Using Sustainable Lubricants In Turbine Engines

SEP 23, 20254 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sustainable Lubricants For Turbine Engines Background And Objectives

The primary objective of this research is to explore the potential of using sustainable lubricants in turbine engines, addressing the environmental concerns associated with conventional lubricants. Sustainable lubricants, derived from renewable sources like vegetable oils or synthetic esters, offer a promising alternative to mineral-based lubricants.

These eco-friendly lubricants have the potential to reduce the environmental impact of turbine engines while maintaining or enhancing their performance. The research aims to investigate the technical feasibility, compatibility, and performance characteristics of sustainable lubricants in turbine engine applications. It will also assess the potential challenges and limitations that need to be addressed for successful implementation.

These eco-friendly lubricants have the potential to reduce the environmental impact of turbine engines while maintaining or enhancing their performance. The research aims to investigate the technical feasibility, compatibility, and performance characteristics of sustainable lubricants in turbine engine applications. It will also assess the potential challenges and limitations that need to be addressed for successful implementation.

Sustainable Lubricants Market Demand Analysis For Turbine Engines

- Market Potential

Turbine engines, widely used in aviation, power generation, and marine applications, have a substantial market demand for sustainable lubricants. The global turbine oil market is projected to grow steadily, driven by increasing energy consumption and the need for efficient and environmentally-friendly solutions. - Environmental Regulations

Stringent environmental regulations and emission standards are driving the adoption of sustainable lubricants in turbine engines. These regulations aim to reduce the environmental impact of lubricants and promote the use of biodegradable and renewable alternatives. - Operational Benefits

Sustainable lubricants offer improved performance, extended equipment life, and reduced maintenance costs. They can enhance the efficiency and reliability of turbine engines, leading to lower operational expenses and increased profitability for end-users. - Industry Trends

The turbine engine industry is increasingly focused on sustainability and eco-friendly practices. Major manufacturers and operators are actively seeking sustainable lubricant solutions to align with their environmental commitments and meet customer demands for greener products and services.

Current Status And Challenges Of Sustainable Lubricants In Turbine Engines

- Sustainability Challenges

Turbine engines require high-performance lubricants with stringent specifications, posing challenges for sustainable alternatives to meet these requirements. - Environmental Regulations

Increasing environmental regulations and emission standards drive the need for more eco-friendly lubricants in turbine engines. - Technical Limitations

Current sustainable lubricants may have limitations in thermal stability, oxidation resistance, and compatibility with engine materials. - Supply Chain Constraints

Limited availability and higher costs of sustainable feedstocks can hinder the widespread adoption of sustainable lubricants. - Performance Trade-offs

Sustainable lubricants may require trade-offs in performance, durability, or maintenance intervals compared to conventional lubricants.

Current Technical Solutions For Sustainable Lubricants In Turbine Engines

01 Turbine engine designs for improved efficiency and reduced emissions

Optimized airflow paths, advanced combustion systems, and lightweight materials.- Turbine engine designs for improved efficiency and reduced emissions: Optimized airflow paths, advanced combustion systems, and lightweight materials to reduce fuel consumption and emissions.

- Turbine engine cooling systems for enhanced durability and efficiency: Advanced cooling techniques like impingement cooling, film cooling, and thermal barrier coatings.

- Turbine engine noise reduction technologies: Noise-absorbing materials, advanced blade designs, and noise-canceling techniques.

- Turbine engine component designs for improved performance and durability: Optimized blade shapes, improved combustor designs, and advanced materials.

- Turbine engine control systems for optimized operation and reduced emissions: Intelligent control systems adjusting fuel flow, air intake, and combustion conditions.

02 Turbine engine cooling systems for enhanced durability and efficiency

Impingement cooling, film cooling, and thermal barrier coatings.Expand Specific Solutions03 Turbine engine control systems for optimized operation and reduced emissions

Sophisticated algorithms, sensors, and actuators to monitor and adjust engine parameters.Expand Specific Solutions04 Turbine engine materials and coatings for improved durability and performance

Advanced materials like ceramic matrix composites, superalloys, and protective coatings.Expand Specific Solutions05 Turbine engine maintenance and repair techniques for extended service life

Advanced inspection methods, repair processes, and specialized coatings or materials.Expand Specific Solutions

Key Players In Sustainable Lubricants For Turbine Engines

The research on using sustainable lubricants in turbine engines is a rapidly evolving field driven by the need for environmentally friendly and high-performance lubricants. The market is still in its early stages, with significant growth potential as the demand for renewable energy sources increases.

Exxon Research & Engineering Co.

Technical Solution: Exxon Research & Engineering Co. has developed advanced synthetic lubricants for turbine engines that offer improved performance compared to conventional mineral oil-based lubricants, leveraging specialized additives and base stocks.

Strengths: Extensive expertise in lubricant formulation, strong R&D capabilities, and a global presence. Weaknesses: Reliance on fossil fuel-based feedstocks, potential challenges in transitioning to sustainable alternatives.

The Lubrizol Corp.

Technical Solution: The Lubrizol Corp. has developed sustainable lubricants for turbine engines based on renewable and biodegradable base stocks, aiming to reduce environmental impact while maintaining high performance and compatibility.

Strengths: Expertise in specialty chemicals and lubricant additives, focus on sustainability. Weaknesses: Limited scale compared to larger oil companies, potential supply chain challenges for renewable feedstocks.

Core Patents And Research On Sustainable Lubricants For Turbine Engines

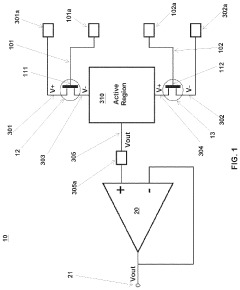

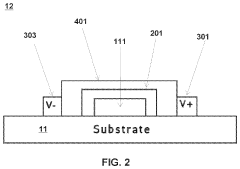

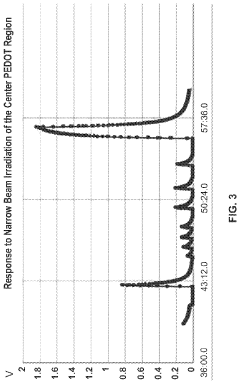

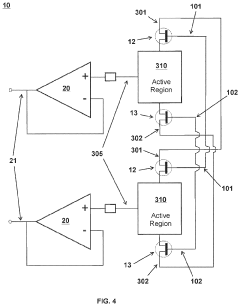

Solid State Tissue Equivalent Detector With Switching Compensation

PatentActiveUS20210151507A1

Innovation

- The use of organic conducting active regions for detecting radiation, the integration of the field effect semiconductor device with the voltage circuitry component, and the ability to maintain the voltage at the output electrode at a constant level while the detector is being irradiated.

Environmental Impact Of Sustainable Lubricants For Turbine Engines

Environmental impacts of sustainable lubricants for turbine engines encompass a wide range of considerations. Conventional lubricants derived from petroleum sources contribute to greenhouse gas emissions, resource depletion, and potential environmental contamination. In contrast, sustainable lubricants, such as those derived from renewable sources like vegetable oils or synthetic esters, offer a more environmentally friendly alternative.

These sustainable lubricants have a lower carbon footprint and are biodegradable, reducing the risk of long-term environmental damage in case of leaks or spills. Additionally, their production processes often involve fewer harmful chemicals and byproducts, further minimizing their environmental impact. However, it's crucial to evaluate the entire life cycle of these lubricants, including their production, use, and disposal, to ensure a comprehensive assessment of their sustainability.

Furthermore, the performance characteristics of sustainable lubricants, such as thermal stability, lubricity, and compatibility with turbine engine materials, must be carefully examined to ensure they meet the stringent operational requirements of turbine engines. Ongoing research and development efforts aim to optimize these properties while maintaining their environmental benefits, paving the way for a more sustainable aviation industry.

These sustainable lubricants have a lower carbon footprint and are biodegradable, reducing the risk of long-term environmental damage in case of leaks or spills. Additionally, their production processes often involve fewer harmful chemicals and byproducts, further minimizing their environmental impact. However, it's crucial to evaluate the entire life cycle of these lubricants, including their production, use, and disposal, to ensure a comprehensive assessment of their sustainability.

Furthermore, the performance characteristics of sustainable lubricants, such as thermal stability, lubricity, and compatibility with turbine engine materials, must be carefully examined to ensure they meet the stringent operational requirements of turbine engines. Ongoing research and development efforts aim to optimize these properties while maintaining their environmental benefits, paving the way for a more sustainable aviation industry.

Regulatory Landscape For Sustainable Lubricants In Turbine Engines

The regulatory landscape for sustainable lubricants in turbine engines is a complex and evolving area, driven by environmental concerns and the need for more efficient and eco-friendly operations. Governments and regulatory bodies around the world have implemented various regulations and standards to promote the use of sustainable lubricants and reduce the environmental impact of turbine engines.

These regulations typically focus on reducing emissions, improving energy efficiency, and minimizing the use of hazardous materials. They may include restrictions on the use of certain chemicals, requirements for biodegradability and low toxicity, as well as guidelines for proper disposal and handling of used lubricants. Additionally, some regulations may provide incentives or tax credits for companies that adopt sustainable lubricant practices.

It is crucial for turbine engine manufacturers and operators to stay informed about the latest regulatory developments and ensure compliance with applicable laws and standards. Failure to comply can result in significant fines, legal liabilities, and reputational damage. Moreover, proactive adoption of sustainable lubricants can provide competitive advantages, such as improved operational efficiency, reduced environmental footprint, and enhanced public perception.

These regulations typically focus on reducing emissions, improving energy efficiency, and minimizing the use of hazardous materials. They may include restrictions on the use of certain chemicals, requirements for biodegradability and low toxicity, as well as guidelines for proper disposal and handling of used lubricants. Additionally, some regulations may provide incentives or tax credits for companies that adopt sustainable lubricant practices.

It is crucial for turbine engine manufacturers and operators to stay informed about the latest regulatory developments and ensure compliance with applicable laws and standards. Failure to comply can result in significant fines, legal liabilities, and reputational damage. Moreover, proactive adoption of sustainable lubricants can provide competitive advantages, such as improved operational efficiency, reduced environmental footprint, and enhanced public perception.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!