Solid-state electrolyte ceramic densification via cold sintering and hot pressing

AUG 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ceramic Electrolyte Background and Objectives

Solid-state electrolytes have emerged as a promising solution to address the safety and performance limitations of conventional liquid electrolytes in lithium-ion batteries. Among various solid-state electrolyte materials, ceramics have garnered significant attention due to their high ionic conductivity, excellent thermal stability, and wide electrochemical window. The development of ceramic electrolytes represents a critical step towards the realization of next-generation energy storage systems with enhanced safety, energy density, and longevity.

The evolution of ceramic electrolyte technology can be traced back to the 1960s, with the discovery of sodium beta-alumina as a fast ion conductor. Since then, research efforts have focused on identifying and optimizing various ceramic materials with superior ionic conductivity and mechanical properties. Notable advancements include the development of NASICON-type materials, perovskite-structured ceramics, and garnet-type oxides. These materials have demonstrated promising ionic conductivities approaching or even surpassing those of liquid electrolytes.

Despite the progress made in ceramic electrolyte development, several challenges persist, particularly in achieving high density and eliminating grain boundary resistance. Traditional sintering methods often require high temperatures and prolonged processing times, which can lead to undesirable phase transitions, grain coarsening, and lithium loss. To address these issues, researchers have been exploring alternative densification techniques, such as cold sintering and hot pressing.

The primary objective of this research is to investigate the potential of combining cold sintering and hot pressing techniques for the densification of ceramic electrolytes. Cold sintering, a relatively new approach, enables the densification of ceramics at significantly lower temperatures through the use of transient liquid phases. Hot pressing, on the other hand, applies simultaneous heat and pressure to achieve high-density ceramics. By integrating these two methods, researchers aim to overcome the limitations of conventional sintering processes and achieve superior ceramic electrolyte properties.

Specifically, this study seeks to optimize the processing parameters for cold sintering and hot pressing of ceramic electrolytes, with a focus on achieving high relative density, minimizing grain boundary resistance, and maintaining the desired crystal structure. The research also aims to elucidate the underlying mechanisms of densification and their impact on the ionic conductivity and mechanical properties of the resulting ceramic electrolytes. Furthermore, the study will explore the scalability and economic viability of this combined approach for potential industrial applications.

By advancing the densification techniques for ceramic electrolytes, this research contributes to the broader goal of developing high-performance solid-state batteries. The successful implementation of dense ceramic electrolytes could pave the way for safer, more energy-dense, and longer-lasting energy storage solutions, with applications ranging from portable electronics to electric vehicles and grid-scale energy storage systems.

The evolution of ceramic electrolyte technology can be traced back to the 1960s, with the discovery of sodium beta-alumina as a fast ion conductor. Since then, research efforts have focused on identifying and optimizing various ceramic materials with superior ionic conductivity and mechanical properties. Notable advancements include the development of NASICON-type materials, perovskite-structured ceramics, and garnet-type oxides. These materials have demonstrated promising ionic conductivities approaching or even surpassing those of liquid electrolytes.

Despite the progress made in ceramic electrolyte development, several challenges persist, particularly in achieving high density and eliminating grain boundary resistance. Traditional sintering methods often require high temperatures and prolonged processing times, which can lead to undesirable phase transitions, grain coarsening, and lithium loss. To address these issues, researchers have been exploring alternative densification techniques, such as cold sintering and hot pressing.

The primary objective of this research is to investigate the potential of combining cold sintering and hot pressing techniques for the densification of ceramic electrolytes. Cold sintering, a relatively new approach, enables the densification of ceramics at significantly lower temperatures through the use of transient liquid phases. Hot pressing, on the other hand, applies simultaneous heat and pressure to achieve high-density ceramics. By integrating these two methods, researchers aim to overcome the limitations of conventional sintering processes and achieve superior ceramic electrolyte properties.

Specifically, this study seeks to optimize the processing parameters for cold sintering and hot pressing of ceramic electrolytes, with a focus on achieving high relative density, minimizing grain boundary resistance, and maintaining the desired crystal structure. The research also aims to elucidate the underlying mechanisms of densification and their impact on the ionic conductivity and mechanical properties of the resulting ceramic electrolytes. Furthermore, the study will explore the scalability and economic viability of this combined approach for potential industrial applications.

By advancing the densification techniques for ceramic electrolytes, this research contributes to the broader goal of developing high-performance solid-state batteries. The successful implementation of dense ceramic electrolytes could pave the way for safer, more energy-dense, and longer-lasting energy storage solutions, with applications ranging from portable electronics to electric vehicles and grid-scale energy storage systems.

Market Analysis for Solid-State Batteries

The solid-state battery market is experiencing rapid growth and attracting significant attention from both industry players and investors. This emerging technology promises to revolutionize energy storage by offering higher energy density, improved safety, and longer lifespan compared to traditional lithium-ion batteries. The global solid-state battery market is projected to expand at a compound annual growth rate (CAGR) of over 30% in the coming years, driven by increasing demand for electric vehicles (EVs) and portable electronic devices.

The automotive sector is expected to be the primary driver of solid-state battery adoption. Major automakers, including Toyota, Volkswagen, and BMW, have announced plans to incorporate solid-state batteries in their future EV models. This shift is fueled by the need for longer driving ranges, faster charging times, and enhanced safety features in electric vehicles. The consumer electronics industry is also showing keen interest in solid-state technology, with potential applications in smartphones, laptops, and wearable devices.

Market demand for solid-state batteries is further bolstered by stringent environmental regulations and government initiatives promoting clean energy solutions. Several countries have set ambitious targets for phasing out internal combustion engine vehicles, creating a favorable landscape for solid-state battery adoption. Additionally, the growing focus on renewable energy storage systems is expected to create new opportunities for solid-state battery applications in grid storage and backup power solutions.

However, the market faces several challenges that need to be addressed before widespread commercialization can occur. The high cost of production remains a significant barrier, with current solid-state batteries being substantially more expensive than their liquid electrolyte counterparts. Scaling up manufacturing processes and improving material availability are crucial factors in reducing costs and making solid-state batteries economically viable for mass-market adoption.

Technical hurdles also persist, particularly in areas such as ceramic electrolyte densification. Research on cold sintering and hot pressing techniques for solid-state electrolyte ceramics is critical in overcoming these challenges and improving battery performance. Advancements in these areas could lead to breakthroughs in energy density, cycle life, and manufacturing efficiency, further driving market growth and adoption.

As the technology matures and production costs decrease, the solid-state battery market is poised for substantial expansion. Industry experts anticipate that solid-state batteries could capture a significant share of the overall battery market within the next decade, potentially reshaping the energy storage landscape and accelerating the transition to electric mobility and renewable energy systems.

The automotive sector is expected to be the primary driver of solid-state battery adoption. Major automakers, including Toyota, Volkswagen, and BMW, have announced plans to incorporate solid-state batteries in their future EV models. This shift is fueled by the need for longer driving ranges, faster charging times, and enhanced safety features in electric vehicles. The consumer electronics industry is also showing keen interest in solid-state technology, with potential applications in smartphones, laptops, and wearable devices.

Market demand for solid-state batteries is further bolstered by stringent environmental regulations and government initiatives promoting clean energy solutions. Several countries have set ambitious targets for phasing out internal combustion engine vehicles, creating a favorable landscape for solid-state battery adoption. Additionally, the growing focus on renewable energy storage systems is expected to create new opportunities for solid-state battery applications in grid storage and backup power solutions.

However, the market faces several challenges that need to be addressed before widespread commercialization can occur. The high cost of production remains a significant barrier, with current solid-state batteries being substantially more expensive than their liquid electrolyte counterparts. Scaling up manufacturing processes and improving material availability are crucial factors in reducing costs and making solid-state batteries economically viable for mass-market adoption.

Technical hurdles also persist, particularly in areas such as ceramic electrolyte densification. Research on cold sintering and hot pressing techniques for solid-state electrolyte ceramics is critical in overcoming these challenges and improving battery performance. Advancements in these areas could lead to breakthroughs in energy density, cycle life, and manufacturing efficiency, further driving market growth and adoption.

As the technology matures and production costs decrease, the solid-state battery market is poised for substantial expansion. Industry experts anticipate that solid-state batteries could capture a significant share of the overall battery market within the next decade, potentially reshaping the energy storage landscape and accelerating the transition to electric mobility and renewable energy systems.

Current Challenges in Ceramic Electrolyte Densification

The densification of ceramic electrolytes remains a significant challenge in the development of solid-state batteries. Traditional sintering methods often require high temperatures and long processing times, which can lead to undesirable grain growth and compositional changes. These factors can negatively impact the ionic conductivity and mechanical properties of the ceramic electrolytes.

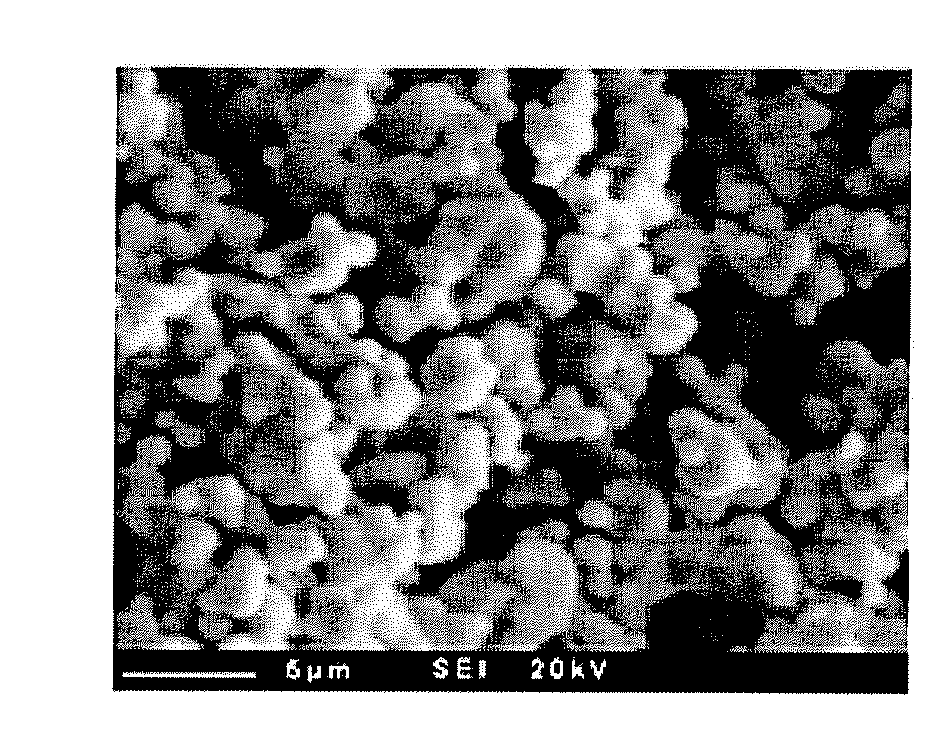

One of the primary challenges is achieving high relative density while maintaining small grain sizes. Conventional sintering techniques typically result in grain coarsening, which can reduce the overall ionic conductivity of the ceramic electrolyte. This trade-off between density and grain size presents a significant hurdle in optimizing the performance of solid-state electrolytes.

Another critical challenge is the control of interfacial resistance between ceramic grains. As the density increases, the number of grain boundaries decreases, which can potentially reduce the overall ionic conductivity. Balancing the need for high density with the preservation of beneficial grain boundary effects is a complex task that requires careful optimization of processing parameters.

The presence of residual porosity in ceramic electrolytes is also a major concern. Even small amounts of porosity can create pathways for dendrite growth, compromising the safety and longevity of solid-state batteries. Achieving full densification without introducing defects or impurities is crucial for ensuring the reliability of these electrolytes.

Temperature sensitivity of ceramic materials poses another challenge. Many promising ceramic electrolyte compositions are thermodynamically unstable at high temperatures, leading to decomposition or phase transitions during conventional sintering processes. This limits the range of applicable materials and complicates the densification process.

Furthermore, the scalability of ceramic electrolyte production remains a significant hurdle. Current laboratory-scale techniques for achieving high-density ceramics often struggle to translate to large-scale manufacturing processes. Developing methods that can produce consistent, high-quality ceramic electrolytes at an industrial scale is essential for the commercialization of solid-state batteries.

The integration of ceramic electrolytes with electrode materials presents additional challenges. Differences in thermal expansion coefficients and chemical compatibilities between the electrolyte and electrodes can lead to interfacial issues during high-temperature processing. Addressing these integration challenges while maintaining the desired electrolyte properties is critical for the overall performance of solid-state batteries.

One of the primary challenges is achieving high relative density while maintaining small grain sizes. Conventional sintering techniques typically result in grain coarsening, which can reduce the overall ionic conductivity of the ceramic electrolyte. This trade-off between density and grain size presents a significant hurdle in optimizing the performance of solid-state electrolytes.

Another critical challenge is the control of interfacial resistance between ceramic grains. As the density increases, the number of grain boundaries decreases, which can potentially reduce the overall ionic conductivity. Balancing the need for high density with the preservation of beneficial grain boundary effects is a complex task that requires careful optimization of processing parameters.

The presence of residual porosity in ceramic electrolytes is also a major concern. Even small amounts of porosity can create pathways for dendrite growth, compromising the safety and longevity of solid-state batteries. Achieving full densification without introducing defects or impurities is crucial for ensuring the reliability of these electrolytes.

Temperature sensitivity of ceramic materials poses another challenge. Many promising ceramic electrolyte compositions are thermodynamically unstable at high temperatures, leading to decomposition or phase transitions during conventional sintering processes. This limits the range of applicable materials and complicates the densification process.

Furthermore, the scalability of ceramic electrolyte production remains a significant hurdle. Current laboratory-scale techniques for achieving high-density ceramics often struggle to translate to large-scale manufacturing processes. Developing methods that can produce consistent, high-quality ceramic electrolytes at an industrial scale is essential for the commercialization of solid-state batteries.

The integration of ceramic electrolytes with electrode materials presents additional challenges. Differences in thermal expansion coefficients and chemical compatibilities between the electrolyte and electrodes can lead to interfacial issues during high-temperature processing. Addressing these integration challenges while maintaining the desired electrolyte properties is critical for the overall performance of solid-state batteries.

Cold Sintering and Hot Pressing Methods

01 Sintering techniques for ceramic electrolytes

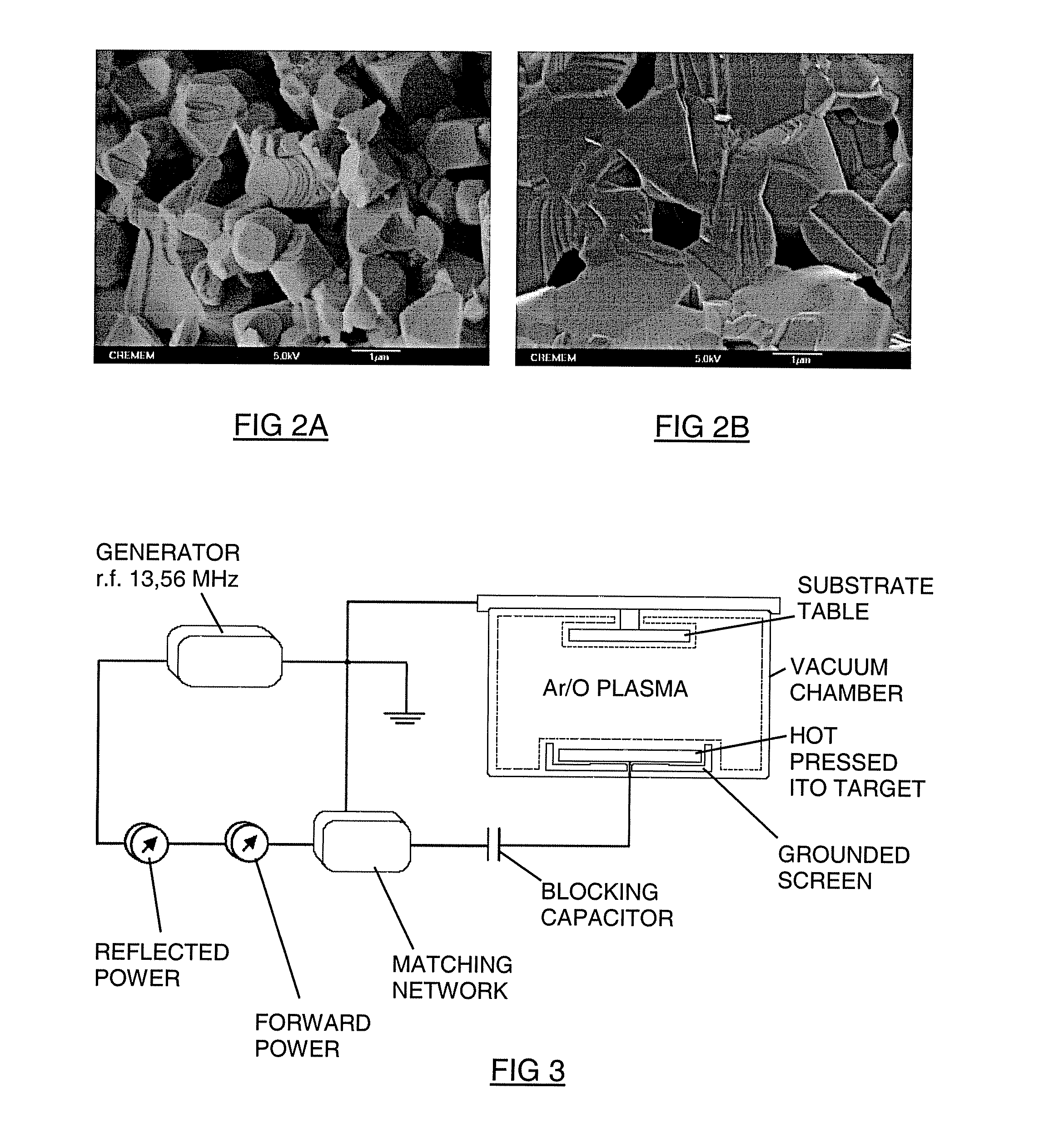

Various sintering techniques are employed to densify solid-state electrolyte ceramics. These methods include conventional sintering, hot pressing, and spark plasma sintering. The choice of sintering method affects the final density, microstructure, and ionic conductivity of the ceramic electrolyte. Optimizing sintering parameters such as temperature, pressure, and time is crucial for achieving high-density ceramics with improved electrochemical properties.- Sintering techniques for ceramic electrolyte densification: Various sintering techniques are employed to achieve high density in solid-state electrolyte ceramics. These methods include conventional sintering, hot pressing, and spark plasma sintering. The choice of sintering method and parameters significantly affects the final density and microstructure of the ceramic electrolyte, which in turn influences its ionic conductivity and overall performance in solid-state batteries.

- Composition optimization for improved densification: The chemical composition of the ceramic electrolyte plays a crucial role in its densification behavior. Researchers focus on optimizing the ratios of primary components and introducing dopants or sintering aids to enhance densification. These compositional modifications can lower sintering temperatures, promote grain growth, and reduce porosity, ultimately leading to higher density electrolytes with improved ionic conductivity.

- Nanostructured materials for enhanced densification: Utilizing nanostructured materials as precursors or additives can significantly improve the densification of solid-state electrolyte ceramics. Nanoparticles or nanofibers with high surface area and reactivity can promote sintering at lower temperatures and shorter times. This approach often results in finer grain structures and higher densities, which can enhance the mechanical and electrochemical properties of the electrolyte.

- Pressure-assisted densification methods: Pressure-assisted techniques are employed to achieve higher densities in solid-state electrolyte ceramics. Methods such as hot isostatic pressing (HIP), cold isostatic pressing (CIP) followed by sintering, and uniaxial pressing combined with sintering are used. These techniques apply external pressure during or before the sintering process, which helps to eliminate pores and achieve near-theoretical densities in the ceramic electrolytes.

- Two-step sintering for controlled grain growth and densification: Two-step sintering processes are developed to control grain growth while achieving high density in solid-state electrolyte ceramics. This method involves an initial high-temperature step to achieve a critical density, followed by a lower temperature step for prolonged sintering. This approach helps to suppress abnormal grain growth, resulting in a uniform microstructure with high density and enhanced ionic conductivity.

02 Composition and additives for enhanced densification

The composition of the ceramic electrolyte and the use of specific additives play a significant role in the densification process. Dopants, sintering aids, and nanoparticles can be incorporated to lower sintering temperatures, promote grain growth, and enhance densification. These additives can also improve the ionic conductivity and mechanical properties of the final ceramic electrolyte.Expand Specific Solutions03 Novel processing methods for ceramic electrolytes

Innovative processing methods are being developed to improve the densification of solid-state electrolyte ceramics. These include sol-gel synthesis, freeze-drying, and solution-based techniques. These methods aim to produce homogeneous precursor powders with controlled particle size and distribution, leading to enhanced sinterability and densification of the ceramic electrolytes.Expand Specific Solutions04 Microstructure control for optimized densification

Controlling the microstructure of ceramic electrolytes during densification is crucial for achieving desired properties. Techniques such as grain boundary engineering, pore elimination, and grain size control are employed to optimize the microstructure. These methods aim to reduce porosity, enhance grain boundary conductivity, and improve overall ionic transport properties of the densified ceramic electrolytes.Expand Specific Solutions05 In-situ densification and composite electrolytes

In-situ densification techniques and the development of composite electrolytes are emerging approaches for improving the densification of solid-state ceramic electrolytes. These methods involve the simultaneous formation and densification of the ceramic phase or the combination of multiple phases to create dense, high-performance electrolytes. Such approaches can lead to improved mechanical properties and enhanced ionic conductivity in the final ceramic electrolyte.Expand Specific Solutions

Key Players in Solid-State Electrolyte Industry

The research on solid-state electrolyte ceramic densification via cold sintering and hot pressing is in an emerging phase, with significant potential for growth. The market size is expanding as demand for advanced energy storage solutions increases. Technologically, the field is progressing rapidly, with varying levels of maturity among key players. Companies like Advanced Industrial Science & Technology, Penn State Research Foundation, and Shanghai Institute of Ceramics are at the forefront, demonstrating advanced capabilities. Other institutions such as Xi'an Jiaotong University, National University of Defense Technology, and Forschungszentrum Jülich GmbH are also making notable contributions, indicating a competitive and collaborative landscape. The involvement of diverse organizations suggests a growing interest in this technology across academic, industrial, and governmental sectors.

Penn State Research Foundation

Technical Solution: Penn State Research Foundation has pioneered research in cold sintering and hot pressing for solid-state electrolyte ceramic densification. Their approach combines low-temperature cold sintering with subsequent hot pressing to achieve high-density ceramics. The process involves using a small amount of transient liquid to facilitate particle rearrangement and dissolution-precipitation at low temperatures (typically <300°C), followed by hot pressing to further densify the material[1][3]. This method has shown success in densifying various ceramic materials, including those used in solid-state batteries, achieving relative densities over 95% while maintaining nanostructured grains[2][4].

Strengths: Achieves high densification at lower temperatures, preserves nanostructures, applicable to a wide range of ceramics. Weaknesses: May require specialized equipment, process optimization can be complex for different materials.

Forschungszentrum Jülich GmbH

Technical Solution: Forschungszentrum Jülich GmbH has developed advanced techniques for solid-state electrolyte ceramic densification, focusing on hot pressing methods. Their approach utilizes high-pressure sintering combined with controlled atmosphere to achieve dense, high-performance ceramic electrolytes. The institute has particularly excelled in the development of oxide-based solid electrolytes for solid oxide fuel cells (SOFCs) and batteries. Their process typically involves applying pressures up to 50 MPa at temperatures ranging from 1200°C to 1500°C, depending on the specific ceramic composition[5][6]. This method has resulted in electrolytes with relative densities exceeding 98% and significantly improved ionic conductivity[7].

Strengths: Achieves very high densification, excellent control over microstructure, suitable for oxide-based electrolytes. Weaknesses: High energy consumption due to high temperatures, potential for grain growth during prolonged sintering.

Innovations in Ceramic Densification Processes

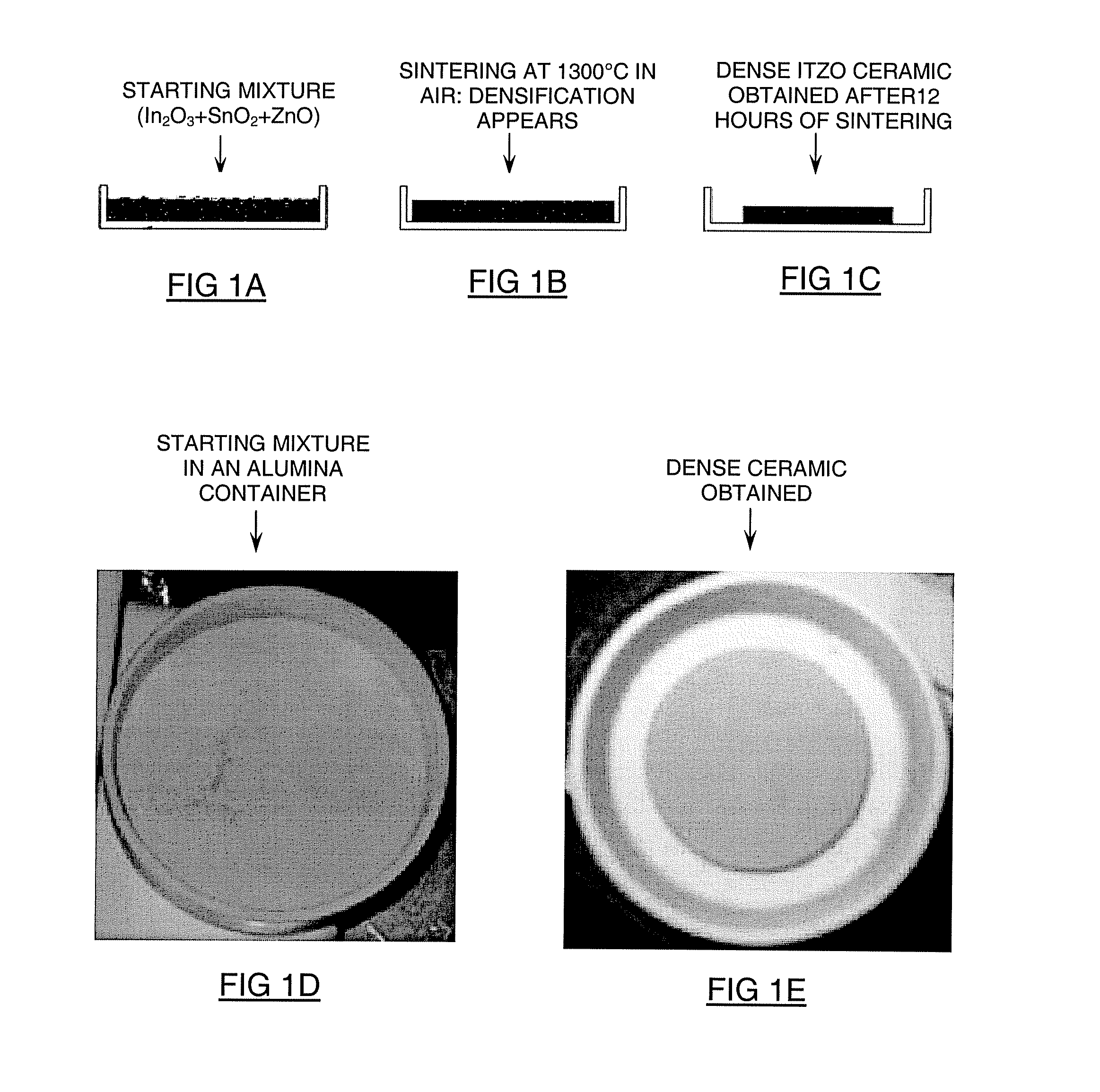

Process for preparing ceramics, ceramics thus obtained and uses thereof, especially as a sputtering target

PatentActiveUS20090315001A1

Innovation

- A process involving mixing an inorganic base material powder with a dopant powder, followed by sintering at high temperatures (above 800°C) under minimal pressure, creating a ceramic with specific dopant levels that generates anion vacancies, allowing for dense ceramic production without extensive compacting or expensive equipment.

Patent

Innovation

- Combining cold sintering and hot pressing techniques to achieve densification of solid-state electrolyte ceramics at lower temperatures.

- Utilizing a two-step process of cold sintering followed by hot pressing to optimize microstructure and reduce porosity.

- Achieving improved ionic conductivity and mechanical properties through the optimized densification process.

Environmental Impact of Sintering Processes

The environmental impact of sintering processes, particularly in the context of solid-state electrolyte ceramic densification via cold sintering and hot pressing, is a crucial consideration in the development and implementation of these technologies. Traditional sintering methods often require high temperatures and long processing times, leading to significant energy consumption and associated greenhouse gas emissions. In contrast, cold sintering and hot pressing techniques offer potential advantages in terms of reduced energy requirements and environmental footprint.

Cold sintering, which operates at relatively low temperatures (typically below 300°C), can substantially reduce energy consumption compared to conventional high-temperature sintering processes. This lower energy demand translates to decreased carbon dioxide emissions and a smaller overall environmental impact. Additionally, the shorter processing times associated with cold sintering contribute to improved energy efficiency and reduced resource utilization.

Hot pressing, while generally requiring higher temperatures than cold sintering, still offers environmental benefits when compared to traditional sintering methods. The application of pressure during the sintering process allows for lower sintering temperatures and shorter processing times, resulting in reduced energy consumption. Furthermore, the improved densification achieved through hot pressing can lead to enhanced material properties, potentially extending the lifespan of the resulting components and reducing the need for frequent replacements.

The use of these advanced sintering techniques can also contribute to the conservation of raw materials. The improved densification achieved through cold sintering and hot pressing often results in higher material utilization rates and reduced waste generation. This efficiency in material use can help mitigate the environmental impact associated with raw material extraction and processing.

Water consumption is another important environmental consideration in sintering processes. Cold sintering, in particular, often involves the use of aqueous solutions or water-based media. While this can lead to increased water usage compared to dry sintering methods, the overall water footprint may still be lower due to the reduced energy requirements and shorter processing times. Proper water management and recycling strategies can further minimize the environmental impact related to water consumption in these processes.

The potential for reduced emissions of harmful substances during cold sintering and hot pressing is also noteworthy. Traditional high-temperature sintering processes can sometimes lead to the release of volatile organic compounds (VOCs) or other pollutants. The lower processing temperatures employed in cold sintering and, to some extent, hot pressing can help mitigate these emissions, contributing to improved air quality and reduced environmental pollution.

In conclusion, the adoption of cold sintering and hot pressing techniques for solid-state electrolyte ceramic densification offers several environmental advantages over conventional sintering methods. These include reduced energy consumption, lower greenhouse gas emissions, improved material utilization, and potentially decreased emissions of harmful substances. However, a comprehensive life cycle assessment would be necessary to fully quantify the environmental benefits and identify any potential trade-offs associated with these advanced sintering processes.

Cold sintering, which operates at relatively low temperatures (typically below 300°C), can substantially reduce energy consumption compared to conventional high-temperature sintering processes. This lower energy demand translates to decreased carbon dioxide emissions and a smaller overall environmental impact. Additionally, the shorter processing times associated with cold sintering contribute to improved energy efficiency and reduced resource utilization.

Hot pressing, while generally requiring higher temperatures than cold sintering, still offers environmental benefits when compared to traditional sintering methods. The application of pressure during the sintering process allows for lower sintering temperatures and shorter processing times, resulting in reduced energy consumption. Furthermore, the improved densification achieved through hot pressing can lead to enhanced material properties, potentially extending the lifespan of the resulting components and reducing the need for frequent replacements.

The use of these advanced sintering techniques can also contribute to the conservation of raw materials. The improved densification achieved through cold sintering and hot pressing often results in higher material utilization rates and reduced waste generation. This efficiency in material use can help mitigate the environmental impact associated with raw material extraction and processing.

Water consumption is another important environmental consideration in sintering processes. Cold sintering, in particular, often involves the use of aqueous solutions or water-based media. While this can lead to increased water usage compared to dry sintering methods, the overall water footprint may still be lower due to the reduced energy requirements and shorter processing times. Proper water management and recycling strategies can further minimize the environmental impact related to water consumption in these processes.

The potential for reduced emissions of harmful substances during cold sintering and hot pressing is also noteworthy. Traditional high-temperature sintering processes can sometimes lead to the release of volatile organic compounds (VOCs) or other pollutants. The lower processing temperatures employed in cold sintering and, to some extent, hot pressing can help mitigate these emissions, contributing to improved air quality and reduced environmental pollution.

In conclusion, the adoption of cold sintering and hot pressing techniques for solid-state electrolyte ceramic densification offers several environmental advantages over conventional sintering methods. These include reduced energy consumption, lower greenhouse gas emissions, improved material utilization, and potentially decreased emissions of harmful substances. However, a comprehensive life cycle assessment would be necessary to fully quantify the environmental benefits and identify any potential trade-offs associated with these advanced sintering processes.

Scale-up and Manufacturing Considerations

Scaling up the production of solid-state electrolyte ceramics using cold sintering and hot pressing techniques presents several challenges and considerations for manufacturers. The transition from laboratory-scale production to industrial-scale manufacturing requires careful planning and optimization of processes to maintain product quality while increasing output.

One of the primary considerations is the design and construction of larger-scale equipment capable of handling increased material volumes. Cold sintering and hot pressing processes typically require specialized presses and furnaces. Scaling these up while maintaining uniform pressure and temperature distribution across larger sample sizes is crucial. Engineers must consider factors such as pressure gradients, heat transfer efficiency, and potential material inhomogeneities that may arise in larger batches.

Material handling and preparation also become more complex at industrial scales. Ensuring consistent particle size distribution, homogeneous mixing of precursors, and uniform moisture content across larger batches is essential for achieving reproducible results. Automated systems for material feeding, mixing, and post-processing may need to be developed to maintain efficiency and reduce variability.

Process control and monitoring systems must be adapted for larger-scale production. This includes implementing advanced sensors and control algorithms to maintain precise temperature and pressure profiles throughout the sintering and pressing cycles. Real-time monitoring and feedback systems can help adjust process parameters to compensate for variations in raw materials or environmental conditions.

Energy efficiency becomes a significant factor in scaled-up manufacturing. Optimizing heating and cooling cycles, recovering waste heat, and exploring alternative energy sources can help reduce production costs and environmental impact. Additionally, the development of continuous or semi-continuous processing methods, as opposed to batch processing, may offer advantages in terms of throughput and energy efficiency.

Quality control and characterization techniques must be adapted for higher production volumes. This may involve the development of in-line or rapid testing methods to ensure consistent product properties without significantly slowing down production. Statistical process control methods and automated inspection systems can help maintain quality standards across larger production runs.

Lastly, considerations for raw material sourcing and supply chain management become more critical at industrial scales. Ensuring a stable supply of high-quality precursors and developing relationships with reliable suppliers are essential for maintaining consistent production. Manufacturers may need to explore alternative raw material sources or develop in-house capabilities for material synthesis to meet increased demand.

One of the primary considerations is the design and construction of larger-scale equipment capable of handling increased material volumes. Cold sintering and hot pressing processes typically require specialized presses and furnaces. Scaling these up while maintaining uniform pressure and temperature distribution across larger sample sizes is crucial. Engineers must consider factors such as pressure gradients, heat transfer efficiency, and potential material inhomogeneities that may arise in larger batches.

Material handling and preparation also become more complex at industrial scales. Ensuring consistent particle size distribution, homogeneous mixing of precursors, and uniform moisture content across larger batches is essential for achieving reproducible results. Automated systems for material feeding, mixing, and post-processing may need to be developed to maintain efficiency and reduce variability.

Process control and monitoring systems must be adapted for larger-scale production. This includes implementing advanced sensors and control algorithms to maintain precise temperature and pressure profiles throughout the sintering and pressing cycles. Real-time monitoring and feedback systems can help adjust process parameters to compensate for variations in raw materials or environmental conditions.

Energy efficiency becomes a significant factor in scaled-up manufacturing. Optimizing heating and cooling cycles, recovering waste heat, and exploring alternative energy sources can help reduce production costs and environmental impact. Additionally, the development of continuous or semi-continuous processing methods, as opposed to batch processing, may offer advantages in terms of throughput and energy efficiency.

Quality control and characterization techniques must be adapted for higher production volumes. This may involve the development of in-line or rapid testing methods to ensure consistent product properties without significantly slowing down production. Statistical process control methods and automated inspection systems can help maintain quality standards across larger production runs.

Lastly, considerations for raw material sourcing and supply chain management become more critical at industrial scales. Ensuring a stable supply of high-quality precursors and developing relationships with reliable suppliers are essential for maintaining consistent production. Manufacturers may need to explore alternative raw material sources or develop in-house capabilities for material synthesis to meet increased demand.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!