Dipropylene Glycol for Enhanced Deodorant Efficacy

JUL 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DPG Deodorant Background

Dipropylene glycol (DPG) has emerged as a key ingredient in the formulation of modern deodorants, playing a crucial role in enhancing their efficacy. The use of DPG in deodorant products dates back to the mid-20th century, when researchers began exploring its potential as a solvent and carrier for active ingredients. Since then, DPG has become an integral component in many deodorant formulations due to its unique properties and versatility.

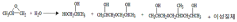

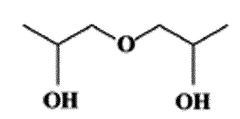

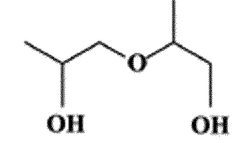

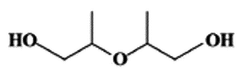

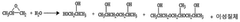

DPG is a colorless, odorless, and hygroscopic liquid that belongs to the family of glycol ethers. Its chemical structure, consisting of two propylene glycol units linked by an ether bond, gives it excellent solvent properties and the ability to mix with both water and oil-based substances. This characteristic makes DPG particularly useful in deodorant formulations, as it can effectively dissolve and disperse a wide range of active ingredients.

The primary function of DPG in deodorants is to act as a carrier for antimicrobial agents and fragrances. By dissolving these components, DPG ensures their even distribution throughout the product and facilitates their delivery to the skin surface. This uniform distribution is essential for maintaining consistent deodorant performance throughout the day.

Moreover, DPG's hygroscopic nature contributes to the moisturizing properties of deodorants, helping to prevent skin dryness and irritation often associated with antiperspirant use. This feature has made DPG-based deodorants particularly appealing to consumers with sensitive skin or those seeking gentler alternatives to traditional antiperspirants.

The evolution of DPG use in deodorants has been driven by ongoing research into its safety, efficacy, and compatibility with other ingredients. Over the years, formulators have refined the concentration and combination of DPG with other components to optimize deodorant performance while minimizing potential skin irritation.

Recent trends in the personal care industry have further highlighted the importance of DPG in deodorant formulations. With growing consumer demand for natural and aluminum-free deodorants, DPG has become even more valuable as a base ingredient that can effectively carry natural antimicrobial agents and essential oils.

The technical goals for DPG in deodorant applications continue to evolve, focusing on enhancing its ability to stabilize formulations, improve fragrance longevity, and increase overall product efficacy. Researchers are also exploring ways to combine DPG with other innovative ingredients to create next-generation deodorants that offer superior odor protection and skin benefits.

As the deodorant market continues to grow and diversify, the role of DPG remains central to product development and innovation. Its versatility and effectiveness make it a cornerstone ingredient in the ongoing quest for more efficient, skin-friendly, and long-lasting deodorant solutions.

DPG is a colorless, odorless, and hygroscopic liquid that belongs to the family of glycol ethers. Its chemical structure, consisting of two propylene glycol units linked by an ether bond, gives it excellent solvent properties and the ability to mix with both water and oil-based substances. This characteristic makes DPG particularly useful in deodorant formulations, as it can effectively dissolve and disperse a wide range of active ingredients.

The primary function of DPG in deodorants is to act as a carrier for antimicrobial agents and fragrances. By dissolving these components, DPG ensures their even distribution throughout the product and facilitates their delivery to the skin surface. This uniform distribution is essential for maintaining consistent deodorant performance throughout the day.

Moreover, DPG's hygroscopic nature contributes to the moisturizing properties of deodorants, helping to prevent skin dryness and irritation often associated with antiperspirant use. This feature has made DPG-based deodorants particularly appealing to consumers with sensitive skin or those seeking gentler alternatives to traditional antiperspirants.

The evolution of DPG use in deodorants has been driven by ongoing research into its safety, efficacy, and compatibility with other ingredients. Over the years, formulators have refined the concentration and combination of DPG with other components to optimize deodorant performance while minimizing potential skin irritation.

Recent trends in the personal care industry have further highlighted the importance of DPG in deodorant formulations. With growing consumer demand for natural and aluminum-free deodorants, DPG has become even more valuable as a base ingredient that can effectively carry natural antimicrobial agents and essential oils.

The technical goals for DPG in deodorant applications continue to evolve, focusing on enhancing its ability to stabilize formulations, improve fragrance longevity, and increase overall product efficacy. Researchers are also exploring ways to combine DPG with other innovative ingredients to create next-generation deodorants that offer superior odor protection and skin benefits.

As the deodorant market continues to grow and diversify, the role of DPG remains central to product development and innovation. Its versatility and effectiveness make it a cornerstone ingredient in the ongoing quest for more efficient, skin-friendly, and long-lasting deodorant solutions.

Market Analysis

The global deodorant market has been experiencing steady growth, driven by increasing hygiene awareness, rising disposable incomes, and changing lifestyle patterns. Within this market, there is a growing demand for more effective and long-lasting deodorant formulations, which has led to increased interest in ingredients like dipropylene glycol (DPG) for enhanced deodorant efficacy.

The deodorant market size was valued at approximately $23.7 billion in 2021 and is projected to reach $33.5 billion by 2028, growing at a CAGR of 5.1% during the forecast period. This growth is particularly strong in emerging economies, where rising urbanization and increasing personal care expenditure are driving market expansion.

Consumer preferences are shifting towards natural and organic deodorants, with a focus on products that offer both odor protection and skin-friendly properties. This trend has created opportunities for DPG-based formulations, as DPG is known for its low irritation potential and ability to enhance the performance of active ingredients in deodorants.

The Asia-Pacific region is expected to witness the fastest growth in the deodorant market, with countries like China and India leading the way. This growth is attributed to the large population base, increasing awareness of personal hygiene, and rising disposable incomes in these countries.

In terms of product types, spray deodorants continue to dominate the market, followed by roll-on and stick deodorants. However, there is a growing demand for innovative formats such as cream deodorants and wipes, which present new opportunities for DPG-based formulations.

The COVID-19 pandemic has had a mixed impact on the deodorant market. While initial lockdowns led to a temporary decrease in demand due to reduced social interactions, the increased focus on personal hygiene has created new opportunities for antimicrobial and long-lasting deodorant products.

Key players in the deodorant market, including Unilever, Procter & Gamble, and Colgate-Palmolive, are investing in research and development to improve product efficacy and meet evolving consumer demands. This has led to increased interest in ingredients like DPG that can enhance the performance of deodorant formulations.

The market for DPG in deodorants is expected to grow as manufacturers seek to improve product efficacy and meet consumer demands for long-lasting odor protection. The global DPG market size was valued at $810 million in 2020 and is projected to reach $1.1 billion by 2027, with a significant portion of this growth attributed to its use in personal care products, including deodorants.

The deodorant market size was valued at approximately $23.7 billion in 2021 and is projected to reach $33.5 billion by 2028, growing at a CAGR of 5.1% during the forecast period. This growth is particularly strong in emerging economies, where rising urbanization and increasing personal care expenditure are driving market expansion.

Consumer preferences are shifting towards natural and organic deodorants, with a focus on products that offer both odor protection and skin-friendly properties. This trend has created opportunities for DPG-based formulations, as DPG is known for its low irritation potential and ability to enhance the performance of active ingredients in deodorants.

The Asia-Pacific region is expected to witness the fastest growth in the deodorant market, with countries like China and India leading the way. This growth is attributed to the large population base, increasing awareness of personal hygiene, and rising disposable incomes in these countries.

In terms of product types, spray deodorants continue to dominate the market, followed by roll-on and stick deodorants. However, there is a growing demand for innovative formats such as cream deodorants and wipes, which present new opportunities for DPG-based formulations.

The COVID-19 pandemic has had a mixed impact on the deodorant market. While initial lockdowns led to a temporary decrease in demand due to reduced social interactions, the increased focus on personal hygiene has created new opportunities for antimicrobial and long-lasting deodorant products.

Key players in the deodorant market, including Unilever, Procter & Gamble, and Colgate-Palmolive, are investing in research and development to improve product efficacy and meet evolving consumer demands. This has led to increased interest in ingredients like DPG that can enhance the performance of deodorant formulations.

The market for DPG in deodorants is expected to grow as manufacturers seek to improve product efficacy and meet consumer demands for long-lasting odor protection. The global DPG market size was valued at $810 million in 2020 and is projected to reach $1.1 billion by 2027, with a significant portion of this growth attributed to its use in personal care products, including deodorants.

Technical Challenges

The development of enhanced deodorant efficacy using dipropylene glycol faces several technical challenges that researchers and manufacturers must address. One of the primary obstacles is achieving optimal solubility and stability of active ingredients in the dipropylene glycol-based formulation. The complex interactions between dipropylene glycol, active deodorant compounds, and other formulation components can lead to issues such as precipitation, phase separation, or reduced efficacy over time.

Another significant challenge lies in maintaining the desired viscosity and texture of the final product. Dipropylene glycol's hygroscopic nature can affect the overall consistency and feel of the deodorant, potentially leading to user dissatisfaction. Balancing the concentration of dipropylene glycol with other ingredients to achieve the ideal texture while preserving efficacy is a delicate process that requires extensive research and formulation expertise.

The volatility of dipropylene glycol also presents a technical hurdle. While its low volatility compared to other glycols is generally advantageous, ensuring consistent performance throughout the product's shelf life remains challenging. Researchers must develop strategies to minimize evaporation and maintain the intended dipropylene glycol concentration, which is crucial for sustained deodorant efficacy.

Skin compatibility and irritation potential pose additional challenges. Although dipropylene glycol is generally considered safe for topical use, individual sensitivities and long-term effects of prolonged exposure must be thoroughly investigated. Developing formulations that maximize deodorant efficacy while minimizing the risk of skin irritation or allergic reactions requires extensive dermatological testing and refinement.

The interaction between dipropylene glycol and packaging materials is another area of concern. Ensuring that the chosen packaging does not degrade or interact unfavorably with the dipropylene glycol-based formulation over time is crucial for maintaining product integrity and efficacy. This necessitates comprehensive compatibility studies and potentially the development of specialized packaging solutions.

Regulatory compliance adds another layer of complexity to the research process. As regulations governing cosmetic ingredients and claims vary across different regions, researchers must navigate a complex landscape of requirements while developing dipropylene glycol-based deodorants. This includes adhering to concentration limits, conducting necessary safety assessments, and providing appropriate documentation to support efficacy claims.

Lastly, the challenge of enhancing the antimicrobial properties of dipropylene glycol-based deodorants without relying on traditional preservatives or harsh chemicals is significant. Researchers must explore innovative approaches to boost the natural deodorizing capabilities of dipropylene glycol or develop synergistic combinations with other ingredients to achieve superior odor control while maintaining a favorable safety profile.

Another significant challenge lies in maintaining the desired viscosity and texture of the final product. Dipropylene glycol's hygroscopic nature can affect the overall consistency and feel of the deodorant, potentially leading to user dissatisfaction. Balancing the concentration of dipropylene glycol with other ingredients to achieve the ideal texture while preserving efficacy is a delicate process that requires extensive research and formulation expertise.

The volatility of dipropylene glycol also presents a technical hurdle. While its low volatility compared to other glycols is generally advantageous, ensuring consistent performance throughout the product's shelf life remains challenging. Researchers must develop strategies to minimize evaporation and maintain the intended dipropylene glycol concentration, which is crucial for sustained deodorant efficacy.

Skin compatibility and irritation potential pose additional challenges. Although dipropylene glycol is generally considered safe for topical use, individual sensitivities and long-term effects of prolonged exposure must be thoroughly investigated. Developing formulations that maximize deodorant efficacy while minimizing the risk of skin irritation or allergic reactions requires extensive dermatological testing and refinement.

The interaction between dipropylene glycol and packaging materials is another area of concern. Ensuring that the chosen packaging does not degrade or interact unfavorably with the dipropylene glycol-based formulation over time is crucial for maintaining product integrity and efficacy. This necessitates comprehensive compatibility studies and potentially the development of specialized packaging solutions.

Regulatory compliance adds another layer of complexity to the research process. As regulations governing cosmetic ingredients and claims vary across different regions, researchers must navigate a complex landscape of requirements while developing dipropylene glycol-based deodorants. This includes adhering to concentration limits, conducting necessary safety assessments, and providing appropriate documentation to support efficacy claims.

Lastly, the challenge of enhancing the antimicrobial properties of dipropylene glycol-based deodorants without relying on traditional preservatives or harsh chemicals is significant. Researchers must explore innovative approaches to boost the natural deodorizing capabilities of dipropylene glycol or develop synergistic combinations with other ingredients to achieve superior odor control while maintaining a favorable safety profile.

Current DPG Solutions

01 Dipropylene glycol as a deodorant active ingredient

Dipropylene glycol is used as an active ingredient in deodorant formulations due to its ability to inhibit bacterial growth and reduce body odor. It acts as a solvent and carrier for other active ingredients, enhancing their efficacy and improving the overall performance of the deodorant product.- Dipropylene glycol as a deodorant active ingredient: Dipropylene glycol is used as an active ingredient in deodorant formulations due to its ability to inhibit bacterial growth and reduce body odor. It acts as a solvent and carrier for other active ingredients, enhancing their efficacy and improving the overall performance of the deodorant product.

- Synergistic effects with other deodorant ingredients: Combining dipropylene glycol with other deodorant ingredients can create synergistic effects, enhancing the overall deodorant efficacy. These combinations may include antimicrobial agents, fragrances, or other odor-neutralizing compounds, resulting in a more effective and long-lasting deodorant product.

- Improved delivery system for deodorant actives: Dipropylene glycol can be used as part of an improved delivery system for deodorant active ingredients. Its properties allow for better dispersion and penetration of active compounds into the skin, leading to enhanced deodorant efficacy and longer-lasting protection against body odor.

- Formulation stability and skin compatibility: The inclusion of dipropylene glycol in deodorant formulations can improve product stability and skin compatibility. It helps to maintain a balanced pH, reduces irritation, and enhances the overall feel of the product on the skin, contributing to better user experience and efficacy.

- Eco-friendly and natural deodorant formulations: Dipropylene glycol can be incorporated into eco-friendly and natural deodorant formulations. Its low toxicity and biodegradability make it suitable for use in products marketed as environmentally conscious or natural, while still maintaining effective deodorant properties.

02 Synergistic effects with other deodorant ingredients

Combining dipropylene glycol with other deodorant ingredients can create synergistic effects, enhancing the overall deodorant efficacy. These combinations may include antimicrobial agents, fragrances, or other odor-neutralizing compounds, resulting in a more effective and long-lasting deodorant product.Expand Specific Solutions03 Formulation techniques for improved efficacy

Various formulation techniques can be employed to enhance the efficacy of dipropylene glycol in deodorant products. These may include optimizing the concentration of dipropylene glycol, using specific delivery systems, or incorporating it into novel product forms such as gels, sticks, or sprays to maximize its deodorizing effects.Expand Specific Solutions04 Skin-friendly and moisturizing properties

Dipropylene glycol exhibits skin-friendly properties and can contribute to the moisturizing effects of deodorant formulations. This dual functionality helps maintain skin health while providing effective odor control, making it a versatile ingredient in deodorant products.Expand Specific Solutions05 Long-lasting odor protection

Deodorant formulations containing dipropylene glycol can provide long-lasting odor protection. The ingredient's properties allow for sustained release of active components and extended efficacy throughout the day, reducing the need for frequent reapplication and improving overall user satisfaction.Expand Specific Solutions

Key Industry Players

The research on dipropylene glycol for enhanced deodorant efficacy is situated in a mature personal care market with significant competition. Major players like Unilever, Colgate-Palmolive, and Procter & Gamble dominate the global deodorant industry, which is projected to reach $30 billion by 2026. The technology is at an advanced stage, with companies like Conopco, Unilever, and Beiersdorf actively developing innovative formulations. Smaller firms such as Firmenich and International Flavors & Fragrances are also contributing to R&D efforts, focusing on improving efficacy and sustainability. The market is characterized by ongoing product differentiation and a shift towards natural and eco-friendly solutions, driving continuous technological advancements in deodorant formulations.

Unilever Plc

Technical Solution: Unilever has developed a novel deodorant formulation incorporating Dipropylene Glycol (DPG) as a key ingredient. Their research focuses on enhancing the solubility and stability of active ingredients in deodorant products. The company utilizes a proprietary blend of DPG with other solvents to create a synergistic effect, improving the overall efficacy of their deodorants. This formulation allows for better dispersion of antimicrobial agents and fragrance compounds, resulting in longer-lasting odor protection[1]. Unilever's approach also involves microencapsulation technology, where DPG acts as a carrier for time-released active ingredients, providing continuous odor control throughout the day[3].

Strengths: Improved solubility of active ingredients, enhanced stability, and longer-lasting odor protection. Weaknesses: Potential higher production costs due to complex formulation and encapsulation technology.

Colgate-Palmolive Co.

Technical Solution: Colgate-Palmolive has developed a DPG-based deodorant system that focuses on skin-friendly formulations. Their research emphasizes the use of DPG as a gentle solvent that helps reduce skin irritation while maintaining deodorant efficacy. The company has patented a unique combination of DPG with natural plant extracts, creating a synergistic antimicrobial effect[2]. This formulation not only combats odor-causing bacteria but also provides a soothing effect on the skin. Colgate-Palmolive's approach includes the development of a controlled-release mechanism, where DPG acts as a carrier for both active ingredients and moisturizing agents, ensuring long-lasting protection and skin hydration[4].

Strengths: Skin-friendly formulation, dual action of odor protection and skin care. Weaknesses: May be less effective against strong body odors compared to more aggressive formulations.

DPG Efficacy Research

Method of deodorizing dipropylene glycol composition and composition obtained therefrom

PatentActiveKR1020210045799A

Innovation

- A method involving mixing dipropylene glycol with alcohol and heating the mixture to remove odor-causing substances, resulting in a high-purity composition with reduced odor.

Dipropylene glycol composition and preparation method therefor

PatentWO2021075923A1

Innovation

- A dipropylene glycol composition with a specific content range of 99.5% or more, combined with isomers like 1,1'-oxybis(2-propanol), 2-(2-hydroxypropoxy)-1-propanol, and 2,2-oxybis(1-propanol, and a deodorizing method involving heating with alcohol to remove odor-causing substances, ensuring high purity and reduced odor.

Regulatory Compliance

Regulatory compliance is a critical aspect of developing and marketing deodorant products containing dipropylene glycol (DPG). As the use of DPG in personal care products becomes more prevalent, manufacturers must navigate a complex landscape of regulations to ensure product safety and legal compliance.

In the United States, the Food and Drug Administration (FDA) regulates deodorants as cosmetic products under the Federal Food, Drug, and Cosmetic Act. While DPG is generally recognized as safe (GRAS) by the FDA, manufacturers must ensure that their products meet all labeling requirements and do not make false or misleading claims. The Cosmetic Ingredient Review (CIR) has also evaluated DPG and found it safe for use in cosmetic products at current concentration levels.

The European Union (EU) regulates cosmetic products under the Cosmetic Products Regulation (EC) No. 1223/2009. DPG is listed in the EU Cosmetic Ingredient Database (CosIng) and is permitted for use in cosmetic products. However, manufacturers must comply with the EU's strict requirements for product safety assessments, labeling, and notification to the Cosmetic Products Notification Portal (CPNP).

In Japan, the Ministry of Health, Labour and Welfare regulates cosmetics under the Pharmaceutical Affairs Law. DPG is listed in the Japanese Standards of Cosmetic Ingredients (JSCI) and is allowed for use in cosmetic products. Manufacturers must ensure compliance with Japanese regulations, including proper labeling and ingredient disclosure.

Environmental regulations also play a role in the use of DPG in deodorants. The chemical is subject to the Toxic Substances Control Act (TSCA) in the United States and the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation in the EU. Manufacturers must comply with reporting requirements and restrictions on the production, import, and use of DPG.

As sustainability becomes increasingly important, companies developing DPG-based deodorants should also consider voluntary compliance with eco-friendly certifications and standards. These may include programs focused on sustainable sourcing, reduced environmental impact, and cruelty-free production methods.

To ensure regulatory compliance, manufacturers should implement robust quality control systems, maintain detailed documentation of safety assessments and product formulations, and stay informed about regulatory changes across different markets. Regular audits and consultations with regulatory experts can help companies navigate the complex and evolving regulatory landscape for DPG-containing deodorants.

In the United States, the Food and Drug Administration (FDA) regulates deodorants as cosmetic products under the Federal Food, Drug, and Cosmetic Act. While DPG is generally recognized as safe (GRAS) by the FDA, manufacturers must ensure that their products meet all labeling requirements and do not make false or misleading claims. The Cosmetic Ingredient Review (CIR) has also evaluated DPG and found it safe for use in cosmetic products at current concentration levels.

The European Union (EU) regulates cosmetic products under the Cosmetic Products Regulation (EC) No. 1223/2009. DPG is listed in the EU Cosmetic Ingredient Database (CosIng) and is permitted for use in cosmetic products. However, manufacturers must comply with the EU's strict requirements for product safety assessments, labeling, and notification to the Cosmetic Products Notification Portal (CPNP).

In Japan, the Ministry of Health, Labour and Welfare regulates cosmetics under the Pharmaceutical Affairs Law. DPG is listed in the Japanese Standards of Cosmetic Ingredients (JSCI) and is allowed for use in cosmetic products. Manufacturers must ensure compliance with Japanese regulations, including proper labeling and ingredient disclosure.

Environmental regulations also play a role in the use of DPG in deodorants. The chemical is subject to the Toxic Substances Control Act (TSCA) in the United States and the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation in the EU. Manufacturers must comply with reporting requirements and restrictions on the production, import, and use of DPG.

As sustainability becomes increasingly important, companies developing DPG-based deodorants should also consider voluntary compliance with eco-friendly certifications and standards. These may include programs focused on sustainable sourcing, reduced environmental impact, and cruelty-free production methods.

To ensure regulatory compliance, manufacturers should implement robust quality control systems, maintain detailed documentation of safety assessments and product formulations, and stay informed about regulatory changes across different markets. Regular audits and consultations with regulatory experts can help companies navigate the complex and evolving regulatory landscape for DPG-containing deodorants.

Environmental Impact

The environmental impact of dipropylene glycol (DPG) in deodorant formulations is a critical consideration for both manufacturers and consumers. DPG is generally regarded as a low-toxicity compound with minimal environmental persistence. However, its widespread use in personal care products necessitates a thorough examination of its ecological footprint.

In aquatic environments, DPG demonstrates relatively rapid biodegradation. Studies have shown that it can be broken down by microorganisms in both aerobic and anaerobic conditions, with complete degradation typically occurring within 28 days. This characteristic reduces the risk of long-term accumulation in water bodies and minimizes potential harm to aquatic ecosystems.

Atmospheric release of DPG is limited due to its low volatility. When released, it undergoes photochemical degradation, further reducing its environmental persistence. The compound does not contribute significantly to the formation of ground-level ozone or other air pollutants, making it a preferable choice over more reactive volatile organic compounds (VOCs) in deodorant formulations.

Soil contamination by DPG is generally not a major concern. Its high water solubility facilitates leaching through soil, preventing accumulation. Microbial communities in soil can effectively degrade DPG, further mitigating any potential long-term impact on terrestrial ecosystems.

From a manufacturing perspective, the production of DPG involves the use of propylene oxide, which can have environmental implications if not properly managed. However, modern production processes have significantly reduced emissions and waste, improving the overall environmental profile of DPG manufacturing.

In terms of resource consumption, DPG is derived from petrochemical sources. While this raises sustainability concerns, its efficient production and multifunctional nature in deodorant formulations can potentially reduce the overall resource footprint compared to using multiple, less versatile ingredients.

The disposal of deodorant products containing DPG presents minimal environmental risks. Most of the compound is likely to be degraded in wastewater treatment processes or natural environments. However, the packaging of deodorant products, often containing plastics, remains a more significant environmental concern than the DPG itself.

As regulations and consumer preferences increasingly prioritize environmentally friendly products, the use of DPG in deodorants may face scrutiny. Manufacturers are exploring bio-based alternatives and green chemistry approaches to further reduce the environmental impact of deodorant formulations while maintaining or enhancing efficacy.

In aquatic environments, DPG demonstrates relatively rapid biodegradation. Studies have shown that it can be broken down by microorganisms in both aerobic and anaerobic conditions, with complete degradation typically occurring within 28 days. This characteristic reduces the risk of long-term accumulation in water bodies and minimizes potential harm to aquatic ecosystems.

Atmospheric release of DPG is limited due to its low volatility. When released, it undergoes photochemical degradation, further reducing its environmental persistence. The compound does not contribute significantly to the formation of ground-level ozone or other air pollutants, making it a preferable choice over more reactive volatile organic compounds (VOCs) in deodorant formulations.

Soil contamination by DPG is generally not a major concern. Its high water solubility facilitates leaching through soil, preventing accumulation. Microbial communities in soil can effectively degrade DPG, further mitigating any potential long-term impact on terrestrial ecosystems.

From a manufacturing perspective, the production of DPG involves the use of propylene oxide, which can have environmental implications if not properly managed. However, modern production processes have significantly reduced emissions and waste, improving the overall environmental profile of DPG manufacturing.

In terms of resource consumption, DPG is derived from petrochemical sources. While this raises sustainability concerns, its efficient production and multifunctional nature in deodorant formulations can potentially reduce the overall resource footprint compared to using multiple, less versatile ingredients.

The disposal of deodorant products containing DPG presents minimal environmental risks. Most of the compound is likely to be degraded in wastewater treatment processes or natural environments. However, the packaging of deodorant products, often containing plastics, remains a more significant environmental concern than the DPG itself.

As regulations and consumer preferences increasingly prioritize environmentally friendly products, the use of DPG in deodorants may face scrutiny. Manufacturers are exploring bio-based alternatives and green chemistry approaches to further reduce the environmental impact of deodorant formulations while maintaining or enhancing efficacy.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!