Turbine Engines With Advanced Lubrication Coatings To Improve Performance And Efficiency

SEP 23, 20254 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Advanced Lubrication Coatings for Turbine Engines Background and Objectives

The primary objective of this research is to develop advanced lubrication coatings for turbine engines, aiming to enhance their performance and efficiency. Turbine engines are widely used in various industries, including aviation, power generation, and transportation. However, their performance can be hindered by friction, wear, and high operating temperatures, leading to reduced efficiency and increased maintenance costs.

Advanced lubrication coatings have the potential to mitigate these issues by reducing friction and wear between moving components, while also providing thermal protection. These coatings can be applied to critical engine parts, such as bearings, gears, and seals, to improve their durability and extend their service life. By reducing friction and wear, these coatings can contribute to improved fuel efficiency, lower emissions, and reduced maintenance requirements, ultimately leading to cost savings and environmental benefits.

Advanced lubrication coatings have the potential to mitigate these issues by reducing friction and wear between moving components, while also providing thermal protection. These coatings can be applied to critical engine parts, such as bearings, gears, and seals, to improve their durability and extend their service life. By reducing friction and wear, these coatings can contribute to improved fuel efficiency, lower emissions, and reduced maintenance requirements, ultimately leading to cost savings and environmental benefits.

Market Demand Analysis for High-Performance Turbine Engines

- Market Size and Growth

Analyze the current and projected market size for high-performance turbine engines, considering factors like aviation, power generation, and industrial applications. Highlight key growth drivers and potential market constraints. - Industry Trends

Examine emerging trends shaping the demand for advanced turbine engines, such as the push for higher efficiency, reduced emissions, and increased reliability. Discuss the impact of regulatory changes and sustainability initiatives. - Application Segments

Identify and evaluate the demand across various application segments, including commercial aviation, military aviation, power generation, and industrial sectors. Assess the unique requirements and growth prospects for each segment. - Regional Analysis

Provide a regional breakdown of the market demand, highlighting key regions with significant growth potential or unique market dynamics. Consider factors like infrastructure development, economic growth, and regional policies. - Competitive Landscape

Analyze the competitive landscape, including major players, their market shares, and strategies. Discuss the impact of new entrants, technological advancements, and shifts in customer preferences on market dynamics.

Current Status and Challenges of Lubrication Coatings for Turbine Engines

- Current Challenges

Existing lubrication coatings face limitations in high-temperature environments, leading to premature degradation and reduced engine efficiency. Thermal stability, oxidation resistance, and adhesion strength are key challenges. - Material Constraints

Conventional coating materials like polymers and ceramics struggle to maintain lubricity and durability under extreme conditions encountered in turbine engines, necessitating the exploration of advanced materials. - Coating Deposition Techniques

Current coating deposition methods, such as physical vapor deposition (PVD) and chemical vapor deposition (CVD), have limitations in terms of coating uniformity, adhesion, and scalability for complex engine components. - Tribological Performance

Achieving optimal tribological performance, including low friction, wear resistance, and compatibility with various lubricants, remains a challenge for lubrication coatings in turbine engines. - Environmental Impact

Concerns over the environmental impact of certain coating materials and deposition processes, such as the use of hazardous chemicals or high energy consumption, need to be addressed.

Existing Solutions for Lubrication Coatings on Turbine Engines

01 Turbine Blade Design

Optimized blade shapes, materials, and coatings reduce aerodynamic losses, improve heat transfer, and increase durability, leading to better overall performance and efficiency.- Turbine Blade Design: Optimized blade shapes, materials, and coatings reduce aerodynamic losses, increase heat resistance, and improve overall performance. Advanced CFD simulations and experimental testing optimize blade designs.

- Combustion Optimization: Optimized fuel injection systems, advanced combustor designs, and lean combustion techniques enhance combustion efficiency and reduce emissions. Computational simulations and experiments optimize the combustion process.

- Turbine Cooling Systems: Advanced cooling techniques like film cooling, impingement cooling, and thermal barrier coatings protect turbine components from high temperatures, improving engine performance and efficiency.

- Compressor Design: Optimized compressor designs, including blade shapes, diffuser geometries, and variable geometry components, reduce aerodynamic losses and improve pressure ratios, increasing efficiency.

- Advanced Materials and Coatings: Lightweight, high-temperature-resistant materials and protective coatings enhance component life, reduce weight, increase operating temperatures, and reduce maintenance requirements.

02 Combustion Optimization

Fuel injection optimization, combustor design modifications, and advanced materials enhance combustion efficiency, reduce emissions, and increase overall engine efficiency.Expand Specific Solutions03 Compressor and Turbine Aerodynamics

Optimizing blade shapes, flow paths, and minimizing losses through CFD analysis and experimental testing enhance overall engine efficiency.Expand Specific Solutions04 Advanced Cooling Systems

Advanced cooling techniques like impingement cooling, film cooling, and thermal barrier coatings improve engine efficiency by allowing higher operating temperatures while maintaining component integrity.Expand Specific Solutions05 Engine Control and Monitoring

Advanced sensors, data analytics, and control algorithms adjust engine parameters, predict maintenance needs, and ensure optimal operation, leading to improved efficiency and reduced downtime.Expand Specific Solutions

Key Players in Advanced Lubrication Coatings for Turbine Engines

The research on turbine engines with advanced lubrication coatings to improve performance and efficiency is a competitive field with various companies at different technological maturity stages. While the market size is substantial due to global demand, the technology itself is still in early development.

Safran Aircraft Engines SAS

Technical Solution: Safran Aircraft Engines has developed a self-lubricating coating for turbine engines, applying a composite coating with solid lubricants to critical components, providing continuous lubrication and reducing friction and wear.

Strengths: Expertise in aircraft engine design and manufacturing, strong R&D capabilities, and innovative technologies. Weaknesses: Limited experience with advanced lubrication coatings, potential compatibility issues.

General Electric Company

Technical Solution: GE has developed advanced lubrication coatings for turbine engines, applying a specialized ceramic material to critical components, reducing friction and wear, allowing higher operating temperatures with optimal lubrication.

Strengths: Extensive experience in turbine engine design and manufacturing, strong R&D capabilities, and access to advanced materials. Weaknesses: High implementation cost, potential compatibility issues.

Core Patents and Technologies for Turbine Engine Lubrication Coatings

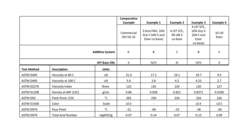

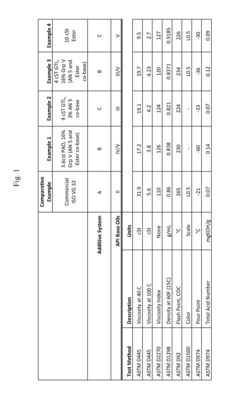

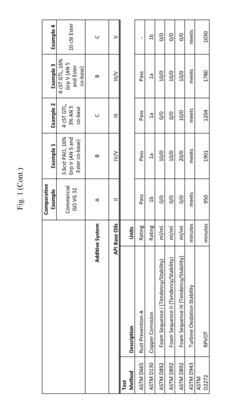

Low viscosity lubricating oil compositions for turbomachines

PatentActiveUS20180119050A1

Innovation

- The use of a low viscosity lubricating oil base stock, which helps to reduce turbine bearing temperatures and increase energy efficiency. the lubricating oil also meets specific physical properties, such as a kinematic viscosity of 16 cst to 22 cst at 40°c according to astm d445, a density of about 0.8 g/ml to 0.9 g/ml according to astm d1298, and an absolute evaporation loss at 150°c of less than about 4% according to astm d972.

Environmental Impact Assessment of Advanced Lubrication Coatings for Turbine Engines

Environmental impacts of advanced lubrication coatings for turbine engines encompass various aspects throughout their lifecycle. During the manufacturing phase, potential emissions and waste generation from coating processes should be assessed and mitigated. The operational phase is crucial, as these coatings aim to enhance engine efficiency, reducing fuel consumption and associated greenhouse gas emissions.

However, the long-term durability and potential wear of these coatings must be evaluated to prevent particulate matter release. End-of-life disposal or recycling methods should also be considered to minimize environmental footprint. Overall, a comprehensive life cycle assessment is necessary to quantify the net environmental benefits and identify areas for improvement in sustainable coating development and application.

However, the long-term durability and potential wear of these coatings must be evaluated to prevent particulate matter release. End-of-life disposal or recycling methods should also be considered to minimize environmental footprint. Overall, a comprehensive life cycle assessment is necessary to quantify the net environmental benefits and identify areas for improvement in sustainable coating development and application.

Regulatory Landscape for Lubrication Coatings in Turbine Engine Industry

The regulatory landscape for lubrication coatings in the turbine engine industry is a complex and evolving area. Stringent environmental regulations have been implemented to mitigate the impact of hazardous substances used in coatings, driving the development of eco-friendly alternatives. Simultaneously, performance and safety standards have become increasingly rigorous, necessitating coatings that can withstand extreme operating conditions while minimizing friction and wear.

Regulatory bodies, such as the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA), play a crucial role in setting guidelines for the use and disposal of lubricants and coatings. These regulations cover various aspects, including material composition, emission limits, and worker safety protocols. Compliance with these regulations is mandatory for turbine engine manufacturers and operators, ensuring environmental protection and occupational health.

Additionally, industry-specific standards and certifications, such as those established by organizations like the International Organization for Standardization (ISO) and the Aerospace Industries Association (AIA), provide guidelines for the performance, testing, and quality control of lubrication coatings. These standards ensure consistency, reliability, and interoperability across the industry, facilitating global trade and collaboration.

Regulatory bodies, such as the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA), play a crucial role in setting guidelines for the use and disposal of lubricants and coatings. These regulations cover various aspects, including material composition, emission limits, and worker safety protocols. Compliance with these regulations is mandatory for turbine engine manufacturers and operators, ensuring environmental protection and occupational health.

Additionally, industry-specific standards and certifications, such as those established by organizations like the International Organization for Standardization (ISO) and the Aerospace Industries Association (AIA), provide guidelines for the performance, testing, and quality control of lubrication coatings. These standards ensure consistency, reliability, and interoperability across the industry, facilitating global trade and collaboration.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!