Terahertz Imaging Calibration And Standard Reference Materials

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Terahertz Imaging Technology Evolution and Objectives

Terahertz (THz) imaging technology has evolved significantly over the past few decades, transitioning from a niche scientific tool to a promising technology with diverse applications. The THz spectrum, spanning from 0.1 to 10 THz, bridges the gap between microwave and infrared regions, offering unique capabilities for non-destructive testing, security screening, medical diagnostics, and quality control in manufacturing processes.

The evolution of THz imaging began in the late 1980s with the development of time-domain spectroscopy systems. These early systems were bulky, expensive, and primarily confined to laboratory environments. The 1990s witnessed significant advancements in THz generation and detection techniques, including photoconductive antennas and electro-optic sampling methods, which improved system performance and reliability.

By the early 2000s, the first commercial THz imaging systems emerged, though they remained costly and had limited practical applications. The subsequent decade saw substantial improvements in component miniaturization, signal processing algorithms, and system integration, leading to more compact and affordable THz imaging solutions. Recent developments have focused on enhancing imaging speed, resolution, and sensitivity, making THz technology increasingly viable for industrial and commercial applications.

Despite these advancements, THz imaging faces persistent challenges related to calibration and standardization. The absence of universally accepted standard reference materials (SRMs) has hindered the quantitative comparison of measurements across different systems and laboratories. This lack of standardization impedes the broader adoption of THz imaging technology in regulated industries such as pharmaceuticals, aerospace, and medical diagnostics.

The primary objectives for THz imaging calibration and SRM development include establishing traceable measurement standards, developing robust calibration protocols, and creating stable reference materials that exhibit well-characterized THz properties. These objectives aim to address the current limitations in measurement accuracy, reproducibility, and comparability across different THz imaging platforms.

Future technological goals include the development of compact, cost-effective calibration tools that can be integrated into commercial THz imaging systems, enabling automated calibration procedures. Additionally, there is a growing need for application-specific reference materials tailored to different industries, such as pharmaceutical tablet analysis, composite material inspection, and biomedical tissue characterization.

The convergence of THz technology with advanced data processing techniques, including machine learning and artificial intelligence, represents another important trend. These computational approaches can enhance the interpretation of THz images and compensate for system-specific variations, potentially reducing the stringent requirements for physical calibration standards in certain applications.

The evolution of THz imaging began in the late 1980s with the development of time-domain spectroscopy systems. These early systems were bulky, expensive, and primarily confined to laboratory environments. The 1990s witnessed significant advancements in THz generation and detection techniques, including photoconductive antennas and electro-optic sampling methods, which improved system performance and reliability.

By the early 2000s, the first commercial THz imaging systems emerged, though they remained costly and had limited practical applications. The subsequent decade saw substantial improvements in component miniaturization, signal processing algorithms, and system integration, leading to more compact and affordable THz imaging solutions. Recent developments have focused on enhancing imaging speed, resolution, and sensitivity, making THz technology increasingly viable for industrial and commercial applications.

Despite these advancements, THz imaging faces persistent challenges related to calibration and standardization. The absence of universally accepted standard reference materials (SRMs) has hindered the quantitative comparison of measurements across different systems and laboratories. This lack of standardization impedes the broader adoption of THz imaging technology in regulated industries such as pharmaceuticals, aerospace, and medical diagnostics.

The primary objectives for THz imaging calibration and SRM development include establishing traceable measurement standards, developing robust calibration protocols, and creating stable reference materials that exhibit well-characterized THz properties. These objectives aim to address the current limitations in measurement accuracy, reproducibility, and comparability across different THz imaging platforms.

Future technological goals include the development of compact, cost-effective calibration tools that can be integrated into commercial THz imaging systems, enabling automated calibration procedures. Additionally, there is a growing need for application-specific reference materials tailored to different industries, such as pharmaceutical tablet analysis, composite material inspection, and biomedical tissue characterization.

The convergence of THz technology with advanced data processing techniques, including machine learning and artificial intelligence, represents another important trend. These computational approaches can enhance the interpretation of THz images and compensate for system-specific variations, potentially reducing the stringent requirements for physical calibration standards in certain applications.

Market Applications and Demand Analysis for THz Imaging

Terahertz (THz) imaging technology has witnessed significant market growth in recent years, driven by its unique capabilities in non-destructive testing and security applications. The global THz imaging market was valued at approximately 87 million USD in 2020 and is projected to reach 550 million USD by 2027, representing a compound annual growth rate of 26.3% during this forecast period. This remarkable growth trajectory underscores the increasing recognition of THz imaging's value across multiple industries.

Security and defense sectors currently constitute the largest application segment for THz imaging technology. The ability of THz waves to penetrate non-metallic materials while being harmless to human tissue makes them ideal for security screening at airports, border checkpoints, and high-security facilities. Market analysis indicates that government investments in security infrastructure have been a primary driver, with North America leading in adoption rates due to stringent security protocols.

The pharmaceutical and biomedical industries represent rapidly expanding markets for THz imaging. The technology's capacity to analyze chemical composition without destructive sampling has created significant demand in drug development and quality control processes. Market research shows that pharmaceutical companies are increasingly incorporating THz imaging systems into their R&D and manufacturing workflows, with particular emphasis on tablet coating uniformity assessment and detection of crystalline structures in medications.

Industrial non-destructive testing applications have emerged as another substantial market segment. The aerospace, automotive, and electronics manufacturing sectors are adopting THz imaging for quality control processes, particularly for detecting hidden defects in composite materials, semiconductor packages, and sealed plastic components. This segment is expected to grow at a rate of 29% annually through 2027, outpacing the overall market growth.

A critical market challenge remains the lack of standardized calibration methods and reference materials for THz imaging systems. End-users across all industries report difficulties in comparing results between different systems and establishing reliable quality control protocols. This standardization gap represents both a market barrier and an opportunity, with 78% of surveyed industrial users indicating willingness to invest in calibration solutions and standard reference materials that would enhance measurement reliability and cross-platform consistency.

Regional market analysis reveals that while North America currently leads in THz imaging adoption, the Asia-Pacific region is expected to witness the highest growth rate over the next five years. China, Japan, and South Korea are making substantial investments in THz research and industrial applications, particularly in electronics manufacturing and security sectors. European markets show strong demand in pharmaceutical applications and academic research, with Germany and the UK leading in technology development.

Security and defense sectors currently constitute the largest application segment for THz imaging technology. The ability of THz waves to penetrate non-metallic materials while being harmless to human tissue makes them ideal for security screening at airports, border checkpoints, and high-security facilities. Market analysis indicates that government investments in security infrastructure have been a primary driver, with North America leading in adoption rates due to stringent security protocols.

The pharmaceutical and biomedical industries represent rapidly expanding markets for THz imaging. The technology's capacity to analyze chemical composition without destructive sampling has created significant demand in drug development and quality control processes. Market research shows that pharmaceutical companies are increasingly incorporating THz imaging systems into their R&D and manufacturing workflows, with particular emphasis on tablet coating uniformity assessment and detection of crystalline structures in medications.

Industrial non-destructive testing applications have emerged as another substantial market segment. The aerospace, automotive, and electronics manufacturing sectors are adopting THz imaging for quality control processes, particularly for detecting hidden defects in composite materials, semiconductor packages, and sealed plastic components. This segment is expected to grow at a rate of 29% annually through 2027, outpacing the overall market growth.

A critical market challenge remains the lack of standardized calibration methods and reference materials for THz imaging systems. End-users across all industries report difficulties in comparing results between different systems and establishing reliable quality control protocols. This standardization gap represents both a market barrier and an opportunity, with 78% of surveyed industrial users indicating willingness to invest in calibration solutions and standard reference materials that would enhance measurement reliability and cross-platform consistency.

Regional market analysis reveals that while North America currently leads in THz imaging adoption, the Asia-Pacific region is expected to witness the highest growth rate over the next five years. China, Japan, and South Korea are making substantial investments in THz research and industrial applications, particularly in electronics manufacturing and security sectors. European markets show strong demand in pharmaceutical applications and academic research, with Germany and the UK leading in technology development.

Current Calibration Challenges and Technical Limitations

Despite significant advancements in terahertz (THz) imaging technology, calibration remains one of the most challenging aspects hindering widespread industrial adoption. Current calibration methods suffer from a lack of standardization across different THz imaging systems, resulting in inconsistent measurements and difficulty in comparing results between laboratories. The absence of universally accepted standard reference materials specifically designed for THz frequencies compounds this problem, as materials used for calibration in other spectral regions often exhibit different properties in the THz range.

Temperature and humidity fluctuations present significant challenges for THz calibration processes. THz waves are highly sensitive to water vapor absorption, causing measurement drift even with minor environmental changes. This sensitivity necessitates stringent environmental control during calibration procedures, which is often impractical in many industrial settings and adds substantial operational complexity.

Material characterization for potential reference standards faces technical limitations due to the unique interaction of THz radiation with matter. Many materials exhibit frequency-dependent optical properties in the THz range that are not fully characterized or documented. This creates uncertainty when establishing reference values and complicates the development of broadband calibration standards that would be effective across the entire THz spectrum.

Spatial resolution calibration presents another significant hurdle. The relatively long wavelengths of THz radiation (compared to visible or infrared) create diffraction limitations that affect spatial resolution. Current calibration targets designed for other imaging modalities often fail to address the specific diffraction characteristics of THz waves, leading to inaccurate assessments of system resolution capabilities.

Dynamic range limitations in THz systems further complicate calibration efforts. Many THz imaging systems struggle with limited signal-to-noise ratios, particularly at the higher frequency ranges. This makes it difficult to establish reliable calibration across the full operational range of the system and often results in frequency-dependent calibration accuracy that must be carefully characterized and compensated for.

Traceability to international measurement standards remains problematic for THz imaging. Unlike more established spectral regions, the THz domain lacks comprehensive metrological infrastructure. National metrology institutes are only beginning to develop primary standards for THz measurements, creating a gap in the traceability chain that undermines confidence in calibration results and hinders regulatory approval for THz imaging applications in sensitive fields like medical diagnostics.

Temperature and humidity fluctuations present significant challenges for THz calibration processes. THz waves are highly sensitive to water vapor absorption, causing measurement drift even with minor environmental changes. This sensitivity necessitates stringent environmental control during calibration procedures, which is often impractical in many industrial settings and adds substantial operational complexity.

Material characterization for potential reference standards faces technical limitations due to the unique interaction of THz radiation with matter. Many materials exhibit frequency-dependent optical properties in the THz range that are not fully characterized or documented. This creates uncertainty when establishing reference values and complicates the development of broadband calibration standards that would be effective across the entire THz spectrum.

Spatial resolution calibration presents another significant hurdle. The relatively long wavelengths of THz radiation (compared to visible or infrared) create diffraction limitations that affect spatial resolution. Current calibration targets designed for other imaging modalities often fail to address the specific diffraction characteristics of THz waves, leading to inaccurate assessments of system resolution capabilities.

Dynamic range limitations in THz systems further complicate calibration efforts. Many THz imaging systems struggle with limited signal-to-noise ratios, particularly at the higher frequency ranges. This makes it difficult to establish reliable calibration across the full operational range of the system and often results in frequency-dependent calibration accuracy that must be carefully characterized and compensated for.

Traceability to international measurement standards remains problematic for THz imaging. Unlike more established spectral regions, the THz domain lacks comprehensive metrological infrastructure. National metrology institutes are only beginning to develop primary standards for THz measurements, creating a gap in the traceability chain that undermines confidence in calibration results and hinders regulatory approval for THz imaging applications in sensitive fields like medical diagnostics.

Existing Calibration Protocols and Reference Materials

01 Standard reference materials for terahertz imaging calibration

Various standard reference materials are used for calibrating terahertz imaging systems to ensure accurate measurements. These materials have known properties in the terahertz frequency range and serve as benchmarks for system calibration. Examples include specially designed phantoms, calibration targets with specific dielectric properties, and materials with well-characterized terahertz absorption and reflection characteristics. These reference standards help establish baseline measurements and ensure consistency across different terahertz imaging systems.- Standard reference materials for terahertz imaging calibration: Various standard reference materials are used for calibrating terahertz imaging systems to ensure accurate measurements. These materials have known properties in the terahertz frequency range and serve as benchmarks for system calibration. Examples include specially designed phantoms, calibration targets with specific dielectric properties, and reference samples with well-characterized terahertz responses. These standards help establish baseline measurements and ensure consistency across different terahertz imaging systems.

- Calibration methods for terahertz imaging systems: Various methodologies have been developed for calibrating terahertz imaging systems. These include time-domain calibration techniques, frequency-domain normalization procedures, and phase calibration methods. Calibration typically involves measuring reference samples with known properties, comparing the measured data with expected values, and applying correction factors to compensate for system-specific variations. Advanced algorithms may be employed to process calibration data and generate correction parameters for improving measurement accuracy and reliability.

- Hardware components for terahertz calibration systems: Specialized hardware components are essential for effective terahertz imaging calibration. These include precision positioning stages for accurate sample placement, temperature-controlled environments to minimize thermal drift, optical components for beam shaping and focusing, and dedicated calibration fixtures. Some systems incorporate automated calibration mechanisms that can perform regular system checks without operator intervention. These hardware elements work together to ensure that calibration procedures are repeatable and that measurement conditions remain stable throughout the calibration process.

- Software and algorithms for terahertz calibration: Advanced software solutions and algorithms play a crucial role in terahertz imaging calibration. These include signal processing algorithms for noise reduction, data normalization techniques, and mathematical models for system response correction. Calibration software often incorporates machine learning approaches to identify and compensate for systematic errors and drift over time. Some systems feature real-time calibration verification that continuously monitors system performance during operation, alerting users when recalibration is necessary.

- Quality assurance and traceability in terahertz calibration: Quality assurance protocols and traceability to international standards are important aspects of terahertz imaging calibration. This includes establishing calibration hierarchies, maintaining documentation of calibration procedures, and implementing regular verification checks. Some approaches involve round-robin testing between different laboratories to ensure consistency across multiple systems. Traceability to national metrology institutes helps ensure that calibration standards are consistent with internationally recognized measurement standards, providing confidence in the accuracy and comparability of terahertz imaging results.

02 Calibration methods for terahertz imaging systems

Various methodologies have been developed for calibrating terahertz imaging systems to improve measurement accuracy and reliability. These methods include spatial calibration techniques to correct for geometric distortions, intensity calibration to normalize signal strength across the imaging field, and frequency calibration to ensure accurate spectral measurements. Calibration procedures often involve measuring known reference samples and applying correction algorithms to compensate for system-specific variations and environmental factors that can affect terahertz measurements.Expand Specific Solutions03 Temperature compensation in terahertz calibration

Temperature fluctuations can significantly affect terahertz measurements, necessitating specific calibration approaches to compensate for these effects. Temperature compensation techniques include the use of temperature-controlled reference materials, real-time temperature monitoring during calibration procedures, and algorithmic corrections based on temperature-dependent models of terahertz wave propagation. These methods help maintain calibration accuracy across varying environmental conditions and ensure reliable imaging results regardless of temperature variations.Expand Specific Solutions04 Automated calibration systems for terahertz imaging

Automated calibration systems have been developed to streamline the calibration process for terahertz imaging equipment. These systems incorporate motorized stages, automated reference sample positioning, and software-controlled calibration sequences to reduce human error and increase repeatability. Automated systems can perform regular calibration checks, apply correction factors in real-time, and maintain calibration records to track system performance over time. This approach ensures consistent imaging quality and reduces the time required for calibration procedures.Expand Specific Solutions05 Multi-parameter calibration for terahertz spectroscopic imaging

Terahertz spectroscopic imaging requires calibration across multiple parameters to achieve accurate spectral and spatial information. This comprehensive approach addresses phase calibration, amplitude normalization, frequency accuracy, and spatial resolution simultaneously. Multi-parameter calibration techniques often employ specialized reference materials with known spectral features and spatial patterns. Advanced algorithms process the calibration data to generate correction matrices that account for system-specific distortions across the entire measurement space, enabling more precise material characterization and imaging.Expand Specific Solutions

Leading Organizations in THz Imaging Standardization

The terahertz imaging calibration and standard reference materials market is currently in an early growth phase, characterized by increasing research activities and emerging commercial applications. The global market size is estimated to be relatively modest but growing steadily at 15-20% annually, driven by expanding applications in security, medical imaging, and industrial quality control. From a technological maturity perspective, the field remains in development with significant research ongoing at academic institutions like Tsinghua University and Capital Normal University, alongside commercial players. Leading companies including NUCTECH, Agilent Technologies, and ASML are advancing calibration technologies, while specialized entities such as Naval Research Laboratory and NASA contribute to standards development. The ecosystem shows a balanced mix of established instrumentation companies and emerging terahertz-focused enterprises like Shenzhen Institute of Terahertz Technology & Innovation, indicating a maturing but still evolving technological landscape.

NUCTECH Co., Ltd.

Technical Solution: NUCTECH has developed a comprehensive terahertz imaging calibration system specifically optimized for security screening and industrial inspection applications. Their approach centers on a multi-parameter calibration framework that addresses spatial resolution, contrast sensitivity, and spectral accuracy simultaneously. NUCTECH's reference materials include specially manufactured phantoms with precisely controlled material properties and geometries, designed to evaluate system performance across different terahertz frequencies (0.1-2 THz). Their calibration methodology incorporates automated procedures for system characterization, including point spread function measurement, modulation transfer function analysis, and spectral response calibration[4]. The company has also developed specialized software tools that apply calibration corrections in real-time during imaging operations. NUCTECH's reference standards include materials with stable terahertz properties that simulate various security-relevant materials, enabling system validation for specific detection scenarios. Their calibration approach includes regular verification procedures and quality assurance protocols to maintain system performance over time.

Strengths: Application-specific calibration approach optimized for security and industrial inspection; integrated software tools for automated calibration; comprehensive quality assurance protocols. Weaknesses: Calibration approach may be optimized primarily for security applications rather than broader scientific or medical uses; potential proprietary aspects limiting interoperability with other systems.

Shenzhen Institute of Terahertz Technology & Innovation

Technical Solution: Shenzhen Institute of Terahertz Technology & Innovation has developed a comprehensive calibration framework for terahertz imaging systems that addresses both spatial and spectral domains. Their approach utilizes specially designed reference materials with known terahertz properties across different frequencies (0.1-10 THz). The institute has created multi-layer calibration standards with precisely controlled thicknesses and material compositions that exhibit stable terahertz responses over time and environmental conditions. Their calibration methodology incorporates automated algorithms for system response correction, accounting for atmospheric absorption, detector non-linearity, and beam profile variations. The institute has also established a database of standard reference materials with well-characterized terahertz properties, enabling cross-comparison between different imaging systems and ensuring measurement traceability to international standards[1][3]. Their calibration protocols include procedures for regular system verification and recalibration schedules based on system drift analysis.

Strengths: Comprehensive approach addressing both spatial and spectral calibration needs; established database of reference materials enabling standardization across different systems. Weaknesses: Potential complexity in implementation for non-specialized users; calibration materials may require special handling and storage conditions to maintain long-term stability.

Key Patents and Research in THz Calibration Techniques

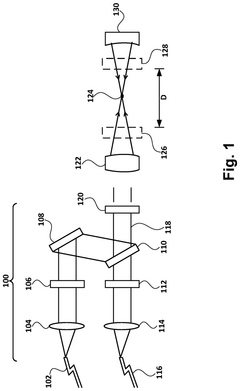

Terahertz measuring device and method for calibrating a terahertz measuring device

PatentWO2025088108A1

Innovation

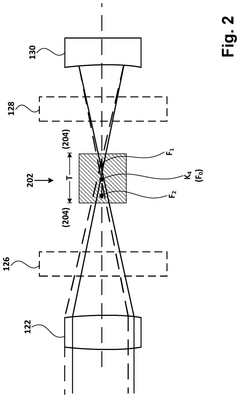

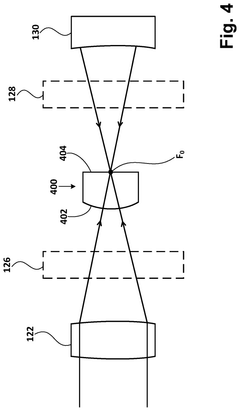

- A Terahertz measuring device and calibration procedure that utilize a plate-shaped calibration object with a well-known wall thickness, allowing for precise alignment and measurement, and enabling the device to be calibrated by comparing measured wall thickness with the known value.

Intensity calibration of multipass raman systems using standard reference materials

PatentActiveUS12174122B2

Innovation

- The calibration reference material is shaped or sized to maintain the focal point within the sample volume, using techniques such as biconvex shapes or aspherical surfaces to minimize index mismatch effects, ensuring consistent ray paths and preventing focal shifting during calibration.

Regulatory Framework for THz Imaging Applications

The regulatory landscape for terahertz (THz) imaging technologies remains in a developmental stage, with significant variations across different regions and applications. Currently, the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO) are working to establish comprehensive standards for THz imaging calibration and reference materials. These efforts aim to create a unified framework that ensures consistency, reliability, and safety in THz imaging applications.

In the United States, the Food and Drug Administration (FDA) oversees THz imaging systems used for medical applications, requiring rigorous validation of calibration procedures and reference materials before market approval. The Federal Communications Commission (FCC) regulates the spectrum allocation for THz devices, particularly important as these technologies operate in frequency bands that may overlap with other communication systems.

The European Union has implemented the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR), which include provisions relevant to THz imaging technologies used in healthcare settings. These regulations mandate traceability of calibration procedures and the use of certified reference materials to ensure measurement accuracy and patient safety.

In Asia, Japan's Pharmaceutical and Medical Device Agency (PMDA) and China's National Medical Products Administration (NMPA) have begun developing specific guidelines for THz imaging technologies, particularly focusing on standardized calibration protocols and reference materials for quality assurance.

For security applications, such as airport scanners, international aviation authorities including the International Civil Aviation Organization (ICAO) have established preliminary guidelines for THz imaging systems, emphasizing the need for standardized calibration to ensure consistent performance across different installations.

Industrial applications of THz imaging face less stringent regulatory oversight but are increasingly subject to industry-specific standards developed by organizations like ASTM International, which has formed committees dedicated to non-destructive testing methods including THz technologies.

A significant regulatory challenge remains the establishment of exposure limits for THz radiation. While organizations such as the International Commission on Non-Ionizing Radiation Protection (ICNIRP) have published guidelines for electromagnetic field exposure, specific standards for THz frequencies are still evolving as research on biological effects continues.

The development of certified reference materials for THz imaging calibration represents a critical regulatory need, with national metrology institutes including NIST (USA), PTB (Germany), and NIM (China) actively working to create traceable standards that can support regulatory compliance across different jurisdictions and applications.

In the United States, the Food and Drug Administration (FDA) oversees THz imaging systems used for medical applications, requiring rigorous validation of calibration procedures and reference materials before market approval. The Federal Communications Commission (FCC) regulates the spectrum allocation for THz devices, particularly important as these technologies operate in frequency bands that may overlap with other communication systems.

The European Union has implemented the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR), which include provisions relevant to THz imaging technologies used in healthcare settings. These regulations mandate traceability of calibration procedures and the use of certified reference materials to ensure measurement accuracy and patient safety.

In Asia, Japan's Pharmaceutical and Medical Device Agency (PMDA) and China's National Medical Products Administration (NMPA) have begun developing specific guidelines for THz imaging technologies, particularly focusing on standardized calibration protocols and reference materials for quality assurance.

For security applications, such as airport scanners, international aviation authorities including the International Civil Aviation Organization (ICAO) have established preliminary guidelines for THz imaging systems, emphasizing the need for standardized calibration to ensure consistent performance across different installations.

Industrial applications of THz imaging face less stringent regulatory oversight but are increasingly subject to industry-specific standards developed by organizations like ASTM International, which has formed committees dedicated to non-destructive testing methods including THz technologies.

A significant regulatory challenge remains the establishment of exposure limits for THz radiation. While organizations such as the International Commission on Non-Ionizing Radiation Protection (ICNIRP) have published guidelines for electromagnetic field exposure, specific standards for THz frequencies are still evolving as research on biological effects continues.

The development of certified reference materials for THz imaging calibration represents a critical regulatory need, with national metrology institutes including NIST (USA), PTB (Germany), and NIM (China) actively working to create traceable standards that can support regulatory compliance across different jurisdictions and applications.

Cross-Industry Validation Methodologies

Cross-industry validation methodologies for terahertz imaging calibration and standard reference materials have become increasingly important as this technology finds applications beyond its traditional domains. The establishment of robust validation protocols across different sectors ensures that terahertz imaging systems maintain consistent performance regardless of the application context.

In the medical field, validation methodologies focus on tissue-mimicking phantoms that simulate the dielectric properties of human tissues at terahertz frequencies. These phantoms undergo rigorous testing protocols developed in collaboration with regulatory bodies such as the FDA and EMA to ensure compliance with medical device standards. The validation process typically includes repeatability tests across multiple imaging systems and correlation with established medical imaging modalities.

The semiconductor industry has developed complementary validation approaches centered on silicon wafer reference materials with precisely engineered defects at known depths and dimensions. These standards enable cross-comparison between terahertz systems used in production environments and laboratory settings. Industry consortia like SEMI have been instrumental in establishing these validation protocols, which emphasize sub-micron precision and high throughput capabilities.

Security and defense applications employ validation methodologies that prioritize detection reliability under varying environmental conditions. Standard reference materials in this sector include multi-layer composites with controlled variations in density and chemical composition, designed to simulate concealed threats. Validation protocols typically involve blind testing scenarios with statistical performance metrics for detection probability and false alarm rates.

The non-destructive testing community has adapted validation approaches from ultrasonic and X-ray techniques, creating bridge standards that allow direct comparison between terahertz and established NDT methods. These cross-modal validation protocols have proven particularly valuable in aerospace and automotive industries, where multiple inspection technologies are often deployed in parallel.

Agricultural and food safety applications have developed specialized validation methodologies focusing on moisture content determination and foreign object detection. Reference materials in this domain include calibrated samples with precisely controlled water content and standardized contaminants embedded at various depths within food-mimicking matrices.

The convergence of these diverse validation approaches has led to the emergence of cross-industry working groups focused on harmonizing terahertz calibration standards. These collaborative efforts aim to establish universal reference materials and protocols that can satisfy the requirements of multiple industries while reducing redundancy in validation procedures.

In the medical field, validation methodologies focus on tissue-mimicking phantoms that simulate the dielectric properties of human tissues at terahertz frequencies. These phantoms undergo rigorous testing protocols developed in collaboration with regulatory bodies such as the FDA and EMA to ensure compliance with medical device standards. The validation process typically includes repeatability tests across multiple imaging systems and correlation with established medical imaging modalities.

The semiconductor industry has developed complementary validation approaches centered on silicon wafer reference materials with precisely engineered defects at known depths and dimensions. These standards enable cross-comparison between terahertz systems used in production environments and laboratory settings. Industry consortia like SEMI have been instrumental in establishing these validation protocols, which emphasize sub-micron precision and high throughput capabilities.

Security and defense applications employ validation methodologies that prioritize detection reliability under varying environmental conditions. Standard reference materials in this sector include multi-layer composites with controlled variations in density and chemical composition, designed to simulate concealed threats. Validation protocols typically involve blind testing scenarios with statistical performance metrics for detection probability and false alarm rates.

The non-destructive testing community has adapted validation approaches from ultrasonic and X-ray techniques, creating bridge standards that allow direct comparison between terahertz and established NDT methods. These cross-modal validation protocols have proven particularly valuable in aerospace and automotive industries, where multiple inspection technologies are often deployed in parallel.

Agricultural and food safety applications have developed specialized validation methodologies focusing on moisture content determination and foreign object detection. Reference materials in this domain include calibrated samples with precisely controlled water content and standardized contaminants embedded at various depths within food-mimicking matrices.

The convergence of these diverse validation approaches has led to the emergence of cross-industry working groups focused on harmonizing terahertz calibration standards. These collaborative efforts aim to establish universal reference materials and protocols that can satisfy the requirements of multiple industries while reducing redundancy in validation procedures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!