Solid-state electrolyte tape casting and roll-to-roll manufacturing readiness

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solid-State Electrolyte Evolution and Objectives

Solid-state electrolytes have emerged as a promising solution to address the safety and performance limitations of conventional liquid electrolytes in lithium-ion batteries. The evolution of solid-state electrolytes can be traced back to the 1970s, with initial research focusing on ceramic and glass-based materials. However, it wasn't until the early 2000s that significant advancements were made in developing high-performance solid electrolytes suitable for practical applications.

The development of solid-state electrolytes has been driven by the increasing demand for safer, higher energy density, and longer-lasting batteries. Early research primarily focused on inorganic ceramic electrolytes, such as LISICON-type materials and garnet-type oxides. These materials exhibited high ionic conductivity but suffered from poor mechanical properties and interfacial issues with electrodes.

In recent years, the focus has shifted towards polymer-based and composite solid electrolytes, which offer improved flexibility and processability. This shift has paved the way for the exploration of advanced manufacturing techniques, including tape casting and roll-to-roll processing, to enable large-scale production of solid-state batteries.

The primary objectives of solid-state electrolyte research and development are multifaceted. Firstly, there is a need to enhance ionic conductivity at room temperature to match or exceed that of liquid electrolytes. This is crucial for achieving high power density and fast charging capabilities in solid-state batteries.

Secondly, improving the mechanical properties and interfacial stability of solid electrolytes is essential to ensure long-term cycling performance and prevent dendrite formation. This involves developing novel material compositions and interface engineering strategies to mitigate issues such as volume changes during cycling and chemical incompatibilities between electrolytes and electrodes.

Another key objective is to develop scalable and cost-effective manufacturing processes for solid-state electrolytes. This is where tape casting and roll-to-roll manufacturing come into play, offering the potential for continuous, high-throughput production of thin, uniform electrolyte layers.

Looking ahead, the field of solid-state electrolytes is expected to continue evolving rapidly. Future research directions may include the development of hybrid electrolyte systems, advanced composite materials, and novel processing techniques to further improve performance and manufacturability. The ultimate goal is to enable the commercialization of solid-state batteries that can outperform current lithium-ion technologies in terms of safety, energy density, and longevity.

The development of solid-state electrolytes has been driven by the increasing demand for safer, higher energy density, and longer-lasting batteries. Early research primarily focused on inorganic ceramic electrolytes, such as LISICON-type materials and garnet-type oxides. These materials exhibited high ionic conductivity but suffered from poor mechanical properties and interfacial issues with electrodes.

In recent years, the focus has shifted towards polymer-based and composite solid electrolytes, which offer improved flexibility and processability. This shift has paved the way for the exploration of advanced manufacturing techniques, including tape casting and roll-to-roll processing, to enable large-scale production of solid-state batteries.

The primary objectives of solid-state electrolyte research and development are multifaceted. Firstly, there is a need to enhance ionic conductivity at room temperature to match or exceed that of liquid electrolytes. This is crucial for achieving high power density and fast charging capabilities in solid-state batteries.

Secondly, improving the mechanical properties and interfacial stability of solid electrolytes is essential to ensure long-term cycling performance and prevent dendrite formation. This involves developing novel material compositions and interface engineering strategies to mitigate issues such as volume changes during cycling and chemical incompatibilities between electrolytes and electrodes.

Another key objective is to develop scalable and cost-effective manufacturing processes for solid-state electrolytes. This is where tape casting and roll-to-roll manufacturing come into play, offering the potential for continuous, high-throughput production of thin, uniform electrolyte layers.

Looking ahead, the field of solid-state electrolytes is expected to continue evolving rapidly. Future research directions may include the development of hybrid electrolyte systems, advanced composite materials, and novel processing techniques to further improve performance and manufacturability. The ultimate goal is to enable the commercialization of solid-state batteries that can outperform current lithium-ion technologies in terms of safety, energy density, and longevity.

Market Analysis for Solid-State Batteries

The solid-state battery market is experiencing rapid growth and attracting significant attention from both established automotive manufacturers and emerging technology companies. This surge in interest is driven by the potential of solid-state batteries to overcome the limitations of traditional lithium-ion batteries, offering higher energy density, improved safety, and faster charging capabilities.

Market projections for solid-state batteries are highly optimistic, with estimates suggesting a compound annual growth rate (CAGR) of over 30% in the coming years. The automotive sector is expected to be the primary driver of this growth, as major car manufacturers are investing heavily in solid-state battery technology to power their next generation of electric vehicles.

The demand for solid-state batteries is not limited to the automotive industry. Consumer electronics, aerospace, and energy storage sectors are also showing keen interest in this technology. The promise of longer-lasting, safer, and more compact batteries is particularly appealing for smartphones, wearables, and other portable devices.

Despite the enthusiasm, the market for solid-state batteries is still in its nascent stages. Current production volumes are low, and costs remain high compared to traditional lithium-ion batteries. However, as manufacturing processes improve and economies of scale are achieved, prices are expected to decrease significantly, making solid-state batteries more competitive in the mass market.

Several key factors are influencing the market dynamics of solid-state batteries. Environmental regulations and government incentives promoting clean energy and electric vehicles are providing a strong impetus for the development and adoption of this technology. Additionally, increasing consumer awareness about the environmental impact of traditional batteries is creating a demand for more sustainable alternatives.

The competitive landscape in the solid-state battery market is intensifying, with both established battery manufacturers and startups vying for market share. Strategic partnerships between automotive companies and battery technology firms are becoming increasingly common, as players seek to secure their position in this emerging market.

While the potential of solid-state batteries is clear, several challenges need to be addressed before widespread commercialization can occur. These include scaling up production, improving manufacturing processes, and ensuring long-term reliability. The success of tape casting and roll-to-roll manufacturing techniques for solid-state electrolytes will play a crucial role in overcoming these hurdles and accelerating market growth.

Market projections for solid-state batteries are highly optimistic, with estimates suggesting a compound annual growth rate (CAGR) of over 30% in the coming years. The automotive sector is expected to be the primary driver of this growth, as major car manufacturers are investing heavily in solid-state battery technology to power their next generation of electric vehicles.

The demand for solid-state batteries is not limited to the automotive industry. Consumer electronics, aerospace, and energy storage sectors are also showing keen interest in this technology. The promise of longer-lasting, safer, and more compact batteries is particularly appealing for smartphones, wearables, and other portable devices.

Despite the enthusiasm, the market for solid-state batteries is still in its nascent stages. Current production volumes are low, and costs remain high compared to traditional lithium-ion batteries. However, as manufacturing processes improve and economies of scale are achieved, prices are expected to decrease significantly, making solid-state batteries more competitive in the mass market.

Several key factors are influencing the market dynamics of solid-state batteries. Environmental regulations and government incentives promoting clean energy and electric vehicles are providing a strong impetus for the development and adoption of this technology. Additionally, increasing consumer awareness about the environmental impact of traditional batteries is creating a demand for more sustainable alternatives.

The competitive landscape in the solid-state battery market is intensifying, with both established battery manufacturers and startups vying for market share. Strategic partnerships between automotive companies and battery technology firms are becoming increasingly common, as players seek to secure their position in this emerging market.

While the potential of solid-state batteries is clear, several challenges need to be addressed before widespread commercialization can occur. These include scaling up production, improving manufacturing processes, and ensuring long-term reliability. The success of tape casting and roll-to-roll manufacturing techniques for solid-state electrolytes will play a crucial role in overcoming these hurdles and accelerating market growth.

Tape Casting Technology Status and Challenges

Tape casting technology has emerged as a promising method for the fabrication of solid-state electrolytes, particularly in the context of roll-to-roll manufacturing for solid-state batteries. The current status of this technology demonstrates significant advancements, yet it also faces several challenges that need to be addressed for widespread industrial adoption.

One of the primary advantages of tape casting is its ability to produce thin, uniform layers of solid-state electrolytes with precise thickness control. This is crucial for achieving high energy density and performance in solid-state batteries. Recent developments have shown that tape casting can produce electrolyte layers as thin as 20-30 micrometers, which is a substantial improvement over traditional manufacturing methods.

However, the scalability of tape casting for large-scale production remains a significant challenge. While laboratory-scale processes have been successful, transitioning to industrial-scale roll-to-roll manufacturing presents hurdles in maintaining consistency and quality across large areas. Issues such as defect formation, thickness variations, and compositional inhomogeneities become more pronounced at larger scales.

Another critical challenge is the selection and optimization of slurry formulations. The rheological properties of the slurry are crucial for successful tape casting, and achieving the right balance of viscosity, stability, and drying behavior is complex. This is particularly challenging for solid-state electrolytes, which often require specific compositions to achieve optimal ionic conductivity and mechanical properties.

The drying and sintering processes following tape casting also present significant technical hurdles. Rapid and uniform drying is essential to prevent cracking and warping of the cast tape. However, achieving this without compromising the electrolyte's properties or introducing defects is challenging, especially in a continuous roll-to-roll process.

Furthermore, the integration of tape-cast solid-state electrolytes into full battery assemblies poses additional challenges. Ensuring good interfacial contact between the electrolyte and electrodes, as well as maintaining mechanical integrity during battery cycling, are critical issues that require further research and development.

From a materials perspective, the development of solid-state electrolyte compositions that are compatible with tape casting processes while maintaining high ionic conductivity and mechanical stability is an ongoing area of research. This includes exploring new ceramic and polymer-ceramic composite electrolytes that can be effectively processed using tape casting techniques.

In conclusion, while tape casting technology for solid-state electrolytes has shown promising results, significant challenges remain in scaling up the process for industrial production. Overcoming these hurdles will require interdisciplinary efforts combining materials science, process engineering, and battery technology to realize the full potential of solid-state batteries in commercial applications.

One of the primary advantages of tape casting is its ability to produce thin, uniform layers of solid-state electrolytes with precise thickness control. This is crucial for achieving high energy density and performance in solid-state batteries. Recent developments have shown that tape casting can produce electrolyte layers as thin as 20-30 micrometers, which is a substantial improvement over traditional manufacturing methods.

However, the scalability of tape casting for large-scale production remains a significant challenge. While laboratory-scale processes have been successful, transitioning to industrial-scale roll-to-roll manufacturing presents hurdles in maintaining consistency and quality across large areas. Issues such as defect formation, thickness variations, and compositional inhomogeneities become more pronounced at larger scales.

Another critical challenge is the selection and optimization of slurry formulations. The rheological properties of the slurry are crucial for successful tape casting, and achieving the right balance of viscosity, stability, and drying behavior is complex. This is particularly challenging for solid-state electrolytes, which often require specific compositions to achieve optimal ionic conductivity and mechanical properties.

The drying and sintering processes following tape casting also present significant technical hurdles. Rapid and uniform drying is essential to prevent cracking and warping of the cast tape. However, achieving this without compromising the electrolyte's properties or introducing defects is challenging, especially in a continuous roll-to-roll process.

Furthermore, the integration of tape-cast solid-state electrolytes into full battery assemblies poses additional challenges. Ensuring good interfacial contact between the electrolyte and electrodes, as well as maintaining mechanical integrity during battery cycling, are critical issues that require further research and development.

From a materials perspective, the development of solid-state electrolyte compositions that are compatible with tape casting processes while maintaining high ionic conductivity and mechanical stability is an ongoing area of research. This includes exploring new ceramic and polymer-ceramic composite electrolytes that can be effectively processed using tape casting techniques.

In conclusion, while tape casting technology for solid-state electrolytes has shown promising results, significant challenges remain in scaling up the process for industrial production. Overcoming these hurdles will require interdisciplinary efforts combining materials science, process engineering, and battery technology to realize the full potential of solid-state batteries in commercial applications.

Current Roll-to-Roll Manufacturing Solutions

01 Manufacturing processes for solid-state electrolytes

Various manufacturing processes are employed for producing solid-state electrolytes, including sol-gel methods, solid-state reactions, and melt-quenching techniques. These processes aim to create high-quality, uniform electrolyte materials with optimal ionic conductivity and mechanical properties. The choice of manufacturing method depends on the specific electrolyte composition and desired characteristics.- Manufacturing processes for solid-state electrolytes: Various manufacturing processes are employed for producing solid-state electrolytes, including sol-gel methods, solid-state reactions, and melt-quenching techniques. These processes aim to create high-quality, uniform electrolyte materials with optimal ionic conductivity and mechanical properties. The choice of manufacturing method depends on the specific electrolyte composition and desired characteristics.

- Scalability and mass production readiness: The readiness for mass production of solid-state electrolytes is a critical factor in their commercialization. Efforts are being made to scale up manufacturing processes, optimize production yields, and reduce costs. This includes developing continuous production methods, improving raw material handling, and enhancing quality control measures to ensure consistent performance in large-scale manufacturing.

- Material composition and optimization: Research focuses on optimizing the composition of solid-state electrolytes to enhance their performance and manufacturability. This involves exploring various ceramic, polymer, and composite materials, as well as dopants and additives that can improve ionic conductivity, mechanical strength, and stability. The goal is to develop electrolyte materials that are both high-performing and suitable for large-scale production.

- Integration with battery manufacturing processes: The integration of solid-state electrolyte production with overall battery manufacturing processes is crucial for commercial viability. This includes developing compatible electrode materials, designing efficient cell assembly methods, and ensuring proper interfacial contact between electrolyte and electrodes. Efforts are being made to adapt existing battery production lines to accommodate solid-state electrolyte technologies.

- Quality control and characterization techniques: Advanced quality control and characterization techniques are essential for ensuring the reliability and consistency of manufactured solid-state electrolytes. This includes developing in-line monitoring systems, non-destructive testing methods, and rapid analysis techniques to assess electrolyte properties such as ionic conductivity, density, and impurity levels during production. These measures are crucial for maintaining high manufacturing readiness levels.

02 Scalability and mass production readiness

The readiness for mass production of solid-state electrolytes is a critical factor in their commercialization. Efforts are being made to scale up production processes, optimize manufacturing equipment, and reduce costs. Challenges include maintaining consistent quality across large batches and developing efficient production lines capable of meeting industry demands.Expand Specific Solutions03 Material composition and optimization

Research focuses on optimizing the composition of solid-state electrolytes to enhance their performance and manufacturability. This includes exploring various ceramic, polymer, and composite materials, as well as investigating dopants and additives to improve ionic conductivity and stability. The goal is to develop electrolyte materials that are both high-performing and suitable for large-scale production.Expand Specific Solutions04 Integration with battery manufacturing processes

The integration of solid-state electrolyte production with existing battery manufacturing processes is crucial for industry adoption. This involves developing compatible assembly techniques, ensuring proper interfacial contact between electrolytes and electrodes, and adapting current production lines to accommodate solid-state technology. Efforts are being made to create seamless manufacturing workflows that incorporate solid-state electrolytes.Expand Specific Solutions05 Quality control and characterization methods

Developing robust quality control and characterization methods is essential for ensuring the reliability and consistency of manufactured solid-state electrolytes. This includes implementing advanced analytical techniques, in-line monitoring systems, and standardized testing protocols. These methods help identify defects, optimize process parameters, and maintain high-quality standards in large-scale production.Expand Specific Solutions

Key Players in Solid-State Battery Industry

The solid-state electrolyte tape casting and roll-to-roll manufacturing readiness for electric vehicle batteries is in an early growth stage, with increasing market potential driven by the demand for safer and more energy-dense batteries. The global market for solid-state batteries is projected to grow significantly in the coming years. Technologically, while progress has been made, challenges remain in scaling up production and improving performance. Companies like GM Global Technology Operations, LG Energy Solution, and Hyundai Motor Co. are actively investing in research and development, while startups such as Sakti3 and Solid Ultrabattery are pushing innovation. Established players like BASF and Nitto Denko are also contributing to advancements in materials and manufacturing processes, indicating a competitive and rapidly evolving landscape.

Uchicago Argonne LLC

Technical Solution: Argonne National Laboratory has developed a scalable manufacturing process for solid-state electrolyte tapes using a combination of tape casting and roll-to-roll techniques. Their approach focuses on sulfide-based electrolytes, which offer high ionic conductivity[1]. The process involves a solvent-free dry polymer coating method, reducing environmental impact and processing costs[2]. Argonne's technique allows for precise control of electrolyte thickness and density, with capabilities to produce tapes as thin as 10 micrometers[3]. They have also developed a novel calendering process to improve the interfacial contact between the electrolyte and electrodes, enhancing overall battery performance[4]. The laboratory has demonstrated the ability to produce electrolyte tapes at speeds of up to 100 feet per minute, showcasing the potential for high-volume manufacturing[5].

Strengths: Solvent-free process, precise thickness control, innovative calendering technique, and high-speed production capability. Weaknesses: Limited to sulfide-based electrolytes, which may have stability issues in some battery chemistries, and potential challenges in scaling up to industrial production levels.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed advanced solid-state electrolyte tape casting techniques for roll-to-roll manufacturing of solid-state batteries. Their process involves creating thin, uniform layers of ceramic electrolytes using a water-based slurry system[1]. The company has achieved electrolyte thicknesses below 20 micrometers, which is crucial for high energy density[2]. They utilize a proprietary binder system that enhances the flexibility of the ceramic tapes, allowing for efficient roll-to-roll processing[3]. LG Energy Solution has also implemented in-line quality control measures, including real-time thickness monitoring and defect detection systems, to ensure consistent production of high-quality electrolyte tapes[4].

Strengths: Advanced tape casting techniques, thin electrolyte layers, proprietary flexible binder system, and integrated quality control. Weaknesses: Potential scalability challenges for mass production and the need for further optimization of the electrolyte composition for improved ionic conductivity.

Core Innovations in Tape Casting Technology

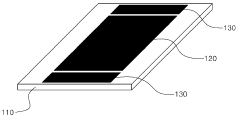

A method of manufacturing solide eflectolyte thin using tape casting

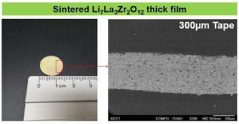

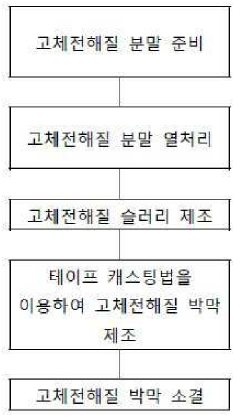

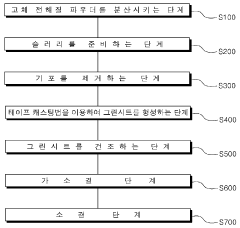

PatentInactiveKR1020180041474A

Innovation

- A tape casting method is employed to manufacture oxide-based solid electrolyte thin films with a thickness of 300 μm or less, involving steps such as preparing electrolyte powder, heat-treating, mixing with a binder and solvent, casting into a thin film, and sintering, to enhance productivity and enable high energy density all-solid-state batteries.

The solid electrolytes plate for gas sensor using tape casting and method of it

PatentInactiveKR1020150109069A

Innovation

- A tape casting method is used to manufacture a solid electrolyte substrate using dense YSZ, GDC, or LGO powders, with a solvent mixture of ethanol and toluene, and additives like polyvinyl butyral and benzyl phthalate, to form a green sheet that is pre-sintered and sintered at controlled conditions, allowing for accurate oxygen ion concentration measurement.

Material Selection and Optimization

The selection and optimization of materials for solid-state electrolyte tape casting and roll-to-roll manufacturing are critical factors in achieving high-performance and cost-effective production of solid-state batteries. The primary focus is on identifying and refining materials that exhibit excellent ionic conductivity, mechanical stability, and compatibility with electrode materials.

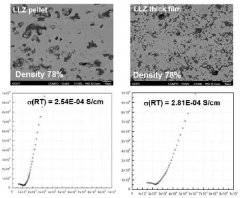

Ceramic-based solid electrolytes, such as LLZO (Li7La3Zr2O12) and LATP (Li1.3Al0.3Ti1.7(PO4)3), have emerged as promising candidates due to their high ionic conductivity and stability. However, their brittle nature poses challenges for tape casting and roll-to-roll processes. To address this, researchers are exploring composite materials that combine ceramic particles with polymer binders to enhance flexibility and processability.

The optimization of particle size distribution is crucial for achieving uniform and dense electrolyte layers. Nanoscale particles can improve sintering behavior and reduce porosity, but they may also increase the overall resistance due to a higher number of grain boundaries. A carefully balanced mixture of nano- and micro-sized particles can lead to improved packing density and enhanced ionic conductivity.

Binder selection plays a vital role in the tape casting process. Water-based binders, such as polyvinyl alcohol (PVA) and carboxymethyl cellulose (CMC), offer environmental benefits but may interact unfavorably with some ceramic electrolytes. Organic binders like polyvinyl butyral (PVB) provide excellent dispersion and green strength but require careful removal during sintering to prevent residual carbon contamination.

Additives and plasticizers are essential for tailoring the rheological properties of the slurry for optimal tape casting performance. Dispersants like fish oil and phosphate esters help achieve homogeneous particle distribution, while plasticizers such as polyethylene glycol (PEG) and dibutyl phthalate (DBP) enhance the flexibility of the green tape.

The development of scalable synthesis methods for high-quality ceramic powders is an ongoing challenge. Sol-gel and solid-state reaction methods are being refined to produce powders with controlled stoichiometry and minimal impurities. Additionally, surface modification techniques are being explored to improve the interface between ceramic particles and polymer binders, enhancing the mechanical properties of the composite electrolyte.

Efforts are also directed towards reducing the sintering temperature of ceramic electrolytes to make them more compatible with roll-to-roll processing. Strategies such as liquid-phase sintering and the use of sintering aids are being investigated to lower the processing temperature while maintaining the desired ionic conductivity and density.

Ceramic-based solid electrolytes, such as LLZO (Li7La3Zr2O12) and LATP (Li1.3Al0.3Ti1.7(PO4)3), have emerged as promising candidates due to their high ionic conductivity and stability. However, their brittle nature poses challenges for tape casting and roll-to-roll processes. To address this, researchers are exploring composite materials that combine ceramic particles with polymer binders to enhance flexibility and processability.

The optimization of particle size distribution is crucial for achieving uniform and dense electrolyte layers. Nanoscale particles can improve sintering behavior and reduce porosity, but they may also increase the overall resistance due to a higher number of grain boundaries. A carefully balanced mixture of nano- and micro-sized particles can lead to improved packing density and enhanced ionic conductivity.

Binder selection plays a vital role in the tape casting process. Water-based binders, such as polyvinyl alcohol (PVA) and carboxymethyl cellulose (CMC), offer environmental benefits but may interact unfavorably with some ceramic electrolytes. Organic binders like polyvinyl butyral (PVB) provide excellent dispersion and green strength but require careful removal during sintering to prevent residual carbon contamination.

Additives and plasticizers are essential for tailoring the rheological properties of the slurry for optimal tape casting performance. Dispersants like fish oil and phosphate esters help achieve homogeneous particle distribution, while plasticizers such as polyethylene glycol (PEG) and dibutyl phthalate (DBP) enhance the flexibility of the green tape.

The development of scalable synthesis methods for high-quality ceramic powders is an ongoing challenge. Sol-gel and solid-state reaction methods are being refined to produce powders with controlled stoichiometry and minimal impurities. Additionally, surface modification techniques are being explored to improve the interface between ceramic particles and polymer binders, enhancing the mechanical properties of the composite electrolyte.

Efforts are also directed towards reducing the sintering temperature of ceramic electrolytes to make them more compatible with roll-to-roll processing. Strategies such as liquid-phase sintering and the use of sintering aids are being investigated to lower the processing temperature while maintaining the desired ionic conductivity and density.

Scalability and Cost-Effectiveness Analysis

The scalability and cost-effectiveness of solid-state electrolyte tape casting and roll-to-roll manufacturing processes are crucial factors in determining their viability for large-scale production of solid-state batteries. These aspects directly impact the potential for widespread adoption and commercialization of this technology.

Tape casting, as a well-established ceramic processing technique, offers significant advantages in terms of scalability. It allows for continuous production of thin, uniform electrolyte sheets with precise thickness control. When combined with roll-to-roll manufacturing, this process can achieve high throughput rates, making it suitable for mass production of solid-state electrolytes.

The roll-to-roll manufacturing approach further enhances scalability by enabling continuous production of long sheets of electrolyte material. This method can significantly increase production capacity compared to batch processes, potentially reducing overall manufacturing time and costs. Additionally, roll-to-roll processes can be easily integrated with other manufacturing steps, such as electrode deposition and cell assembly, streamlining the entire battery production line.

Cost-effectiveness is another critical aspect of this manufacturing approach. The continuous nature of tape casting and roll-to-roll processes can lead to reduced labor costs and improved material utilization. By minimizing waste and optimizing raw material usage, these methods can potentially lower the overall production costs of solid-state electrolytes.

However, challenges remain in achieving optimal cost-effectiveness. The initial investment in specialized equipment for tape casting and roll-to-roll manufacturing can be substantial. Moreover, the cost of raw materials for solid-state electrolytes, particularly high-purity ceramic powders, remains a significant factor in overall production expenses.

To improve cost-effectiveness, ongoing research focuses on developing more efficient processing techniques, exploring alternative raw materials, and optimizing formulations. Efforts are also being made to increase the yield and quality of the produced electrolyte sheets, as defects and inconsistencies can lead to increased costs due to rejected materials.

The scalability of these manufacturing processes also depends on the ability to maintain consistent quality across large production volumes. This requires precise control over process parameters such as slurry composition, casting speed, drying conditions, and sintering profiles. Advances in in-line quality control and process monitoring technologies are essential to ensure uniform electrolyte properties and performance at scale.

As the technology matures, economies of scale are expected to play a significant role in improving cost-effectiveness. Increased production volumes can lead to reduced costs through bulk purchasing of raw materials, improved equipment utilization, and streamlined operations. This, in turn, could make solid-state batteries more competitive with traditional lithium-ion batteries in terms of manufacturing costs.

Tape casting, as a well-established ceramic processing technique, offers significant advantages in terms of scalability. It allows for continuous production of thin, uniform electrolyte sheets with precise thickness control. When combined with roll-to-roll manufacturing, this process can achieve high throughput rates, making it suitable for mass production of solid-state electrolytes.

The roll-to-roll manufacturing approach further enhances scalability by enabling continuous production of long sheets of electrolyte material. This method can significantly increase production capacity compared to batch processes, potentially reducing overall manufacturing time and costs. Additionally, roll-to-roll processes can be easily integrated with other manufacturing steps, such as electrode deposition and cell assembly, streamlining the entire battery production line.

Cost-effectiveness is another critical aspect of this manufacturing approach. The continuous nature of tape casting and roll-to-roll processes can lead to reduced labor costs and improved material utilization. By minimizing waste and optimizing raw material usage, these methods can potentially lower the overall production costs of solid-state electrolytes.

However, challenges remain in achieving optimal cost-effectiveness. The initial investment in specialized equipment for tape casting and roll-to-roll manufacturing can be substantial. Moreover, the cost of raw materials for solid-state electrolytes, particularly high-purity ceramic powders, remains a significant factor in overall production expenses.

To improve cost-effectiveness, ongoing research focuses on developing more efficient processing techniques, exploring alternative raw materials, and optimizing formulations. Efforts are also being made to increase the yield and quality of the produced electrolyte sheets, as defects and inconsistencies can lead to increased costs due to rejected materials.

The scalability of these manufacturing processes also depends on the ability to maintain consistent quality across large production volumes. This requires precise control over process parameters such as slurry composition, casting speed, drying conditions, and sintering profiles. Advances in in-line quality control and process monitoring technologies are essential to ensure uniform electrolyte properties and performance at scale.

As the technology matures, economies of scale are expected to play a significant role in improving cost-effectiveness. Increased production volumes can lead to reduced costs through bulk purchasing of raw materials, improved equipment utilization, and streamlined operations. This, in turn, could make solid-state batteries more competitive with traditional lithium-ion batteries in terms of manufacturing costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!