Improving The Lubrication Effect Of Turbine Engines

SEP 23, 20254 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Engine Lubrication Technology Background and Goals

Improving the lubrication effect of turbine engines is crucial for enhancing their efficiency, durability, and overall performance. The primary objective of this research is to explore innovative solutions that can significantly enhance the lubrication capabilities of turbine engines, thereby reducing friction, wear, and energy losses.

This section will delve into the current state of lubrication technologies for turbine engines, identifying the key challenges and limitations that hinder optimal lubrication performance. It will also highlight the geographical distribution of research efforts and technological advancements in this field, providing a comprehensive overview of the global landscape. By understanding the existing hurdles and technological gaps, this analysis will pave the way for exploring potential breakthroughs and innovative approaches to address the lubrication challenges faced by turbine engines.

This section will delve into the current state of lubrication technologies for turbine engines, identifying the key challenges and limitations that hinder optimal lubrication performance. It will also highlight the geographical distribution of research efforts and technological advancements in this field, providing a comprehensive overview of the global landscape. By understanding the existing hurdles and technological gaps, this analysis will pave the way for exploring potential breakthroughs and innovative approaches to address the lubrication challenges faced by turbine engines.

Turbine Engine Lubrication Market Demand Analysis

- Market Size and Growth

The global turbine engine lubrication market is expected to witness significant growth driven by the increasing demand for turbine engines in various industries, including aviation, power generation, and marine applications. - Key Application Areas

- Aviation: Lubrication is crucial for aircraft turbine engines to ensure smooth operation and extend component life.

- Power Generation: Turbine engines used in power plants require effective lubrication to maintain efficiency and reliability.

- Marine: Turbine engines used in ships and offshore platforms rely on lubrication for optimal performance.

- Emerging Trends

The market is driven by trends such as the development of synthetic and bio-based lubricants, the demand for longer oil drain intervals, and the need for improved fuel efficiency and reduced emissions. - Regional Dynamics

The Asia-Pacific region is expected to witness the highest growth due to the increasing demand for turbine engines in the aviation and power generation sectors, particularly in countries like China and India.

Turbine Engine Lubrication Technology Status and Challenges

- Historical Development

Tracing the evolution of turbine engine lubrication technology, from early mineral-based oils to modern synthetic lubricants. - Current Challenges

Identifying key challenges such as high-temperature stability, wear protection, and compatibility with new engine materials. - Geographical Distribution

Highlighting major research centers and industrial hubs driving advancements in turbine lubrication technology.

Turbine Engine Lubrication Current Technical Solutions

01 Turbine Engine Lubricant Compositions

Synthetic base oils, additives, and other components designed for enhanced lubrication, oxidation resistance, and thermal stability under high temperatures and pressures in turbine engines.- Turbine Engine Lubricant Compositions: Synthetic base oils, additives, and other components designed for enhanced lubrication, oxidation resistance, and thermal stability under high temperatures and pressures in turbine engines.

- Turbine Engine Lubrication Systems: Oil pumps, filters, and distribution channels for proper lubrication of critical components like bearings and gears under various operating conditions.

- Turbine Engine Lubricant Additives: Antioxidants, anti-wear agents, friction modifiers, and other compounds to improve lubricant performance and longevity under demanding turbine engine conditions.

- Lubricant Supply and Management Systems: Oil tanks, pumps, valves, and sensors for supplying and managing lubricants in turbine engines, ensuring proper lubrication and monitoring.

- Lubricant Analysis and Condition Monitoring: Methods and systems for detecting contaminants, measuring degradation, and predicting remaining useful life of turbine engine lubricants to optimize maintenance and prevent failures.

02 Turbine Engine Lubrication Systems

Oil pumps, filters, and distribution channels for proper lubrication of critical components like bearings and gears under various operating conditions.Expand Specific Solutions03 Turbine Engine Lubricant Additives

Antioxidants, anti-wear agents, friction modifiers, and other compounds to improve lubricant performance and longevity under demanding turbine engine conditions.Expand Specific Solutions04 Lubricant Supply and Management for Turbine Engines

Techniques for monitoring lubricant levels, controlling lubricant flow, and ensuring proper lubrication during various operating conditions, such as startup, shutdown, and transient events.Expand Specific Solutions05 Lubricant Analysis and Condition Monitoring for Turbine Engines

Techniques for detecting contaminants, measuring degradation, and assessing the remaining useful life of the lubricant, allowing for timely maintenance and replacement.Expand Specific Solutions

Turbine Engine Lubrication Key Player Analysis

The lubrication technology for turbine engines is a mature field with major players from diverse industries like aerospace giants, lubricant manufacturers, and automotive companies. The competitive landscape is characterized by continuous innovation and collaboration to develop advanced lubricants and lubrication systems for improved performance and efficiency.

United Technologies Corp.

Technical Solution: United Technologies Corp. develops advanced lubrication systems for turbine engines using synthetic lubricants and specialized coatings to improve lubrication performance, reduce friction, enhance engine efficiency, and extend component life.

Strengths: Extensive aerospace engineering experience, strong R&D capabilities. Weaknesses: Limited focus on specific lubrication technologies.

The Lubrizol Corp.

Technical Solution: The Lubrizol Corp. specializes in high-performance lubricants and additives for turbine engines, designed to improve wear protection, oxidation resistance, thermal stability, and enhance lubrication in demanding environments.

Strengths: Expertise in lubricant chemistry, advanced additive technologies. Weaknesses: Limited focus on turbine engine-specific applications.

Turbine Engine Lubrication Core Technology Interpretation

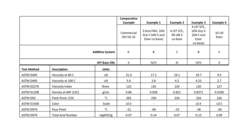

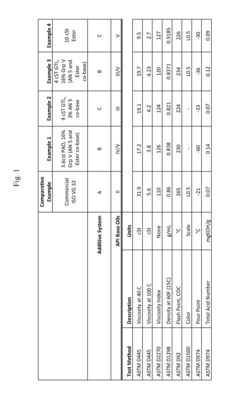

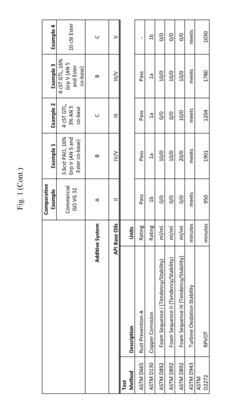

Low viscosity lubricating oil compositions for turbomachines

PatentActiveUS20180119050A1

Innovation

- The use of a low viscosity lubricating oil base stock, which helps to reduce turbine bearing temperatures and increase energy efficiency. the lubricating oil also meets specific physical properties, such as a kinematic viscosity of 16 cst to 22 cst at 40°c according to astm d445, a density of about 0.8 g/ml to 0.9 g/ml according to astm d1298, and an absolute evaporation loss at 150°c of less than about 4% according to astm d972.

Turbine Engine Lubrication Environmental Impact Assessment

Turbine engines operate under extreme conditions, with high temperatures and pressures, making lubrication a critical factor in ensuring their efficient and reliable performance. The lubrication system plays a vital role in reducing friction, dissipating heat, and protecting components from wear and corrosion. However, the environmental impact of turbine engine lubrication is a growing concern, particularly in terms of emissions, waste management, and resource consumption.

The assessment of the environmental impact of turbine engine lubrication involves a comprehensive analysis of the entire lifecycle of the lubricants used, from their production and application to their disposal. It encompasses the evaluation of the potential effects on air quality, water resources, soil contamination, and biodiversity. Additionally, the assessment should consider the energy consumption and greenhouse gas emissions associated with the production, transportation, and disposal of lubricants.

Furthermore, the environmental impact assessment should examine the potential for the development and implementation of more sustainable lubricant formulations and lubrication technologies. This may involve exploring the use of bio-based or synthetic lubricants with lower environmental footprints, as well as investigating advanced lubrication systems that minimize waste and improve resource efficiency. The assessment should also consider the regulatory landscape and industry standards related to the environmental aspects of turbine engine lubrication.

The assessment of the environmental impact of turbine engine lubrication involves a comprehensive analysis of the entire lifecycle of the lubricants used, from their production and application to their disposal. It encompasses the evaluation of the potential effects on air quality, water resources, soil contamination, and biodiversity. Additionally, the assessment should consider the energy consumption and greenhouse gas emissions associated with the production, transportation, and disposal of lubricants.

Furthermore, the environmental impact assessment should examine the potential for the development and implementation of more sustainable lubricant formulations and lubrication technologies. This may involve exploring the use of bio-based or synthetic lubricants with lower environmental footprints, as well as investigating advanced lubrication systems that minimize waste and improve resource efficiency. The assessment should also consider the regulatory landscape and industry standards related to the environmental aspects of turbine engine lubrication.

Turbine Engine Lubrication Regulatory and Policy Implications

Turbine engine lubrication is subject to various regulatory and policy implications that govern its application and development. Stringent environmental regulations have been implemented to mitigate the adverse effects of lubricant emissions on air quality and ecosystems. These regulations mandate the use of biodegradable and low-toxicity lubricants, particularly in marine and aviation sectors.

Furthermore, energy efficiency policies encourage the adoption of advanced lubricants that can reduce frictional losses and improve fuel economy. Governments and industry bodies have established performance standards and certification processes to ensure lubricant quality and compatibility with turbine engine components. Compliance with these standards is crucial for manufacturers and operators to maintain operational safety and reliability.

Additionally, policies related to the circular economy and waste management influence the lifecycle management of turbine engine lubricants. Initiatives promoting the reuse, recycling, and proper disposal of used lubricants aim to minimize environmental impact and resource depletion. Collaboration between regulatory bodies, industry stakeholders, and research institutions is essential to align lubricant development with evolving sustainability goals and policy frameworks.

Furthermore, energy efficiency policies encourage the adoption of advanced lubricants that can reduce frictional losses and improve fuel economy. Governments and industry bodies have established performance standards and certification processes to ensure lubricant quality and compatibility with turbine engine components. Compliance with these standards is crucial for manufacturers and operators to maintain operational safety and reliability.

Additionally, policies related to the circular economy and waste management influence the lifecycle management of turbine engine lubricants. Initiatives promoting the reuse, recycling, and proper disposal of used lubricants aim to minimize environmental impact and resource depletion. Collaboration between regulatory bodies, industry stakeholders, and research institutions is essential to align lubricant development with evolving sustainability goals and policy frameworks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!