Submersible pumps: bridging technological gaps in remote areas.

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Submersible Pump Evolution and Objectives

Submersible pumps have undergone significant evolution since their inception in the early 20th century. Initially designed for dewatering mines and wells, these pumps have transformed into versatile tools capable of addressing diverse water management challenges in remote areas. The technological progression of submersible pumps has been driven by the need for more efficient, reliable, and adaptable solutions in challenging environments.

The primary objective of modern submersible pump technology is to bridge the technological gaps in remote areas, where access to electricity and maintenance resources is often limited. This goal encompasses several key aspects, including energy efficiency, durability, and ease of installation and maintenance. Manufacturers are focusing on developing pumps that can operate effectively in harsh conditions, such as those with high sediment content or extreme temperatures, while minimizing energy consumption and maximizing operational lifespan.

One of the most significant trends in submersible pump evolution is the integration of renewable energy sources, particularly solar power. Solar-powered submersible pumps have emerged as a game-changing solution for remote areas lacking reliable grid connectivity. These systems combine photovoltaic panels with efficient DC motors, enabling water extraction and distribution without the need for fossil fuels or extensive power infrastructure.

Another crucial objective in the development of submersible pumps for remote areas is the implementation of smart technologies. Remote monitoring and control systems allow operators to manage pump performance, diagnose issues, and optimize operations from afar. This reduces the need for frequent on-site maintenance visits, which can be costly and logistically challenging in isolated locations.

Material science advancements have also played a pivotal role in enhancing pump durability and efficiency. The use of corrosion-resistant alloys, advanced polymers, and composite materials has extended pump lifespan and improved performance in aggressive environments. These innovations are particularly crucial for applications in areas with poor water quality or extreme climatic conditions.

The evolution of submersible pump technology is further characterized by a focus on modular design and standardization. This approach aims to simplify installation, maintenance, and part replacement, making it easier for local communities to manage and sustain their water supply systems. Standardized components and plug-and-play designs reduce the need for specialized skills and tools, empowering remote communities to take ownership of their water infrastructure.

Looking ahead, the objectives for submersible pump technology in remote areas include further improvements in energy efficiency, the development of ultra-low-flow pumps for water-scarce regions, and the integration of artificial intelligence for predictive maintenance and optimal resource management. These advancements will continue to bridge the technological gaps, ensuring sustainable access to water resources in even the most challenging and isolated environments.

The primary objective of modern submersible pump technology is to bridge the technological gaps in remote areas, where access to electricity and maintenance resources is often limited. This goal encompasses several key aspects, including energy efficiency, durability, and ease of installation and maintenance. Manufacturers are focusing on developing pumps that can operate effectively in harsh conditions, such as those with high sediment content or extreme temperatures, while minimizing energy consumption and maximizing operational lifespan.

One of the most significant trends in submersible pump evolution is the integration of renewable energy sources, particularly solar power. Solar-powered submersible pumps have emerged as a game-changing solution for remote areas lacking reliable grid connectivity. These systems combine photovoltaic panels with efficient DC motors, enabling water extraction and distribution without the need for fossil fuels or extensive power infrastructure.

Another crucial objective in the development of submersible pumps for remote areas is the implementation of smart technologies. Remote monitoring and control systems allow operators to manage pump performance, diagnose issues, and optimize operations from afar. This reduces the need for frequent on-site maintenance visits, which can be costly and logistically challenging in isolated locations.

Material science advancements have also played a pivotal role in enhancing pump durability and efficiency. The use of corrosion-resistant alloys, advanced polymers, and composite materials has extended pump lifespan and improved performance in aggressive environments. These innovations are particularly crucial for applications in areas with poor water quality or extreme climatic conditions.

The evolution of submersible pump technology is further characterized by a focus on modular design and standardization. This approach aims to simplify installation, maintenance, and part replacement, making it easier for local communities to manage and sustain their water supply systems. Standardized components and plug-and-play designs reduce the need for specialized skills and tools, empowering remote communities to take ownership of their water infrastructure.

Looking ahead, the objectives for submersible pump technology in remote areas include further improvements in energy efficiency, the development of ultra-low-flow pumps for water-scarce regions, and the integration of artificial intelligence for predictive maintenance and optimal resource management. These advancements will continue to bridge the technological gaps, ensuring sustainable access to water resources in even the most challenging and isolated environments.

Remote Area Water Demand Analysis

Remote areas face unique challenges in accessing clean water, making the analysis of water demand crucial for implementing effective solutions. These regions often lack reliable infrastructure and suffer from water scarcity, impacting both human populations and local ecosystems. The demand for water in remote areas is influenced by various factors, including population density, climate conditions, and economic activities.

In many remote locations, the primary water sources are groundwater aquifers, surface water bodies, and rainwater harvesting. The demand for water typically spans domestic use, agriculture, and small-scale industrial activities. Domestic water demand in remote areas is often underestimated due to limited data collection capabilities. However, studies suggest that per capita water consumption in these regions can range from 20 to 50 liters per day, depending on availability and cultural practices.

Agricultural water demand in remote areas is significant, particularly in regions where subsistence farming is prevalent. Irrigation needs vary widely based on crop types, soil conditions, and local climate. In arid and semi-arid remote areas, agriculture can account for up to 80% of total water demand. This high consumption often leads to competition between agricultural and domestic water needs, emphasizing the importance of efficient water management strategies.

Climate change is exacerbating water scarcity in many remote regions, altering precipitation patterns and increasing the frequency of droughts. This shift is driving up water demand for both human consumption and ecosystem maintenance. Additionally, as remote areas develop and populations grow, there is an increasing need for water in small-scale industries and local businesses, further straining limited resources.

The lack of reliable data on water demand in remote areas poses a significant challenge for policymakers and water resource managers. Traditional methods of data collection are often impractical or too costly in these regions. Innovative approaches, such as satellite imagery analysis and community-based monitoring systems, are being explored to improve data accuracy and availability.

Understanding the water demand in remote areas is crucial for designing appropriate water supply systems, including the implementation of submersible pump technologies. Accurate demand analysis helps in sizing pumps correctly, determining optimal well depths, and planning for future capacity needs. It also informs decisions on water storage requirements and distribution network designs, ensuring that water supply solutions are sustainable and meet the long-term needs of remote communities.

In many remote locations, the primary water sources are groundwater aquifers, surface water bodies, and rainwater harvesting. The demand for water typically spans domestic use, agriculture, and small-scale industrial activities. Domestic water demand in remote areas is often underestimated due to limited data collection capabilities. However, studies suggest that per capita water consumption in these regions can range from 20 to 50 liters per day, depending on availability and cultural practices.

Agricultural water demand in remote areas is significant, particularly in regions where subsistence farming is prevalent. Irrigation needs vary widely based on crop types, soil conditions, and local climate. In arid and semi-arid remote areas, agriculture can account for up to 80% of total water demand. This high consumption often leads to competition between agricultural and domestic water needs, emphasizing the importance of efficient water management strategies.

Climate change is exacerbating water scarcity in many remote regions, altering precipitation patterns and increasing the frequency of droughts. This shift is driving up water demand for both human consumption and ecosystem maintenance. Additionally, as remote areas develop and populations grow, there is an increasing need for water in small-scale industries and local businesses, further straining limited resources.

The lack of reliable data on water demand in remote areas poses a significant challenge for policymakers and water resource managers. Traditional methods of data collection are often impractical or too costly in these regions. Innovative approaches, such as satellite imagery analysis and community-based monitoring systems, are being explored to improve data accuracy and availability.

Understanding the water demand in remote areas is crucial for designing appropriate water supply systems, including the implementation of submersible pump technologies. Accurate demand analysis helps in sizing pumps correctly, determining optimal well depths, and planning for future capacity needs. It also informs decisions on water storage requirements and distribution network designs, ensuring that water supply solutions are sustainable and meet the long-term needs of remote communities.

Submersible Pump Challenges in Remote Locations

Submersible pumps face unique challenges in remote areas, primarily due to limited infrastructure, harsh environmental conditions, and lack of technical expertise. These challenges significantly impact the reliability, efficiency, and maintenance of pump systems, hindering their effectiveness in providing essential water supply for various applications.

One of the primary obstacles is the unreliable or non-existent power supply in remote locations. Conventional submersible pumps rely on a stable electrical grid, which is often unavailable in these areas. This necessitates the development of alternative power solutions, such as solar-powered systems or hybrid energy configurations, to ensure consistent pump operation.

Environmental factors pose another set of challenges. Remote areas often experience extreme temperatures, high humidity, or corrosive conditions that can accelerate pump wear and reduce operational lifespan. Additionally, water sources in these regions may contain higher levels of contaminants, sediments, or minerals, which can lead to increased pump clogging, erosion, and overall degradation of pump components.

The lack of skilled technicians and maintenance personnel in remote areas further complicates the situation. Regular maintenance, troubleshooting, and repairs become difficult to perform, leading to extended downtime and reduced system reliability. This challenge is compounded by the limited availability of spare parts and the logistical difficulties in transporting equipment to these isolated locations.

Communication and monitoring present additional hurdles. Remote pump installations often lack real-time monitoring capabilities, making it challenging to detect and respond to issues promptly. This can result in prolonged periods of inefficient operation or complete system failure before problems are identified and addressed.

The economic constraints of remote communities also play a role in the challenges faced by submersible pump systems. The high initial costs of robust, reliable pumps and the ongoing expenses associated with maintenance and repairs can be prohibitive for many remote areas with limited financial resources.

Addressing these challenges requires innovative approaches in pump design, power management, and maintenance strategies. Developing pumps with enhanced durability, self-diagnostic capabilities, and compatibility with renewable energy sources is crucial. Additionally, implementing remote monitoring systems and training local communities in basic maintenance procedures can significantly improve the long-term viability of submersible pump installations in remote areas.

One of the primary obstacles is the unreliable or non-existent power supply in remote locations. Conventional submersible pumps rely on a stable electrical grid, which is often unavailable in these areas. This necessitates the development of alternative power solutions, such as solar-powered systems or hybrid energy configurations, to ensure consistent pump operation.

Environmental factors pose another set of challenges. Remote areas often experience extreme temperatures, high humidity, or corrosive conditions that can accelerate pump wear and reduce operational lifespan. Additionally, water sources in these regions may contain higher levels of contaminants, sediments, or minerals, which can lead to increased pump clogging, erosion, and overall degradation of pump components.

The lack of skilled technicians and maintenance personnel in remote areas further complicates the situation. Regular maintenance, troubleshooting, and repairs become difficult to perform, leading to extended downtime and reduced system reliability. This challenge is compounded by the limited availability of spare parts and the logistical difficulties in transporting equipment to these isolated locations.

Communication and monitoring present additional hurdles. Remote pump installations often lack real-time monitoring capabilities, making it challenging to detect and respond to issues promptly. This can result in prolonged periods of inefficient operation or complete system failure before problems are identified and addressed.

The economic constraints of remote communities also play a role in the challenges faced by submersible pump systems. The high initial costs of robust, reliable pumps and the ongoing expenses associated with maintenance and repairs can be prohibitive for many remote areas with limited financial resources.

Addressing these challenges requires innovative approaches in pump design, power management, and maintenance strategies. Developing pumps with enhanced durability, self-diagnostic capabilities, and compatibility with renewable energy sources is crucial. Additionally, implementing remote monitoring systems and training local communities in basic maintenance procedures can significantly improve the long-term viability of submersible pump installations in remote areas.

Current Remote Area Pump Solutions

01 Design and construction of submersible pumps

This category focuses on the structural aspects and design innovations of submersible pumps. It includes improvements in pump housing, impeller design, and overall construction to enhance efficiency and durability in underwater environments. These advancements aim to optimize pump performance, increase lifespan, and improve reliability in various submersible applications.- Design and construction of submersible pumps: Submersible pumps are designed to operate while fully submerged in liquid. They typically consist of a sealed motor coupled to a pump body, allowing for efficient operation in deep wells or underwater environments. The design focuses on waterproofing, heat dissipation, and durability to withstand harsh conditions.

- Control systems for submersible pumps: Advanced control systems are implemented to optimize the performance of submersible pumps. These systems may include sensors, variable frequency drives, and intelligent algorithms to monitor and adjust pump operation based on factors such as flow rate, pressure, and power consumption. Remote monitoring and control capabilities are often integrated for improved efficiency and maintenance.

- Energy efficiency improvements in submersible pumps: Innovations in submersible pump technology focus on enhancing energy efficiency. This includes the development of high-efficiency motors, optimized impeller designs, and the use of advanced materials to reduce friction and wear. Energy-saving features such as automatic shut-off and variable speed operation are incorporated to minimize power consumption.

- Specialized submersible pumps for specific applications: Submersible pumps are designed for various specialized applications, such as wastewater treatment, oil and gas extraction, and deep-sea exploration. These pumps may incorporate features like corrosion-resistant materials, solids handling capabilities, or high-pressure operation to meet the unique requirements of different industries and environments.

- Maintenance and reliability enhancements for submersible pumps: Innovations in submersible pump technology focus on improving reliability and ease of maintenance. This includes the development of self-diagnostic systems, modular designs for easy component replacement, and the use of wear-resistant materials. Advanced sealing technologies and protective coatings are employed to extend the operational life of pumps in challenging environments.

02 Control systems for submersible pumps

This point covers the development of advanced control systems for submersible pumps. It includes innovations in pump monitoring, automation, and remote operation capabilities. These control systems aim to improve pump efficiency, prevent failures, and enable real-time adjustments based on operating conditions, enhancing overall performance and reliability.Expand Specific Solutions03 Energy efficiency in submersible pumps

This category focuses on improving the energy efficiency of submersible pumps. It includes innovations in motor design, power management systems, and the use of alternative energy sources. These advancements aim to reduce power consumption, minimize operational costs, and enhance the overall sustainability of submersible pump systems.Expand Specific Solutions04 Specialized submersible pumps for specific applications

This point covers the development of submersible pumps tailored for specific industries or applications. It includes pumps designed for oil and gas extraction, wastewater treatment, mining, and other specialized fields. These pumps feature unique characteristics and materials to meet the demands of their intended environments and operational requirements.Expand Specific Solutions05 Maintenance and reliability improvements for submersible pumps

This category focuses on enhancing the maintenance aspects and overall reliability of submersible pumps. It includes innovations in self-diagnostic systems, wear-resistant materials, and easy-to-service designs. These advancements aim to reduce downtime, extend service intervals, and improve the overall lifespan of submersible pump systems.Expand Specific Solutions

Key Manufacturers and Market Landscape

The submersible pump market is in a mature growth phase, with a global market size expected to reach $14.5 billion by 2026. The technology has evolved significantly, bridging gaps in remote areas through improved efficiency and reliability. Key players like Schlumberger, Baker Hughes, and Halliburton dominate the market with advanced solutions. Emerging companies such as Zhejiang Doyin Technology and Guangzhou Xinheng Pump are also making strides in innovation. The industry is characterized by intense competition, driving continuous technological advancements in areas like energy efficiency, remote monitoring, and adaptability to harsh environments. This competitive landscape is fostering rapid improvements in submersible pump technology for remote applications.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has developed advanced submersible pump systems specifically designed for remote and challenging environments. Their REDA Maximus ESP (Electric Submersible Pump) system incorporates innovative features such as a high-efficiency motor, advanced gas-handling capabilities, and remote monitoring technology. The system utilizes a permanent magnet motor that improves efficiency by up to 20% compared to traditional induction motors[1]. Additionally, Schlumberger's Lift IQ production life cycle management service enables real-time monitoring and optimization of pump performance, reducing downtime and improving overall system reliability in remote areas[2].

Strengths: Industry-leading technology, global presence, and extensive R&D capabilities. Weaknesses: High initial costs and potential over-reliance on oil and gas industry.

Flowserve Management Co.

Technical Solution: Flowserve has developed the SUBM submersible pump series, designed for various applications including those in remote areas. The SUBM pumps feature a modular design that allows for easy customization and maintenance, crucial for remote installations. Flowserve's pumps incorporate advanced materials such as duplex stainless steel and super duplex alloys, providing excellent corrosion resistance and extending pump life in harsh environments[5]. Additionally, Flowserve's IPS Wireless Condition Monitoring system enables remote monitoring of pump performance, vibration, and temperature, allowing for predictive maintenance strategies in hard-to-reach locations[6].

Strengths: Modular design for easy maintenance and advanced materials for durability. Weaknesses: May have limited experience in certain extreme remote environments compared to oil and gas specialists.

Innovative Designs for Remote Applications

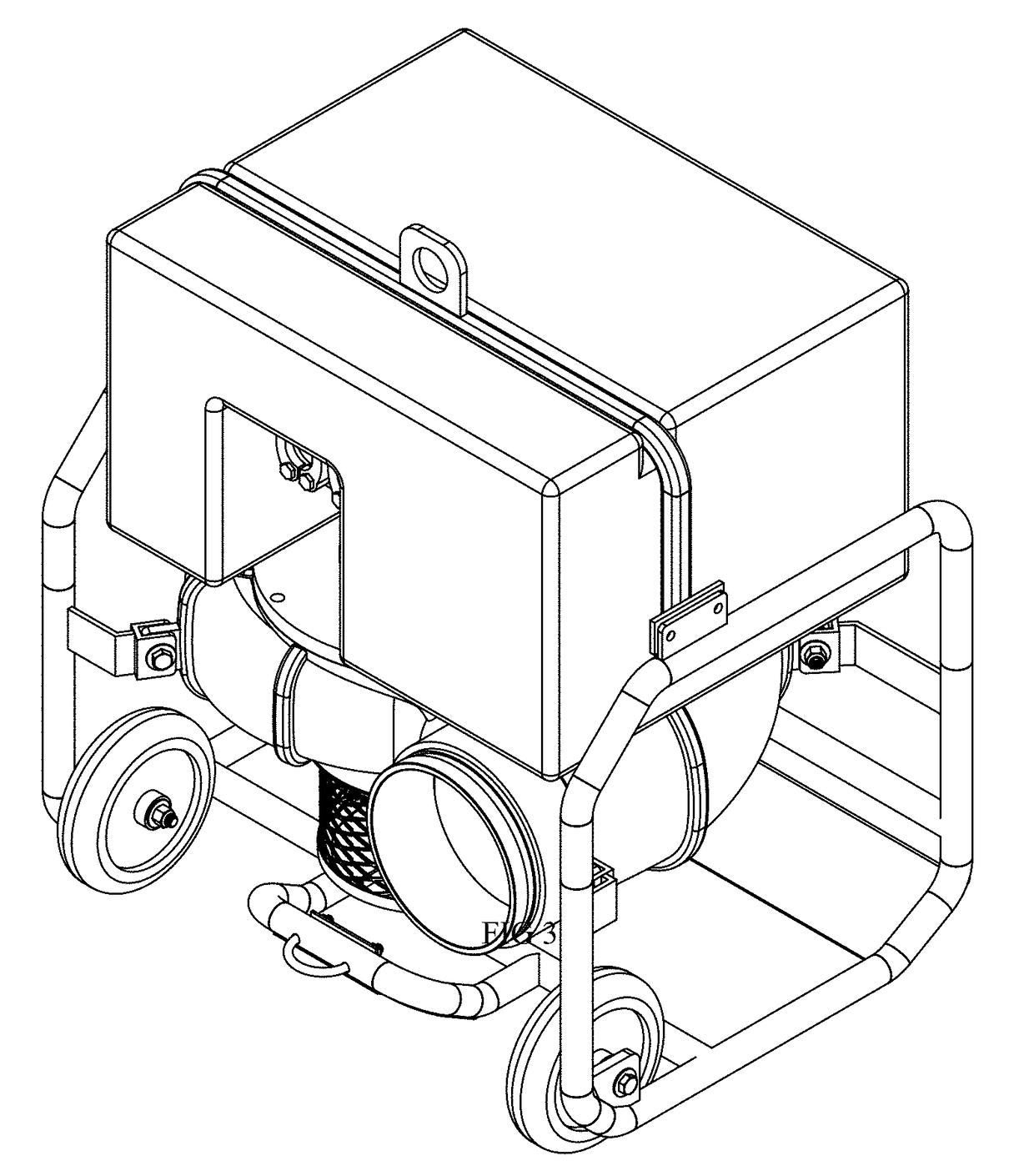

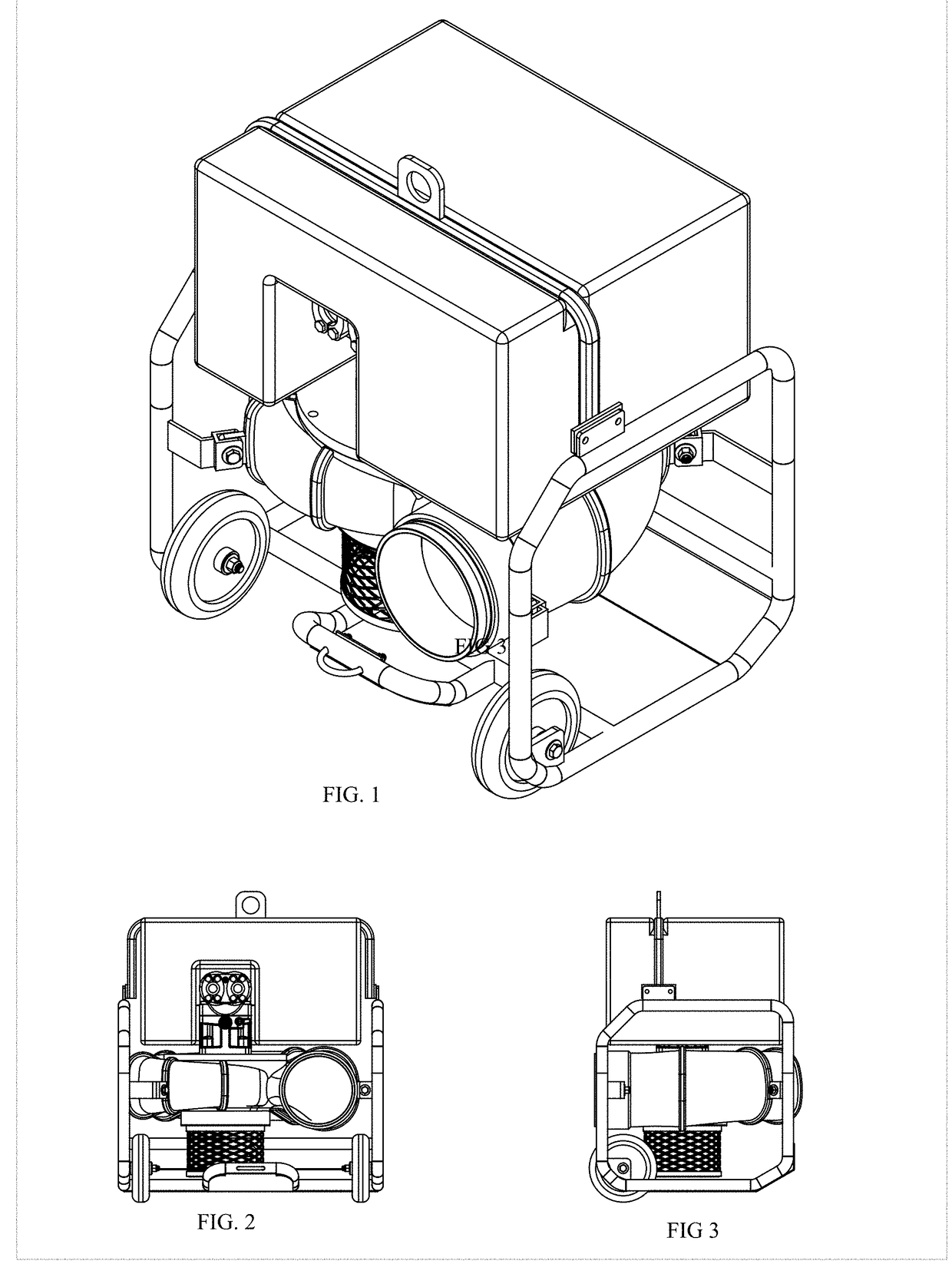

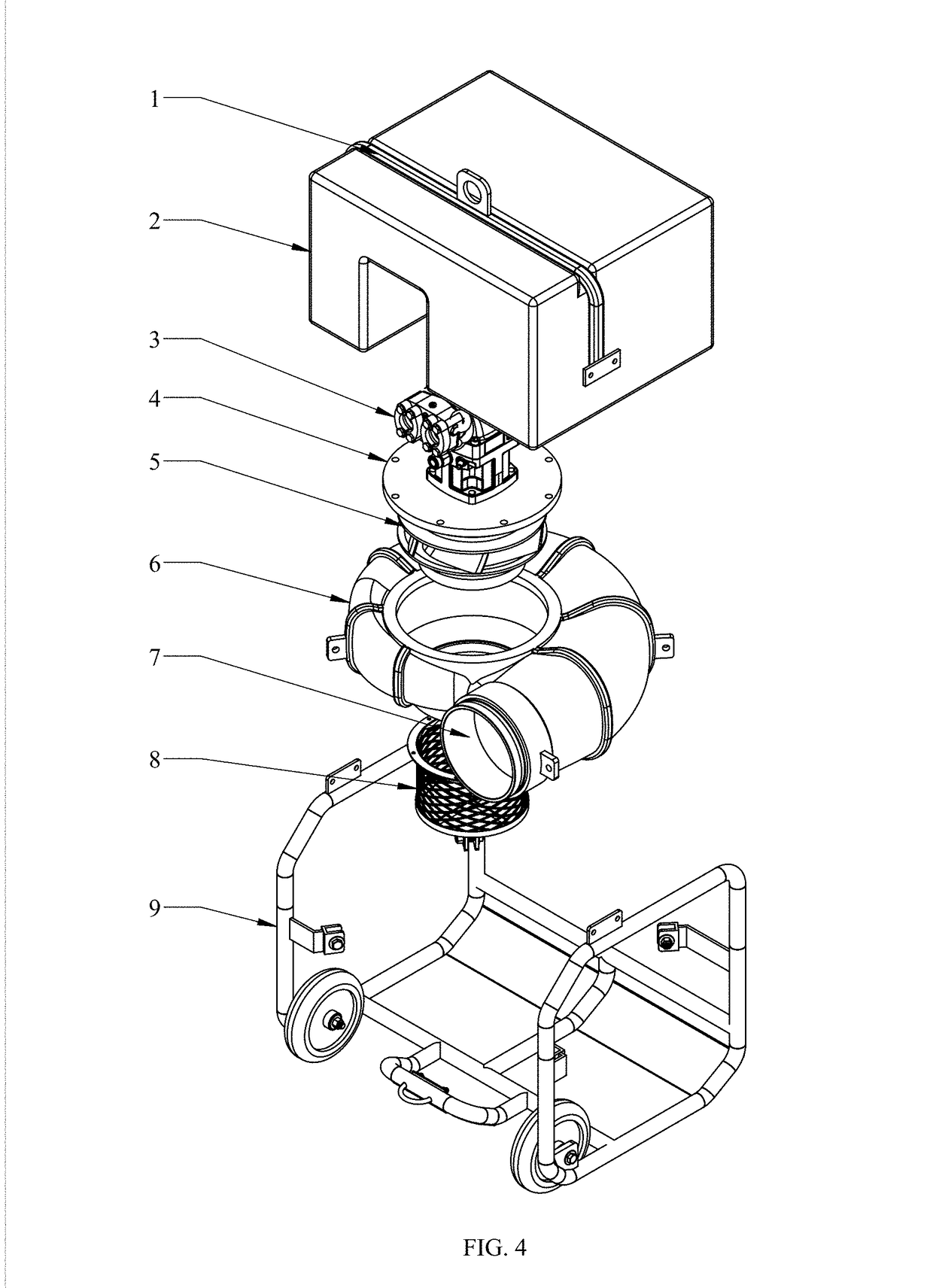

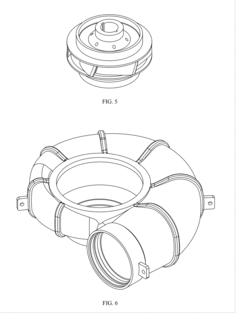

Composite constructed floating submersible water supply pump

PatentInactiveUS20170268522A1

Innovation

- A composite constructed floating submersible water supply pump made from fiber-reinforced thermoset or thermoplastic layers and isotropic fiber-reinforced composite materials, providing a lightweight, corrosion-resistant, and durable solution for high-volume water transfer without the need for heavy equipment.

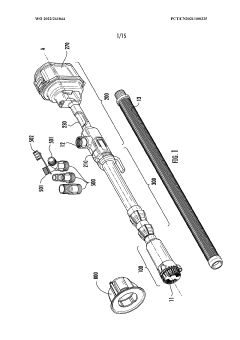

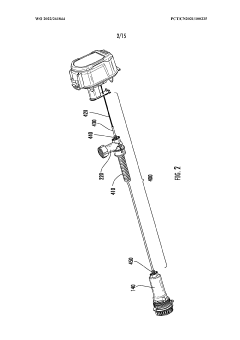

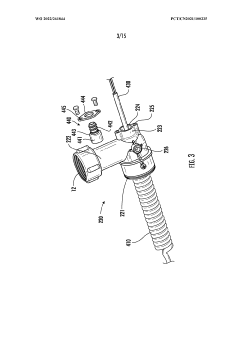

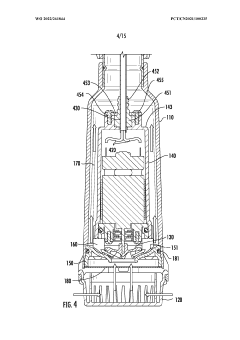

Portable pump with telescopic tubes

PatentWO2022261844A1

Innovation

- The cable assembly is integrated within the adjustable pole assembly, improving safety and reducing environmental exposure.

- The pole assembly's length is adjustable, allowing the pump to reach narrow or deep areas more easily.

- The cable assembly includes a spring-shaped section that adapts to changes in pole length, ensuring consistent power supply.

Environmental Impact Assessment

The environmental impact of submersible pumps in remote areas is a critical consideration for sustainable development. These pumps, while essential for water access, can have both positive and negative effects on local ecosystems. One of the primary benefits is the reduction of surface water depletion, as submersible pumps extract water from deeper aquifers, potentially preserving shallow water sources crucial for local flora and fauna.

However, the installation and operation of submersible pumps can lead to soil disturbance and potential habitat disruption. The construction of well sites and associated infrastructure may result in localized vegetation removal and soil compaction. This can affect local biodiversity and potentially lead to increased erosion in sensitive areas.

Energy consumption is another significant environmental factor. In remote areas, submersible pumps often rely on diesel generators or solar panels for power. While solar-powered systems offer a cleaner alternative, the production and disposal of solar panels present their own environmental challenges. Diesel-powered systems contribute to air pollution and greenhouse gas emissions, impacting both local air quality and global climate change efforts.

Water quality is a key concern in the environmental assessment of submersible pump systems. Improper installation or maintenance can lead to groundwater contamination, potentially introducing pollutants into the water supply. This risk is particularly acute in areas with limited environmental monitoring capabilities.

The extraction of groundwater through submersible pumps can also affect the local hydrological cycle. Overextraction may lead to aquifer depletion, land subsidence, and changes in groundwater flow patterns. These alterations can have far-reaching consequences on surrounding ecosystems, particularly in arid or semi-arid regions where water resources are already scarce.

Noise pollution, though often overlooked, is another environmental concern. The operation of pumps and associated machinery can disrupt local wildlife, potentially affecting breeding patterns and habitat use. This impact is especially significant in remote areas where natural soundscapes are an integral part of the ecosystem.

To mitigate these environmental impacts, careful planning and implementation of best practices are essential. This includes conducting thorough environmental impact assessments before installation, implementing water conservation measures, and adopting renewable energy sources where possible. Regular monitoring of water quality, groundwater levels, and local ecosystems is crucial to detect and address any adverse effects promptly.

In conclusion, while submersible pumps offer significant benefits in bridging technological gaps in remote areas, their environmental impact must be carefully managed. Balancing the need for water access with environmental conservation requires a holistic approach, considering both immediate and long-term ecological consequences.

However, the installation and operation of submersible pumps can lead to soil disturbance and potential habitat disruption. The construction of well sites and associated infrastructure may result in localized vegetation removal and soil compaction. This can affect local biodiversity and potentially lead to increased erosion in sensitive areas.

Energy consumption is another significant environmental factor. In remote areas, submersible pumps often rely on diesel generators or solar panels for power. While solar-powered systems offer a cleaner alternative, the production and disposal of solar panels present their own environmental challenges. Diesel-powered systems contribute to air pollution and greenhouse gas emissions, impacting both local air quality and global climate change efforts.

Water quality is a key concern in the environmental assessment of submersible pump systems. Improper installation or maintenance can lead to groundwater contamination, potentially introducing pollutants into the water supply. This risk is particularly acute in areas with limited environmental monitoring capabilities.

The extraction of groundwater through submersible pumps can also affect the local hydrological cycle. Overextraction may lead to aquifer depletion, land subsidence, and changes in groundwater flow patterns. These alterations can have far-reaching consequences on surrounding ecosystems, particularly in arid or semi-arid regions where water resources are already scarce.

Noise pollution, though often overlooked, is another environmental concern. The operation of pumps and associated machinery can disrupt local wildlife, potentially affecting breeding patterns and habitat use. This impact is especially significant in remote areas where natural soundscapes are an integral part of the ecosystem.

To mitigate these environmental impacts, careful planning and implementation of best practices are essential. This includes conducting thorough environmental impact assessments before installation, implementing water conservation measures, and adopting renewable energy sources where possible. Regular monitoring of water quality, groundwater levels, and local ecosystems is crucial to detect and address any adverse effects promptly.

In conclusion, while submersible pumps offer significant benefits in bridging technological gaps in remote areas, their environmental impact must be carefully managed. Balancing the need for water access with environmental conservation requires a holistic approach, considering both immediate and long-term ecological consequences.

Maintenance Strategies for Remote Installations

Maintenance strategies for remote installations of submersible pumps are crucial for ensuring their longevity and reliability in challenging environments. These strategies must address the unique challenges posed by limited accessibility, harsh conditions, and resource constraints.

Preventive maintenance forms the cornerstone of effective remote pump management. Regular inspections and servicing schedules should be implemented to identify potential issues before they escalate. This approach involves periodic checks of pump components, including impellers, seals, and bearings, as well as monitoring of electrical systems and control panels. Remote monitoring technologies play a vital role in this process, allowing for real-time data collection and analysis of pump performance metrics.

Condition-based maintenance represents an advanced approach, utilizing sensor data and predictive analytics to optimize maintenance timing. By continuously monitoring parameters such as vibration, temperature, and power consumption, operators can detect early signs of wear or malfunction. This strategy reduces unnecessary maintenance interventions while preventing unexpected failures, ultimately extending the pump's operational lifespan.

Redundancy and modular design are essential considerations for remote submersible pump installations. Implementing redundant systems or easily replaceable modular components allows for quick repairs and minimizes downtime. This approach is particularly valuable in areas where extended periods without water supply can have severe consequences for local communities or industries.

Training local technicians is a critical aspect of maintenance strategies for remote areas. Developing a skilled local workforce capable of performing routine maintenance and basic repairs reduces response times and reliance on external specialists. This approach not only improves pump reliability but also contributes to community empowerment and sustainable development.

Remote diagnostics and troubleshooting capabilities are increasingly important in maintenance strategies. Advanced communication technologies enable off-site experts to guide local personnel through complex repair procedures, reducing the need for costly site visits. Additionally, the use of augmented reality tools can provide real-time visual assistance, enhancing the effectiveness of remote support.

Inventory management and spare parts logistics pose significant challenges in remote areas. Developing robust supply chains and maintaining strategic parts inventories are crucial for timely repairs. Innovative approaches, such as 3D printing of certain components on-site, may offer solutions to reduce lead times and inventory costs.

In conclusion, effective maintenance strategies for remote submersible pump installations require a multifaceted approach. By combining preventive and condition-based maintenance, leveraging remote monitoring technologies, implementing redundant systems, training local technicians, utilizing remote diagnostics, and optimizing spare parts management, operators can significantly enhance the reliability and longevity of these critical water supply systems in challenging remote environments.

Preventive maintenance forms the cornerstone of effective remote pump management. Regular inspections and servicing schedules should be implemented to identify potential issues before they escalate. This approach involves periodic checks of pump components, including impellers, seals, and bearings, as well as monitoring of electrical systems and control panels. Remote monitoring technologies play a vital role in this process, allowing for real-time data collection and analysis of pump performance metrics.

Condition-based maintenance represents an advanced approach, utilizing sensor data and predictive analytics to optimize maintenance timing. By continuously monitoring parameters such as vibration, temperature, and power consumption, operators can detect early signs of wear or malfunction. This strategy reduces unnecessary maintenance interventions while preventing unexpected failures, ultimately extending the pump's operational lifespan.

Redundancy and modular design are essential considerations for remote submersible pump installations. Implementing redundant systems or easily replaceable modular components allows for quick repairs and minimizes downtime. This approach is particularly valuable in areas where extended periods without water supply can have severe consequences for local communities or industries.

Training local technicians is a critical aspect of maintenance strategies for remote areas. Developing a skilled local workforce capable of performing routine maintenance and basic repairs reduces response times and reliance on external specialists. This approach not only improves pump reliability but also contributes to community empowerment and sustainable development.

Remote diagnostics and troubleshooting capabilities are increasingly important in maintenance strategies. Advanced communication technologies enable off-site experts to guide local personnel through complex repair procedures, reducing the need for costly site visits. Additionally, the use of augmented reality tools can provide real-time visual assistance, enhancing the effectiveness of remote support.

Inventory management and spare parts logistics pose significant challenges in remote areas. Developing robust supply chains and maintaining strategic parts inventories are crucial for timely repairs. Innovative approaches, such as 3D printing of certain components on-site, may offer solutions to reduce lead times and inventory costs.

In conclusion, effective maintenance strategies for remote submersible pump installations require a multifaceted approach. By combining preventive and condition-based maintenance, leveraging remote monitoring technologies, implementing redundant systems, training local technicians, utilizing remote diagnostics, and optimizing spare parts management, operators can significantly enhance the reliability and longevity of these critical water supply systems in challenging remote environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!