Mechanical complexity reduction through advanced KERS

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

KERS Evolution and Objectives

Kinetic Energy Recovery Systems (KERS) have undergone significant evolution since their inception in the automotive industry, particularly in motorsports. The technology's development can be traced back to the early 2000s when Formula 1 teams began exploring ways to harness and reuse energy that would otherwise be lost during braking. The primary objective of KERS has always been to improve vehicle efficiency and performance by capturing kinetic energy during deceleration and storing it for later use.

The evolution of KERS has been marked by several key milestones. Initially, mechanical flywheel-based systems were explored, offering a simple yet effective means of energy storage. However, these systems were often bulky and presented integration challenges. As technology progressed, electrical KERS became more prevalent, utilizing motor-generator units coupled with battery storage. This shift allowed for more flexible energy management and improved packaging within vehicles.

In recent years, the focus has shifted towards reducing the mechanical complexity of KERS while enhancing its efficiency and reliability. Advanced KERS aims to simplify the system architecture, minimize weight, and improve energy conversion rates. The objectives of this research include developing more compact and lightweight components, enhancing the durability of energy storage units, and optimizing control algorithms for seamless energy flow management.

One of the key goals in KERS evolution is to broaden its applicability beyond high-performance racing environments. Researchers are exploring ways to adapt KERS technology for mainstream passenger vehicles, commercial trucks, and even public transportation systems. This expansion requires addressing challenges such as cost-effectiveness, ease of maintenance, and compatibility with various vehicle platforms.

Another important objective in KERS development is to increase the energy recovery and storage capacity while maintaining system simplicity. This involves investigating novel materials for energy storage, such as advanced supercapacitors or high-density batteries, which can offer rapid charge and discharge capabilities without compromising on longevity or safety.

The integration of KERS with other vehicle systems is also a critical area of focus. Advanced KERS seeks to create synergies with regenerative braking systems, traction control, and powertrain management to maximize overall vehicle efficiency. This holistic approach aims to reduce fuel consumption and emissions while enhancing driving dynamics and performance.

As environmental concerns and energy efficiency regulations become more stringent, the evolution of KERS is increasingly aligned with sustainability goals. Research efforts are directed towards developing systems that not only improve vehicle performance but also contribute significantly to reducing carbon footprints in the transportation sector. This includes exploring the potential of KERS in hybrid and electric vehicle architectures to extend range and optimize energy usage.

The evolution of KERS has been marked by several key milestones. Initially, mechanical flywheel-based systems were explored, offering a simple yet effective means of energy storage. However, these systems were often bulky and presented integration challenges. As technology progressed, electrical KERS became more prevalent, utilizing motor-generator units coupled with battery storage. This shift allowed for more flexible energy management and improved packaging within vehicles.

In recent years, the focus has shifted towards reducing the mechanical complexity of KERS while enhancing its efficiency and reliability. Advanced KERS aims to simplify the system architecture, minimize weight, and improve energy conversion rates. The objectives of this research include developing more compact and lightweight components, enhancing the durability of energy storage units, and optimizing control algorithms for seamless energy flow management.

One of the key goals in KERS evolution is to broaden its applicability beyond high-performance racing environments. Researchers are exploring ways to adapt KERS technology for mainstream passenger vehicles, commercial trucks, and even public transportation systems. This expansion requires addressing challenges such as cost-effectiveness, ease of maintenance, and compatibility with various vehicle platforms.

Another important objective in KERS development is to increase the energy recovery and storage capacity while maintaining system simplicity. This involves investigating novel materials for energy storage, such as advanced supercapacitors or high-density batteries, which can offer rapid charge and discharge capabilities without compromising on longevity or safety.

The integration of KERS with other vehicle systems is also a critical area of focus. Advanced KERS seeks to create synergies with regenerative braking systems, traction control, and powertrain management to maximize overall vehicle efficiency. This holistic approach aims to reduce fuel consumption and emissions while enhancing driving dynamics and performance.

As environmental concerns and energy efficiency regulations become more stringent, the evolution of KERS is increasingly aligned with sustainability goals. Research efforts are directed towards developing systems that not only improve vehicle performance but also contribute significantly to reducing carbon footprints in the transportation sector. This includes exploring the potential of KERS in hybrid and electric vehicle architectures to extend range and optimize energy usage.

Market Demand for Efficient KERS

The market demand for efficient Kinetic Energy Recovery Systems (KERS) has been steadily growing across various industries, particularly in the automotive and transportation sectors. This surge in demand is primarily driven by the global push for energy efficiency, reduced emissions, and sustainable transportation solutions.

In the automotive industry, KERS has gained significant traction, especially in high-performance vehicles and motorsports. Formula 1 racing, for instance, has been at the forefront of KERS adoption, showcasing its potential for energy recovery and performance enhancement. This has led to increased interest from mainstream automotive manufacturers looking to incorporate KERS technology into their consumer vehicles.

The commercial vehicle sector has also shown a growing appetite for KERS solutions. Fleet operators are increasingly recognizing the potential of KERS to reduce fuel consumption and operating costs, particularly in urban environments with frequent start-stop cycles. This has created a substantial market opportunity for KERS manufacturers targeting buses, delivery vans, and other commercial vehicles.

Public transportation systems, particularly in densely populated urban areas, represent another significant market for KERS technology. City buses and light rail systems can benefit greatly from the energy recovery capabilities of KERS, leading to reduced energy consumption and lower operational costs for transit authorities.

The industrial sector has also begun to explore the potential of KERS in various applications. Heavy machinery, such as cranes and excavators, can utilize KERS to recover energy from repetitive lifting and lowering operations, thereby improving overall energy efficiency and reducing fuel consumption.

Market analysts project substantial growth in the KERS market over the coming years. Factors contributing to this growth include stringent emissions regulations, increasing focus on sustainability, and the ongoing electrification trend in the transportation sector. The global KERS market is expected to expand at a compound annual growth rate (CAGR) of over 20% in the next five years.

However, the market demand for efficient KERS is not without challenges. The complexity and cost of current KERS solutions remain significant barriers to widespread adoption, particularly in price-sensitive market segments. This underscores the need for research and development efforts focused on reducing the mechanical complexity of KERS while maintaining or improving its efficiency.

As the technology matures and becomes more cost-effective, it is anticipated that KERS will find applications in an even broader range of industries and use cases. This includes potential adoption in renewable energy systems, such as wind turbines, where KERS could help smooth out power output fluctuations and improve overall system efficiency.

In the automotive industry, KERS has gained significant traction, especially in high-performance vehicles and motorsports. Formula 1 racing, for instance, has been at the forefront of KERS adoption, showcasing its potential for energy recovery and performance enhancement. This has led to increased interest from mainstream automotive manufacturers looking to incorporate KERS technology into their consumer vehicles.

The commercial vehicle sector has also shown a growing appetite for KERS solutions. Fleet operators are increasingly recognizing the potential of KERS to reduce fuel consumption and operating costs, particularly in urban environments with frequent start-stop cycles. This has created a substantial market opportunity for KERS manufacturers targeting buses, delivery vans, and other commercial vehicles.

Public transportation systems, particularly in densely populated urban areas, represent another significant market for KERS technology. City buses and light rail systems can benefit greatly from the energy recovery capabilities of KERS, leading to reduced energy consumption and lower operational costs for transit authorities.

The industrial sector has also begun to explore the potential of KERS in various applications. Heavy machinery, such as cranes and excavators, can utilize KERS to recover energy from repetitive lifting and lowering operations, thereby improving overall energy efficiency and reducing fuel consumption.

Market analysts project substantial growth in the KERS market over the coming years. Factors contributing to this growth include stringent emissions regulations, increasing focus on sustainability, and the ongoing electrification trend in the transportation sector. The global KERS market is expected to expand at a compound annual growth rate (CAGR) of over 20% in the next five years.

However, the market demand for efficient KERS is not without challenges. The complexity and cost of current KERS solutions remain significant barriers to widespread adoption, particularly in price-sensitive market segments. This underscores the need for research and development efforts focused on reducing the mechanical complexity of KERS while maintaining or improving its efficiency.

As the technology matures and becomes more cost-effective, it is anticipated that KERS will find applications in an even broader range of industries and use cases. This includes potential adoption in renewable energy systems, such as wind turbines, where KERS could help smooth out power output fluctuations and improve overall system efficiency.

KERS Challenges and Limitations

Despite the promising potential of Kinetic Energy Recovery Systems (KERS) in enhancing vehicle efficiency, several challenges and limitations hinder its widespread adoption and optimal performance. One of the primary obstacles is the system's mechanical complexity, which often leads to increased weight and packaging issues within vehicles. This complexity not only raises manufacturing costs but also impacts the overall vehicle dynamics and fuel efficiency gains.

The integration of KERS components, such as flywheels or hydraulic accumulators, into existing vehicle architectures presents significant design challenges. Engineers must carefully balance the space requirements of these systems with other critical vehicle components, often resulting in compromises that may affect performance or practicality. Additionally, the added weight of KERS can partially offset its efficiency benefits, particularly in smaller vehicles where weight considerations are crucial.

Durability and reliability concerns also pose substantial challenges for KERS implementation. The high-speed rotation of flywheels or the frequent pressure changes in hydraulic systems can lead to increased wear and potential failure points. This necessitates robust engineering solutions and high-quality materials, further driving up costs and complexity. Moreover, ensuring consistent performance across varying driving conditions and maintaining system efficiency over the vehicle's lifetime remains a significant technical hurdle.

Another limitation of current KERS technology is its energy storage capacity. While effective for short-term energy recovery and deployment, such as during braking and acceleration events, KERS typically lacks the capacity for long-term energy storage. This limitation restricts its usefulness in scenarios requiring sustained power output or energy conservation over extended periods.

Safety considerations present additional challenges, particularly for flywheel-based systems. The high rotational speeds involved create potential risks in the event of system failure or vehicle collisions. Addressing these safety concerns often requires the implementation of complex containment and fail-safe mechanisms, further adding to the system's complexity and cost.

The control and management of energy flow within KERS systems also present significant technical challenges. Optimizing the timing and magnitude of energy recovery and deployment to maximize efficiency gains requires sophisticated control algorithms and sensors. These systems must seamlessly integrate with existing vehicle control units and adapt to various driving conditions and driver behaviors.

Lastly, the cost-effectiveness of KERS remains a significant barrier to widespread adoption, especially in mass-market vehicles. The additional components and complexity introduced by KERS can substantially increase vehicle production costs, potentially outweighing the fuel efficiency benefits for consumers. This economic challenge necessitates continued research and development to simplify KERS designs and reduce manufacturing costs while maintaining or improving performance.

The integration of KERS components, such as flywheels or hydraulic accumulators, into existing vehicle architectures presents significant design challenges. Engineers must carefully balance the space requirements of these systems with other critical vehicle components, often resulting in compromises that may affect performance or practicality. Additionally, the added weight of KERS can partially offset its efficiency benefits, particularly in smaller vehicles where weight considerations are crucial.

Durability and reliability concerns also pose substantial challenges for KERS implementation. The high-speed rotation of flywheels or the frequent pressure changes in hydraulic systems can lead to increased wear and potential failure points. This necessitates robust engineering solutions and high-quality materials, further driving up costs and complexity. Moreover, ensuring consistent performance across varying driving conditions and maintaining system efficiency over the vehicle's lifetime remains a significant technical hurdle.

Another limitation of current KERS technology is its energy storage capacity. While effective for short-term energy recovery and deployment, such as during braking and acceleration events, KERS typically lacks the capacity for long-term energy storage. This limitation restricts its usefulness in scenarios requiring sustained power output or energy conservation over extended periods.

Safety considerations present additional challenges, particularly for flywheel-based systems. The high rotational speeds involved create potential risks in the event of system failure or vehicle collisions. Addressing these safety concerns often requires the implementation of complex containment and fail-safe mechanisms, further adding to the system's complexity and cost.

The control and management of energy flow within KERS systems also present significant technical challenges. Optimizing the timing and magnitude of energy recovery and deployment to maximize efficiency gains requires sophisticated control algorithms and sensors. These systems must seamlessly integrate with existing vehicle control units and adapt to various driving conditions and driver behaviors.

Lastly, the cost-effectiveness of KERS remains a significant barrier to widespread adoption, especially in mass-market vehicles. The additional components and complexity introduced by KERS can substantially increase vehicle production costs, potentially outweighing the fuel efficiency benefits for consumers. This economic challenge necessitates continued research and development to simplify KERS designs and reduce manufacturing costs while maintaining or improving performance.

Current KERS Simplification Solutions

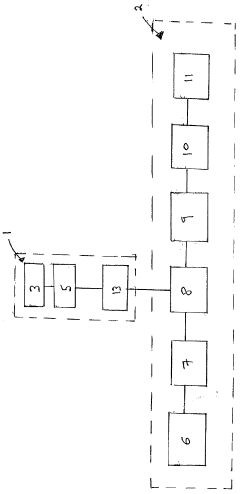

01 Flywheel-based KERS systems

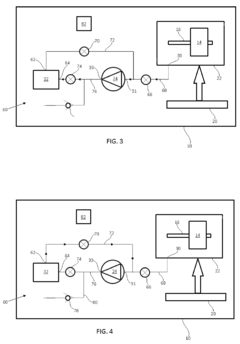

Flywheel-based KERS systems store kinetic energy in a rotating mass. These systems can be mechanically complex due to the need for high-speed bearings, vacuum enclosures, and precise balancing. However, they offer high power density and efficiency compared to other energy storage methods.- Flywheel-based KERS systems: Flywheel-based KERS systems store kinetic energy in a rotating mass. These systems can be mechanically complex due to the need for high-speed bearings, vacuum enclosures, and precise balancing. However, they offer high power density and efficiency compared to other energy storage methods.

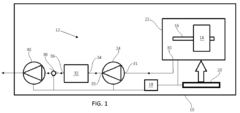

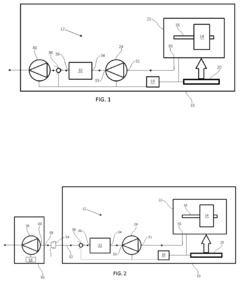

- Hydraulic KERS systems: Hydraulic KERS systems use fluid power to store and release energy. These systems involve pumps, accumulators, and valves, which can add mechanical complexity. However, they can be advantageous in heavy-duty applications due to their robustness and high power density.

- Electric KERS systems: Electric KERS systems use motor-generators and batteries or supercapacitors to store and release energy. While they may have fewer moving parts than mechanical systems, they can still be complex due to power electronics, cooling systems, and battery management. These systems are widely used in hybrid and electric vehicles.

- Integration with transmission systems: KERS integration with vehicle transmissions can increase mechanical complexity but may improve overall system efficiency. This integration can involve clutches, planetary gearsets, and control systems to manage power flow between the KERS, engine, and wheels.

- Mechanical complexity reduction strategies: Various strategies are employed to reduce the mechanical complexity of KERS, including modular designs, simplified power transfer mechanisms, and integrated control systems. These approaches aim to improve reliability, reduce maintenance requirements, and lower manufacturing costs while maintaining system performance.

02 Hydraulic KERS systems

Hydraulic KERS systems use pressurized fluid to store and release energy. While potentially less complex than flywheel systems, they still require specialized components such as high-pressure accumulators, hydraulic motors/pumps, and control valves. These systems can be advantageous in heavy vehicles due to their robustness and power density.Expand Specific Solutions03 Electric KERS systems

Electric KERS systems use motor-generators and batteries or supercapacitors to store and release energy. While electrically complex, they can be mechanically simpler than flywheel or hydraulic systems. However, they may require sophisticated power electronics and thermal management systems to handle high power flows.Expand Specific Solutions04 Hybrid KERS configurations

Hybrid KERS configurations combine multiple energy storage technologies to leverage their respective advantages. These systems can be highly complex, requiring intricate control strategies to manage energy flow between different subsystems. However, they can offer improved performance and efficiency in certain applications.Expand Specific Solutions05 KERS integration and packaging

Integrating KERS into existing vehicle architectures presents significant mechanical challenges. Compact packaging, thermal management, and vibration isolation are crucial considerations. Advanced designs may incorporate the KERS into the vehicle's drivetrain or suspension components to reduce complexity and improve efficiency.Expand Specific Solutions

Key KERS Industry Players

The research on mechanical complexity reduction through advanced KERS is in a developing stage, with the market showing significant growth potential. The technology's maturity varies among key players, with companies like Volvo Lastvagnar AB, Valeo Systèmes de Contrôle Moteur SAS, and Marelli Europe SpA leading in innovation. Punch Flybrid Ltd and Magna PT B.V. & Co. KG are also making strides in KERS development. The competitive landscape is diverse, including automotive giants like Robert Bosch GmbH and Bayerische Motoren Werke AG, alongside specialized firms such as Flybrid Automotive Ltd. This mix of established manufacturers and niche players indicates a dynamic market with opportunities for technological breakthroughs and market expansion.

Valeo Systèmes de Contrôle Moteur SAS

Technical Solution: Valeo has pioneered a compact and efficient KERS solution using a high-speed electric motor-generator coupled with an advanced energy storage system. Their system employs a unique dual-rotor design that allows for rapid energy conversion and storage[5]. The motor-generator can switch between energy recovery and power boost modes in milliseconds, providing seamless operation[6]. Valeo's KERS utilizes advanced power electronics and thermal management systems to ensure high efficiency and reliability. The system can recover up to 70% of braking energy and provide power boosts of up to 60 kW for short durations[7]. Valeo's KERS is particularly suited for hybrid and electric vehicles, offering a lightweight solution that can be easily integrated into various vehicle architectures.

Strengths: Compact design, rapid energy conversion, and high efficiency. Weaknesses: Limited power output compared to some mechanical systems and potential high cost of electrical components.

Marelli Europe SpA

Technical Solution: Marelli has developed a hybrid KERS solution that combines the benefits of both mechanical and electrical systems. Their approach uses a compact flywheel coupled with an electric motor-generator, allowing for flexible energy management[8]. The system employs advanced materials such as carbon fiber for the flywheel to reduce weight and increase energy density. Marelli's KERS features a sophisticated control system that optimizes energy recovery and deployment based on real-time vehicle data and predictive algorithms[9]. The system can recover up to 150 kJ of energy per braking event and provide power boosts of up to 80 kW[10]. Marelli's hybrid KERS is particularly effective in reducing mechanical complexity by integrating multiple functions into a single, compact unit, making it suitable for a wide range of vehicle types, from small city cars to high-performance sports vehicles.

Strengths: Flexible energy management, high power output, and adaptability to various vehicle types. Weaknesses: Potential complexity in system integration and balancing mechanical and electrical components.

Core KERS Complexity Reduction Innovations

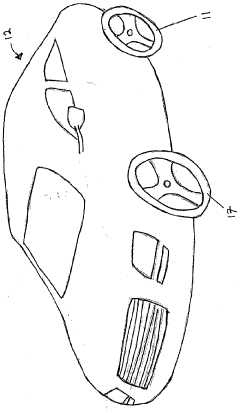

Vehicle kinetic energy recovery system

PatentInactiveGB2477160A

Innovation

- A kinetic energy recovery system utilizing a spare road wheel, which is removably attachable and proportionally sized to the vehicle, allowing it to store and reuse energy without increasing the vehicle's weight or affecting its handling, by being integrated into the existing spare wheel storage location.

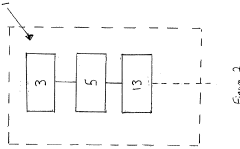

Kinetic energy recovery system

PatentActiveEP3106664A1

Innovation

- A kinetic energy recovery system utilizing a flywheel in a vacuum enclosure with a scroll vacuum pumping arrangement and a secondary vacuum enclosure providing backing pressure, allowing for periodic evacuation to maintain reduced pressures and minimize energy consumption.

KERS Integration Strategies

KERS integration strategies play a crucial role in reducing mechanical complexity while enhancing energy recovery efficiency. One key approach involves modular design principles, which allow for easier integration of KERS components into existing vehicle architectures. This modular approach enables manufacturers to standardize KERS units across different vehicle models, reducing development costs and simplifying maintenance procedures.

Advanced integration techniques focus on optimizing the placement of KERS components within the vehicle's powertrain. By strategically positioning the energy storage system, such as high-performance flywheels or advanced batteries, engineers can minimize the impact on vehicle dynamics and weight distribution. This careful integration helps maintain optimal handling characteristics while maximizing energy recovery potential.

Another important strategy is the development of intelligent control systems that seamlessly coordinate KERS operation with other vehicle systems. These advanced control algorithms optimize energy recovery during braking events, manage power distribution during acceleration, and ensure smooth transitions between conventional and KERS-assisted propulsion modes. By integrating KERS controls with existing vehicle management systems, manufacturers can reduce the need for separate control units, further simplifying the overall system architecture.

Lightweight materials and compact designs are also essential elements of KERS integration strategies. The use of advanced composites and high-strength alloys in KERS components helps reduce overall system weight, mitigating the impact on vehicle performance. Additionally, innovative packaging solutions, such as integrating the KERS motor-generator unit directly into the transmission housing, can significantly reduce the space requirements and complexity of the system.

Standardization efforts across the automotive industry are driving the development of universal KERS interfaces and communication protocols. These initiatives aim to create a more modular and interchangeable approach to KERS integration, allowing for easier adoption across different vehicle platforms and manufacturers. This standardization not only simplifies the integration process but also promotes economies of scale in KERS component production.

Lastly, advanced simulation and modeling tools are being employed to optimize KERS integration strategies before physical prototyping. These virtual development environments allow engineers to evaluate various integration scenarios, predict system performance, and identify potential issues early in the design process. This approach significantly reduces development time and costs while ensuring optimal KERS integration and performance.

Advanced integration techniques focus on optimizing the placement of KERS components within the vehicle's powertrain. By strategically positioning the energy storage system, such as high-performance flywheels or advanced batteries, engineers can minimize the impact on vehicle dynamics and weight distribution. This careful integration helps maintain optimal handling characteristics while maximizing energy recovery potential.

Another important strategy is the development of intelligent control systems that seamlessly coordinate KERS operation with other vehicle systems. These advanced control algorithms optimize energy recovery during braking events, manage power distribution during acceleration, and ensure smooth transitions between conventional and KERS-assisted propulsion modes. By integrating KERS controls with existing vehicle management systems, manufacturers can reduce the need for separate control units, further simplifying the overall system architecture.

Lightweight materials and compact designs are also essential elements of KERS integration strategies. The use of advanced composites and high-strength alloys in KERS components helps reduce overall system weight, mitigating the impact on vehicle performance. Additionally, innovative packaging solutions, such as integrating the KERS motor-generator unit directly into the transmission housing, can significantly reduce the space requirements and complexity of the system.

Standardization efforts across the automotive industry are driving the development of universal KERS interfaces and communication protocols. These initiatives aim to create a more modular and interchangeable approach to KERS integration, allowing for easier adoption across different vehicle platforms and manufacturers. This standardization not only simplifies the integration process but also promotes economies of scale in KERS component production.

Lastly, advanced simulation and modeling tools are being employed to optimize KERS integration strategies before physical prototyping. These virtual development environments allow engineers to evaluate various integration scenarios, predict system performance, and identify potential issues early in the design process. This approach significantly reduces development time and costs while ensuring optimal KERS integration and performance.

Environmental Impact of Advanced KERS

Advanced Kinetic Energy Recovery Systems (KERS) have the potential to significantly reduce the environmental impact of transportation and industrial processes. By capturing and reusing kinetic energy that would otherwise be lost as heat during braking or deceleration, these systems can substantially improve energy efficiency and reduce overall emissions.

One of the primary environmental benefits of advanced KERS is the reduction in fuel consumption and greenhouse gas emissions. In automotive applications, KERS can recover up to 70% of the energy typically lost during braking, leading to fuel savings of 10-25% in urban driving conditions. This translates to a proportional decrease in CO2 emissions, contributing to climate change mitigation efforts.

The environmental impact extends beyond direct emissions reduction. Advanced KERS technologies often utilize lightweight materials and compact designs, reducing the overall weight of vehicles. This weight reduction further enhances fuel efficiency and reduces the environmental footprint associated with material production and transportation.

In industrial settings, KERS can be applied to heavy machinery and manufacturing equipment, recovering energy from repetitive motions and cyclical processes. This not only reduces energy consumption but also minimizes the need for cooling systems, as less heat is generated. Consequently, the overall environmental impact of industrial operations is diminished.

The adoption of advanced KERS also promotes the development and use of renewable energy technologies. The energy storage capabilities of KERS systems can be integrated with renewable energy sources, such as solar and wind power, to smooth out intermittent supply and improve grid stability. This synergy enhances the viability and adoption of clean energy solutions.

Furthermore, the longevity and recyclability of advanced KERS components contribute to reduced waste and resource consumption. Many KERS systems utilize materials that can be easily recycled or repurposed at the end of their lifecycle, aligning with circular economy principles and minimizing the environmental impact of disposal.

However, it is important to consider the potential negative environmental impacts associated with the production and disposal of KERS components, particularly batteries and electronic systems. Proper lifecycle management and responsible sourcing of materials are crucial to maximizing the net positive environmental impact of these technologies.

In conclusion, advanced KERS technologies offer significant potential for reducing the environmental impact of transportation and industrial processes. Through improved energy efficiency, reduced emissions, and synergies with renewable energy systems, these innovations contribute to a more sustainable future. As research continues to focus on mechanical complexity reduction, the environmental benefits of KERS are likely to increase, further solidifying its role in global sustainability efforts.

One of the primary environmental benefits of advanced KERS is the reduction in fuel consumption and greenhouse gas emissions. In automotive applications, KERS can recover up to 70% of the energy typically lost during braking, leading to fuel savings of 10-25% in urban driving conditions. This translates to a proportional decrease in CO2 emissions, contributing to climate change mitigation efforts.

The environmental impact extends beyond direct emissions reduction. Advanced KERS technologies often utilize lightweight materials and compact designs, reducing the overall weight of vehicles. This weight reduction further enhances fuel efficiency and reduces the environmental footprint associated with material production and transportation.

In industrial settings, KERS can be applied to heavy machinery and manufacturing equipment, recovering energy from repetitive motions and cyclical processes. This not only reduces energy consumption but also minimizes the need for cooling systems, as less heat is generated. Consequently, the overall environmental impact of industrial operations is diminished.

The adoption of advanced KERS also promotes the development and use of renewable energy technologies. The energy storage capabilities of KERS systems can be integrated with renewable energy sources, such as solar and wind power, to smooth out intermittent supply and improve grid stability. This synergy enhances the viability and adoption of clean energy solutions.

Furthermore, the longevity and recyclability of advanced KERS components contribute to reduced waste and resource consumption. Many KERS systems utilize materials that can be easily recycled or repurposed at the end of their lifecycle, aligning with circular economy principles and minimizing the environmental impact of disposal.

However, it is important to consider the potential negative environmental impacts associated with the production and disposal of KERS components, particularly batteries and electronic systems. Proper lifecycle management and responsible sourcing of materials are crucial to maximizing the net positive environmental impact of these technologies.

In conclusion, advanced KERS technologies offer significant potential for reducing the environmental impact of transportation and industrial processes. Through improved energy efficiency, reduced emissions, and synergies with renewable energy systems, these innovations contribute to a more sustainable future. As research continues to focus on mechanical complexity reduction, the environmental benefits of KERS are likely to increase, further solidifying its role in global sustainability efforts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!