Longitudinal wave-based diagnostics in aerospace engineering

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace NDT Evolution

Non-destructive testing (NDT) in aerospace engineering has undergone significant evolution over the past decades, driven by the increasing complexity of aircraft structures and the need for more reliable and efficient inspection methods. The development of longitudinal wave-based diagnostics represents a crucial milestone in this evolution, offering enhanced capabilities for detecting and characterizing defects in aerospace materials and components.

In the early stages of aerospace NDT, visual inspection and basic mechanical testing were the primary methods used. However, as aircraft designs became more sophisticated and safety standards more stringent, the need for more advanced NDT techniques became apparent. The introduction of ultrasonic testing in the mid-20th century marked a significant leap forward, allowing for the detection of internal flaws without damaging the material.

Longitudinal wave-based diagnostics emerged as a refinement of ultrasonic testing, offering improved resolution and sensitivity. This technique utilizes high-frequency sound waves that travel through the material in a direction parallel to the wave propagation. The ability of longitudinal waves to penetrate deep into materials while maintaining high sensitivity to defects made them particularly suitable for aerospace applications.

The adoption of longitudinal wave-based diagnostics in aerospace engineering was further accelerated by advancements in transducer technology and signal processing. These improvements enabled more precise control over wave generation and detection, leading to enhanced accuracy in defect identification and characterization. The integration of computer-aided analysis and automation also played a crucial role in making longitudinal wave-based diagnostics more efficient and reliable.

As the aerospace industry moved towards composite materials, the importance of longitudinal wave-based diagnostics grew even further. These materials presented new challenges for NDT, as their anisotropic nature and complex internal structures made traditional inspection methods less effective. Longitudinal waves proved to be particularly adept at detecting delaminations, voids, and other defects common in composite structures.

Recent developments in longitudinal wave-based diagnostics have focused on improving data interpretation and visualization. Advanced signal processing algorithms and 3D imaging techniques have enhanced the ability to locate and characterize defects with greater precision. This has led to more accurate assessments of structural integrity and better-informed maintenance decisions.

The evolution of longitudinal wave-based diagnostics in aerospace NDT continues to be driven by the industry's push for lighter, stronger, and more complex aircraft structures. Ongoing research aims to further improve the resolution, speed, and reliability of these techniques, as well as their integration with other NDT methods for comprehensive structural health monitoring.

In the early stages of aerospace NDT, visual inspection and basic mechanical testing were the primary methods used. However, as aircraft designs became more sophisticated and safety standards more stringent, the need for more advanced NDT techniques became apparent. The introduction of ultrasonic testing in the mid-20th century marked a significant leap forward, allowing for the detection of internal flaws without damaging the material.

Longitudinal wave-based diagnostics emerged as a refinement of ultrasonic testing, offering improved resolution and sensitivity. This technique utilizes high-frequency sound waves that travel through the material in a direction parallel to the wave propagation. The ability of longitudinal waves to penetrate deep into materials while maintaining high sensitivity to defects made them particularly suitable for aerospace applications.

The adoption of longitudinal wave-based diagnostics in aerospace engineering was further accelerated by advancements in transducer technology and signal processing. These improvements enabled more precise control over wave generation and detection, leading to enhanced accuracy in defect identification and characterization. The integration of computer-aided analysis and automation also played a crucial role in making longitudinal wave-based diagnostics more efficient and reliable.

As the aerospace industry moved towards composite materials, the importance of longitudinal wave-based diagnostics grew even further. These materials presented new challenges for NDT, as their anisotropic nature and complex internal structures made traditional inspection methods less effective. Longitudinal waves proved to be particularly adept at detecting delaminations, voids, and other defects common in composite structures.

Recent developments in longitudinal wave-based diagnostics have focused on improving data interpretation and visualization. Advanced signal processing algorithms and 3D imaging techniques have enhanced the ability to locate and characterize defects with greater precision. This has led to more accurate assessments of structural integrity and better-informed maintenance decisions.

The evolution of longitudinal wave-based diagnostics in aerospace NDT continues to be driven by the industry's push for lighter, stronger, and more complex aircraft structures. Ongoing research aims to further improve the resolution, speed, and reliability of these techniques, as well as their integration with other NDT methods for comprehensive structural health monitoring.

Market Demand Analysis

The aerospace industry has witnessed a growing demand for advanced diagnostic technologies, with longitudinal wave-based diagnostics emerging as a promising solution. This market is driven by the increasing complexity of aerospace systems and the critical need for reliable, non-destructive testing methods. The global aerospace non-destructive testing market, which includes longitudinal wave-based diagnostics, is projected to experience significant growth in the coming years.

One of the primary factors fueling this demand is the aging fleet of commercial and military aircraft worldwide. As these aircraft continue to operate beyond their initial design life, there is an urgent need for more sophisticated diagnostic tools to ensure their structural integrity and safety. Longitudinal wave-based diagnostics offer a non-invasive approach to detect internal defects, corrosion, and fatigue damage in aerospace components, making it an attractive option for maintenance, repair, and overhaul (MRO) operations.

The rise of composite materials in aerospace manufacturing has also contributed to the increased demand for advanced diagnostic technologies. Traditional inspection methods are often less effective on composite structures, creating a market opportunity for longitudinal wave-based diagnostics. This technology can provide more accurate and detailed information about the internal structure of composite components, addressing a critical industry need.

Furthermore, the push for lighter, more fuel-efficient aircraft has led to the development of thinner, more complex structures. These designs require more frequent and thorough inspections to maintain safety standards, driving the demand for advanced diagnostic tools. Longitudinal wave-based diagnostics offer the precision and depth of analysis necessary for these modern aerospace structures.

The space sector is another area contributing to the market demand for longitudinal wave-based diagnostics. With the increasing commercialization of space and the development of reusable launch vehicles, there is a growing need for reliable inspection technologies that can withstand the extreme conditions of space travel. Longitudinal wave-based diagnostics show promise in this area, offering the potential for in-situ monitoring of spacecraft components.

Regulatory bodies in the aerospace industry are also influencing market demand. Stricter safety regulations and the need for more comprehensive documentation of aircraft health are pushing operators and manufacturers to adopt more advanced diagnostic technologies. Longitudinal wave-based diagnostics align well with these regulatory trends, offering detailed, quantifiable data on component integrity.

As the aerospace industry continues to evolve, the market for longitudinal wave-based diagnostics is expected to expand. The technology's ability to provide real-time, high-resolution data on structural health aligns with the industry's move towards predictive maintenance and condition-based monitoring. This shift from reactive to proactive maintenance strategies is likely to further drive demand for advanced diagnostic technologies in the coming years.

One of the primary factors fueling this demand is the aging fleet of commercial and military aircraft worldwide. As these aircraft continue to operate beyond their initial design life, there is an urgent need for more sophisticated diagnostic tools to ensure their structural integrity and safety. Longitudinal wave-based diagnostics offer a non-invasive approach to detect internal defects, corrosion, and fatigue damage in aerospace components, making it an attractive option for maintenance, repair, and overhaul (MRO) operations.

The rise of composite materials in aerospace manufacturing has also contributed to the increased demand for advanced diagnostic technologies. Traditional inspection methods are often less effective on composite structures, creating a market opportunity for longitudinal wave-based diagnostics. This technology can provide more accurate and detailed information about the internal structure of composite components, addressing a critical industry need.

Furthermore, the push for lighter, more fuel-efficient aircraft has led to the development of thinner, more complex structures. These designs require more frequent and thorough inspections to maintain safety standards, driving the demand for advanced diagnostic tools. Longitudinal wave-based diagnostics offer the precision and depth of analysis necessary for these modern aerospace structures.

The space sector is another area contributing to the market demand for longitudinal wave-based diagnostics. With the increasing commercialization of space and the development of reusable launch vehicles, there is a growing need for reliable inspection technologies that can withstand the extreme conditions of space travel. Longitudinal wave-based diagnostics show promise in this area, offering the potential for in-situ monitoring of spacecraft components.

Regulatory bodies in the aerospace industry are also influencing market demand. Stricter safety regulations and the need for more comprehensive documentation of aircraft health are pushing operators and manufacturers to adopt more advanced diagnostic technologies. Longitudinal wave-based diagnostics align well with these regulatory trends, offering detailed, quantifiable data on component integrity.

As the aerospace industry continues to evolve, the market for longitudinal wave-based diagnostics is expected to expand. The technology's ability to provide real-time, high-resolution data on structural health aligns with the industry's move towards predictive maintenance and condition-based monitoring. This shift from reactive to proactive maintenance strategies is likely to further drive demand for advanced diagnostic technologies in the coming years.

Current Challenges

Longitudinal wave-based diagnostics in aerospace engineering face several significant challenges that hinder their widespread adoption and effectiveness. One of the primary obstacles is the complexity of aerospace structures, which often consist of multiple layers of different materials, intricate geometries, and various components. This complexity makes it difficult to accurately interpret the longitudinal wave signals and distinguish between normal structural features and potential defects or damages.

The harsh operating environments of aerospace systems pose another major challenge. Extreme temperatures, high-altitude conditions, and intense vibrations can affect the propagation and reception of longitudinal waves, potentially leading to inaccurate or unreliable diagnostic results. Additionally, the presence of ambient noise and electromagnetic interference in aerospace environments further complicates the signal analysis process.

Another significant hurdle is the need for high-resolution imaging and precise defect localization. Aerospace components often require detection of minute flaws or damages that could compromise structural integrity. Achieving the necessary spatial resolution and sensitivity with longitudinal wave-based techniques remains a challenge, particularly for complex geometries and hard-to-reach areas within aircraft structures.

The integration of longitudinal wave-based diagnostic systems into existing aerospace platforms presents logistical and technical difficulties. Retrofitting older aircraft with new diagnostic technologies can be costly and time-consuming, while ensuring compatibility with existing systems and maintenance procedures adds another layer of complexity.

Data interpretation and analysis pose substantial challenges in longitudinal wave-based diagnostics. The vast amount of data generated during inspections requires advanced signal processing algorithms and machine learning techniques to effectively identify and classify defects. Developing robust and reliable automated analysis methods that can handle the diverse range of aerospace materials and structures is an ongoing challenge in the field.

The need for real-time or near-real-time diagnostics in aerospace applications adds further complexity to the implementation of longitudinal wave-based techniques. Rapid assessment of structural health during flight or between missions is crucial for ensuring safety and operational efficiency. However, achieving this level of immediacy while maintaining accuracy and reliability remains a significant technical hurdle.

Lastly, the aerospace industry's stringent certification and regulatory requirements present a challenge for the adoption of new diagnostic technologies. Demonstrating the reliability, accuracy, and safety of longitudinal wave-based diagnostic systems to meet these standards requires extensive testing and validation, which can be time-consuming and resource-intensive.

The harsh operating environments of aerospace systems pose another major challenge. Extreme temperatures, high-altitude conditions, and intense vibrations can affect the propagation and reception of longitudinal waves, potentially leading to inaccurate or unreliable diagnostic results. Additionally, the presence of ambient noise and electromagnetic interference in aerospace environments further complicates the signal analysis process.

Another significant hurdle is the need for high-resolution imaging and precise defect localization. Aerospace components often require detection of minute flaws or damages that could compromise structural integrity. Achieving the necessary spatial resolution and sensitivity with longitudinal wave-based techniques remains a challenge, particularly for complex geometries and hard-to-reach areas within aircraft structures.

The integration of longitudinal wave-based diagnostic systems into existing aerospace platforms presents logistical and technical difficulties. Retrofitting older aircraft with new diagnostic technologies can be costly and time-consuming, while ensuring compatibility with existing systems and maintenance procedures adds another layer of complexity.

Data interpretation and analysis pose substantial challenges in longitudinal wave-based diagnostics. The vast amount of data generated during inspections requires advanced signal processing algorithms and machine learning techniques to effectively identify and classify defects. Developing robust and reliable automated analysis methods that can handle the diverse range of aerospace materials and structures is an ongoing challenge in the field.

The need for real-time or near-real-time diagnostics in aerospace applications adds further complexity to the implementation of longitudinal wave-based techniques. Rapid assessment of structural health during flight or between missions is crucial for ensuring safety and operational efficiency. However, achieving this level of immediacy while maintaining accuracy and reliability remains a significant technical hurdle.

Lastly, the aerospace industry's stringent certification and regulatory requirements present a challenge for the adoption of new diagnostic technologies. Demonstrating the reliability, accuracy, and safety of longitudinal wave-based diagnostic systems to meet these standards requires extensive testing and validation, which can be time-consuming and resource-intensive.

Existing NDT Solutions

01 Ultrasound-based diagnostic techniques

Longitudinal wave-based diagnostics often utilize ultrasound technology for medical imaging and analysis. These techniques involve sending high-frequency sound waves into the body and analyzing the reflected echoes to create images of internal structures. This non-invasive approach is widely used for various diagnostic purposes, including organ examination, fetal monitoring, and cardiovascular assessments.- Ultrasound-based diagnostic techniques: Longitudinal wave-based diagnostics often utilize ultrasound technology for medical imaging and analysis. These techniques involve sending high-frequency sound waves into the body and analyzing the reflected echoes to create images of internal structures. This non-invasive approach is widely used for various diagnostic purposes, including organ examination, fetal monitoring, and cardiovascular assessments.

- Seismic wave analysis for geological diagnostics: Longitudinal waves are employed in seismic surveys for geological diagnostics. This technique involves generating seismic waves and analyzing their propagation through different layers of the Earth's crust. The data collected can be used to identify subsurface structures, locate mineral deposits, and assess potential earthquake risks.

- Acoustic emission testing for material diagnostics: Longitudinal waves are used in acoustic emission testing to diagnose the structural integrity of materials and components. This method involves detecting and analyzing stress waves generated by defects or deformations within a material under load. It is particularly useful for non-destructive testing in industries such as aerospace, construction, and manufacturing.

- Sonar-based underwater diagnostics: Longitudinal waves in the form of sound waves are utilized in sonar systems for underwater diagnostics. These systems emit sound pulses and analyze the returning echoes to detect and locate underwater objects, map the seafloor, and measure water depth. Sonar technology is crucial for marine research, navigation, and underwater exploration.

- Laser-based photoacoustic imaging: This diagnostic technique combines optical and acoustic principles by using laser pulses to generate ultrasound waves in biological tissues. The resulting acoustic signals are detected and used to create high-resolution images of tissue structures and functional properties. This method is particularly useful for early cancer detection, vascular imaging, and brain function studies.

02 Seismic wave analysis for geological diagnostics

Longitudinal waves are employed in seismic surveys for geological diagnostics. This technique involves generating seismic waves and analyzing their propagation through different layers of the Earth's crust. The data collected can be used to identify subsurface structures, locate mineral deposits, and assess potential earthquake risks.Expand Specific Solutions03 Acoustic emission testing for material diagnostics

Longitudinal waves are used in acoustic emission testing to diagnose material integrity and detect defects. This method involves monitoring and analyzing the acoustic waves generated by materials under stress or during deformation. It is particularly useful in non-destructive testing of structures, pressure vessels, and composite materials.Expand Specific Solutions04 Electromagnetic wave-based diagnostics

While not strictly longitudinal, electromagnetic waves are sometimes used in conjunction with longitudinal wave techniques for diagnostic purposes. This approach combines different wave types to enhance diagnostic capabilities, particularly in medical imaging and material analysis. Examples include the use of radio waves in MRI or the combination of ultrasound and electromagnetic waves in certain advanced imaging techniques.Expand Specific Solutions05 Signal processing and analysis in wave-based diagnostics

Advanced signal processing and analysis techniques are crucial in longitudinal wave-based diagnostics. These methods involve filtering, amplification, and interpretation of wave signals to extract meaningful diagnostic information. Machine learning and artificial intelligence are increasingly being applied to enhance the accuracy and efficiency of wave signal analysis in various diagnostic applications.Expand Specific Solutions

Key Industry Players

The research on longitudinal wave-based diagnostics in aerospace engineering is in a developing stage, with growing market potential due to increasing demand for advanced non-destructive testing methods in the aerospace sector. The technology's maturity varies among key players, with established institutions like Beihang University, Nanjing University of Aeronautics & Astronautics, and the Chinese Academy of Sciences Institute of Acoustics leading in academic research. Industry giants such as Boeing and Airbus are likely investing in practical applications, while specialized companies like Southwest Research Institute and Beijing Precision Machinery & Engineering Research Co. Ltd. are focusing on developing tailored solutions. The competitive landscape is diverse, with a mix of academic, governmental, and commercial entities contributing to advancements in this field.

Chinese Academy of Sciences Institute of Acoustics

Technical Solution: The Chinese Academy of Sciences Institute of Acoustics has conducted extensive research on longitudinal wave-based diagnostics for aerospace applications. Their work includes the development of advanced transducer technologies for generating high-frequency, focused longitudinal waves capable of detecting micro-cracks and delaminations in composite materials[7]. The institute has also made significant progress in the field of nonlinear ultrasonic techniques, which can detect early-stage damage before it becomes visible through conventional methods. Their research encompasses the use of coded excitation signals to improve the signal-to-noise ratio in challenging aerospace inspection environments. Additionally, the institute has developed innovative data fusion algorithms that combine information from multiple ultrasonic modes, including longitudinal waves, to provide comprehensive structural assessments[8].

Strengths: Strong focus on fundamental research and novel transducer technologies, expertise in nonlinear ultrasonic techniques. Weaknesses: May face challenges in translating research findings into practical industrial applications, potential limitations in access to certain international collaborations.

Southwest Research Institute

Technical Solution: Southwest Research Institute (SwRI) has made significant advancements in longitudinal wave-based diagnostics for aerospace engineering. Their approach combines traditional ultrasonic testing with advanced signal processing and artificial intelligence. SwRI has developed a patented technique called Spatially Controlled Acoustic Source Technology (SCAST) that uses phased array transducers to generate highly focused longitudinal waves for improved defect detection in complex aerospace structures[9]. The institute has also pioneered the use of guided waves for long-range inspection of aircraft fuselages and wings, significantly reducing inspection times. SwRI's research extends to the development of portable, handheld devices that utilize longitudinal waves for on-site inspections of aerospace components, improving maintenance efficiency and reducing aircraft downtime[10].

Strengths: Innovative combination of ultrasonic technology with AI, development of practical, field-deployable solutions. Weaknesses: May face competition from larger aerospace companies with more resources, potential challenges in scaling up technology for widespread industry adoption.

Core Innovations

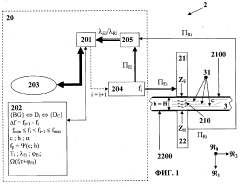

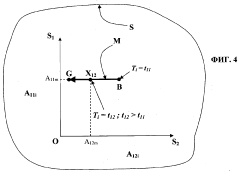

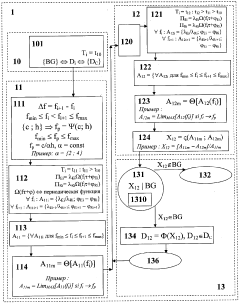

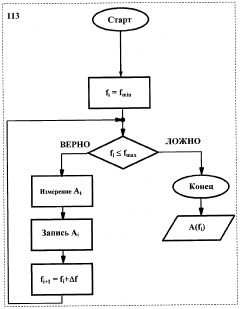

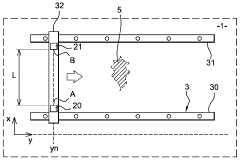

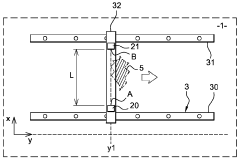

Method and device for determining the internal integrity of a changing composite medium

PatentWO2012127314A1

Innovation

- A method using ultrasonic waves with dimensionless coefficients calculated at different times to assess internal integrity, comparing these against pre-registered control functions to emit alarms and provide wear rate data, enhancing sensitivity and reliability through transverse wave measurements and selective frequency analysis.

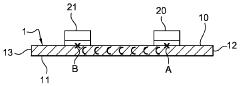

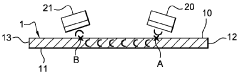

Method of non-destructive checking using lamb waves to determine zones of a structure comprising defects

PatentWO2010040719A1

Innovation

- A method utilizing Lamb waves generated at one point and detected at another, with transducers moved to sweep the structure, identifying segments with potential defects by abnormal attenuation, allowing for quicker defect detection and focused inspection on probable zones.

Regulatory Framework

The regulatory framework surrounding longitudinal wave-based diagnostics in aerospace engineering is complex and multifaceted, involving various national and international bodies. The Federal Aviation Administration (FAA) in the United States plays a crucial role in setting standards and regulations for aerospace technologies, including diagnostic methods. The FAA's Advisory Circulars and Technical Standard Orders provide guidance on the implementation and use of diagnostic technologies in aircraft maintenance and inspection.

Internationally, the International Civil Aviation Organization (ICAO) establishes global standards for aviation safety, which include provisions for aircraft maintenance and inspection techniques. These standards are often adopted or adapted by national aviation authorities worldwide, ensuring a level of consistency in regulatory approaches across different countries.

The European Union Aviation Safety Agency (EASA) is another key player in the regulatory landscape, particularly for European aerospace manufacturers and operators. EASA's regulations and certification processes often address advanced diagnostic technologies, including those based on longitudinal wave principles.

In the context of aerospace engineering, regulatory bodies typically require extensive testing and validation of new diagnostic technologies before they can be approved for use in aircraft maintenance and inspection. This process often involves rigorous safety assessments, reliability studies, and performance evaluations to ensure that the technology meets stringent aerospace standards.

Specific regulations may address the accuracy, reliability, and repeatability of longitudinal wave-based diagnostic methods. These regulations often stipulate the minimum detection capabilities, resolution requirements, and acceptable error margins for such technologies when used in critical aerospace applications.

Furthermore, regulatory frameworks often include provisions for the training and certification of personnel who operate these advanced diagnostic systems. This ensures that the technology is not only reliable but also used correctly and effectively in aerospace maintenance and inspection processes.

As longitudinal wave-based diagnostics continue to evolve, regulatory bodies are likely to update their frameworks to accommodate new capabilities and applications. This may include revisions to existing standards or the development of new guidelines specifically tailored to emerging wave-based diagnostic technologies in aerospace engineering.

Internationally, the International Civil Aviation Organization (ICAO) establishes global standards for aviation safety, which include provisions for aircraft maintenance and inspection techniques. These standards are often adopted or adapted by national aviation authorities worldwide, ensuring a level of consistency in regulatory approaches across different countries.

The European Union Aviation Safety Agency (EASA) is another key player in the regulatory landscape, particularly for European aerospace manufacturers and operators. EASA's regulations and certification processes often address advanced diagnostic technologies, including those based on longitudinal wave principles.

In the context of aerospace engineering, regulatory bodies typically require extensive testing and validation of new diagnostic technologies before they can be approved for use in aircraft maintenance and inspection. This process often involves rigorous safety assessments, reliability studies, and performance evaluations to ensure that the technology meets stringent aerospace standards.

Specific regulations may address the accuracy, reliability, and repeatability of longitudinal wave-based diagnostic methods. These regulations often stipulate the minimum detection capabilities, resolution requirements, and acceptable error margins for such technologies when used in critical aerospace applications.

Furthermore, regulatory frameworks often include provisions for the training and certification of personnel who operate these advanced diagnostic systems. This ensures that the technology is not only reliable but also used correctly and effectively in aerospace maintenance and inspection processes.

As longitudinal wave-based diagnostics continue to evolve, regulatory bodies are likely to update their frameworks to accommodate new capabilities and applications. This may include revisions to existing standards or the development of new guidelines specifically tailored to emerging wave-based diagnostic technologies in aerospace engineering.

Safety Considerations

Safety considerations play a crucial role in the development and implementation of longitudinal wave-based diagnostics in aerospace engineering. The use of these advanced diagnostic techniques requires careful attention to potential risks and hazards associated with both the technology itself and its application in aerospace environments.

One primary safety concern is the potential impact of longitudinal waves on sensitive aircraft components and systems. The propagation of these waves through aerospace structures must be carefully controlled to prevent unintended interference with critical systems, such as avionics or fuel management. Researchers must establish safe operating parameters and develop robust shielding mechanisms to ensure that diagnostic procedures do not compromise the integrity of aircraft systems.

Another important safety aspect is the interpretation of diagnostic results. Inaccurate or misinterpreted data from longitudinal wave-based diagnostics could lead to incorrect assessments of structural integrity, potentially resulting in catastrophic failures. To mitigate this risk, rigorous validation protocols and data analysis techniques must be developed and implemented. These should include redundant measurement systems and cross-verification with other established diagnostic methods.

The human factor in safety must also be considered. Technicians and engineers working with longitudinal wave-based diagnostic equipment require specialized training to operate the technology safely and interpret results accurately. Proper safety protocols, including personal protective equipment and operational guidelines, must be established to protect personnel from any potential hazards associated with the diagnostic equipment.

Environmental factors pose additional safety challenges. Aerospace vehicles operate in extreme conditions, including high altitudes, extreme temperatures, and varying atmospheric pressures. The diagnostic equipment must be designed to function reliably and safely under these conditions without introducing new risks or compromising existing safety measures.

Regulatory compliance is a critical component of safety considerations. As longitudinal wave-based diagnostics are integrated into aerospace engineering practices, they must meet stringent industry standards and regulatory requirements. This includes obtaining necessary certifications and approvals from aviation authorities to ensure that the technology meets established safety benchmarks.

Long-term safety implications must also be evaluated. The cumulative effects of repeated diagnostic procedures on aerospace structures over time need to be thoroughly studied to prevent any degradation of material properties or structural integrity. This requires extensive testing and monitoring programs to track the long-term impact of longitudinal wave diagnostics on various aerospace materials and components.

One primary safety concern is the potential impact of longitudinal waves on sensitive aircraft components and systems. The propagation of these waves through aerospace structures must be carefully controlled to prevent unintended interference with critical systems, such as avionics or fuel management. Researchers must establish safe operating parameters and develop robust shielding mechanisms to ensure that diagnostic procedures do not compromise the integrity of aircraft systems.

Another important safety aspect is the interpretation of diagnostic results. Inaccurate or misinterpreted data from longitudinal wave-based diagnostics could lead to incorrect assessments of structural integrity, potentially resulting in catastrophic failures. To mitigate this risk, rigorous validation protocols and data analysis techniques must be developed and implemented. These should include redundant measurement systems and cross-verification with other established diagnostic methods.

The human factor in safety must also be considered. Technicians and engineers working with longitudinal wave-based diagnostic equipment require specialized training to operate the technology safely and interpret results accurately. Proper safety protocols, including personal protective equipment and operational guidelines, must be established to protect personnel from any potential hazards associated with the diagnostic equipment.

Environmental factors pose additional safety challenges. Aerospace vehicles operate in extreme conditions, including high altitudes, extreme temperatures, and varying atmospheric pressures. The diagnostic equipment must be designed to function reliably and safely under these conditions without introducing new risks or compromising existing safety measures.

Regulatory compliance is a critical component of safety considerations. As longitudinal wave-based diagnostics are integrated into aerospace engineering practices, they must meet stringent industry standards and regulatory requirements. This includes obtaining necessary certifications and approvals from aviation authorities to ensure that the technology meets established safety benchmarks.

Long-term safety implications must also be evaluated. The cumulative effects of repeated diagnostic procedures on aerospace structures over time need to be thoroughly studied to prevent any degradation of material properties or structural integrity. This requires extensive testing and monitoring programs to track the long-term impact of longitudinal wave diagnostics on various aerospace materials and components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!