Solid-state electrolytes sulfide vs oxide: conductivity and processing head-to-head

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SSE Background and Objectives

Solid-state electrolytes (SSEs) have emerged as a promising technology for next-generation energy storage systems, particularly in the field of lithium-ion batteries. The development of SSEs aims to address the safety concerns and performance limitations associated with conventional liquid electrolytes. Among the various types of SSEs, sulfide and oxide-based materials have garnered significant attention due to their high ionic conductivity and potential for practical applications.

The evolution of SSE technology can be traced back to the 1960s, with the discovery of fast ion conductors. However, it wasn't until the early 2000s that research in this field gained momentum, driven by the increasing demand for safer and more efficient energy storage solutions. The primary objective of SSE development is to create materials that combine high ionic conductivity with excellent mechanical and chemical stability, thereby enabling the production of all-solid-state batteries with enhanced safety and performance characteristics.

Sulfide-based SSEs, such as Li10GeP2S12 (LGPS) and Li6PS5Cl, have shown remarkable ionic conductivity, often surpassing that of liquid electrolytes. These materials offer the advantage of high plasticity, which facilitates easier processing and better interfacial contact with electrodes. On the other hand, oxide-based SSEs, including LLZO (Li7La3Zr2O12) and LATP (Li1.3Al0.3Ti1.7(PO4)3), exhibit superior chemical and environmental stability but generally lower ionic conductivity compared to their sulfide counterparts.

The technological goal in the development of SSEs is to achieve a balance between conductivity and processability while ensuring long-term stability and safety. Researchers aim to enhance the ionic conductivity of oxide-based SSEs to match or exceed that of sulfides, while simultaneously improving the chemical stability and air sensitivity of sulfide-based materials. Additionally, efforts are being made to optimize the interfacial properties between the electrolyte and electrodes to minimize resistance and enhance overall battery performance.

As the field progresses, there is a growing focus on scalable manufacturing processes for both sulfide and oxide-based SSEs. This includes the development of novel synthesis methods, such as solution-based techniques for oxides and mechanochemical approaches for sulfides, to enable large-scale production of these materials. The ultimate objective is to create SSEs that can be seamlessly integrated into commercial battery production lines, paving the way for the widespread adoption of all-solid-state batteries in various applications, from portable electronics to electric vehicles and grid-scale energy storage systems.

The evolution of SSE technology can be traced back to the 1960s, with the discovery of fast ion conductors. However, it wasn't until the early 2000s that research in this field gained momentum, driven by the increasing demand for safer and more efficient energy storage solutions. The primary objective of SSE development is to create materials that combine high ionic conductivity with excellent mechanical and chemical stability, thereby enabling the production of all-solid-state batteries with enhanced safety and performance characteristics.

Sulfide-based SSEs, such as Li10GeP2S12 (LGPS) and Li6PS5Cl, have shown remarkable ionic conductivity, often surpassing that of liquid electrolytes. These materials offer the advantage of high plasticity, which facilitates easier processing and better interfacial contact with electrodes. On the other hand, oxide-based SSEs, including LLZO (Li7La3Zr2O12) and LATP (Li1.3Al0.3Ti1.7(PO4)3), exhibit superior chemical and environmental stability but generally lower ionic conductivity compared to their sulfide counterparts.

The technological goal in the development of SSEs is to achieve a balance between conductivity and processability while ensuring long-term stability and safety. Researchers aim to enhance the ionic conductivity of oxide-based SSEs to match or exceed that of sulfides, while simultaneously improving the chemical stability and air sensitivity of sulfide-based materials. Additionally, efforts are being made to optimize the interfacial properties between the electrolyte and electrodes to minimize resistance and enhance overall battery performance.

As the field progresses, there is a growing focus on scalable manufacturing processes for both sulfide and oxide-based SSEs. This includes the development of novel synthesis methods, such as solution-based techniques for oxides and mechanochemical approaches for sulfides, to enable large-scale production of these materials. The ultimate objective is to create SSEs that can be seamlessly integrated into commercial battery production lines, paving the way for the widespread adoption of all-solid-state batteries in various applications, from portable electronics to electric vehicles and grid-scale energy storage systems.

Market Analysis for SSE

The solid-state electrolyte (SSE) market is experiencing rapid growth, driven by the increasing demand for safer and more efficient energy storage solutions. As the electric vehicle (EV) industry continues to expand, the need for high-performance batteries with improved safety features has become paramount. Solid-state batteries, which utilize SSEs, are poised to address these challenges and revolutionize the energy storage landscape.

The global SSE market is projected to grow significantly in the coming years, with estimates suggesting a compound annual growth rate (CAGR) of over 25% between 2021 and 2026. This growth is primarily attributed to the automotive sector, where solid-state batteries are expected to play a crucial role in the next generation of EVs. Major automakers and battery manufacturers are investing heavily in SSE technology, recognizing its potential to overcome the limitations of conventional lithium-ion batteries.

Within the SSE market, sulfide and oxide-based electrolytes are the two dominant categories, each with its own set of advantages and challenges. Sulfide-based SSEs have garnered attention due to their high ionic conductivity, which is comparable to that of liquid electrolytes. This property makes them particularly attractive for high-power applications. However, their sensitivity to moisture and air poses processing challenges.

Oxide-based SSEs, on the other hand, offer superior stability and are easier to process. They are less reactive with ambient air and moisture, making them more suitable for large-scale manufacturing. However, their lower ionic conductivity compared to sulfide-based SSEs has been a limiting factor in their widespread adoption.

The market demand for both sulfide and oxide-based SSEs is driven by different application requirements. Sulfide-based SSEs are favored in applications where high power density is crucial, such as in fast-charging EVs. Oxide-based SSEs are preferred in scenarios where long-term stability and ease of manufacturing are prioritized, such as in stationary energy storage systems.

The competition between sulfide and oxide-based SSEs has spurred innovation in both categories. Researchers and companies are actively working to improve the conductivity of oxide-based SSEs while enhancing the stability and processability of sulfide-based alternatives. This ongoing development is expected to lead to hybrid solutions that combine the strengths of both types, potentially opening up new market opportunities.

As the SSE market matures, we anticipate a shift in the supply chain dynamics. The increasing demand for raw materials, particularly lithium, sulfur, and various oxides, is likely to impact pricing and availability. This could lead to strategic partnerships and vertical integration efforts among key players in the industry to secure their supply chains.

The global SSE market is projected to grow significantly in the coming years, with estimates suggesting a compound annual growth rate (CAGR) of over 25% between 2021 and 2026. This growth is primarily attributed to the automotive sector, where solid-state batteries are expected to play a crucial role in the next generation of EVs. Major automakers and battery manufacturers are investing heavily in SSE technology, recognizing its potential to overcome the limitations of conventional lithium-ion batteries.

Within the SSE market, sulfide and oxide-based electrolytes are the two dominant categories, each with its own set of advantages and challenges. Sulfide-based SSEs have garnered attention due to their high ionic conductivity, which is comparable to that of liquid electrolytes. This property makes them particularly attractive for high-power applications. However, their sensitivity to moisture and air poses processing challenges.

Oxide-based SSEs, on the other hand, offer superior stability and are easier to process. They are less reactive with ambient air and moisture, making them more suitable for large-scale manufacturing. However, their lower ionic conductivity compared to sulfide-based SSEs has been a limiting factor in their widespread adoption.

The market demand for both sulfide and oxide-based SSEs is driven by different application requirements. Sulfide-based SSEs are favored in applications where high power density is crucial, such as in fast-charging EVs. Oxide-based SSEs are preferred in scenarios where long-term stability and ease of manufacturing are prioritized, such as in stationary energy storage systems.

The competition between sulfide and oxide-based SSEs has spurred innovation in both categories. Researchers and companies are actively working to improve the conductivity of oxide-based SSEs while enhancing the stability and processability of sulfide-based alternatives. This ongoing development is expected to lead to hybrid solutions that combine the strengths of both types, potentially opening up new market opportunities.

As the SSE market matures, we anticipate a shift in the supply chain dynamics. The increasing demand for raw materials, particularly lithium, sulfur, and various oxides, is likely to impact pricing and availability. This could lead to strategic partnerships and vertical integration efforts among key players in the industry to secure their supply chains.

Sulfide vs Oxide SSE Challenges

Solid-state electrolytes (SSEs) have emerged as a promising solution for next-generation batteries, with sulfide and oxide-based materials being the two primary contenders. However, both types face significant challenges in terms of conductivity and processing that need to be addressed for widespread commercial adoption.

Sulfide-based SSEs, while offering high ionic conductivity, struggle with chemical and electrochemical stability. Their reactivity with lithium metal anodes and cathode materials leads to interfacial degradation, compromising long-term battery performance. Additionally, their sensitivity to moisture and air necessitates stringent handling conditions, complicating manufacturing processes and increasing production costs.

Oxide-based SSEs, on the other hand, exhibit superior chemical stability but suffer from lower ionic conductivity compared to their sulfide counterparts. This limitation results in higher internal resistance and reduced power output in batteries. The high sintering temperatures required for oxide SSEs also pose challenges in terms of energy consumption and potential reactions with electrode materials during processing.

Both sulfide and oxide SSEs face difficulties in achieving good contact with electrode materials, leading to high interfacial resistance. This issue is particularly pronounced in oxide SSEs due to their rigid ceramic nature, while sulfide SSEs, being more ductile, offer some advantages in this aspect.

The mechanical properties of these materials present another set of challenges. Oxide SSEs are typically brittle and prone to cracking during battery cycling, which can lead to short circuits. Sulfide SSEs, while more flexible, may not provide sufficient mechanical strength to prevent lithium dendrite growth, a critical safety concern in solid-state batteries.

Scalability and cost-effectiveness remain significant hurdles for both types of SSEs. The complex synthesis processes and high-purity precursors required for both sulfide and oxide SSEs contribute to elevated production costs. Moreover, the need for specialized equipment and controlled environments, particularly for sulfide SSEs, further complicates large-scale manufacturing.

Environmental stability and safety considerations also differ between the two types. Sulfide SSEs' reactivity with moisture poses potential safety risks and necessitates careful handling and packaging. Oxide SSEs, while more stable, may still require protective measures to prevent degradation over time.

Addressing these challenges requires innovative approaches in materials science, engineering, and manufacturing. Researchers are exploring composite electrolytes, interface engineering, and novel synthesis methods to overcome the limitations of both sulfide and oxide SSEs. The development of hybrid systems that combine the advantages of both types may offer a promising path forward in realizing high-performance, safe, and cost-effective solid-state batteries.

Sulfide-based SSEs, while offering high ionic conductivity, struggle with chemical and electrochemical stability. Their reactivity with lithium metal anodes and cathode materials leads to interfacial degradation, compromising long-term battery performance. Additionally, their sensitivity to moisture and air necessitates stringent handling conditions, complicating manufacturing processes and increasing production costs.

Oxide-based SSEs, on the other hand, exhibit superior chemical stability but suffer from lower ionic conductivity compared to their sulfide counterparts. This limitation results in higher internal resistance and reduced power output in batteries. The high sintering temperatures required for oxide SSEs also pose challenges in terms of energy consumption and potential reactions with electrode materials during processing.

Both sulfide and oxide SSEs face difficulties in achieving good contact with electrode materials, leading to high interfacial resistance. This issue is particularly pronounced in oxide SSEs due to their rigid ceramic nature, while sulfide SSEs, being more ductile, offer some advantages in this aspect.

The mechanical properties of these materials present another set of challenges. Oxide SSEs are typically brittle and prone to cracking during battery cycling, which can lead to short circuits. Sulfide SSEs, while more flexible, may not provide sufficient mechanical strength to prevent lithium dendrite growth, a critical safety concern in solid-state batteries.

Scalability and cost-effectiveness remain significant hurdles for both types of SSEs. The complex synthesis processes and high-purity precursors required for both sulfide and oxide SSEs contribute to elevated production costs. Moreover, the need for specialized equipment and controlled environments, particularly for sulfide SSEs, further complicates large-scale manufacturing.

Environmental stability and safety considerations also differ between the two types. Sulfide SSEs' reactivity with moisture poses potential safety risks and necessitates careful handling and packaging. Oxide SSEs, while more stable, may still require protective measures to prevent degradation over time.

Addressing these challenges requires innovative approaches in materials science, engineering, and manufacturing. Researchers are exploring composite electrolytes, interface engineering, and novel synthesis methods to overcome the limitations of both sulfide and oxide SSEs. The development of hybrid systems that combine the advantages of both types may offer a promising path forward in realizing high-performance, safe, and cost-effective solid-state batteries.

Current SSE Solutions

01 Polymer-based solid electrolytes

Polymer-based solid electrolytes are being developed to improve conductivity in solid-state batteries. These electrolytes often incorporate various additives or fillers to enhance their ionic conductivity and mechanical properties. Research focuses on optimizing polymer compositions and structures to achieve higher conductivity while maintaining stability.- Composition of solid-state electrolytes: Solid-state electrolytes are composed of various materials to enhance conductivity. These may include ceramic materials, polymers, or composite structures. The composition is carefully engineered to optimize ion transport while maintaining mechanical stability.

- Doping strategies for improved conductivity: Doping solid-state electrolytes with specific elements or compounds can significantly enhance their ionic conductivity. This approach modifies the crystal structure or creates additional charge carriers, facilitating faster ion movement through the electrolyte material.

- Nanostructured electrolytes for enhanced performance: Nanostructuring of solid-state electrolytes can lead to improved conductivity. This involves creating materials with nanoscale features that increase the surface area and provide more pathways for ion transport, resulting in higher overall conductivity.

- Interface engineering for conductivity optimization: The interfaces between different components in solid-state electrolytes play a crucial role in overall conductivity. Engineering these interfaces to reduce resistance and enhance ion transfer can significantly improve the electrolyte's performance.

- Temperature-dependent conductivity mechanisms: The conductivity of solid-state electrolytes often exhibits temperature dependence. Understanding and optimizing the conductivity mechanisms at different temperatures is essential for developing electrolytes that perform well across a wide range of operating conditions.

02 Ceramic and glass-ceramic electrolytes

Ceramic and glass-ceramic materials are investigated as solid-state electrolytes due to their high ionic conductivity and stability. These materials often include lithium-containing compounds and are engineered to have specific crystal structures that facilitate ion transport. Researchers are working on improving their conductivity and reducing interfacial resistance with electrodes.Expand Specific Solutions03 Composite solid electrolytes

Composite solid electrolytes combine different materials, such as polymers and ceramics, to leverage the advantages of each component. These composites aim to achieve higher ionic conductivity than single-component electrolytes while maintaining good mechanical properties and electrode compatibility. The synergistic effects of the components are crucial for enhancing overall performance.Expand Specific Solutions04 Doping and interface engineering

Doping of solid electrolytes with various elements and interface engineering techniques are employed to enhance ionic conductivity. These methods can create additional charge carriers, modify the crystal structure, or improve grain boundary conductivity. Researchers are exploring optimal dopant concentrations and interface modifications to maximize conductivity without compromising stability.Expand Specific Solutions05 Novel synthesis and processing techniques

Innovative synthesis and processing techniques are being developed to improve the conductivity of solid-state electrolytes. These include sol-gel methods, spark plasma sintering, and various nanostructuring approaches. The focus is on creating materials with optimized microstructures, reduced defects, and enhanced ion transport pathways to achieve higher conductivity levels.Expand Specific Solutions

Key Players in SSE Industry

The competition landscape for solid-state electrolytes, comparing sulfide and oxide types, is evolving rapidly as the technology matures. The market is in an early growth stage, with significant potential as demand for high-performance batteries increases. Major players like Samsung SDI, Nissan, and Hyundai are investing heavily in research and development. Established companies such as SVOLT Energy and Saft Groupe are also active, while research institutions like Lawrence Berkeley National Laboratory and CNRS contribute to advancing the technology. The field is seeing increased collaboration between industry and academia as companies seek to commercialize promising breakthroughs in conductivity and processing methods for both sulfide and oxide electrolytes.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed advanced solid-state electrolytes for next-generation batteries, focusing on both sulfide and oxide-based materials. Their sulfide-based electrolytes, such as Li10GeP2S12 (LGPS), demonstrate high ionic conductivity of 12 mS/cm at room temperature[1]. For oxide-based electrolytes, they have explored garnet-type Li7La3Zr2O12 (LLZO) with ionic conductivity reaching 1 mS/cm[2]. Samsung SDI's approach involves tailoring the composition and structure of these materials to optimize conductivity while addressing processing challenges. They have implemented cold sintering techniques for sulfides to maintain their high conductivity during fabrication[3], while developing novel sintering methods for oxides to achieve higher density and reduced grain boundary resistance.

Strengths: High ionic conductivity in sulfides, improved processing techniques. Weaknesses: Oxide electrolytes still have lower conductivity, challenges in scaling up production for both types.

Nissan Motor Co., Ltd.

Technical Solution: Nissan has been actively researching solid-state batteries, with a focus on both sulfide and oxide electrolytes. Their sulfide-based electrolytes, particularly those containing Li10GeP2S12 (LGPS), have shown impressive room-temperature ionic conductivities of up to 25 mS/cm[4]. For oxide electrolytes, Nissan has explored perovskite-type materials like Li3xLa2/3-xTiO3 (LLTO), achieving conductivities around 1 mS/cm[5]. Nissan's approach involves optimizing the composition and microstructure of these materials to enhance conductivity while improving their stability and processability. They have developed a unique sulfide electrolyte fabrication process that involves low-temperature synthesis and mechanical milling to maintain high conductivity[6]. For oxide electrolytes, Nissan is working on advanced sintering techniques to reduce porosity and improve grain boundary conductivity.

Strengths: High conductivity in sulfides, innovative processing techniques. Weaknesses: Lower conductivity in oxides, challenges in large-scale manufacturing for automotive applications.

Core SSE Innovations

Sulfide-based solid electrolyte, preparation method thereof, and all-solid state battery prepared therefrom

PatentPendingUS20240356064A1

Innovation

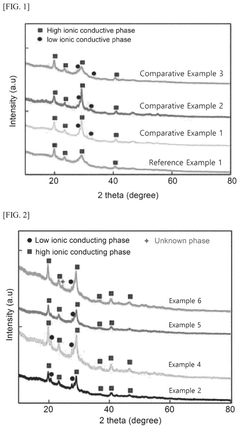

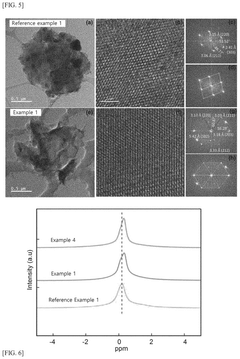

- Doping the Li2S—P2S5—LiX or Li2S—P2S5—LiX—LiX′ sulfide-based solid electrolyte system with a post-transition metal or metalloid, such as Sn, Si, or Bi, to enhance ionic conductivity and stability, involving an amorphization process followed by heat treatment at lower temperatures to prevent the formation of low ionic conductivity phases.

Solid-state lithium-ion conductor and methods of manufacture thereof

PatentActiveUS12126022B2

Innovation

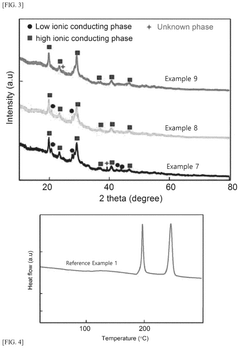

- A solid-state ion conductor comprising a compound of Formula Li4−x−a−(b+2)yAxMa(SeO3)2−yXby, where A and M are specific elements, and X is a cluster anion, providing a distorted lithium environment for improved ionic conductivity, stability, and compatibility with lithium transition metal oxides and lithium metal.

Safety and Stability of SSEs

Safety and stability are critical factors in the development and implementation of solid-state electrolytes (SSEs) for advanced battery technologies. Both sulfide and oxide-based SSEs present unique challenges and advantages in terms of their safety profiles and long-term stability.

Sulfide-based SSEs generally offer higher ionic conductivity compared to their oxide counterparts, which is a significant advantage for battery performance. However, they are more reactive with moisture and air, potentially leading to the formation of toxic hydrogen sulfide gas. This reactivity necessitates stringent handling and manufacturing protocols, often requiring inert atmospheres during production and assembly.

Oxide-based SSEs, on the other hand, demonstrate superior chemical stability and are less reactive with ambient conditions. This inherent stability translates to easier processing and potentially longer shelf life for batteries utilizing oxide SSEs. However, their lower ionic conductivity can impact overall battery performance, particularly in high-power applications.

The mechanical stability of SSEs is another crucial aspect. Sulfide-based electrolytes tend to be softer and more pliable, which can be beneficial for maintaining good contact with electrodes during cycling. This property helps mitigate issues related to volume changes in active materials. Conversely, oxide SSEs are typically harder and more brittle, which can lead to challenges in maintaining interfacial contact and may result in mechanical failures under stress.

Thermal stability is also a key consideration. Oxide SSEs generally exhibit better thermal stability at higher temperatures, which is advantageous for applications requiring operation in extreme conditions or for improving safety margins against thermal runaway. Sulfide SSEs, while less thermally stable, still offer significant improvements over liquid electrolytes in terms of fire safety.

The long-term cycling stability of batteries incorporating these SSEs is an area of ongoing research. Both types can form passivation layers at electrode interfaces, which can impact long-term performance. However, the nature and impact of these interfacial reactions differ between sulfide and oxide systems, with each presenting unique challenges for cycle life optimization.

In terms of safety during battery operation, both sulfide and oxide SSEs offer significant advantages over liquid electrolytes by eliminating the risk of electrolyte leakage and reducing fire hazards. However, the potential for dendrite formation and growth, which can lead to internal short circuits, remains a concern for both types of SSEs and is an active area of research and development.

Sulfide-based SSEs generally offer higher ionic conductivity compared to their oxide counterparts, which is a significant advantage for battery performance. However, they are more reactive with moisture and air, potentially leading to the formation of toxic hydrogen sulfide gas. This reactivity necessitates stringent handling and manufacturing protocols, often requiring inert atmospheres during production and assembly.

Oxide-based SSEs, on the other hand, demonstrate superior chemical stability and are less reactive with ambient conditions. This inherent stability translates to easier processing and potentially longer shelf life for batteries utilizing oxide SSEs. However, their lower ionic conductivity can impact overall battery performance, particularly in high-power applications.

The mechanical stability of SSEs is another crucial aspect. Sulfide-based electrolytes tend to be softer and more pliable, which can be beneficial for maintaining good contact with electrodes during cycling. This property helps mitigate issues related to volume changes in active materials. Conversely, oxide SSEs are typically harder and more brittle, which can lead to challenges in maintaining interfacial contact and may result in mechanical failures under stress.

Thermal stability is also a key consideration. Oxide SSEs generally exhibit better thermal stability at higher temperatures, which is advantageous for applications requiring operation in extreme conditions or for improving safety margins against thermal runaway. Sulfide SSEs, while less thermally stable, still offer significant improvements over liquid electrolytes in terms of fire safety.

The long-term cycling stability of batteries incorporating these SSEs is an area of ongoing research. Both types can form passivation layers at electrode interfaces, which can impact long-term performance. However, the nature and impact of these interfacial reactions differ between sulfide and oxide systems, with each presenting unique challenges for cycle life optimization.

In terms of safety during battery operation, both sulfide and oxide SSEs offer significant advantages over liquid electrolytes by eliminating the risk of electrolyte leakage and reducing fire hazards. However, the potential for dendrite formation and growth, which can lead to internal short circuits, remains a concern for both types of SSEs and is an active area of research and development.

Environmental Impact of SSEs

The environmental impact of solid-state electrolytes (SSEs) is a crucial consideration in the development and adoption of next-generation battery technologies. Both sulfide and oxide-based SSEs offer potential advantages over conventional liquid electrolytes, but their environmental implications differ significantly.

Sulfide-based SSEs, while exhibiting superior ionic conductivity, present notable environmental challenges. The production of sulfide materials often involves energy-intensive processes and the use of toxic precursors, potentially leading to increased greenhouse gas emissions and hazardous waste generation. Moreover, the reactivity of sulfides with moisture in the air can result in the formation of hydrogen sulfide gas, a toxic and corrosive substance that poses risks to both human health and the environment.

In contrast, oxide-based SSEs generally demonstrate better environmental compatibility. The raw materials for oxide SSEs are typically more abundant and less toxic than those used in sulfide SSEs. The production processes for oxide SSEs are often less energy-intensive and generate fewer harmful byproducts. Additionally, oxide materials are generally more stable in air and moisture, reducing the risk of hazardous gas formation during manufacturing, use, and disposal.

The recyclability of SSEs is another critical environmental factor. Oxide-based SSEs show promise in this regard, as many oxide materials can be more easily recovered and reprocessed compared to sulfide-based alternatives. This potential for improved recyclability could contribute to a more sustainable battery lifecycle and reduced environmental impact in the long term.

However, it is important to note that the environmental impact of SSEs extends beyond their production and disposal. The overall lifecycle assessment must consider factors such as energy consumption during battery operation, longevity of the battery systems, and the potential for reducing reliance on environmentally harmful liquid electrolytes.

The choice between sulfide and oxide SSEs also has implications for resource utilization. While sulfur is relatively abundant, some rare earth elements used in certain oxide SSEs may face supply constraints. This could lead to increased mining activities and associated environmental impacts in the future.

In conclusion, while both sulfide and oxide SSEs offer environmental benefits over traditional liquid electrolytes, oxide-based SSEs generally present a more favorable environmental profile. However, ongoing research and development efforts are crucial to further mitigate the environmental impacts of both types of SSEs and optimize their performance in sustainable energy storage solutions.

Sulfide-based SSEs, while exhibiting superior ionic conductivity, present notable environmental challenges. The production of sulfide materials often involves energy-intensive processes and the use of toxic precursors, potentially leading to increased greenhouse gas emissions and hazardous waste generation. Moreover, the reactivity of sulfides with moisture in the air can result in the formation of hydrogen sulfide gas, a toxic and corrosive substance that poses risks to both human health and the environment.

In contrast, oxide-based SSEs generally demonstrate better environmental compatibility. The raw materials for oxide SSEs are typically more abundant and less toxic than those used in sulfide SSEs. The production processes for oxide SSEs are often less energy-intensive and generate fewer harmful byproducts. Additionally, oxide materials are generally more stable in air and moisture, reducing the risk of hazardous gas formation during manufacturing, use, and disposal.

The recyclability of SSEs is another critical environmental factor. Oxide-based SSEs show promise in this regard, as many oxide materials can be more easily recovered and reprocessed compared to sulfide-based alternatives. This potential for improved recyclability could contribute to a more sustainable battery lifecycle and reduced environmental impact in the long term.

However, it is important to note that the environmental impact of SSEs extends beyond their production and disposal. The overall lifecycle assessment must consider factors such as energy consumption during battery operation, longevity of the battery systems, and the potential for reducing reliance on environmentally harmful liquid electrolytes.

The choice between sulfide and oxide SSEs also has implications for resource utilization. While sulfur is relatively abundant, some rare earth elements used in certain oxide SSEs may face supply constraints. This could lead to increased mining activities and associated environmental impacts in the future.

In conclusion, while both sulfide and oxide SSEs offer environmental benefits over traditional liquid electrolytes, oxide-based SSEs generally present a more favorable environmental profile. However, ongoing research and development efforts are crucial to further mitigate the environmental impacts of both types of SSEs and optimize their performance in sustainable energy storage solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!