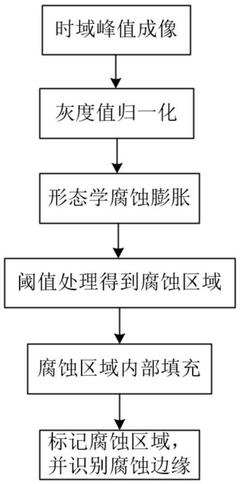

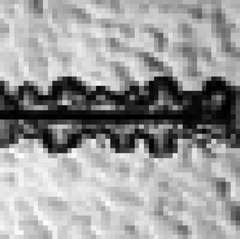

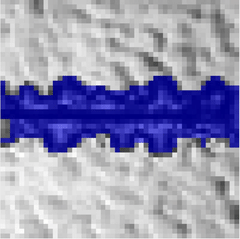

Method for nondestructive testing of metal corrosion area under anticorrosive coating based on terahertz time-domain spectroscopy

PatentPendingCN119915769A

Innovation

- The terahertz time domain spectroscopy technology combined with computer image processing is used to detect the reflected time domain waveform signal of the metal substrate through the terahertz time domain spectroscopy imaging system, and image processing is performed using peak search algorithm and morphological operations to achieve non-destructive detection of metal corrosion areas under the anti-corrosion coating.

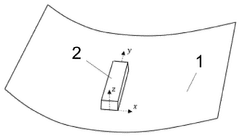

Device for testing adhesive bonds and method of testing adhesive bonds and/or bonding properties of surfaces with the device

PatentWO2025119831A1

Innovation

- A device comprising a bistable or multistable mechanical structure and a carrier, where the mechanical structure has at least two stable configurations, and the carrier is used to create a material-to-material connection with the structure to test adhesive bonds by changing the geometry of the adhesive-filled gap and applying stress.

Industrial Implementation Challenges

Despite the promising potential of terahertz non-destructive testing for coatings and adhesive bonds, several significant challenges impede widespread industrial implementation. The high cost of terahertz equipment remains a primary barrier, with comprehensive systems typically ranging from $100,000 to $500,000, making the initial investment prohibitive for many small and medium enterprises. This economic constraint limits adoption to large corporations or specialized testing facilities that can justify the expense through high-volume operations.

Technical limitations further complicate industrial deployment. Current terahertz systems often struggle with spatial resolution constraints, typically achieving only 200-300 μm resolution at 1 THz, which proves insufficient for detecting microscopic defects in thin coatings or adhesive layers. Additionally, the relatively slow scanning speed of most commercial systems creates bottlenecks in production environments where rapid inspection is essential for maintaining throughput.

Environmental factors present another layer of implementation challenges. Terahertz waves are highly sensitive to atmospheric water vapor, necessitating controlled testing environments or complex signal processing algorithms to compensate for humidity variations. Many industrial settings cannot easily accommodate these requirements, limiting practical applications in standard production facilities.

Integration with existing manufacturing processes poses significant engineering challenges. Unlike established NDT methods such as ultrasound or X-ray, which have standardized interfaces and protocols, terahertz systems often require custom integration solutions. This necessitates substantial engineering resources and process modifications that many companies are reluctant to undertake without clear return on investment projections.

The shortage of qualified personnel trained in terahertz technology interpretation represents another substantial barrier. The specialized knowledge required to properly configure equipment, conduct tests, and accurately interpret terahertz data is not widely available in the industrial workforce. This skills gap necessitates extensive training programs or reliance on external consultants, adding to implementation costs and complexity.

Regulatory and standardization issues further complicate industrial adoption. Unlike established NDT methods, terahertz testing lacks comprehensive international standards and protocols, creating uncertainty regarding certification and compliance. Industries with strict regulatory requirements, such as aerospace and automotive manufacturing, are particularly hesitant to adopt technologies without clear standardization frameworks that ensure consistent results across different systems and operators.

Technical limitations further complicate industrial deployment. Current terahertz systems often struggle with spatial resolution constraints, typically achieving only 200-300 μm resolution at 1 THz, which proves insufficient for detecting microscopic defects in thin coatings or adhesive layers. Additionally, the relatively slow scanning speed of most commercial systems creates bottlenecks in production environments where rapid inspection is essential for maintaining throughput.

Environmental factors present another layer of implementation challenges. Terahertz waves are highly sensitive to atmospheric water vapor, necessitating controlled testing environments or complex signal processing algorithms to compensate for humidity variations. Many industrial settings cannot easily accommodate these requirements, limiting practical applications in standard production facilities.

Integration with existing manufacturing processes poses significant engineering challenges. Unlike established NDT methods such as ultrasound or X-ray, which have standardized interfaces and protocols, terahertz systems often require custom integration solutions. This necessitates substantial engineering resources and process modifications that many companies are reluctant to undertake without clear return on investment projections.

The shortage of qualified personnel trained in terahertz technology interpretation represents another substantial barrier. The specialized knowledge required to properly configure equipment, conduct tests, and accurately interpret terahertz data is not widely available in the industrial workforce. This skills gap necessitates extensive training programs or reliance on external consultants, adding to implementation costs and complexity.

Regulatory and standardization issues further complicate industrial adoption. Unlike established NDT methods, terahertz testing lacks comprehensive international standards and protocols, creating uncertainty regarding certification and compliance. Industries with strict regulatory requirements, such as aerospace and automotive manufacturing, are particularly hesitant to adopt technologies without clear standardization frameworks that ensure consistent results across different systems and operators.

Safety Standards and Compliance Requirements

Terahertz non-destructive testing applications in coating and adhesive bond inspection must adhere to comprehensive safety standards and compliance requirements across multiple regulatory frameworks. The International Electrotechnical Commission (IEC) has established specific guidelines for terahertz radiation equipment, including IEC 60825 which classifies terahertz devices based on their potential hazards and establishes corresponding safety measures for each classification level.

In the United States, the Food and Drug Administration (FDA) regulates terahertz imaging systems through the Center for Devices and Radiological Health (CDRH), particularly when these systems are used for medical or consumer applications. The Occupational Safety and Health Administration (OSHA) has also implemented workplace safety standards that address potential exposure risks to non-ionizing radiation, including terahertz frequencies.

European regulations are governed by the European Committee for Electrotechnical Standardization (CENELEC), which has adopted harmonized standards aligned with the EU's Radio Equipment Directive (RED) and Electromagnetic Compatibility Directive (EMC). These standards establish specific requirements for terahertz equipment used in industrial testing environments, including maximum permissible exposure limits for operators.

The International Commission on Non-Ionizing Radiation Protection (ICNIRP) has published guidelines specifically addressing terahertz radiation exposure limits, which many national regulatory bodies have incorporated into their compliance frameworks. These guidelines establish threshold limit values (TLVs) for occupational and general public exposure to terahertz radiation.

For industrial applications in coating and adhesive bond testing, additional compliance requirements may include conformity with ISO 9712 for personnel qualification in non-destructive testing, and ISO 17025 for testing and calibration laboratories. These standards ensure that operators are properly trained and that testing procedures are conducted according to validated methodologies.

Equipment manufacturers must also comply with product safety standards such as IEC 61010 for measurement equipment safety and IEC 61326 for electromagnetic compatibility. Documentation requirements typically include detailed safety protocols, risk assessments, and operator training materials that address potential hazards associated with terahertz radiation exposure.

As terahertz technology continues to evolve, regulatory frameworks are being updated to address emerging safety concerns. Recent developments include more stringent requirements for shielding, automated safety interlocks, and real-time monitoring of radiation levels. Compliance with these evolving standards is essential for organizations implementing terahertz non-destructive testing solutions for coating and adhesive bond inspection applications.

In the United States, the Food and Drug Administration (FDA) regulates terahertz imaging systems through the Center for Devices and Radiological Health (CDRH), particularly when these systems are used for medical or consumer applications. The Occupational Safety and Health Administration (OSHA) has also implemented workplace safety standards that address potential exposure risks to non-ionizing radiation, including terahertz frequencies.

European regulations are governed by the European Committee for Electrotechnical Standardization (CENELEC), which has adopted harmonized standards aligned with the EU's Radio Equipment Directive (RED) and Electromagnetic Compatibility Directive (EMC). These standards establish specific requirements for terahertz equipment used in industrial testing environments, including maximum permissible exposure limits for operators.

The International Commission on Non-Ionizing Radiation Protection (ICNIRP) has published guidelines specifically addressing terahertz radiation exposure limits, which many national regulatory bodies have incorporated into their compliance frameworks. These guidelines establish threshold limit values (TLVs) for occupational and general public exposure to terahertz radiation.

For industrial applications in coating and adhesive bond testing, additional compliance requirements may include conformity with ISO 9712 for personnel qualification in non-destructive testing, and ISO 17025 for testing and calibration laboratories. These standards ensure that operators are properly trained and that testing procedures are conducted according to validated methodologies.

Equipment manufacturers must also comply with product safety standards such as IEC 61010 for measurement equipment safety and IEC 61326 for electromagnetic compatibility. Documentation requirements typically include detailed safety protocols, risk assessments, and operator training materials that address potential hazards associated with terahertz radiation exposure.

As terahertz technology continues to evolve, regulatory frameworks are being updated to address emerging safety concerns. Recent developments include more stringent requirements for shielding, automated safety interlocks, and real-time monitoring of radiation levels. Compliance with these evolving standards is essential for organizations implementing terahertz non-destructive testing solutions for coating and adhesive bond inspection applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!