Case Studies: THz Deployment For Aerospace Composite Inspection

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

THz Technology Background and Aerospace Inspection Goals

Terahertz (THz) technology represents a significant advancement in non-destructive testing (NDT) methodologies, operating in the frequency range between microwave and infrared radiation (0.1-10 THz). This electromagnetic spectrum region offers unique capabilities for material inspection, particularly for aerospace composites, due to its non-ionizing nature and ability to penetrate non-metallic materials while providing high-resolution imaging.

The evolution of THz technology began in the late 1980s with the development of time-domain spectroscopy systems, but practical applications were limited by technological constraints. The past two decades have witnessed remarkable progress in THz source and detector technologies, transitioning from bulky, expensive laboratory equipment to more compact, field-deployable systems. This technological maturation has enabled the aerospace industry to consider THz inspection as a viable solution for composite material evaluation.

Aerospace composites, including carbon fiber reinforced polymers (CFRP) and glass fiber reinforced polymers (GFRP), have revolutionized aircraft design by offering superior strength-to-weight ratios compared to traditional metallic materials. However, these materials present unique inspection challenges due to their heterogeneous structure and susceptibility to internal defects that may not be visible on the surface, such as delaminations, voids, and moisture ingress.

Current inspection methods for aerospace composites include ultrasonic testing, radiography, and thermography, each with inherent limitations. Ultrasonic techniques struggle with highly attenuative materials, radiography poses radiation safety concerns, and thermography offers limited depth resolution. THz technology addresses these limitations by providing non-contact, non-ionizing inspection with the ability to detect subsurface defects at high resolution.

The primary technical goals for THz deployment in aerospace composite inspection include: developing systems capable of detecting critical defects (typically 1-2mm) at depths up to 10mm in composite structures; achieving inspection speeds compatible with production environments; creating reliable data processing algorithms for automated defect recognition; and establishing industry-accepted standards for THz inspection procedures and equipment qualification.

Additionally, the aerospace industry seeks portable THz systems that can be deployed for in-service inspection of aircraft components, reducing maintenance downtime and enhancing safety. The technology must demonstrate reliability in varied environmental conditions and provide quantitative assessment of defect characteristics such as size, depth, and nature.

The convergence of advanced THz hardware development with sophisticated signal processing techniques presents a promising pathway toward meeting these goals. Recent advancements in semiconductor-based THz sources, photoconductive antennas, and quantum cascade lasers have significantly improved system performance while reducing size and cost, making industrial implementation increasingly feasible for aerospace applications.

The evolution of THz technology began in the late 1980s with the development of time-domain spectroscopy systems, but practical applications were limited by technological constraints. The past two decades have witnessed remarkable progress in THz source and detector technologies, transitioning from bulky, expensive laboratory equipment to more compact, field-deployable systems. This technological maturation has enabled the aerospace industry to consider THz inspection as a viable solution for composite material evaluation.

Aerospace composites, including carbon fiber reinforced polymers (CFRP) and glass fiber reinforced polymers (GFRP), have revolutionized aircraft design by offering superior strength-to-weight ratios compared to traditional metallic materials. However, these materials present unique inspection challenges due to their heterogeneous structure and susceptibility to internal defects that may not be visible on the surface, such as delaminations, voids, and moisture ingress.

Current inspection methods for aerospace composites include ultrasonic testing, radiography, and thermography, each with inherent limitations. Ultrasonic techniques struggle with highly attenuative materials, radiography poses radiation safety concerns, and thermography offers limited depth resolution. THz technology addresses these limitations by providing non-contact, non-ionizing inspection with the ability to detect subsurface defects at high resolution.

The primary technical goals for THz deployment in aerospace composite inspection include: developing systems capable of detecting critical defects (typically 1-2mm) at depths up to 10mm in composite structures; achieving inspection speeds compatible with production environments; creating reliable data processing algorithms for automated defect recognition; and establishing industry-accepted standards for THz inspection procedures and equipment qualification.

Additionally, the aerospace industry seeks portable THz systems that can be deployed for in-service inspection of aircraft components, reducing maintenance downtime and enhancing safety. The technology must demonstrate reliability in varied environmental conditions and provide quantitative assessment of defect characteristics such as size, depth, and nature.

The convergence of advanced THz hardware development with sophisticated signal processing techniques presents a promising pathway toward meeting these goals. Recent advancements in semiconductor-based THz sources, photoconductive antennas, and quantum cascade lasers have significantly improved system performance while reducing size and cost, making industrial implementation increasingly feasible for aerospace applications.

Market Demand for Advanced Composite Inspection Solutions

The aerospace industry has witnessed a significant shift towards advanced composite materials in aircraft manufacturing, with modern aircraft like the Boeing 787 and Airbus A350 comprising over 50% composite materials by weight. This transition has created an urgent demand for sophisticated inspection technologies capable of detecting defects in these complex materials. The global non-destructive testing (NDT) market for aerospace composites was valued at approximately $780 million in 2022 and is projected to grow at a CAGR of 7.8% through 2028, highlighting the expanding market for advanced inspection solutions.

Traditional inspection methods such as ultrasonic testing and X-ray radiography face limitations when applied to aerospace composites, particularly in detecting subsurface defects, delaminations, and moisture ingress without causing damage to the material. This has created a substantial market gap for non-contact, high-resolution inspection technologies like Terahertz (THz) imaging systems that can provide comprehensive defect detection capabilities.

Aircraft manufacturers and maintenance, repair, and overhaul (MRO) service providers represent the primary market segments demanding advanced composite inspection solutions. These stakeholders require technologies that can be integrated into production lines for quality control and deployed in maintenance facilities for regular inspections. The increasing service life of modern aircraft, now extending beyond 25 years, further amplifies the need for reliable inspection technologies to ensure structural integrity throughout the operational lifecycle.

Regulatory pressures from aviation authorities worldwide have intensified the market demand for advanced inspection solutions. The Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have implemented stringent airworthiness directives requiring comprehensive inspection protocols for composite structures, creating a compliance-driven market for technologies like THz imaging systems.

Cost considerations remain a significant factor influencing market adoption. While aerospace operators recognize the value of advanced inspection technologies in preventing catastrophic failures and reducing maintenance downtime, the return on investment must be clearly demonstrated. THz inspection systems that can reduce inspection time by 30% compared to conventional methods while improving defect detection rates have shown promising market acceptance.

The defense aerospace sector represents another substantial market segment, with military aircraft operators seeking technologies capable of rapidly assessing battle damage and ensuring airworthiness under field conditions. This segment values portable THz systems that can be deployed in various operational environments with minimal setup requirements.

Traditional inspection methods such as ultrasonic testing and X-ray radiography face limitations when applied to aerospace composites, particularly in detecting subsurface defects, delaminations, and moisture ingress without causing damage to the material. This has created a substantial market gap for non-contact, high-resolution inspection technologies like Terahertz (THz) imaging systems that can provide comprehensive defect detection capabilities.

Aircraft manufacturers and maintenance, repair, and overhaul (MRO) service providers represent the primary market segments demanding advanced composite inspection solutions. These stakeholders require technologies that can be integrated into production lines for quality control and deployed in maintenance facilities for regular inspections. The increasing service life of modern aircraft, now extending beyond 25 years, further amplifies the need for reliable inspection technologies to ensure structural integrity throughout the operational lifecycle.

Regulatory pressures from aviation authorities worldwide have intensified the market demand for advanced inspection solutions. The Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have implemented stringent airworthiness directives requiring comprehensive inspection protocols for composite structures, creating a compliance-driven market for technologies like THz imaging systems.

Cost considerations remain a significant factor influencing market adoption. While aerospace operators recognize the value of advanced inspection technologies in preventing catastrophic failures and reducing maintenance downtime, the return on investment must be clearly demonstrated. THz inspection systems that can reduce inspection time by 30% compared to conventional methods while improving defect detection rates have shown promising market acceptance.

The defense aerospace sector represents another substantial market segment, with military aircraft operators seeking technologies capable of rapidly assessing battle damage and ensuring airworthiness under field conditions. This segment values portable THz systems that can be deployed in various operational environments with minimal setup requirements.

Current State and Challenges of THz Inspection Technology

Terahertz (THz) inspection technology for aerospace composite materials has witnessed significant advancements globally, yet faces several critical challenges that impede its widespread industrial adoption. Currently, THz systems operate in the frequency range of 0.1-10 THz, offering unique capabilities for non-destructive testing of aerospace composites due to their ability to penetrate non-metallic materials while providing high resolution imaging.

The state-of-the-art THz inspection systems primarily utilize either time-domain spectroscopy (TDS) or continuous-wave (CW) approaches. TDS systems provide broadband spectral information but suffer from slower acquisition speeds, while CW systems offer faster scanning capabilities at the expense of spectral diversity. Recent developments have focused on improving signal-to-noise ratios and acquisition speeds, with some commercial systems now capable of scanning speeds up to 10 m²/hour for aerospace applications.

Geographically, THz technology development shows distinct regional characteristics. North America leads in system integration and aerospace applications, with NASA and major aerospace manufacturers conducting extensive research. Europe demonstrates strength in fundamental THz research and algorithm development, particularly in Germany and the UK. Meanwhile, Asia, especially China and Japan, has made significant progress in component manufacturing and miniaturization of THz systems.

Despite these advancements, several technical challenges persist. The primary limitation remains the relatively low penetration depth in carbon fiber reinforced polymers (CFRPs), typically limited to 2-5 mm depending on the material composition. This restricts inspection capabilities for thicker aerospace components. Additionally, signal attenuation in composites with higher carbon content presents significant challenges for defect detection in such materials.

Data processing and interpretation represent another major hurdle. The complex nature of THz signals when interacting with multi-layered composite structures necessitates sophisticated algorithms for accurate defect characterization. Current automated defect recognition systems still struggle with distinguishing between actual defects and material variations in aerospace composites.

Practical deployment challenges include the need for precise positioning systems during scanning, as standoff distance variations can significantly impact measurement accuracy. Environmental factors such as humidity also affect THz measurements, requiring controlled inspection environments or compensation algorithms. Furthermore, the relatively high cost of THz systems compared to conventional NDT methods remains a barrier to widespread industrial adoption.

Standardization represents a critical gap in the current THz inspection landscape. Unlike established NDT methods, THz inspection lacks comprehensive industry standards for equipment calibration, measurement protocols, and defect classification criteria specific to aerospace composites, hindering comparison between different systems and widespread acceptance by certification authorities.

The state-of-the-art THz inspection systems primarily utilize either time-domain spectroscopy (TDS) or continuous-wave (CW) approaches. TDS systems provide broadband spectral information but suffer from slower acquisition speeds, while CW systems offer faster scanning capabilities at the expense of spectral diversity. Recent developments have focused on improving signal-to-noise ratios and acquisition speeds, with some commercial systems now capable of scanning speeds up to 10 m²/hour for aerospace applications.

Geographically, THz technology development shows distinct regional characteristics. North America leads in system integration and aerospace applications, with NASA and major aerospace manufacturers conducting extensive research. Europe demonstrates strength in fundamental THz research and algorithm development, particularly in Germany and the UK. Meanwhile, Asia, especially China and Japan, has made significant progress in component manufacturing and miniaturization of THz systems.

Despite these advancements, several technical challenges persist. The primary limitation remains the relatively low penetration depth in carbon fiber reinforced polymers (CFRPs), typically limited to 2-5 mm depending on the material composition. This restricts inspection capabilities for thicker aerospace components. Additionally, signal attenuation in composites with higher carbon content presents significant challenges for defect detection in such materials.

Data processing and interpretation represent another major hurdle. The complex nature of THz signals when interacting with multi-layered composite structures necessitates sophisticated algorithms for accurate defect characterization. Current automated defect recognition systems still struggle with distinguishing between actual defects and material variations in aerospace composites.

Practical deployment challenges include the need for precise positioning systems during scanning, as standoff distance variations can significantly impact measurement accuracy. Environmental factors such as humidity also affect THz measurements, requiring controlled inspection environments or compensation algorithms. Furthermore, the relatively high cost of THz systems compared to conventional NDT methods remains a barrier to widespread industrial adoption.

Standardization represents a critical gap in the current THz inspection landscape. Unlike established NDT methods, THz inspection lacks comprehensive industry standards for equipment calibration, measurement protocols, and defect classification criteria specific to aerospace composites, hindering comparison between different systems and widespread acceptance by certification authorities.

Current THz Deployment Solutions for Composite Inspection

01 THz imaging systems for inspection applications

THz imaging technology is used for non-destructive inspection of various materials and structures. These systems utilize terahertz radiation to penetrate materials that are opaque to visible light but transparent to THz waves. The technology enables detection of hidden defects, foreign objects, and structural anomalies without damaging the inspected items. Advanced THz imaging systems incorporate specialized optics and detectors to achieve high-resolution images for quality control and security applications.- THz imaging systems for inspection applications: Terahertz imaging systems are used for non-destructive inspection of various materials and objects. These systems utilize THz radiation to penetrate materials that are opaque to visible light but transparent to THz waves. The imaging capabilities allow for detection of hidden defects, foreign objects, or structural anomalies without damaging the inspected item. Advanced THz imaging systems may incorporate specialized optics, detectors, and signal processing algorithms to enhance image quality and detection sensitivity.

- THz spectroscopy for material characterization and inspection: THz spectroscopy techniques enable detailed material characterization and inspection by analyzing the interaction between terahertz radiation and the material under test. Different materials exhibit unique spectral signatures in the THz range, allowing for identification and differentiation. This technology can detect chemical composition, moisture content, and material properties that are not visible using conventional inspection methods. THz spectroscopy is particularly valuable for quality control in manufacturing and security screening applications.

- Portable and integrated THz inspection devices: Portable and integrated THz inspection devices have been developed to enable field deployment and on-site inspection capabilities. These compact systems integrate THz sources, detectors, and processing units into handheld or easily transportable devices. The miniaturization of THz technology allows for real-time inspection in various environments without requiring samples to be brought to a laboratory. These devices often feature user-friendly interfaces and automated analysis capabilities to facilitate use by non-specialists.

- THz security and safety inspection systems: THz technology is applied in security and safety inspection systems for detecting concealed objects, weapons, explosives, and contraband. The non-ionizing nature of THz radiation makes it safer than X-rays for human screening while still providing the ability to see through clothing and packaging materials. These systems can identify both metallic and non-metallic threats, offering advantages over traditional metal detectors. Advanced signal processing algorithms help distinguish between benign items and potential threats, reducing false alarms.

- Industrial quality control using THz inspection: THz inspection technology is implemented in industrial quality control processes to monitor manufacturing consistency and product integrity. The non-destructive nature of THz waves allows for inspection of sealed packages, detection of contaminants, verification of coating thickness, and identification of structural defects in various materials including plastics, ceramics, and composites. These systems can be integrated into production lines for real-time monitoring and automated rejection of defective products, improving manufacturing efficiency and product quality.

02 THz spectroscopy for material characterization

THz spectroscopy techniques are employed to characterize and identify materials based on their unique spectral signatures in the terahertz frequency range. This technology enables the analysis of molecular structures, chemical compositions, and material properties. THz spectroscopy systems can detect subtle differences between similar materials and are particularly useful for identifying substances in pharmaceutical, security, and industrial quality control applications.Expand Specific Solutions03 Portable THz inspection devices

Portable THz inspection devices have been developed to enable on-site inspection capabilities in various environments. These compact systems integrate THz sources, detectors, and processing units into handheld or easily transportable configurations. The portability allows for real-time inspection in field conditions, production lines, and security checkpoints. These devices typically feature simplified user interfaces and automated analysis algorithms to facilitate operation by non-specialist personnel.Expand Specific Solutions04 THz technology for security and contraband detection

THz inspection systems are specifically designed for security applications to detect concealed weapons, explosives, and contraband. These systems can penetrate clothing, packaging materials, and other non-metallic barriers to reveal hidden objects. The non-ionizing nature of THz radiation makes it safer than X-ray technology for scanning people. Advanced signal processing algorithms help identify suspicious materials based on their characteristic THz signatures, enhancing detection capabilities at airports, borders, and secure facilities.Expand Specific Solutions05 Industrial quality control using THz inspection

THz technology is implemented in industrial quality control processes to inspect manufactured products for defects and ensure compliance with specifications. These systems can detect internal flaws, measure coating thickness, verify assembly integrity, and identify material inconsistencies in production environments. The non-destructive nature of THz inspection allows for 100% quality control without compromising product integrity. Automated THz inspection systems can be integrated into production lines for real-time monitoring and feedback control.Expand Specific Solutions

Key Industry Players in THz Aerospace Inspection

The terahertz (THz) deployment for aerospace composite inspection market is currently in an early growth phase, characterized by increasing adoption of advanced non-destructive testing technologies. The global market size is estimated to reach approximately $350-400 million by 2025, with a CAGR of 15-20%. From a technical maturity perspective, companies like Boeing, Airbus Group, and Mitsubishi Electric are leading commercial applications, while academic institutions such as MIT, Rensselaer Polytechnic Institute, and Harbin Institute of Technology are advancing fundamental research. TeraView Ltd. has established itself as a specialized provider of THz imaging systems, while larger corporations like Canon and Coherent are integrating THz capabilities into their inspection portfolios. The technology is transitioning from laboratory research to practical field deployment, with aerospace manufacturers increasingly recognizing its value for detecting defects in composite materials that traditional methods cannot identify.

The Boeing Co.

Technical Solution: Boeing has developed advanced THz inspection systems specifically designed for aerospace composite materials. Their technology utilizes pulsed terahertz time-domain spectroscopy (THz-TDS) to detect subsurface defects in carbon fiber reinforced polymers (CFRP) and other composite structures. Boeing's approach incorporates automated scanning systems that can inspect large aircraft components with high precision. The system generates 3D volumetric data of internal structures, allowing for detection of delaminations, foreign object debris, and moisture ingress without physical contact with the material. Boeing has integrated this technology into their production lines, using machine learning algorithms to automatically identify and classify defects in composite structures, significantly reducing inspection time compared to traditional ultrasonic methods.

Strengths: High resolution detection of subsurface defects in thick composite materials; non-contact and non-destructive inspection capability; integration with automated production systems. Weaknesses: Higher initial equipment costs compared to conventional methods; requires specialized training for operators; data processing for large components can be time-intensive.

TeraView Ltd.

Technical Solution: TeraView has developed specialized THz inspection systems for aerospace composites through their TeraPulse platform. Their technology utilizes terahertz pulsed imaging (TPI) and terahertz time-domain spectroscopy (THz-TDS) to provide both imaging and spectroscopic information about composite materials. TeraView's systems can detect subsurface defects including delaminations, voids, and foreign object debris in carbon fiber reinforced polymers (CFRP) and glass fiber composites. Their proprietary software allows for 3D visualization of internal structures and automated defect recognition. TeraView has demonstrated the capability to inspect complex curved surfaces and components with varying thickness, which is particularly valuable for aerospace applications. Their systems have been validated through extensive testing with major aerospace manufacturers and have shown the ability to detect defects as small as 50 micrometers in depth at speeds compatible with production environments. TeraView's technology has been successfully applied to inspect critical aerospace components including wing panels, fuselage sections, and engine components.

Strengths: High-resolution 3D imaging capabilities; excellent detection of interfacial defects between composite layers; comprehensive software suite for data analysis and interpretation. Weaknesses: Higher cost compared to conventional NDT methods; limited penetration in highly conductive carbon fiber materials; requires specialized expertise for system operation and data interpretation.

Critical THz Sensing Technologies for Aerospace Applications

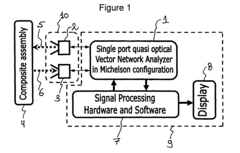

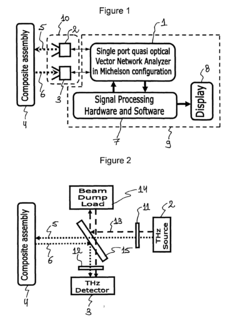

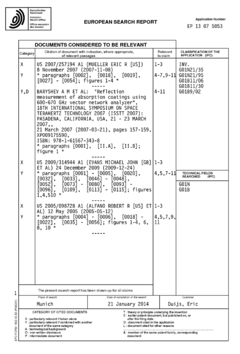

Method and system for inspection of composite assemblies using terahertz radiation

PatentInactiveEP2835629A1

Innovation

- A method using terahertz radiation to create two or three-dimensional images of composite assemblies without contact or destruction, utilizing electronic and electro-optical components to illuminate, detect, and record terahertz radiation responses, enabling detection and analysis of various material conditions without prior knowledge of the assembly's structure or configuration.

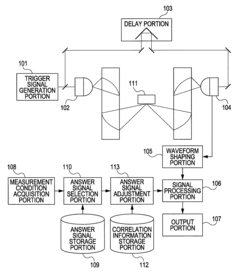

Inspection apparatus and inspection method by using terahertz wave

PatentInactiveUS20090189078A1

Innovation

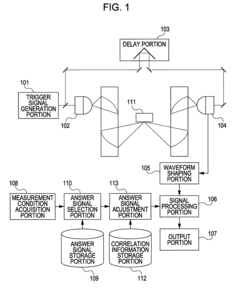

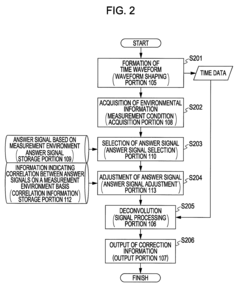

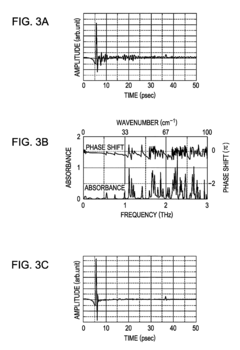

- The apparatus includes a terahertz wave generation and detection portion, waveform shaping, measurement condition acquisition, answer signal storage, selection, and signal processing to adapt to changing environments by selecting and fine-adjusting answer signals based on current measurement conditions, thereby reducing the influence of environmental changes.

Safety and Regulatory Framework for Aerospace NDT Technologies

The implementation of THz technology for aerospace composite inspection must adhere to stringent safety and regulatory frameworks established by aviation authorities worldwide. The Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have developed comprehensive guidelines for Non-Destructive Testing (NDT) technologies, which THz systems must comply with before widespread adoption in aerospace maintenance operations.

Regulatory standards such as ASTM E2580 and ARP6328 provide specific requirements for qualification and certification of NDT personnel working with advanced inspection technologies. These standards ensure that operators using THz systems possess adequate training and understanding of the technology's capabilities and limitations, minimizing the risk of misinterpretation of inspection results.

From a safety perspective, THz radiation occupies a unique position in the electromagnetic spectrum between microwaves and infrared light. Unlike X-rays, THz waves are non-ionizing and generally considered safe for human exposure at the power levels used in inspection applications. However, regulatory bodies including the International Commission on Non-Ionizing Radiation Protection (ICNIRP) have established exposure limits that must be observed during THz system operation.

Equipment certification represents another critical regulatory aspect. THz inspection systems deployed in aerospace environments must obtain certification under DO-160 standards, which specify environmental conditions and test procedures for airborne equipment. Additionally, any THz system used for critical safety inspections must demonstrate reliability through Probability of Detection (POD) studies as outlined in MIL-HDBK-1823A.

Data security and integrity frameworks are increasingly important as THz inspection systems become integrated with digital maintenance management systems. Regulations such as the NIST Cybersecurity Framework provide guidelines for protecting inspection data, which may contain sensitive information about aircraft structural integrity.

Recent regulatory developments have focused on creating performance-based standards rather than prescriptive requirements, allowing for technological innovation while maintaining safety. The SAE G-3T committee is currently developing aerospace-specific guidelines for THz inspection technology implementation, expected to address calibration procedures, system performance verification, and acceptance criteria for various composite defect types.

For international deployment, THz inspection systems must navigate varying regulatory landscapes, with mutual recognition agreements between major aviation authorities facilitating global acceptance. Manufacturers of THz inspection equipment must demonstrate compliance with these regulatory frameworks through extensive documentation and testing before their systems can be approved for use in safety-critical aerospace applications.

Regulatory standards such as ASTM E2580 and ARP6328 provide specific requirements for qualification and certification of NDT personnel working with advanced inspection technologies. These standards ensure that operators using THz systems possess adequate training and understanding of the technology's capabilities and limitations, minimizing the risk of misinterpretation of inspection results.

From a safety perspective, THz radiation occupies a unique position in the electromagnetic spectrum between microwaves and infrared light. Unlike X-rays, THz waves are non-ionizing and generally considered safe for human exposure at the power levels used in inspection applications. However, regulatory bodies including the International Commission on Non-Ionizing Radiation Protection (ICNIRP) have established exposure limits that must be observed during THz system operation.

Equipment certification represents another critical regulatory aspect. THz inspection systems deployed in aerospace environments must obtain certification under DO-160 standards, which specify environmental conditions and test procedures for airborne equipment. Additionally, any THz system used for critical safety inspections must demonstrate reliability through Probability of Detection (POD) studies as outlined in MIL-HDBK-1823A.

Data security and integrity frameworks are increasingly important as THz inspection systems become integrated with digital maintenance management systems. Regulations such as the NIST Cybersecurity Framework provide guidelines for protecting inspection data, which may contain sensitive information about aircraft structural integrity.

Recent regulatory developments have focused on creating performance-based standards rather than prescriptive requirements, allowing for technological innovation while maintaining safety. The SAE G-3T committee is currently developing aerospace-specific guidelines for THz inspection technology implementation, expected to address calibration procedures, system performance verification, and acceptance criteria for various composite defect types.

For international deployment, THz inspection systems must navigate varying regulatory landscapes, with mutual recognition agreements between major aviation authorities facilitating global acceptance. Manufacturers of THz inspection equipment must demonstrate compliance with these regulatory frameworks through extensive documentation and testing before their systems can be approved for use in safety-critical aerospace applications.

Cost-Benefit Analysis of THz Implementation in Aerospace Industry

The implementation of Terahertz (THz) technology for aerospace composite inspection represents a significant investment decision for industry stakeholders. This cost-benefit analysis examines the financial implications of adopting THz systems compared to traditional inspection methods currently employed in aerospace manufacturing and maintenance operations.

Initial capital expenditure for THz systems remains substantial, with comprehensive inspection platforms ranging from $500,000 to $2 million depending on system capabilities, resolution requirements, and scanning area coverage. However, these costs have decreased approximately 30% over the past five years as the technology matures and more suppliers enter the market.

Operational cost savings present a compelling case for THz adoption. Studies conducted at major aerospace manufacturers indicate that THz inspection can reduce inspection time by 40-60% compared to ultrasonic testing for certain composite components. This efficiency translates to approximately $75,000-$150,000 in annual labor savings per production line. Additionally, the non-contact nature of THz inspection eliminates the need for coupling agents, reducing consumable costs by an estimated $20,000-$30,000 annually.

Quality-related cost benefits are particularly significant. Field data from early adopters demonstrates a 25-35% improvement in defect detection rates for subsurface anomalies in composite structures. This enhanced detection capability potentially prevents in-service failures that could cost millions in repairs, liability, and reputational damage. One aerospace OEM reported avoiding approximately $3.8 million in potential warranty claims over a two-year period following THz implementation.

Return on investment (ROI) calculations indicate that most aerospace manufacturers can expect to recoup their THz system investments within 2.5-4 years, depending on production volume and inspection requirements. This timeline has improved significantly from the 5-7 year ROI period observed in early adoption cases from 2015-2017.

Long-term economic benefits extend beyond direct cost savings. THz technology enables more rapid product development cycles by providing detailed subsurface imaging during prototyping phases. This capability has been credited with reducing time-to-market by 15-20% for new composite components, creating competitive advantages that are difficult to quantify but strategically valuable.

Environmental and regulatory compliance benefits also factor into the cost-benefit equation. THz systems eliminate hazardous chemicals associated with some traditional inspection methods, reducing environmental compliance costs by an estimated $15,000-$25,000 annually for medium-sized operations.

Initial capital expenditure for THz systems remains substantial, with comprehensive inspection platforms ranging from $500,000 to $2 million depending on system capabilities, resolution requirements, and scanning area coverage. However, these costs have decreased approximately 30% over the past five years as the technology matures and more suppliers enter the market.

Operational cost savings present a compelling case for THz adoption. Studies conducted at major aerospace manufacturers indicate that THz inspection can reduce inspection time by 40-60% compared to ultrasonic testing for certain composite components. This efficiency translates to approximately $75,000-$150,000 in annual labor savings per production line. Additionally, the non-contact nature of THz inspection eliminates the need for coupling agents, reducing consumable costs by an estimated $20,000-$30,000 annually.

Quality-related cost benefits are particularly significant. Field data from early adopters demonstrates a 25-35% improvement in defect detection rates for subsurface anomalies in composite structures. This enhanced detection capability potentially prevents in-service failures that could cost millions in repairs, liability, and reputational damage. One aerospace OEM reported avoiding approximately $3.8 million in potential warranty claims over a two-year period following THz implementation.

Return on investment (ROI) calculations indicate that most aerospace manufacturers can expect to recoup their THz system investments within 2.5-4 years, depending on production volume and inspection requirements. This timeline has improved significantly from the 5-7 year ROI period observed in early adoption cases from 2015-2017.

Long-term economic benefits extend beyond direct cost savings. THz technology enables more rapid product development cycles by providing detailed subsurface imaging during prototyping phases. This capability has been credited with reducing time-to-market by 15-20% for new composite components, creating competitive advantages that are difficult to quantify but strategically valuable.

Environmental and regulatory compliance benefits also factor into the cost-benefit equation. THz systems eliminate hazardous chemicals associated with some traditional inspection methods, reducing environmental compliance costs by an estimated $15,000-$25,000 annually for medium-sized operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!