Solid-state electrolyte interphase formation and mechanical properties

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SEI Formation Background and Objectives

The solid-electrolyte interphase (SEI) formation is a critical process in the development of advanced battery technologies, particularly in the realm of solid-state batteries. This phenomenon has been a subject of intense research due to its significant impact on battery performance, safety, and longevity. The SEI layer forms at the interface between the electrode and the electrolyte, acting as a protective barrier that prevents further decomposition of the electrolyte while allowing ion transport.

The evolution of SEI research can be traced back to the early days of lithium-ion battery development in the 1970s and 1980s. Initially, the formation of this layer was seen as a detrimental side reaction. However, as understanding grew, researchers recognized its crucial role in stabilizing the electrode-electrolyte interface. This paradigm shift led to a surge in research efforts aimed at controlling and optimizing SEI formation.

In recent years, the focus has shifted towards solid-state electrolytes as a promising alternative to liquid electrolytes, offering potential improvements in safety and energy density. However, the formation and properties of the SEI layer in solid-state systems present unique challenges and opportunities that differ from traditional liquid electrolyte systems.

The primary objectives of current research on SEI formation in solid-state electrolytes are multifaceted. Firstly, there is a need to understand the fundamental mechanisms of SEI formation in these systems, including the chemical and electrochemical reactions involved, the kinetics of layer growth, and the factors influencing its composition and structure.

Secondly, researchers aim to elucidate the mechanical properties of the SEI layer in solid-state systems. This includes investigating its elasticity, hardness, and adhesion to both the electrode and electrolyte surfaces. Understanding these properties is crucial for predicting and mitigating issues related to interfacial stability and mechanical degradation during battery cycling.

Another key objective is to develop in situ and operando characterization techniques that allow for real-time observation of SEI formation and evolution. This is particularly challenging in solid-state systems due to the confined nature of the interfaces and the high sensitivity of the materials involved.

Furthermore, there is a growing emphasis on tailoring the SEI layer to enhance its functionality. This involves exploring additives and surface treatments that can promote the formation of a more stable and ion-conductive SEI, as well as investigating ways to control its thickness and uniformity.

Ultimately, the overarching goal of this research is to leverage the understanding of SEI formation and mechanical properties to design more efficient, durable, and high-performance solid-state batteries. This knowledge is expected to play a pivotal role in overcoming current limitations and paving the way for the next generation of energy storage technologies.

The evolution of SEI research can be traced back to the early days of lithium-ion battery development in the 1970s and 1980s. Initially, the formation of this layer was seen as a detrimental side reaction. However, as understanding grew, researchers recognized its crucial role in stabilizing the electrode-electrolyte interface. This paradigm shift led to a surge in research efforts aimed at controlling and optimizing SEI formation.

In recent years, the focus has shifted towards solid-state electrolytes as a promising alternative to liquid electrolytes, offering potential improvements in safety and energy density. However, the formation and properties of the SEI layer in solid-state systems present unique challenges and opportunities that differ from traditional liquid electrolyte systems.

The primary objectives of current research on SEI formation in solid-state electrolytes are multifaceted. Firstly, there is a need to understand the fundamental mechanisms of SEI formation in these systems, including the chemical and electrochemical reactions involved, the kinetics of layer growth, and the factors influencing its composition and structure.

Secondly, researchers aim to elucidate the mechanical properties of the SEI layer in solid-state systems. This includes investigating its elasticity, hardness, and adhesion to both the electrode and electrolyte surfaces. Understanding these properties is crucial for predicting and mitigating issues related to interfacial stability and mechanical degradation during battery cycling.

Another key objective is to develop in situ and operando characterization techniques that allow for real-time observation of SEI formation and evolution. This is particularly challenging in solid-state systems due to the confined nature of the interfaces and the high sensitivity of the materials involved.

Furthermore, there is a growing emphasis on tailoring the SEI layer to enhance its functionality. This involves exploring additives and surface treatments that can promote the formation of a more stable and ion-conductive SEI, as well as investigating ways to control its thickness and uniformity.

Ultimately, the overarching goal of this research is to leverage the understanding of SEI formation and mechanical properties to design more efficient, durable, and high-performance solid-state batteries. This knowledge is expected to play a pivotal role in overcoming current limitations and paving the way for the next generation of energy storage technologies.

Market Demand for Advanced Batteries

The market demand for advanced batteries, particularly those incorporating solid-state electrolyte technology, has been experiencing significant growth in recent years. This surge is primarily driven by the increasing adoption of electric vehicles (EVs), renewable energy storage systems, and portable electronic devices. The automotive industry, in particular, has been a major catalyst for the development of solid-state batteries, as they offer potential advantages in terms of safety, energy density, and charging speed compared to conventional lithium-ion batteries.

The global electric vehicle market has been expanding rapidly, with major automakers investing heavily in EV production and battery technology. This shift towards electrification has created a strong demand for batteries with improved performance, safety, and longevity. Solid-state batteries, with their potential to address these requirements, have garnered significant attention from both manufacturers and consumers.

In the renewable energy sector, the need for efficient and reliable energy storage solutions has also contributed to the growing demand for advanced battery technologies. As countries worldwide aim to increase their reliance on renewable energy sources, the market for grid-scale energy storage systems has expanded, creating opportunities for solid-state battery technologies to play a crucial role in stabilizing power grids and managing intermittent energy generation.

The consumer electronics industry has also shown interest in solid-state battery technology, driven by the demand for longer-lasting, faster-charging, and safer devices. Smartphones, laptops, and wearable devices could benefit from the potential advantages offered by solid-state batteries, such as higher energy density and improved safety characteristics.

Market analysts project substantial growth in the solid-state battery market over the coming years. The increasing focus on research and development in this field, coupled with growing investments from major technology companies and automotive manufacturers, indicates a strong market potential for solid-state battery technology.

However, challenges remain in terms of scalability, manufacturing costs, and performance optimization. The successful commercialization of solid-state batteries will depend on overcoming these hurdles and demonstrating clear advantages over existing lithium-ion technologies. As research on solid-state electrolyte interphase formation and mechanical properties progresses, it is expected to address some of these challenges and potentially accelerate market adoption.

The demand for advanced batteries extends beyond consumer applications, with aerospace, defense, and medical industries also showing interest in the technology. These sectors require high-performance, reliable, and safe energy storage solutions, further expanding the potential market for solid-state batteries.

The global electric vehicle market has been expanding rapidly, with major automakers investing heavily in EV production and battery technology. This shift towards electrification has created a strong demand for batteries with improved performance, safety, and longevity. Solid-state batteries, with their potential to address these requirements, have garnered significant attention from both manufacturers and consumers.

In the renewable energy sector, the need for efficient and reliable energy storage solutions has also contributed to the growing demand for advanced battery technologies. As countries worldwide aim to increase their reliance on renewable energy sources, the market for grid-scale energy storage systems has expanded, creating opportunities for solid-state battery technologies to play a crucial role in stabilizing power grids and managing intermittent energy generation.

The consumer electronics industry has also shown interest in solid-state battery technology, driven by the demand for longer-lasting, faster-charging, and safer devices. Smartphones, laptops, and wearable devices could benefit from the potential advantages offered by solid-state batteries, such as higher energy density and improved safety characteristics.

Market analysts project substantial growth in the solid-state battery market over the coming years. The increasing focus on research and development in this field, coupled with growing investments from major technology companies and automotive manufacturers, indicates a strong market potential for solid-state battery technology.

However, challenges remain in terms of scalability, manufacturing costs, and performance optimization. The successful commercialization of solid-state batteries will depend on overcoming these hurdles and demonstrating clear advantages over existing lithium-ion technologies. As research on solid-state electrolyte interphase formation and mechanical properties progresses, it is expected to address some of these challenges and potentially accelerate market adoption.

The demand for advanced batteries extends beyond consumer applications, with aerospace, defense, and medical industries also showing interest in the technology. These sectors require high-performance, reliable, and safe energy storage solutions, further expanding the potential market for solid-state batteries.

Current Challenges in SEI Research

The research on solid-state electrolyte interphase (SEI) formation and mechanical properties faces several significant challenges that hinder progress in this critical area of battery technology. One of the primary obstacles is the complexity of the SEI formation process, which involves intricate chemical reactions at the electrode-electrolyte interface. This complexity makes it difficult to accurately model and predict SEI growth and composition, leading to uncertainties in battery performance and longevity predictions.

Another major challenge lies in the dynamic nature of the SEI layer. As batteries undergo repeated charge-discharge cycles, the SEI continuously evolves, changing its structure and composition. This evolution affects the mechanical properties of the SEI, making it challenging to maintain consistent performance over the battery's lifetime. Researchers struggle to develop methods for in-situ characterization of the SEI during battery operation, which is crucial for understanding its real-time behavior and properties.

The mechanical properties of the SEI are particularly challenging to study due to its nanoscale thickness and heterogeneous composition. Traditional mechanical testing methods are often inadequate for characterizing such thin and delicate layers. Developing new techniques and instruments capable of accurately measuring the mechanical properties of the SEI without disrupting its structure remains a significant hurdle in the field.

Furthermore, the interplay between the SEI's chemical composition and its mechanical properties presents a complex research challenge. The SEI's ability to withstand mechanical stress while maintaining its protective function is critical for battery performance and safety. However, establishing clear correlations between specific chemical components and mechanical behaviors is an ongoing struggle for researchers.

The environmental sensitivity of the SEI adds another layer of complexity to research efforts. Exposure to air or moisture can rapidly alter the SEI's properties, making ex-situ analysis problematic. This necessitates the development of advanced in-situ and operando characterization techniques, which are technically challenging and often require specialized equipment.

Lastly, the variability in SEI formation across different electrode materials and electrolyte compositions poses a significant challenge. What works for one system may not be applicable to another, making it difficult to establish universal principles or models for SEI formation and properties. This variability necessitates extensive experimental work and complicates efforts to develop standardized research methodologies in the field.

Another major challenge lies in the dynamic nature of the SEI layer. As batteries undergo repeated charge-discharge cycles, the SEI continuously evolves, changing its structure and composition. This evolution affects the mechanical properties of the SEI, making it challenging to maintain consistent performance over the battery's lifetime. Researchers struggle to develop methods for in-situ characterization of the SEI during battery operation, which is crucial for understanding its real-time behavior and properties.

The mechanical properties of the SEI are particularly challenging to study due to its nanoscale thickness and heterogeneous composition. Traditional mechanical testing methods are often inadequate for characterizing such thin and delicate layers. Developing new techniques and instruments capable of accurately measuring the mechanical properties of the SEI without disrupting its structure remains a significant hurdle in the field.

Furthermore, the interplay between the SEI's chemical composition and its mechanical properties presents a complex research challenge. The SEI's ability to withstand mechanical stress while maintaining its protective function is critical for battery performance and safety. However, establishing clear correlations between specific chemical components and mechanical behaviors is an ongoing struggle for researchers.

The environmental sensitivity of the SEI adds another layer of complexity to research efforts. Exposure to air or moisture can rapidly alter the SEI's properties, making ex-situ analysis problematic. This necessitates the development of advanced in-situ and operando characterization techniques, which are technically challenging and often require specialized equipment.

Lastly, the variability in SEI formation across different electrode materials and electrolyte compositions poses a significant challenge. What works for one system may not be applicable to another, making it difficult to establish universal principles or models for SEI formation and properties. This variability necessitates extensive experimental work and complicates efforts to develop standardized research methodologies in the field.

Existing SEI Characterization Techniques

01 Composition and structure of solid-state electrolyte interphase

The mechanical properties of the solid-state electrolyte interphase (SEI) are significantly influenced by its composition and structure. Research focuses on developing SEI layers with optimal chemical components and physical arrangements to enhance mechanical stability and durability. This includes investigating various inorganic and organic materials, as well as their ratios and layering techniques, to create a robust SEI that can withstand mechanical stress during battery operation.- Composition and structure of solid-state electrolyte interphase: The composition and structure of the solid-state electrolyte interphase (SEI) play a crucial role in determining its mechanical properties. Research focuses on optimizing the chemical composition and nanostructure of the SEI to enhance its stability, flexibility, and durability under various mechanical stresses.

- Impact of mechanical properties on battery performance: The mechanical properties of the solid-state electrolyte interphase significantly influence battery performance, including cycle life, capacity retention, and safety. Studies investigate how factors such as elasticity, hardness, and fracture toughness of the SEI affect the overall electrochemical behavior and longevity of solid-state batteries.

- Characterization techniques for SEI mechanical properties: Advanced characterization techniques are employed to analyze the mechanical properties of the solid-state electrolyte interphase. These methods include nanoindentation, atomic force microscopy, and in-situ electron microscopy, which provide insights into the SEI's elastic modulus, hardness, and deformation behavior under various conditions.

- Strategies to enhance SEI mechanical stability: Researchers are developing strategies to improve the mechanical stability of the solid-state electrolyte interphase. These approaches include the use of additives, surface modifications, and engineered interfaces to create a more robust and flexible SEI that can withstand volume changes and mechanical stresses during battery operation.

- Modeling and simulation of SEI mechanical behavior: Computational modeling and simulation techniques are utilized to predict and understand the mechanical behavior of the solid-state electrolyte interphase. These methods help in designing improved SEI structures, optimizing material compositions, and forecasting long-term mechanical stability under various operating conditions.

02 Impact of electrolyte additives on SEI mechanical properties

Electrolyte additives play a crucial role in modifying the mechanical properties of the SEI layer. Researchers are exploring various additives that can enhance the flexibility, hardness, and adhesion of the SEI to the electrode surface. These additives can alter the formation process of the SEI, resulting in improved mechanical characteristics that contribute to better battery performance and longevity.Expand Specific Solutions03 Characterization techniques for SEI mechanical properties

Advanced characterization techniques are being developed and employed to accurately measure and analyze the mechanical properties of the SEI layer. These include atomic force microscopy (AFM), nanoindentation, and in-situ electron microscopy methods. Such techniques allow researchers to study the elasticity, hardness, and fracture toughness of the SEI, providing crucial insights for optimizing its mechanical performance in solid-state batteries.Expand Specific Solutions04 Relationship between SEI mechanical properties and battery performance

The mechanical properties of the SEI layer have a direct impact on the overall performance and safety of solid-state batteries. Studies are focusing on understanding how the mechanical stability of the SEI affects factors such as ion transport, interfacial resistance, and capacity retention. This research aims to establish correlations between SEI mechanical properties and long-term battery cycling performance, as well as safety aspects related to dendrite formation and short-circuiting.Expand Specific Solutions05 Engineering approaches to enhance SEI mechanical properties

Various engineering approaches are being explored to enhance the mechanical properties of the SEI layer. These include surface modification of electrodes, introduction of artificial SEI layers, and development of novel solid electrolyte materials that promote the formation of mechanically robust SEI. Researchers are also investigating the use of nanostructured materials and composite designs to create SEI layers with improved mechanical strength and flexibility.Expand Specific Solutions

Key Players in Solid-State Battery Industry

The research on solid-state electrolyte interphase formation and mechanical properties is in a rapidly evolving phase, with significant market potential in the electric vehicle and energy storage sectors. The industry is transitioning from early-stage research to commercial applications, driven by the demand for safer and more efficient batteries. Key players like QuantumScape, LG Energy Solution, and Solvay are investing heavily in this technology, indicating its growing maturity. Universities such as MIT, Stanford, and ShanghaiTech are contributing fundamental research, while automotive giants like Honda, Hyundai, and Mercedes-Benz are exploring practical applications, signaling a competitive and diverse landscape in this field.

GM Global Technology Operations LLC

Technical Solution: GM is investing heavily in solid-state battery technology, with a focus on lithium-metal anodes and sulfide-based solid electrolytes. Their research includes the development of novel electrolyte compositions that promote stable SEI formation while maintaining high ionic conductivity[7]. GM's approach also involves the use of advanced characterization techniques, such as in-situ electron microscopy and spectroscopy, to study the evolution of the SEI layer during battery operation[8]. The company is particularly interested in understanding and improving the mechanical properties of the electrolyte-electrode interface to prevent issues such as delamination and crack formation during cycling. GM is collaborating with academic institutions to develop computational models that can predict SEI formation and mechanical behavior under various operating conditions[9].

Strengths: Extensive resources for research and development, integration with vehicle design expertise. Weaknesses: Potential challenges in transitioning from traditional lithium-ion to solid-state battery production at scale.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution is actively researching solid-state electrolytes and their interface with electrodes. Their approach involves developing composite electrolytes that combine the benefits of ceramic and polymer materials to enhance both ionic conductivity and mechanical properties[4]. The company is focusing on sulfide-based solid electrolytes due to their high ionic conductivity and relatively low interfacial resistance[5]. LG Energy Solution is also investigating the use of artificial SEI layers to improve the stability of the electrode-electrolyte interface and mitigate dendrite formation[6]. Their research extends to understanding the mechanical properties of the electrolyte-electrode interface under various operating conditions to ensure long-term stability and safety.

Strengths: Strong manufacturing capabilities and experience in battery production. Weaknesses: Balancing the trade-offs between different solid electrolyte materials and ensuring compatibility with existing production processes.

Innovations in SEI Engineering

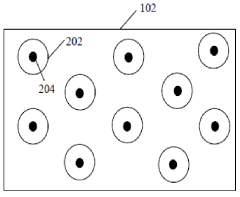

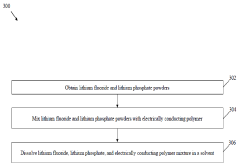

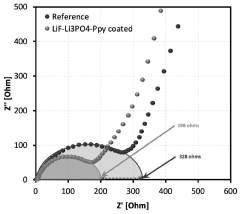

Solid electrolyte interphase (SEI) and a method for its preparation

PatentActiveIN202141055967A

Innovation

- A solid electrolyte interphase (SEI) comprising a porous polymer matrix embedded with metal precursors like lithium fluoride and lithium phosphate, coated on the current collector to prevent dendrite formation and enhance battery performance and safety, prepared through a method involving mixing metal precursors with an electrically conducting polymer and solvent, followed by solvent removal.

New components for electrolyte compositions

PatentWO2020025502A1

Innovation

- Development of new chemical components, including specific solvents, additives, and electrolyte salts, which can be used in various combinations to improve the quality of the solid electrolyte interphase (SEI), chemical stability, ionic conductivity, and thermal stability, thereby addressing the limitations of existing electrolyte compositions.

Environmental Impact of SEI Materials

The formation and composition of the solid-electrolyte interphase (SEI) in lithium-ion batteries have significant environmental implications. As the SEI layer forms during the initial charging cycles, it consumes electrolyte components and lithium ions, which can lead to capacity loss and reduced battery efficiency. This process not only affects the battery's performance but also has broader environmental consequences.

The materials used in SEI formation, primarily organic and inorganic compounds, can have varying degrees of environmental impact. Some organic components, such as ethylene carbonate and dimethyl carbonate, are derived from petrochemical sources, contributing to carbon emissions during their production. Inorganic components like lithium fluoride and lithium carbonate may require energy-intensive mining and processing, further increasing the environmental footprint of battery production.

Moreover, the stability and durability of the SEI layer directly influence the battery's lifespan. A more stable SEI can lead to longer-lasting batteries, reducing the frequency of battery replacements and, consequently, the overall environmental impact of battery production and disposal. Conversely, an unstable SEI may result in accelerated battery degradation, necessitating more frequent replacements and increasing electronic waste.

The disposal and recycling of batteries with SEI layers present additional environmental challenges. The complex chemical composition of the SEI can complicate recycling processes, potentially requiring more energy-intensive or chemically harsh methods to recover valuable materials. This complexity may also increase the risk of harmful substances leaching into the environment if batteries are not properly disposed of or recycled.

Research into more environmentally friendly SEI materials and formation processes is ongoing. Efforts are being made to develop SEI components that are derived from renewable sources or have a lower environmental impact during production. Additionally, studies are exploring ways to enhance SEI stability and reduce its thickness, which could lead to more efficient batteries with longer lifespans and reduced material consumption.

The environmental impact of SEI materials extends beyond the battery itself, affecting the entire lifecycle of energy storage systems. As the demand for lithium-ion batteries continues to grow, particularly in electric vehicles and renewable energy storage, the cumulative environmental effects of SEI formation and materials become increasingly significant. This underscores the importance of continued research and development in this area to minimize the environmental footprint of battery technology while maximizing its benefits in supporting the transition to cleaner energy systems.

The materials used in SEI formation, primarily organic and inorganic compounds, can have varying degrees of environmental impact. Some organic components, such as ethylene carbonate and dimethyl carbonate, are derived from petrochemical sources, contributing to carbon emissions during their production. Inorganic components like lithium fluoride and lithium carbonate may require energy-intensive mining and processing, further increasing the environmental footprint of battery production.

Moreover, the stability and durability of the SEI layer directly influence the battery's lifespan. A more stable SEI can lead to longer-lasting batteries, reducing the frequency of battery replacements and, consequently, the overall environmental impact of battery production and disposal. Conversely, an unstable SEI may result in accelerated battery degradation, necessitating more frequent replacements and increasing electronic waste.

The disposal and recycling of batteries with SEI layers present additional environmental challenges. The complex chemical composition of the SEI can complicate recycling processes, potentially requiring more energy-intensive or chemically harsh methods to recover valuable materials. This complexity may also increase the risk of harmful substances leaching into the environment if batteries are not properly disposed of or recycled.

Research into more environmentally friendly SEI materials and formation processes is ongoing. Efforts are being made to develop SEI components that are derived from renewable sources or have a lower environmental impact during production. Additionally, studies are exploring ways to enhance SEI stability and reduce its thickness, which could lead to more efficient batteries with longer lifespans and reduced material consumption.

The environmental impact of SEI materials extends beyond the battery itself, affecting the entire lifecycle of energy storage systems. As the demand for lithium-ion batteries continues to grow, particularly in electric vehicles and renewable energy storage, the cumulative environmental effects of SEI formation and materials become increasingly significant. This underscores the importance of continued research and development in this area to minimize the environmental footprint of battery technology while maximizing its benefits in supporting the transition to cleaner energy systems.

Safety Considerations in Solid-State Batteries

Safety considerations are paramount in the development and implementation of solid-state batteries, particularly in relation to the formation and mechanical properties of the solid-state electrolyte interphase (SEI). The unique characteristics of solid-state batteries present both advantages and challenges in terms of safety compared to traditional liquid electrolyte batteries.

One of the primary safety benefits of solid-state batteries is the elimination of flammable liquid electrolytes, which significantly reduces the risk of fire and explosion. However, the formation of the SEI layer in solid-state batteries introduces new safety concerns that must be carefully addressed. The mechanical properties of the SEI layer play a crucial role in maintaining the structural integrity of the battery and preventing short circuits.

The interface between the solid electrolyte and electrodes is a critical area for safety considerations. As the battery cycles, mechanical stresses can lead to the formation of cracks or voids in the SEI layer. These defects can potentially create pathways for dendrite growth, which may result in internal short circuits. Research into improving the mechanical strength and flexibility of the SEI layer is essential to mitigate these risks.

Another safety aspect to consider is the volume changes that occur during charging and discharging cycles. Unlike liquid electrolytes, which can accommodate these changes, solid electrolytes may experience stress and strain that can lead to mechanical failure. This can compromise the safety of the battery by creating internal short circuits or exposing reactive materials.

The thermal stability of solid-state batteries is generally superior to that of liquid electrolyte batteries. However, the formation of the SEI layer can still generate heat, which must be managed effectively to prevent thermal runaway. Proper thermal management systems and battery designs are crucial to ensure safe operation under various conditions, including high-temperature environments.

The chemical stability of the SEI layer is another important safety consideration. Reactions between the solid electrolyte and electrode materials can lead to the formation of undesirable compounds that may degrade battery performance or compromise safety. Research into stable electrolyte-electrode combinations and protective coatings is ongoing to address these issues.

Lastly, the manufacturing processes for solid-state batteries must be carefully controlled to ensure consistent SEI formation and mechanical properties. Impurities or defects introduced during production can significantly impact safety performance. Developing robust quality control measures and standardized testing protocols is essential for the widespread adoption of solid-state battery technology.

One of the primary safety benefits of solid-state batteries is the elimination of flammable liquid electrolytes, which significantly reduces the risk of fire and explosion. However, the formation of the SEI layer in solid-state batteries introduces new safety concerns that must be carefully addressed. The mechanical properties of the SEI layer play a crucial role in maintaining the structural integrity of the battery and preventing short circuits.

The interface between the solid electrolyte and electrodes is a critical area for safety considerations. As the battery cycles, mechanical stresses can lead to the formation of cracks or voids in the SEI layer. These defects can potentially create pathways for dendrite growth, which may result in internal short circuits. Research into improving the mechanical strength and flexibility of the SEI layer is essential to mitigate these risks.

Another safety aspect to consider is the volume changes that occur during charging and discharging cycles. Unlike liquid electrolytes, which can accommodate these changes, solid electrolytes may experience stress and strain that can lead to mechanical failure. This can compromise the safety of the battery by creating internal short circuits or exposing reactive materials.

The thermal stability of solid-state batteries is generally superior to that of liquid electrolyte batteries. However, the formation of the SEI layer can still generate heat, which must be managed effectively to prevent thermal runaway. Proper thermal management systems and battery designs are crucial to ensure safe operation under various conditions, including high-temperature environments.

The chemical stability of the SEI layer is another important safety consideration. Reactions between the solid electrolyte and electrode materials can lead to the formation of undesirable compounds that may degrade battery performance or compromise safety. Research into stable electrolyte-electrode combinations and protective coatings is ongoing to address these issues.

Lastly, the manufacturing processes for solid-state batteries must be carefully controlled to ensure consistent SEI formation and mechanical properties. Impurities or defects introduced during production can significantly impact safety performance. Developing robust quality control measures and standardized testing protocols is essential for the widespread adoption of solid-state battery technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!