Solid-state cells with anode-free designs: cycle life and safety trade-offs

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anode-Free SSB Background

Solid-state batteries (SSBs) have emerged as a promising next-generation energy storage technology, offering potential advantages in safety, energy density, and longevity compared to conventional lithium-ion batteries. Within this field, anode-free solid-state batteries represent a cutting-edge design that aims to push the boundaries of energy density and simplify battery architecture.

Anode-free SSBs eliminate the need for a separate anode material, instead utilizing lithium metal that is deposited directly on the current collector during charging. This design offers several theoretical advantages, including increased energy density, reduced cell weight, and potentially lower manufacturing costs. By removing the traditional graphite or silicon anode, more space is available for the cathode material, potentially increasing the overall energy capacity of the cell.

The concept of anode-free batteries is not entirely new, with early research dating back to the 1970s. However, the combination of this design with solid-state electrolytes has gained significant traction in recent years due to advancements in solid electrolyte materials and increased focus on high-energy-density battery solutions for electric vehicles and other applications.

One of the key challenges in anode-free SSB development is managing the growth and dissolution of lithium metal during cycling. Unlike traditional lithium-ion batteries, where lithium ions intercalate into a host material, anode-free designs require the repeated plating and stripping of lithium metal. This process can lead to issues such as dendrite formation, volume changes, and electrolyte degradation, all of which can impact the cell's cycle life and safety.

The solid electrolyte plays a crucial role in anode-free SSB performance. It must possess high ionic conductivity, good mechanical properties to withstand volume changes, and excellent chemical stability against lithium metal. Various materials have been explored for this purpose, including ceramic oxides, sulfides, and polymer-based electrolytes, each with its own set of advantages and challenges.

Safety considerations are paramount in anode-free SSB research. While solid electrolytes generally offer improved safety compared to liquid electrolytes, the use of lithium metal introduces new safety concerns. Researchers must carefully balance the trade-offs between high energy density and long-term stability, developing strategies to mitigate risks associated with lithium dendrite growth and potential short-circuiting.

The development of anode-free SSBs intersects with broader trends in battery research, including the pursuit of higher energy densities, faster charging capabilities, and more sustainable battery technologies. As such, advancements in this field have the potential to significantly impact various sectors, from electric vehicles to portable electronics and grid-scale energy storage.

Anode-free SSBs eliminate the need for a separate anode material, instead utilizing lithium metal that is deposited directly on the current collector during charging. This design offers several theoretical advantages, including increased energy density, reduced cell weight, and potentially lower manufacturing costs. By removing the traditional graphite or silicon anode, more space is available for the cathode material, potentially increasing the overall energy capacity of the cell.

The concept of anode-free batteries is not entirely new, with early research dating back to the 1970s. However, the combination of this design with solid-state electrolytes has gained significant traction in recent years due to advancements in solid electrolyte materials and increased focus on high-energy-density battery solutions for electric vehicles and other applications.

One of the key challenges in anode-free SSB development is managing the growth and dissolution of lithium metal during cycling. Unlike traditional lithium-ion batteries, where lithium ions intercalate into a host material, anode-free designs require the repeated plating and stripping of lithium metal. This process can lead to issues such as dendrite formation, volume changes, and electrolyte degradation, all of which can impact the cell's cycle life and safety.

The solid electrolyte plays a crucial role in anode-free SSB performance. It must possess high ionic conductivity, good mechanical properties to withstand volume changes, and excellent chemical stability against lithium metal. Various materials have been explored for this purpose, including ceramic oxides, sulfides, and polymer-based electrolytes, each with its own set of advantages and challenges.

Safety considerations are paramount in anode-free SSB research. While solid electrolytes generally offer improved safety compared to liquid electrolytes, the use of lithium metal introduces new safety concerns. Researchers must carefully balance the trade-offs between high energy density and long-term stability, developing strategies to mitigate risks associated with lithium dendrite growth and potential short-circuiting.

The development of anode-free SSBs intersects with broader trends in battery research, including the pursuit of higher energy densities, faster charging capabilities, and more sustainable battery technologies. As such, advancements in this field have the potential to significantly impact various sectors, from electric vehicles to portable electronics and grid-scale energy storage.

Market Analysis

The market for solid-state batteries with anode-free designs is experiencing significant growth and attracting substantial investment due to their potential to revolutionize energy storage technology. This innovative approach addresses key challenges in the battery industry, particularly in terms of energy density, safety, and longevity.

The demand for high-performance batteries is driven by several sectors, including electric vehicles (EVs), consumer electronics, and renewable energy storage systems. The EV market, in particular, is a major driver for solid-state battery development, as automakers seek to improve driving range, reduce charging times, and enhance safety features. The global EV market is projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years, creating a substantial opportunity for advanced battery technologies.

Consumer electronics manufacturers are also showing keen interest in solid-state batteries with anode-free designs. The promise of longer-lasting devices with improved safety characteristics aligns well with consumer demands for more reliable and durable products. This sector's growth, coupled with the increasing integration of IoT devices, is expected to further boost the demand for high-performance batteries.

The renewable energy sector presents another significant market opportunity. As the world transitions towards cleaner energy sources, the need for efficient and safe energy storage solutions becomes paramount. Solid-state batteries with anode-free designs could play a crucial role in grid-scale energy storage, helping to balance supply and demand in renewable energy systems.

However, the market faces several challenges. The technology is still in its early stages, and scaling up production to meet potential demand remains a significant hurdle. The high cost of materials and manufacturing processes currently limits widespread adoption, although economies of scale are expected to drive down costs over time.

Competition in this space is intensifying, with both established battery manufacturers and startups vying for market share. Major automotive companies are also investing heavily in solid-state battery technology, recognizing its potential to transform the EV landscape.

Despite these challenges, the market outlook for solid-state batteries with anode-free designs remains highly positive. Industry analysts predict substantial growth in the coming decades, with some estimates suggesting that solid-state batteries could capture a significant portion of the battery market by 2030. The potential for improved safety, longer cycle life, and higher energy density makes this technology particularly attractive across multiple industries, positioning it as a key player in the future of energy storage solutions.

The demand for high-performance batteries is driven by several sectors, including electric vehicles (EVs), consumer electronics, and renewable energy storage systems. The EV market, in particular, is a major driver for solid-state battery development, as automakers seek to improve driving range, reduce charging times, and enhance safety features. The global EV market is projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years, creating a substantial opportunity for advanced battery technologies.

Consumer electronics manufacturers are also showing keen interest in solid-state batteries with anode-free designs. The promise of longer-lasting devices with improved safety characteristics aligns well with consumer demands for more reliable and durable products. This sector's growth, coupled with the increasing integration of IoT devices, is expected to further boost the demand for high-performance batteries.

The renewable energy sector presents another significant market opportunity. As the world transitions towards cleaner energy sources, the need for efficient and safe energy storage solutions becomes paramount. Solid-state batteries with anode-free designs could play a crucial role in grid-scale energy storage, helping to balance supply and demand in renewable energy systems.

However, the market faces several challenges. The technology is still in its early stages, and scaling up production to meet potential demand remains a significant hurdle. The high cost of materials and manufacturing processes currently limits widespread adoption, although economies of scale are expected to drive down costs over time.

Competition in this space is intensifying, with both established battery manufacturers and startups vying for market share. Major automotive companies are also investing heavily in solid-state battery technology, recognizing its potential to transform the EV landscape.

Despite these challenges, the market outlook for solid-state batteries with anode-free designs remains highly positive. Industry analysts predict substantial growth in the coming decades, with some estimates suggesting that solid-state batteries could capture a significant portion of the battery market by 2030. The potential for improved safety, longer cycle life, and higher energy density makes this technology particularly attractive across multiple industries, positioning it as a key player in the future of energy storage solutions.

Technical Challenges

The development of solid-state batteries with anode-free designs presents several significant technical challenges that researchers and engineers must overcome. One of the primary obstacles is the inherent trade-off between cycle life and safety in these innovative cell configurations.

The absence of a pre-deposited anode in anode-free designs leads to increased complexity in managing lithium plating and stripping processes. This complexity can result in uneven lithium deposition during charging, potentially causing dendrite formation. Dendrites not only reduce the cell's cycle life but also pose serious safety risks, as they can penetrate the solid electrolyte and cause short circuits.

Another critical challenge lies in the interface between the solid electrolyte and the lithium metal that forms during cycling. The high reactivity of lithium metal with most solid electrolytes can lead to the formation of resistive interfacial layers, impeding ion transport and reducing overall cell performance. This interfacial instability contributes to capacity fade over time and limits the achievable cycle life of the battery.

The mechanical stress induced during repeated cycling presents yet another hurdle. As lithium is deposited and stripped, volume changes occur, which can cause mechanical degradation of the solid electrolyte. This degradation may manifest as cracks or delamination, compromising the cell's structural integrity and potentially creating pathways for dendrite growth.

Furthermore, the high current densities required for fast charging in anode-free designs exacerbate these issues. Rapid lithium deposition can lead to more pronounced dendrite formation and accelerated degradation of the electrolyte-electrode interface, further shortening the cell's lifespan and increasing safety risks.

The selection and optimization of solid electrolyte materials also present significant challenges. While some materials offer excellent ionic conductivity, they may lack the mechanical strength to withstand the stresses of cycling. Conversely, materials with superior mechanical properties might suffer from lower ionic conductivity, necessitating a careful balance in material selection and design.

Addressing these technical challenges requires a multifaceted approach. Researchers must focus on developing advanced solid electrolytes that combine high ionic conductivity with strong mechanical properties and chemical stability against lithium metal. Novel interface engineering strategies are needed to mitigate the formation of resistive layers and improve the stability of the electrolyte-electrode interface.

Additionally, innovative cell designs that can accommodate volume changes and distribute current more evenly across the electrode surface are crucial for enhancing both safety and cycle life. The development of sophisticated control algorithms for charging and discharging processes may also help in managing lithium deposition and stripping more effectively, reducing the risk of dendrite formation.

The absence of a pre-deposited anode in anode-free designs leads to increased complexity in managing lithium plating and stripping processes. This complexity can result in uneven lithium deposition during charging, potentially causing dendrite formation. Dendrites not only reduce the cell's cycle life but also pose serious safety risks, as they can penetrate the solid electrolyte and cause short circuits.

Another critical challenge lies in the interface between the solid electrolyte and the lithium metal that forms during cycling. The high reactivity of lithium metal with most solid electrolytes can lead to the formation of resistive interfacial layers, impeding ion transport and reducing overall cell performance. This interfacial instability contributes to capacity fade over time and limits the achievable cycle life of the battery.

The mechanical stress induced during repeated cycling presents yet another hurdle. As lithium is deposited and stripped, volume changes occur, which can cause mechanical degradation of the solid electrolyte. This degradation may manifest as cracks or delamination, compromising the cell's structural integrity and potentially creating pathways for dendrite growth.

Furthermore, the high current densities required for fast charging in anode-free designs exacerbate these issues. Rapid lithium deposition can lead to more pronounced dendrite formation and accelerated degradation of the electrolyte-electrode interface, further shortening the cell's lifespan and increasing safety risks.

The selection and optimization of solid electrolyte materials also present significant challenges. While some materials offer excellent ionic conductivity, they may lack the mechanical strength to withstand the stresses of cycling. Conversely, materials with superior mechanical properties might suffer from lower ionic conductivity, necessitating a careful balance in material selection and design.

Addressing these technical challenges requires a multifaceted approach. Researchers must focus on developing advanced solid electrolytes that combine high ionic conductivity with strong mechanical properties and chemical stability against lithium metal. Novel interface engineering strategies are needed to mitigate the formation of resistive layers and improve the stability of the electrolyte-electrode interface.

Additionally, innovative cell designs that can accommodate volume changes and distribute current more evenly across the electrode surface are crucial for enhancing both safety and cycle life. The development of sophisticated control algorithms for charging and discharging processes may also help in managing lithium deposition and stripping more effectively, reducing the risk of dendrite formation.

Current Anode-Free Designs

01 Anode-free solid-state cell design

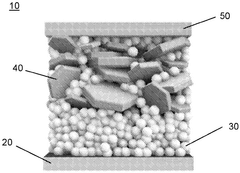

Anode-free solid-state cell designs eliminate the need for a pre-formed anode, reducing cell weight and potentially increasing energy density. These designs typically use a lithium metal anode that forms in situ during the first charge cycle. This approach can improve safety by reducing the risk of lithium dendrite formation and enhancing cycle life through better interfacial stability.- Anode-free solid-state cell design: Solid-state cells with anode-free designs eliminate the need for a pre-formed anode, reducing cell weight and potentially increasing energy density. These cells typically use a lithium metal anode that forms in situ during the first charge cycle. This design can improve safety by reducing the risk of dendrite formation and short circuits.

- Electrolyte composition for improved cycle life: Specialized electrolyte compositions are crucial for enhancing the cycle life of anode-free solid-state cells. These electrolytes often include additives that form stable interfaces between the lithium metal and the solid electrolyte, preventing degradation and improving long-term performance.

- Safety features in anode-free designs: Safety enhancements in anode-free solid-state cells include the use of non-flammable solid electrolytes, incorporation of current interrupt devices, and implementation of protective layers to prevent short circuits. These features aim to mitigate risks associated with thermal runaway and improve overall cell safety.

- Cathode optimization for anode-free cells: Optimizing cathode materials and structures is essential for anode-free solid-state cells to achieve high capacity and stable cycling. This includes developing high-voltage cathodes, improving cathode-electrolyte interfaces, and engineering cathode porosity to accommodate volume changes during cycling.

- Manufacturing processes for anode-free solid-state cells: Advanced manufacturing techniques are developed to produce anode-free solid-state cells with consistent quality and performance. These processes focus on precise control of layer thicknesses, interface engineering, and integration of safety features during cell assembly to ensure optimal cycle life and safety.

02 Solid electrolyte composition and structure

The composition and structure of solid electrolytes play a crucial role in the performance and safety of anode-free solid-state cells. Advanced ceramic or polymer-based electrolytes with high ionic conductivity and mechanical stability can improve cycle life by preventing dendrite growth and enhancing interfacial contact. Composite electrolytes combining different materials may offer superior properties.Expand Specific Solutions03 Cathode optimization for anode-free designs

Optimizing cathode materials and structures is essential for anode-free solid-state cells. High-capacity cathodes with stable interfaces can improve cycle life and overall cell performance. Techniques such as surface coating, doping, or nanostructuring of cathode materials can enhance their compatibility with solid electrolytes and improve cycling stability.Expand Specific Solutions04 Safety features and mechanisms

Incorporating specific safety features and mechanisms in anode-free solid-state cells is crucial. These may include pressure-relief mechanisms, thermal management systems, and protective layers to prevent short circuits. Advanced monitoring and control systems can detect potential safety issues early and take preventive actions, enhancing overall cell safety.Expand Specific Solutions05 Manufacturing processes for improved performance

Developing and optimizing manufacturing processes for anode-free solid-state cells is key to achieving high performance and safety. This includes techniques for precise layer deposition, interface engineering, and cell assembly under controlled conditions. Advanced manufacturing methods can lead to more uniform and defect-free structures, improving cycle life and safety.Expand Specific Solutions

Key Industry Players

The research on cycle life and safety trade-offs of solid-state cells with anode-free designs is in an early development stage, with a growing market potential due to the increasing demand for high-performance batteries. The technology is still maturing, with major players like LG Energy Solution, Samsung SDI, and Toyota Motor Corp. investing heavily in R&D. Companies such as Our Next Energy and Factorial are also making significant strides in this field. The competitive landscape is characterized by a mix of established battery manufacturers and innovative startups, all racing to overcome technical challenges and commercialize this promising technology. As the industry progresses, collaborations between automotive companies and battery developers are becoming more prevalent, accelerating the pace of innovation.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has made significant strides in anode-free solid-state battery technology, focusing on balancing cycle life and safety. Their approach involves a thin lithium metal anode that forms during the initial charge, coupled with a composite solid electrolyte. This electrolyte combines ceramic and polymer materials to achieve high ionic conductivity while maintaining flexibility. LG's research has shown that their anode-free cells can achieve over 800 cycles with 80% capacity retention[4]. The company has also developed a novel interfacial layer between the cathode and electrolyte to mitigate side reactions and improve long-term stability. Safety features include a ceramic-rich layer near the anode to mechanically suppress lithium dendrite growth[5][6].

Strengths: Balanced approach to cycle life and safety, innovative composite electrolyte design. Weaknesses: Lower cycle life compared to some competitors, potential challenges in scaling up production.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed a novel anode-free solid-state battery design that significantly improves cycle life and safety. Their approach utilizes a lithium metal anode that forms in situ during the first charge, eliminating the need for a pre-deposited anode. This design incorporates a proprietary solid electrolyte with high ionic conductivity and excellent mechanical properties to suppress lithium dendrite growth[1]. The company has also implemented a protective coating on the cathode to enhance the electrode-electrolyte interface stability. Samsung's research shows that their anode-free cells can achieve over 1000 cycles with minimal capacity fade, while maintaining a high energy density of over 900 Wh/L[2][3].

Strengths: High energy density, improved safety due to solid electrolyte, potential for long cycle life. Weaknesses: Challenges in mass production, potential high costs, need for further optimization of the electrode-electrolyte interface.

Cycle Life Innovations

All-solid-state battery

PatentWO2025143840A1

Innovation

- An anode-free all-solid-state battery design where lithium metal is formed on the negative electrode current collector during charging, using a sulfide-based solid electrolyte with a Group 2 element and argyrodite-type crystal structure, allowing for low confining pressures and improved adhesion between electrodes.

Anode-free sodium all-solid-state battery

PatentWO2025085362A1

Innovation

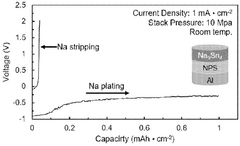

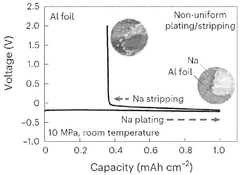

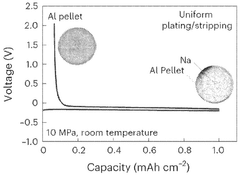

- The development of an anode-free sodium solid-state battery cell using a solid electrolyte separator made from sodium borohydride particles and a current collector formed from compressed metal particles, such as aluminum, to facilitate direct sodium deposition and improve solid-solid contact.

Performance Trade-offs

The performance trade-offs in anode-free solid-state batteries (SSBs) present a complex landscape of advantages and challenges. These innovative designs offer significant improvements in energy density by eliminating the traditional graphite anode, potentially increasing the overall energy capacity of the cell. However, this advancement comes at the cost of certain performance aspects that must be carefully considered.

One of the primary trade-offs lies in the cycle life of anode-free SSBs. While these cells can achieve higher initial energy densities, they often suffer from rapid capacity fade over repeated charge-discharge cycles. This degradation is largely attributed to the formation and growth of lithium dendrites at the lithium metal-solid electrolyte interface. As cycling progresses, these dendrites can lead to short circuits and compromise the overall safety of the cell.

Safety considerations form another critical aspect of the performance trade-offs. Anode-free designs inherently involve the use of lithium metal, which is highly reactive. The absence of a stable SEI (Solid Electrolyte Interphase) layer, typically formed on graphite anodes, exposes the lithium metal directly to the solid electrolyte. This can lead to increased reactivity and potential thermal runaway events, especially under high-stress conditions or elevated temperatures.

The mechanical stability of the cell is also affected in anode-free designs. During cycling, the volume changes associated with lithium plating and stripping can induce significant mechanical stress on the solid electrolyte. This stress may lead to the formation of cracks or voids in the electrolyte, further exacerbating dendrite growth and potentially compromising the cell's structural integrity.

Furthermore, the power capability of anode-free SSBs often lags behind their conventional counterparts. The kinetics of lithium ion transport at the lithium metal-solid electrolyte interface can be slower, leading to limitations in charge and discharge rates. This trade-off between energy density and power density must be carefully balanced depending on the intended application of the battery.

Researchers are actively exploring strategies to mitigate these trade-offs. These include developing advanced solid electrolytes with improved mechanical properties and ionic conductivity, engineering interface layers to enhance stability, and optimizing cell designs to better accommodate volume changes. The goal is to strike a balance that maximizes the benefits of anode-free designs while minimizing the associated performance and safety risks.

One of the primary trade-offs lies in the cycle life of anode-free SSBs. While these cells can achieve higher initial energy densities, they often suffer from rapid capacity fade over repeated charge-discharge cycles. This degradation is largely attributed to the formation and growth of lithium dendrites at the lithium metal-solid electrolyte interface. As cycling progresses, these dendrites can lead to short circuits and compromise the overall safety of the cell.

Safety considerations form another critical aspect of the performance trade-offs. Anode-free designs inherently involve the use of lithium metal, which is highly reactive. The absence of a stable SEI (Solid Electrolyte Interphase) layer, typically formed on graphite anodes, exposes the lithium metal directly to the solid electrolyte. This can lead to increased reactivity and potential thermal runaway events, especially under high-stress conditions or elevated temperatures.

The mechanical stability of the cell is also affected in anode-free designs. During cycling, the volume changes associated with lithium plating and stripping can induce significant mechanical stress on the solid electrolyte. This stress may lead to the formation of cracks or voids in the electrolyte, further exacerbating dendrite growth and potentially compromising the cell's structural integrity.

Furthermore, the power capability of anode-free SSBs often lags behind their conventional counterparts. The kinetics of lithium ion transport at the lithium metal-solid electrolyte interface can be slower, leading to limitations in charge and discharge rates. This trade-off between energy density and power density must be carefully balanced depending on the intended application of the battery.

Researchers are actively exploring strategies to mitigate these trade-offs. These include developing advanced solid electrolytes with improved mechanical properties and ionic conductivity, engineering interface layers to enhance stability, and optimizing cell designs to better accommodate volume changes. The goal is to strike a balance that maximizes the benefits of anode-free designs while minimizing the associated performance and safety risks.

Regulatory Considerations

The regulatory landscape for solid-state batteries with anode-free designs is evolving rapidly as this technology advances. Safety considerations are paramount in the development and commercialization of these batteries, particularly given their potential use in electric vehicles and other high-energy applications. Regulatory bodies worldwide are closely monitoring the progress of solid-state battery technology and are working to establish appropriate safety standards and testing protocols.

One of the primary regulatory focuses is on the thermal stability and fire safety of solid-state batteries. Unlike traditional lithium-ion batteries with liquid electrolytes, solid-state batteries are expected to have a lower risk of thermal runaway and fire. However, regulatory agencies are still developing specific testing procedures to verify these safety claims and ensure that solid-state batteries meet or exceed existing safety standards for battery systems.

Cycle life considerations are also being incorporated into regulatory frameworks. As the longevity of batteries directly impacts their environmental footprint and economic viability, regulators are increasingly interested in standardized methods for assessing and reporting cycle life performance. This is particularly relevant for anode-free designs, which may offer improved energy density but face challenges in maintaining long-term cycling stability.

Environmental regulations are another critical aspect of the regulatory landscape. The materials used in solid-state batteries, including potential rare earth elements and specialized ceramics, are subject to scrutiny regarding their sourcing, processing, and end-of-life management. Regulators are working to ensure that the entire lifecycle of solid-state batteries aligns with sustainability goals and circular economy principles.

Transportation regulations are being reviewed and updated to accommodate the unique characteristics of solid-state batteries. Current regulations for the shipment of lithium-ion batteries may need to be adapted for solid-state technologies, considering their different safety profiles and potential for higher energy densities.

As research continues on the trade-offs between cycle life and safety in anode-free solid-state cells, regulatory bodies are likely to require extensive data on long-term performance and safety under various operating conditions. This may include accelerated aging tests, abuse tolerance evaluations, and detailed failure mode analyses specific to anode-free designs.

Standardization efforts are underway to establish uniform testing and certification procedures for solid-state batteries. These standards will be crucial for ensuring consistency in safety evaluations and performance claims across different manufacturers and technologies. Regulatory agencies are collaborating with industry stakeholders and research institutions to develop these standards, which will likely evolve as more data becomes available on the long-term behavior of solid-state cells.

One of the primary regulatory focuses is on the thermal stability and fire safety of solid-state batteries. Unlike traditional lithium-ion batteries with liquid electrolytes, solid-state batteries are expected to have a lower risk of thermal runaway and fire. However, regulatory agencies are still developing specific testing procedures to verify these safety claims and ensure that solid-state batteries meet or exceed existing safety standards for battery systems.

Cycle life considerations are also being incorporated into regulatory frameworks. As the longevity of batteries directly impacts their environmental footprint and economic viability, regulators are increasingly interested in standardized methods for assessing and reporting cycle life performance. This is particularly relevant for anode-free designs, which may offer improved energy density but face challenges in maintaining long-term cycling stability.

Environmental regulations are another critical aspect of the regulatory landscape. The materials used in solid-state batteries, including potential rare earth elements and specialized ceramics, are subject to scrutiny regarding their sourcing, processing, and end-of-life management. Regulators are working to ensure that the entire lifecycle of solid-state batteries aligns with sustainability goals and circular economy principles.

Transportation regulations are being reviewed and updated to accommodate the unique characteristics of solid-state batteries. Current regulations for the shipment of lithium-ion batteries may need to be adapted for solid-state technologies, considering their different safety profiles and potential for higher energy densities.

As research continues on the trade-offs between cycle life and safety in anode-free solid-state cells, regulatory bodies are likely to require extensive data on long-term performance and safety under various operating conditions. This may include accelerated aging tests, abuse tolerance evaluations, and detailed failure mode analyses specific to anode-free designs.

Standardization efforts are underway to establish uniform testing and certification procedures for solid-state batteries. These standards will be crucial for ensuring consistency in safety evaluations and performance claims across different manufacturers and technologies. Regulatory agencies are collaborating with industry stakeholders and research institutions to develop these standards, which will likely evolve as more data becomes available on the long-term behavior of solid-state cells.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!