Dry Coating Methods: Roll-To-Roll Dry Electrode Best Practices

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Roll-To-Roll Dry Electrode Technology Evolution

The evolution of Roll-To-Roll (R2R) dry electrode technology represents a significant paradigm shift in battery manufacturing, moving away from traditional slurry-based wet coating methods toward more environmentally friendly and cost-effective dry coating processes. This technological progression began in the early 2000s with rudimentary powder application techniques that suffered from poor adhesion and uniformity issues.

By 2010, the first generation of commercial dry electrode coating systems emerged, primarily utilizing electrostatic deposition methods. These systems demonstrated the basic feasibility of dry coating but were limited by low throughput and inconsistent electrode quality. The breakthrough came around 2015 when dry polymer binder systems were developed, enabling better particle cohesion without liquid solvents.

The period between 2016-2019 saw significant advancements in dry mixing technologies, where active materials, conductive additives, and binders could be homogeneously blended in precise ratios before deposition. This development addressed previous uniformity challenges and improved electrode performance metrics.

From 2020 onwards, the integration of advanced process monitoring tools, including real-time laser thickness measurement and optical inspection systems, has enabled closed-loop quality control. These innovations have substantially improved coating consistency and reduced defect rates in high-speed production environments.

Recent technological milestones include the development of specialized dry binder systems with activation temperatures compatible with heat-sensitive electrode materials, expanding the range of applicable battery chemistries. Additionally, multi-layer dry deposition techniques have emerged, allowing for gradient electrode structures that optimize both power and energy density characteristics.

The current state-of-the-art R2R dry electrode systems can achieve production speeds approaching 30-50 meters per minute with thickness variations below ±2%, representing performance metrics increasingly competitive with conventional wet processes. Energy consumption analyses indicate up to 70% reduction in manufacturing energy requirements compared to traditional solvent-based methods.

Looking forward, the technology roadmap suggests further integration with Industry 4.0 principles, incorporating AI-driven process optimization and predictive maintenance capabilities. Material innovations focusing on specialized dry binder systems and surface modification techniques are expected to further enhance electrode performance while maintaining the sustainability advantages of solvent-free manufacturing.

By 2010, the first generation of commercial dry electrode coating systems emerged, primarily utilizing electrostatic deposition methods. These systems demonstrated the basic feasibility of dry coating but were limited by low throughput and inconsistent electrode quality. The breakthrough came around 2015 when dry polymer binder systems were developed, enabling better particle cohesion without liquid solvents.

The period between 2016-2019 saw significant advancements in dry mixing technologies, where active materials, conductive additives, and binders could be homogeneously blended in precise ratios before deposition. This development addressed previous uniformity challenges and improved electrode performance metrics.

From 2020 onwards, the integration of advanced process monitoring tools, including real-time laser thickness measurement and optical inspection systems, has enabled closed-loop quality control. These innovations have substantially improved coating consistency and reduced defect rates in high-speed production environments.

Recent technological milestones include the development of specialized dry binder systems with activation temperatures compatible with heat-sensitive electrode materials, expanding the range of applicable battery chemistries. Additionally, multi-layer dry deposition techniques have emerged, allowing for gradient electrode structures that optimize both power and energy density characteristics.

The current state-of-the-art R2R dry electrode systems can achieve production speeds approaching 30-50 meters per minute with thickness variations below ±2%, representing performance metrics increasingly competitive with conventional wet processes. Energy consumption analyses indicate up to 70% reduction in manufacturing energy requirements compared to traditional solvent-based methods.

Looking forward, the technology roadmap suggests further integration with Industry 4.0 principles, incorporating AI-driven process optimization and predictive maintenance capabilities. Material innovations focusing on specialized dry binder systems and surface modification techniques are expected to further enhance electrode performance while maintaining the sustainability advantages of solvent-free manufacturing.

Market Demand for Advanced Battery Manufacturing

The global battery market is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicles (EVs) and renewable energy storage systems. This growth trajectory has created an urgent demand for more efficient, cost-effective battery manufacturing technologies, with dry electrode coating methods emerging as a critical innovation frontier. Market research indicates that the global lithium-ion battery market is projected to reach $129.3 billion by 2027, with a compound annual growth rate exceeding 18% between 2022 and 2027.

Roll-to-roll dry electrode manufacturing represents a paradigm shift from traditional slurry-based processes, offering substantial advantages that align with market demands. The elimination of toxic NMP (N-Methyl-2-pyrrolidone) solvents addresses growing environmental regulations and sustainability requirements across major markets including Europe, North America, and Asia. This alignment with regulatory trends is creating strong market pull for dry coating technologies.

Battery manufacturers are facing intense pressure to reduce production costs while increasing energy density. Dry electrode coating methods directly address these needs by eliminating energy-intensive drying processes, which currently account for approximately 20% of battery production energy consumption. Industry analysis suggests that successful implementation of roll-to-roll dry electrode technologies could reduce manufacturing costs by 10-30% while increasing production throughput by up to 50%.

The EV market's explosive growth is perhaps the strongest driver for advanced battery manufacturing technologies. Major automotive manufacturers have committed over $300 billion to electrification initiatives, creating demand for batteries that exceeds current production capacity. This supply-demand gap is compelling manufacturers to adopt innovative production methods that can scale rapidly while maintaining quality and performance standards.

Energy storage systems for grid applications represent another significant market segment demanding advanced battery manufacturing. As renewable energy integration accelerates globally, the need for high-capacity, cost-effective storage solutions is growing at approximately 25% annually. Dry electrode technologies that can produce batteries with higher energy density and longer cycle life are particularly valuable in this application space.

The market is also increasingly demanding batteries with enhanced sustainability profiles. Dry coating methods reduce environmental impact through elimination of solvent recovery systems, decreased energy consumption, and potential for easier recycling processes. These sustainability benefits are becoming key differentiators as customers and regulators place greater emphasis on full lifecycle environmental impact of battery technologies.

Asian markets, particularly China, South Korea, and Japan, currently dominate battery manufacturing, but significant investments in North America and Europe indicate regional market expansion that will further drive demand for advanced manufacturing technologies like roll-to-roll dry electrode coating methods.

Roll-to-roll dry electrode manufacturing represents a paradigm shift from traditional slurry-based processes, offering substantial advantages that align with market demands. The elimination of toxic NMP (N-Methyl-2-pyrrolidone) solvents addresses growing environmental regulations and sustainability requirements across major markets including Europe, North America, and Asia. This alignment with regulatory trends is creating strong market pull for dry coating technologies.

Battery manufacturers are facing intense pressure to reduce production costs while increasing energy density. Dry electrode coating methods directly address these needs by eliminating energy-intensive drying processes, which currently account for approximately 20% of battery production energy consumption. Industry analysis suggests that successful implementation of roll-to-roll dry electrode technologies could reduce manufacturing costs by 10-30% while increasing production throughput by up to 50%.

The EV market's explosive growth is perhaps the strongest driver for advanced battery manufacturing technologies. Major automotive manufacturers have committed over $300 billion to electrification initiatives, creating demand for batteries that exceeds current production capacity. This supply-demand gap is compelling manufacturers to adopt innovative production methods that can scale rapidly while maintaining quality and performance standards.

Energy storage systems for grid applications represent another significant market segment demanding advanced battery manufacturing. As renewable energy integration accelerates globally, the need for high-capacity, cost-effective storage solutions is growing at approximately 25% annually. Dry electrode technologies that can produce batteries with higher energy density and longer cycle life are particularly valuable in this application space.

The market is also increasingly demanding batteries with enhanced sustainability profiles. Dry coating methods reduce environmental impact through elimination of solvent recovery systems, decreased energy consumption, and potential for easier recycling processes. These sustainability benefits are becoming key differentiators as customers and regulators place greater emphasis on full lifecycle environmental impact of battery technologies.

Asian markets, particularly China, South Korea, and Japan, currently dominate battery manufacturing, but significant investments in North America and Europe indicate regional market expansion that will further drive demand for advanced manufacturing technologies like roll-to-roll dry electrode coating methods.

Technical Challenges in Dry Electrode Coating

Dry electrode coating technology for lithium-ion batteries faces several significant technical challenges that impede its widespread industrial adoption. The primary challenge lies in achieving uniform particle distribution across the electrode surface. Unlike traditional wet coating methods where solvents help disperse active materials evenly, dry coating relies on mechanical forces to distribute particles, often resulting in inhomogeneous distribution that affects battery performance and cycle life.

Adhesion between the electrode material and current collector presents another major hurdle. Wet processes benefit from binders dissolved in solvents that create strong adhesive bonds upon drying. In contrast, dry coating methods must develop alternative binding mechanisms, often requiring precise control of temperature, pressure, and material properties to achieve adequate adhesion without compromising electrical conductivity.

Porosity control remains exceptionally challenging in dry electrode manufacturing. The electrode microstructure significantly impacts electrolyte penetration, ion transport, and ultimately battery performance. Wet processes naturally create porous structures during solvent evaporation, whereas dry methods require sophisticated engineering approaches to generate and maintain optimal pore networks throughout the electrode.

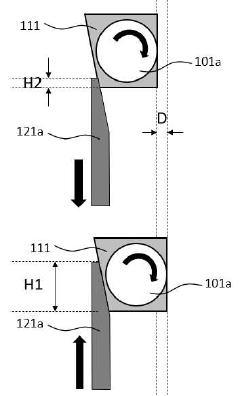

Thickness uniformity across large-area electrodes represents a persistent challenge in roll-to-roll dry coating operations. Even minor variations in thickness can lead to uneven current distribution, localized heating, and accelerated degradation. The absence of liquid-phase processing makes it difficult to self-level the coating, requiring precise mechanical control systems that add complexity to manufacturing equipment.

Scalability issues further complicate industrial implementation. Laboratory-scale dry coating techniques often fail to translate directly to high-throughput production environments. Challenges include maintaining consistent quality at increased speeds, managing heat generation during continuous operation, and developing in-line quality control methods suitable for dry processes.

Material handling complications arise from the cohesive and electrostatic properties of dry powders. Active materials, conductive additives, and binder particles tend to agglomerate or segregate during processing, creating quality inconsistencies. Additionally, fine particles pose health and safety concerns, necessitating sophisticated containment and filtration systems that add cost and complexity.

Process parameter sensitivity represents another significant challenge, as dry coating methods typically have narrower processing windows than their wet counterparts. Small variations in temperature, pressure, or material properties can dramatically affect coating quality, requiring advanced process control systems and extensive optimization efforts to establish robust manufacturing protocols.

Adhesion between the electrode material and current collector presents another major hurdle. Wet processes benefit from binders dissolved in solvents that create strong adhesive bonds upon drying. In contrast, dry coating methods must develop alternative binding mechanisms, often requiring precise control of temperature, pressure, and material properties to achieve adequate adhesion without compromising electrical conductivity.

Porosity control remains exceptionally challenging in dry electrode manufacturing. The electrode microstructure significantly impacts electrolyte penetration, ion transport, and ultimately battery performance. Wet processes naturally create porous structures during solvent evaporation, whereas dry methods require sophisticated engineering approaches to generate and maintain optimal pore networks throughout the electrode.

Thickness uniformity across large-area electrodes represents a persistent challenge in roll-to-roll dry coating operations. Even minor variations in thickness can lead to uneven current distribution, localized heating, and accelerated degradation. The absence of liquid-phase processing makes it difficult to self-level the coating, requiring precise mechanical control systems that add complexity to manufacturing equipment.

Scalability issues further complicate industrial implementation. Laboratory-scale dry coating techniques often fail to translate directly to high-throughput production environments. Challenges include maintaining consistent quality at increased speeds, managing heat generation during continuous operation, and developing in-line quality control methods suitable for dry processes.

Material handling complications arise from the cohesive and electrostatic properties of dry powders. Active materials, conductive additives, and binder particles tend to agglomerate or segregate during processing, creating quality inconsistencies. Additionally, fine particles pose health and safety concerns, necessitating sophisticated containment and filtration systems that add cost and complexity.

Process parameter sensitivity represents another significant challenge, as dry coating methods typically have narrower processing windows than their wet counterparts. Small variations in temperature, pressure, or material properties can dramatically affect coating quality, requiring advanced process control systems and extensive optimization efforts to establish robust manufacturing protocols.

Current Dry Coating Methodologies and Processes

01 Electrostatic dry coating methods for electrode manufacturing

Electrostatic dry coating techniques utilize electric fields to deposit electrode materials onto current collectors in roll-to-roll processes. This method eliminates the need for solvents, reducing environmental impact and processing time. The electrostatic forces ensure uniform particle distribution and strong adhesion to the substrate, improving coating efficiency and electrode performance. This approach is particularly effective for lithium-ion battery electrode manufacturing, offering enhanced energy density and production throughput.- Electrostatic dry coating methods for electrode manufacturing: Electrostatic dry coating techniques utilize electric fields to deposit electrode materials onto substrate surfaces in roll-to-roll processes. This method eliminates the need for solvents, reducing environmental impact and processing time. The charged particles are attracted to the oppositely charged substrate, creating uniform coatings with improved adhesion. This technique allows for precise control of coating thickness and reduces material waste, significantly enhancing manufacturing efficiency for battery electrodes.

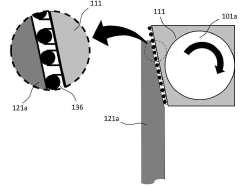

- Powder-based dry coating technologies for electrode fabrication: Powder-based dry coating technologies involve direct application of electrode powder materials onto current collectors without using liquid solvents. These methods include powder spraying, powder pressing, and powder rolling techniques that enable continuous roll-to-roll manufacturing. The elimination of drying steps significantly reduces energy consumption and processing time. These technologies allow for higher material loading capacities and more uniform distribution of active materials, resulting in improved electrode performance and manufacturing efficiency.

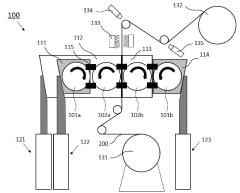

- Advanced roll-to-roll machinery design for dry electrode coating: Specialized machinery designs for roll-to-roll dry electrode coating focus on optimizing the mechanical aspects of the coating process. These designs incorporate precision tension control systems, advanced roller configurations, and specialized coating heads to ensure uniform material distribution. The machinery often features modular designs that allow for quick changeovers between different electrode formulations and thicknesses. Innovations in web handling, alignment systems, and process monitoring capabilities significantly improve coating precision and production throughput.

- Dry coating formulation optimization for enhanced electrode performance: Optimizing dry coating formulations involves careful selection and preparation of active materials, binders, and conductive additives to achieve desired electrode properties without liquid processing. These formulations are specifically engineered for dry application methods, with modified particle size distributions, surface treatments, and binding mechanisms. Dry binder systems that can be activated through heat or pressure are particularly important for ensuring proper adhesion and cohesion within the electrode structure. These optimized formulations enable efficient coating while maintaining or improving the electrochemical performance of the final battery.

- Process monitoring and quality control systems for dry electrode coating: Advanced monitoring and quality control systems are essential for maintaining consistency in roll-to-roll dry electrode coating processes. These systems incorporate real-time measurement technologies such as laser thickness gauges, optical inspection systems, and electrical property sensors to continuously monitor coating quality. Automated feedback control mechanisms adjust process parameters to maintain optimal coating conditions. Data analytics and machine learning algorithms help identify patterns and predict potential defects before they occur, significantly reducing waste and improving overall manufacturing efficiency.

02 Powder-based dry coating technologies for roll-to-roll processing

Powder-based dry coating technologies involve direct application of electrode powder materials onto substrates without liquid media. These methods include powder spraying, powder pressing, and powder deposition techniques that can be integrated into continuous roll-to-roll manufacturing lines. The absence of drying steps significantly increases production efficiency and reduces energy consumption. Advanced powder formulations with optimized particle size distribution and flow properties enhance coating uniformity and adhesion strength, resulting in high-quality electrodes for energy storage applications.Expand Specific Solutions03 Mechanical dry coating and calendering processes

Mechanical dry coating methods employ physical forces such as compression, vibration, or impact to apply and adhere electrode materials to current collectors. These techniques often incorporate calendering processes to control electrode thickness and density. The combination of dry coating and mechanical calendering improves particle-to-particle contact and electrode-substrate adhesion without using binders or solvents. This approach enables precise control over electrode microstructure, porosity, and mechanical properties, leading to enhanced electrochemical performance and manufacturing efficiency.Expand Specific Solutions04 Advanced roll-to-roll equipment design for dry electrode coating

Specialized equipment designs for roll-to-roll dry electrode coating focus on optimizing material handling, deposition uniformity, and process control. These systems incorporate features such as precision tension control, multi-stage coating stations, in-line quality monitoring, and automated material feeding mechanisms. Advanced equipment designs enable continuous high-speed production while maintaining coating quality and thickness uniformity. Integration of real-time process monitoring and feedback control systems further enhances manufacturing efficiency and product consistency.Expand Specific Solutions05 Novel dry electrode formulations and additives for improved coating efficiency

Innovative dry electrode formulations incorporate specialized additives and material modifications to enhance coating efficiency without liquid processing. These formulations may include dry binders, surface-modified active materials, and conductive additives with optimized morphology and surface properties. The careful selection and combination of materials improve powder flowability, adhesion characteristics, and electrode integrity during the dry coating process. These advancements in material science contribute to higher production yields, better electrode performance, and reduced manufacturing costs in roll-to-roll dry electrode manufacturing.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The roll-to-roll dry electrode manufacturing landscape is currently in a transitional phase from early development to commercial scaling, with market size projected to grow significantly as EV battery production expands globally. The technology is approaching maturity with key players demonstrating varying levels of implementation success. Companies like LG Energy Solution, Samsung SDI, and Enevate are leading innovation in silicon-dominant anodes using dry coating methods, while traditional manufacturers such as Toyota Industries and Nissan-AESC are integrating these processes into production lines. Academic-industrial partnerships involving Fraunhofer-Gesellschaft and Dresden University of Technology are accelerating technological refinement. The competitive landscape features both established battery manufacturers and specialized equipment providers like Matthews International, creating a dynamic ecosystem focused on improving energy density, reducing production costs, and enhancing manufacturing sustainability.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has pioneered a comprehensive roll-to-roll dry electrode coating platform called "Z-STREAM" that integrates multiple innovative approaches. Their technology employs a dual-phase mixing system where active materials and conductive additives are first dry-blended in a high-shear mixer, followed by a proprietary polymer binder application process that creates uniform particle coating without solvents. The electrode material is then fed into a specialized electrostatic deposition chamber where controlled electric fields direct the particles onto the current collector substrate with precision. LG's system features adaptive tension control mechanisms that compensate for substrate deformation during coating, ensuring consistent material distribution. The company has implemented real-time laser thickness monitoring that provides feedback to the deposition system, automatically adjusting parameters to maintain coating uniformity. Their calendering subsystem incorporates multi-stage compression with controlled temperature gradients to optimize electrode density while preserving porosity necessary for electrolyte penetration. This integrated approach has enabled LG to achieve electrode production rates up to 40% faster than conventional wet processes.

Strengths: Significantly reduced manufacturing footprint (up to 70% smaller than wet coating facilities), elimination of energy-intensive drying processes, improved electrode microstructure with more uniform particle distribution, and enhanced fast-charging capabilities. Weaknesses: Higher sensitivity to raw material quality variations, more complex process parameter optimization, and challenges with ultra-thin electrode production.

GM Global Technology Operations LLC

Technical Solution: GM Global Technology Operations has developed an advanced roll-to-roll dry electrode coating platform called "UltraDry" specifically optimized for automotive-grade battery production. Their technology employs a proprietary dry powder application process where cathode or anode materials are precisely formulated with minimal binder content (typically 1-3%) and directly deposited onto current collectors through electrostatic attraction. GM's system features a multi-stage particle preparation process that creates optimized size distribution and surface characteristics before deposition. The technology incorporates specialized vibration-assisted deposition that enhances particle distribution uniformity across the substrate width. Their process includes an innovative non-contact pre-consolidation step using controlled electromagnetic fields to stabilize the powder layer before mechanical calendering. GM has implemented an adaptive calendering system with real-time density feedback that automatically adjusts compression parameters to maintain target porosity and adhesion strength. The company's roll-to-roll system operates at speeds up to 20 meters per minute while maintaining coating thickness uniformity within ±5μm. This technology has enabled GM to reduce electrode production costs by approximately 20-25% while improving energy density by eliminating inactive components like excess binders and residual solvents.

Strengths: Elimination of toxic solvents and associated environmental controls, reduced energy consumption by approximately 40-50%, increased production throughput, and improved electrode performance with better ionic conductivity. Weaknesses: Higher initial capital investment for specialized equipment, more complex process control requirements, and challenges with achieving certain specialized electrode formulations.

Key Patents in Roll-To-Roll Dry Electrode Technology

Roll-to-roll dry process for electrodes using rollers with differential line speeds to increase fibrillation of a binder

PatentPendingUS20250226378A1

Innovation

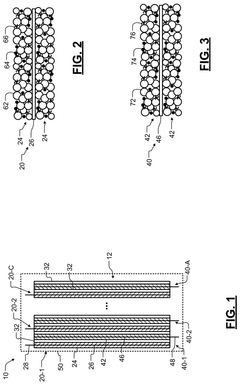

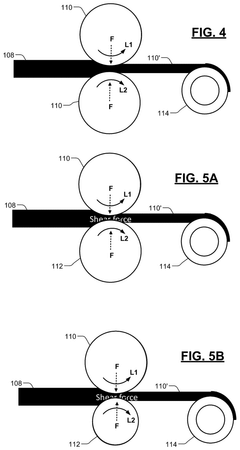

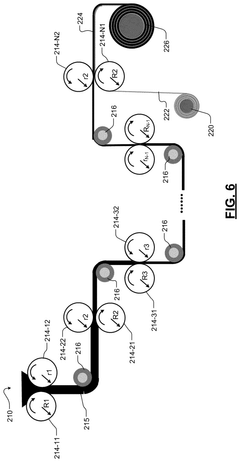

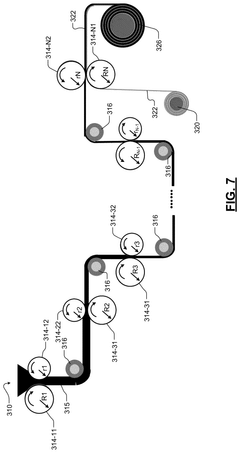

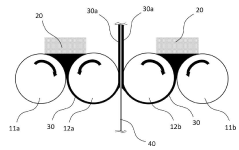

- A roll-to-roll manufacturing process utilizing rollers with differential line speeds and/or diameters to apply both pressing and shear forces to the active material layer, enhancing binder fibrillation and ensuring uniform thickness.

Coating equipment for dry coating of electrode active materials

PatentInactiveKR1020230142043A

Innovation

- A dry coating device with four rollers that are independently controlled using servo presses, allowing precise adjustment of the gaps between them, and incorporating inclined surface blocks and pistons to enhance control and reduce device volume.

Environmental Impact and Sustainability Advantages

Roll-to-roll dry electrode manufacturing represents a significant advancement in sustainable battery production technology. Traditional wet electrode manufacturing processes rely heavily on toxic solvents like N-Methyl-2-pyrrolidone (NMP), which pose substantial environmental and health risks. The elimination of these solvents in dry coating methods delivers immediate environmental benefits through reduced hazardous waste generation and decreased volatile organic compound (VOC) emissions, which contribute to air pollution and climate change.

Energy consumption analysis reveals that dry electrode manufacturing can reduce energy requirements by up to 40-60% compared to conventional methods. This reduction stems primarily from eliminating energy-intensive drying and solvent recovery processes. The environmental impact assessment of roll-to-roll dry coating shows a potential reduction in carbon footprint by approximately 30-50% across the manufacturing lifecycle, representing a significant contribution to climate change mitigation efforts in the rapidly expanding battery industry.

Water conservation represents another critical sustainability advantage of dry electrode manufacturing. While conventional wet processes consume substantial quantities of water for slurry preparation and equipment cleaning, dry coating methods require minimal water input. Quantitative studies indicate water usage reductions of up to 80-90%, a particularly valuable benefit in regions facing water scarcity challenges.

The waste reduction profile of dry electrode manufacturing extends beyond solvent elimination. The precision of dry powder deposition typically results in material utilization improvements of 10-15% compared to wet coating methods. This efficiency translates directly to reduced raw material extraction requirements and decreased solid waste generation, further enhancing the sustainability profile of battery production.

From a lifecycle perspective, batteries produced using dry electrode technologies demonstrate improved environmental performance. The absence of residual solvents contributes to enhanced battery safety and potentially longer service life. End-of-life considerations also favor dry-processed electrodes, as they may facilitate more efficient recycling processes due to the absence of solvent contamination in recovered materials.

Regulatory compliance represents an additional sustainability advantage. As environmental regulations continue to tighten globally, particularly regarding solvent emissions and hazardous waste management, dry electrode manufacturing positions battery producers advantageously for future regulatory frameworks. This proactive alignment with sustainability-focused regulations potentially reduces compliance costs and business continuity risks associated with regulatory changes.

Energy consumption analysis reveals that dry electrode manufacturing can reduce energy requirements by up to 40-60% compared to conventional methods. This reduction stems primarily from eliminating energy-intensive drying and solvent recovery processes. The environmental impact assessment of roll-to-roll dry coating shows a potential reduction in carbon footprint by approximately 30-50% across the manufacturing lifecycle, representing a significant contribution to climate change mitigation efforts in the rapidly expanding battery industry.

Water conservation represents another critical sustainability advantage of dry electrode manufacturing. While conventional wet processes consume substantial quantities of water for slurry preparation and equipment cleaning, dry coating methods require minimal water input. Quantitative studies indicate water usage reductions of up to 80-90%, a particularly valuable benefit in regions facing water scarcity challenges.

The waste reduction profile of dry electrode manufacturing extends beyond solvent elimination. The precision of dry powder deposition typically results in material utilization improvements of 10-15% compared to wet coating methods. This efficiency translates directly to reduced raw material extraction requirements and decreased solid waste generation, further enhancing the sustainability profile of battery production.

From a lifecycle perspective, batteries produced using dry electrode technologies demonstrate improved environmental performance. The absence of residual solvents contributes to enhanced battery safety and potentially longer service life. End-of-life considerations also favor dry-processed electrodes, as they may facilitate more efficient recycling processes due to the absence of solvent contamination in recovered materials.

Regulatory compliance represents an additional sustainability advantage. As environmental regulations continue to tighten globally, particularly regarding solvent emissions and hazardous waste management, dry electrode manufacturing positions battery producers advantageously for future regulatory frameworks. This proactive alignment with sustainability-focused regulations potentially reduces compliance costs and business continuity risks associated with regulatory changes.

Quality Control and Process Optimization Strategies

Quality control and process optimization are critical components for successful implementation of roll-to-roll dry electrode manufacturing. Effective monitoring systems must be established throughout the production line to ensure consistent electrode quality. Real-time monitoring technologies, including laser-based thickness measurements, optical inspection systems, and infrared thermal imaging, provide immediate feedback on coating uniformity, adhesion strength, and potential defects. These systems enable operators to detect anomalies before they propagate through the production process.

Statistical Process Control (SPC) methodologies play a vital role in maintaining process stability. By establishing control limits for critical parameters such as coating weight, porosity, and adhesion strength, manufacturers can identify process drift before it affects product quality. Implementation of Design of Experiments (DOE) approaches helps optimize process parameters by systematically evaluating the impact of variables like web speed, powder composition, and electrostatic field strength on final electrode properties.

Advanced data analytics and machine learning algorithms are increasingly being deployed to identify complex patterns in manufacturing data that may not be apparent through traditional analysis. These tools can predict potential quality issues before they occur by recognizing subtle changes in process parameters or material properties. Predictive maintenance strategies based on equipment performance data help prevent unexpected downtime and ensure consistent production quality.

Material flow optimization represents another critical aspect of process improvement. Careful management of powder handling systems, including precise control of particle size distribution and moisture content, significantly impacts coating uniformity. Implementing closed-loop feedback systems that automatically adjust process parameters based on real-time quality measurements can reduce variability and minimize waste.

Energy efficiency considerations should not be overlooked in process optimization. Dry coating methods typically consume less energy than traditional solvent-based processes, but further optimization can be achieved through careful thermal management and recovery systems. Manufacturers should establish comprehensive validation protocols that include accelerated aging tests, electrochemical performance evaluation, and mechanical durability assessments to ensure that process improvements do not compromise long-term electrode performance.

Cross-functional teams comprising process engineers, materials scientists, and quality specialists should regularly review performance data and implement continuous improvement initiatives. Documentation of best practices and lessons learned creates an institutional knowledge base that accelerates future optimization efforts and supports technology transfer across manufacturing facilities.

Statistical Process Control (SPC) methodologies play a vital role in maintaining process stability. By establishing control limits for critical parameters such as coating weight, porosity, and adhesion strength, manufacturers can identify process drift before it affects product quality. Implementation of Design of Experiments (DOE) approaches helps optimize process parameters by systematically evaluating the impact of variables like web speed, powder composition, and electrostatic field strength on final electrode properties.

Advanced data analytics and machine learning algorithms are increasingly being deployed to identify complex patterns in manufacturing data that may not be apparent through traditional analysis. These tools can predict potential quality issues before they occur by recognizing subtle changes in process parameters or material properties. Predictive maintenance strategies based on equipment performance data help prevent unexpected downtime and ensure consistent production quality.

Material flow optimization represents another critical aspect of process improvement. Careful management of powder handling systems, including precise control of particle size distribution and moisture content, significantly impacts coating uniformity. Implementing closed-loop feedback systems that automatically adjust process parameters based on real-time quality measurements can reduce variability and minimize waste.

Energy efficiency considerations should not be overlooked in process optimization. Dry coating methods typically consume less energy than traditional solvent-based processes, but further optimization can be achieved through careful thermal management and recovery systems. Manufacturers should establish comprehensive validation protocols that include accelerated aging tests, electrochemical performance evaluation, and mechanical durability assessments to ensure that process improvements do not compromise long-term electrode performance.

Cross-functional teams comprising process engineers, materials scientists, and quality specialists should regularly review performance data and implement continuous improvement initiatives. Documentation of best practices and lessons learned creates an institutional knowledge base that accelerates future optimization efforts and supports technology transfer across manufacturing facilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!