The future of EREV in global logistics chains

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EREV Technology Evolution

Extended Range Electric Vehicles (EREVs) have undergone significant technological evolution since their inception, marking key milestones in the advancement of sustainable transportation solutions for global logistics chains. The journey of EREV technology can be traced through several distinct phases, each characterized by notable improvements in performance, efficiency, and practicality.

In the early stages of EREV development, the focus was primarily on proving the concept and addressing fundamental challenges such as limited electric range and high battery costs. These initial models demonstrated the potential of combining electric and combustion powertrains but were often hampered by weight issues and complex control systems.

As battery technology progressed, the second generation of EREVs saw substantial improvements in electric range and overall efficiency. This phase was marked by the integration of more advanced lithium-ion batteries, which offered higher energy density and faster charging capabilities. Concurrently, powertrain management systems became more sophisticated, optimizing the interplay between electric and combustion modes.

The third phase of EREV evolution brought about a paradigm shift in design philosophy. Engineers began to approach EREVs as purpose-built vehicles rather than adaptations of existing models. This led to the development of dedicated EREV platforms, which allowed for better weight distribution, improved aerodynamics, and more efficient packaging of components.

Recent advancements have ushered in the current generation of EREVs, characterized by significantly extended electric ranges, fast-charging capabilities, and enhanced connectivity features. The integration of artificial intelligence and machine learning algorithms has further optimized energy management, predictive maintenance, and route planning, making EREVs increasingly attractive for long-haul logistics operations.

Looking ahead, the future evolution of EREV technology is poised to address several key areas. One major focus is the development of even more energy-dense batteries, potentially incorporating solid-state technology, which could dramatically increase range while reducing weight and charging times. Another area of innovation is the improvement of regenerative braking systems, aiming to recover a higher percentage of kinetic energy during deceleration.

Additionally, the integration of advanced driver assistance systems (ADAS) and autonomous driving capabilities is expected to play a crucial role in the next generation of EREVs. These technologies have the potential to further optimize energy usage, enhance safety, and improve overall operational efficiency in logistics chains.

As environmental regulations become more stringent globally, EREV technology is also evolving to meet and exceed emission standards. This includes the development of cleaner range extenders, potentially utilizing hydrogen fuel cells or advanced biofuels, to further reduce the carbon footprint of these vehicles when operating in hybrid mode.

In the early stages of EREV development, the focus was primarily on proving the concept and addressing fundamental challenges such as limited electric range and high battery costs. These initial models demonstrated the potential of combining electric and combustion powertrains but were often hampered by weight issues and complex control systems.

As battery technology progressed, the second generation of EREVs saw substantial improvements in electric range and overall efficiency. This phase was marked by the integration of more advanced lithium-ion batteries, which offered higher energy density and faster charging capabilities. Concurrently, powertrain management systems became more sophisticated, optimizing the interplay between electric and combustion modes.

The third phase of EREV evolution brought about a paradigm shift in design philosophy. Engineers began to approach EREVs as purpose-built vehicles rather than adaptations of existing models. This led to the development of dedicated EREV platforms, which allowed for better weight distribution, improved aerodynamics, and more efficient packaging of components.

Recent advancements have ushered in the current generation of EREVs, characterized by significantly extended electric ranges, fast-charging capabilities, and enhanced connectivity features. The integration of artificial intelligence and machine learning algorithms has further optimized energy management, predictive maintenance, and route planning, making EREVs increasingly attractive for long-haul logistics operations.

Looking ahead, the future evolution of EREV technology is poised to address several key areas. One major focus is the development of even more energy-dense batteries, potentially incorporating solid-state technology, which could dramatically increase range while reducing weight and charging times. Another area of innovation is the improvement of regenerative braking systems, aiming to recover a higher percentage of kinetic energy during deceleration.

Additionally, the integration of advanced driver assistance systems (ADAS) and autonomous driving capabilities is expected to play a crucial role in the next generation of EREVs. These technologies have the potential to further optimize energy usage, enhance safety, and improve overall operational efficiency in logistics chains.

As environmental regulations become more stringent globally, EREV technology is also evolving to meet and exceed emission standards. This includes the development of cleaner range extenders, potentially utilizing hydrogen fuel cells or advanced biofuels, to further reduce the carbon footprint of these vehicles when operating in hybrid mode.

Global Logistics Market Needs

The global logistics market is experiencing a significant shift towards sustainable and efficient transportation solutions, driven by increasing environmental concerns and the need for cost-effective operations. Extended Range Electric Vehicles (EREVs) are emerging as a promising technology to address these market needs, particularly in the context of long-haul transportation and last-mile delivery services.

The demand for EREVs in global logistics chains is primarily fueled by the growing emphasis on reducing carbon emissions and meeting stringent environmental regulations. Many countries and regions have set ambitious targets for reducing greenhouse gas emissions, putting pressure on logistics companies to adopt cleaner transportation technologies. EREVs offer a viable solution by combining the benefits of electric propulsion with the extended range capabilities of conventional vehicles, making them suitable for various logistics applications.

In the e-commerce sector, which has seen exponential growth in recent years, there is a rising need for efficient and environmentally friendly delivery vehicles. EREVs can meet this demand by providing zero-emission operations in urban areas while maintaining the flexibility to cover longer distances when needed. This dual capability is particularly valuable for logistics companies that need to navigate both congested city centers and suburban or rural areas.

The global logistics market is also witnessing a trend towards optimizing operational costs. EREVs can contribute to this goal by reducing fuel consumption and maintenance costs compared to traditional internal combustion engine vehicles. While the initial investment in EREV technology may be higher, the long-term operational savings and potential government incentives make them an attractive option for logistics fleet operators.

Another key market need that EREVs address is the requirement for reliable and consistent performance across diverse geographical and climatic conditions. Global logistics chains often span multiple countries and regions, necessitating vehicles that can operate efficiently in various environments. EREVs, with their hybrid powertrain systems, can adapt to different terrains and weather conditions more effectively than pure electric vehicles, ensuring uninterrupted logistics operations.

The increasing focus on supply chain resilience and flexibility in the wake of global disruptions has also created a demand for versatile transportation solutions. EREVs can play a crucial role in this context by offering the ability to switch between electric and conventional power sources, providing logistics companies with greater operational flexibility and reducing their vulnerability to fuel supply disruptions.

As the global logistics market continues to evolve, there is a growing need for data-driven and connected transportation solutions. EREVs, equipped with advanced telematics and IoT capabilities, can meet this demand by providing real-time data on vehicle performance, route optimization, and energy consumption. This integration of technology aligns with the broader trend of digitalization in the logistics industry, enabling more efficient fleet management and improved decision-making.

The demand for EREVs in global logistics chains is primarily fueled by the growing emphasis on reducing carbon emissions and meeting stringent environmental regulations. Many countries and regions have set ambitious targets for reducing greenhouse gas emissions, putting pressure on logistics companies to adopt cleaner transportation technologies. EREVs offer a viable solution by combining the benefits of electric propulsion with the extended range capabilities of conventional vehicles, making them suitable for various logistics applications.

In the e-commerce sector, which has seen exponential growth in recent years, there is a rising need for efficient and environmentally friendly delivery vehicles. EREVs can meet this demand by providing zero-emission operations in urban areas while maintaining the flexibility to cover longer distances when needed. This dual capability is particularly valuable for logistics companies that need to navigate both congested city centers and suburban or rural areas.

The global logistics market is also witnessing a trend towards optimizing operational costs. EREVs can contribute to this goal by reducing fuel consumption and maintenance costs compared to traditional internal combustion engine vehicles. While the initial investment in EREV technology may be higher, the long-term operational savings and potential government incentives make them an attractive option for logistics fleet operators.

Another key market need that EREVs address is the requirement for reliable and consistent performance across diverse geographical and climatic conditions. Global logistics chains often span multiple countries and regions, necessitating vehicles that can operate efficiently in various environments. EREVs, with their hybrid powertrain systems, can adapt to different terrains and weather conditions more effectively than pure electric vehicles, ensuring uninterrupted logistics operations.

The increasing focus on supply chain resilience and flexibility in the wake of global disruptions has also created a demand for versatile transportation solutions. EREVs can play a crucial role in this context by offering the ability to switch between electric and conventional power sources, providing logistics companies with greater operational flexibility and reducing their vulnerability to fuel supply disruptions.

As the global logistics market continues to evolve, there is a growing need for data-driven and connected transportation solutions. EREVs, equipped with advanced telematics and IoT capabilities, can meet this demand by providing real-time data on vehicle performance, route optimization, and energy consumption. This integration of technology aligns with the broader trend of digitalization in the logistics industry, enabling more efficient fleet management and improved decision-making.

EREV Challenges in Logistics

Extended Range Electric Vehicles (EREVs) face several significant challenges in the context of global logistics chains. One of the primary obstacles is the limited range of these vehicles compared to traditional diesel-powered trucks. While EREVs offer improved fuel efficiency and reduced emissions, their battery capacity often falls short of the long-distance requirements typical in logistics operations. This limitation necessitates frequent charging stops, potentially disrupting tight delivery schedules and increasing overall transit times.

Infrastructure development poses another substantial challenge for EREV adoption in logistics. The current charging network is inadequate to support widespread use of EREVs, particularly along major transportation corridors and at logistics hubs. The lack of fast-charging stations capable of rapidly replenishing EREV batteries creates bottlenecks in the supply chain, hindering the seamless integration of these vehicles into existing logistics operations.

The high initial cost of EREVs compared to conventional vehicles presents a significant barrier to adoption for many logistics companies. While the long-term operational costs may be lower due to reduced fuel consumption and maintenance requirements, the upfront investment can be prohibitive, especially for smaller operators with limited capital. This financial hurdle slows the transition to more sustainable transportation solutions within the logistics sector.

Payload capacity is another critical challenge for EREVs in logistics applications. The weight of the battery packs necessary for extended range operation can significantly reduce the available payload capacity of the vehicle. This limitation may require more trips or larger fleets to transport the same volume of goods, potentially offsetting some of the environmental benefits and cost savings associated with EREV technology.

The reliability and durability of EREVs in demanding logistics environments remain concerns for fleet operators. The complex electrical systems and battery technologies used in these vehicles may be more susceptible to wear and tear under heavy-duty use, potentially leading to increased downtime and maintenance costs. This uncertainty about long-term performance and reliability can deter logistics companies from making substantial investments in EREV fleets.

Lastly, the integration of EREVs into existing fleet management systems and logistics software presents technological challenges. These vehicles require specialized monitoring and optimization tools to manage battery life, plan efficient routes considering charging needs, and coordinate with charging infrastructure. Developing and implementing these systems across global logistics chains requires significant investment in software development and training.

Infrastructure development poses another substantial challenge for EREV adoption in logistics. The current charging network is inadequate to support widespread use of EREVs, particularly along major transportation corridors and at logistics hubs. The lack of fast-charging stations capable of rapidly replenishing EREV batteries creates bottlenecks in the supply chain, hindering the seamless integration of these vehicles into existing logistics operations.

The high initial cost of EREVs compared to conventional vehicles presents a significant barrier to adoption for many logistics companies. While the long-term operational costs may be lower due to reduced fuel consumption and maintenance requirements, the upfront investment can be prohibitive, especially for smaller operators with limited capital. This financial hurdle slows the transition to more sustainable transportation solutions within the logistics sector.

Payload capacity is another critical challenge for EREVs in logistics applications. The weight of the battery packs necessary for extended range operation can significantly reduce the available payload capacity of the vehicle. This limitation may require more trips or larger fleets to transport the same volume of goods, potentially offsetting some of the environmental benefits and cost savings associated with EREV technology.

The reliability and durability of EREVs in demanding logistics environments remain concerns for fleet operators. The complex electrical systems and battery technologies used in these vehicles may be more susceptible to wear and tear under heavy-duty use, potentially leading to increased downtime and maintenance costs. This uncertainty about long-term performance and reliability can deter logistics companies from making substantial investments in EREV fleets.

Lastly, the integration of EREVs into existing fleet management systems and logistics software presents technological challenges. These vehicles require specialized monitoring and optimization tools to manage battery life, plan efficient routes considering charging needs, and coordinate with charging infrastructure. Developing and implementing these systems across global logistics chains requires significant investment in software development and training.

Current EREV Solutions

01 Powertrain configuration for EREV

Extended Range Electric Vehicles (EREVs) utilize a unique powertrain configuration that combines an electric motor with an internal combustion engine. The electric motor serves as the primary power source, while the internal combustion engine acts as a range extender, generating electricity to charge the battery when needed. This configuration allows for increased driving range compared to pure electric vehicles.- Powertrain configuration for EREV: Extended Range Electric Vehicles (EREVs) utilize a unique powertrain configuration that combines an electric motor with an internal combustion engine. The electric motor serves as the primary power source, while the internal combustion engine acts as a range extender, generating electricity to charge the battery when needed. This configuration allows for increased driving range compared to pure electric vehicles.

- Battery management systems for EREV: Advanced battery management systems are crucial for optimizing the performance and efficiency of EREVs. These systems monitor and control battery charging, discharging, and overall health. They also manage power distribution between the electric motor and range extender, ensuring optimal energy usage and extending battery life.

- Range extender technologies: EREVs employ various range extender technologies to supplement the electric powertrain. These may include small, efficient internal combustion engines, fuel cells, or other alternative power sources. The range extender is designed to operate at its most efficient point, generating electricity to charge the battery or power the electric motor directly when needed.

- Energy recovery and regenerative braking: EREVs incorporate advanced energy recovery systems, including regenerative braking. These systems capture kinetic energy during deceleration and braking, converting it into electrical energy to recharge the battery. This technology helps to extend the vehicle's electric range and improve overall efficiency.

- Intelligent control systems for EREV: Sophisticated control systems are employed in EREVs to manage the interaction between the electric powertrain and range extender. These systems use advanced algorithms and real-time data to optimize power distribution, predict energy needs, and seamlessly switch between electric and range-extended modes. This intelligent control enhances overall vehicle performance, efficiency, and driving experience.

02 Battery management systems for EREV

Advanced battery management systems are crucial for optimizing the performance and efficiency of EREVs. These systems monitor and control battery charging, discharging, and overall health. They also manage the interaction between the battery, electric motor, and range extender to ensure optimal energy usage and extend battery life.Expand Specific Solutions03 Range extender technologies

EREVs employ various range extender technologies to supplement the electric powertrain. These may include small, efficient internal combustion engines, fuel cells, or other alternative power sources. The range extender is designed to operate at its most efficient point, generating electricity to charge the battery or power the electric motor directly when needed.Expand Specific Solutions04 Energy management and control strategies

Sophisticated energy management and control strategies are implemented in EREVs to optimize the use of electric and range extender power sources. These strategies determine when to engage the range extender, how to distribute power between the electric motor and range extender, and how to manage regenerative braking to maximize overall efficiency and driving range.Expand Specific Solutions05 Charging infrastructure for EREV

EREVs require specialized charging infrastructure to support their dual power sources. This includes high-power charging stations for rapid battery charging, as well as conventional fuel stations for the range extender. The charging system may also incorporate smart charging technologies to optimize charging times and reduce strain on the electrical grid.Expand Specific Solutions

Key EREV Manufacturers

The global logistics industry is witnessing a significant shift towards Extended Range Electric Vehicles (EREVs) as a sustainable transportation solution. This market is in its early growth stage, with increasing adoption driven by environmental regulations and cost-efficiency demands. The global EREV market size is projected to expand rapidly, with estimates suggesting substantial growth in the coming years. Technologically, EREVs are advancing quickly, with major players like GM Global Technology Operations LLC, Ford Global Technologies LLC, and Cummins, Inc. leading innovation. These companies are investing heavily in R&D to improve battery technology, range extension, and overall vehicle efficiency. As the technology matures, we can expect increased competition and market penetration, potentially reshaping global logistics chains.

GM Global Technology Operations LLC

Technical Solution: GM's approach to EREV (Extended Range Electric Vehicles) in global logistics chains focuses on their Ultium platform, which offers flexible battery and drive unit options. For logistics applications, GM is developing EREVs with larger battery packs and more efficient range extenders. Their system can provide up to 400 miles of range, with the first 40-60 miles on pure electric power[1]. GM is also working on integrating their EREV technology with smart charging infrastructure to optimize energy usage in logistics hubs[2]. The company is exploring the use of hydrogen fuel cells as range extenders for longer-haul logistics applications, potentially offering zero-emission solutions for extended routes[3].

Strengths: Flexible Ultium platform allows for customization to specific logistics needs. Integration with smart charging infrastructure optimizes energy usage. Weaknesses: Limited real-world data on long-term performance in logistics applications. Higher initial cost compared to traditional ICE vehicles.

Ford Global Technologies LLC

Technical Solution: Ford's EREV strategy for global logistics chains centers on their PowerBoost hybrid technology, which they are adapting for commercial vehicles. Their system combines a high-capacity battery with a fuel-efficient gasoline engine, providing an all-electric range of up to 30 miles before switching to hybrid mode[4]. Ford is developing larger battery options specifically for logistics applications, aiming to increase the all-electric range to 50-60 miles. The company is also investing in predictive energy management systems that optimize the use of electric and gasoline power based on route characteristics and load weight[5]. Ford is collaborating with major logistics companies to pilot test their EREV technology in real-world scenarios, gathering data to improve efficiency and reliability[6].

Strengths: Proven PowerBoost technology adaptable to various vehicle sizes. Predictive energy management system optimizes power usage. Weaknesses: Currently limited all-electric range compared to some competitors. Dependency on gasoline for extended range may not meet future zero-emission regulations in some regions.

EREV Innovations Analysis

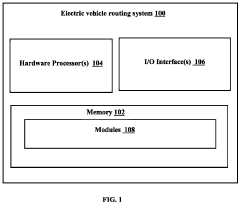

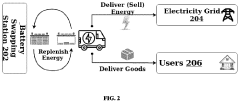

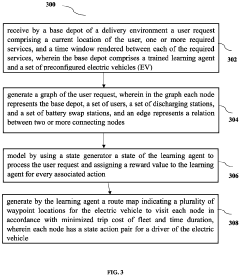

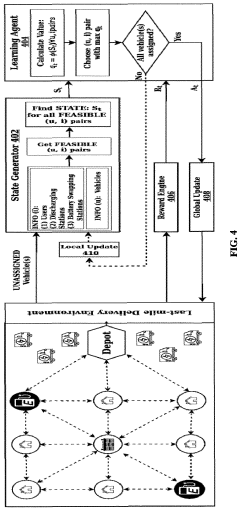

Method and system of electric vehicle route planning for multi-service delivery and on-route energy replenishment

PatentActiveEP4371808A1

Innovation

- A system utilizing a trained learning agent to generate route maps for electric vehicles, which processes user requests and optimizes routes by minimizing trip costs and time durations through a graph-based approach, incorporating neural networks and a replay buffer for continuous learning and feedback integration.

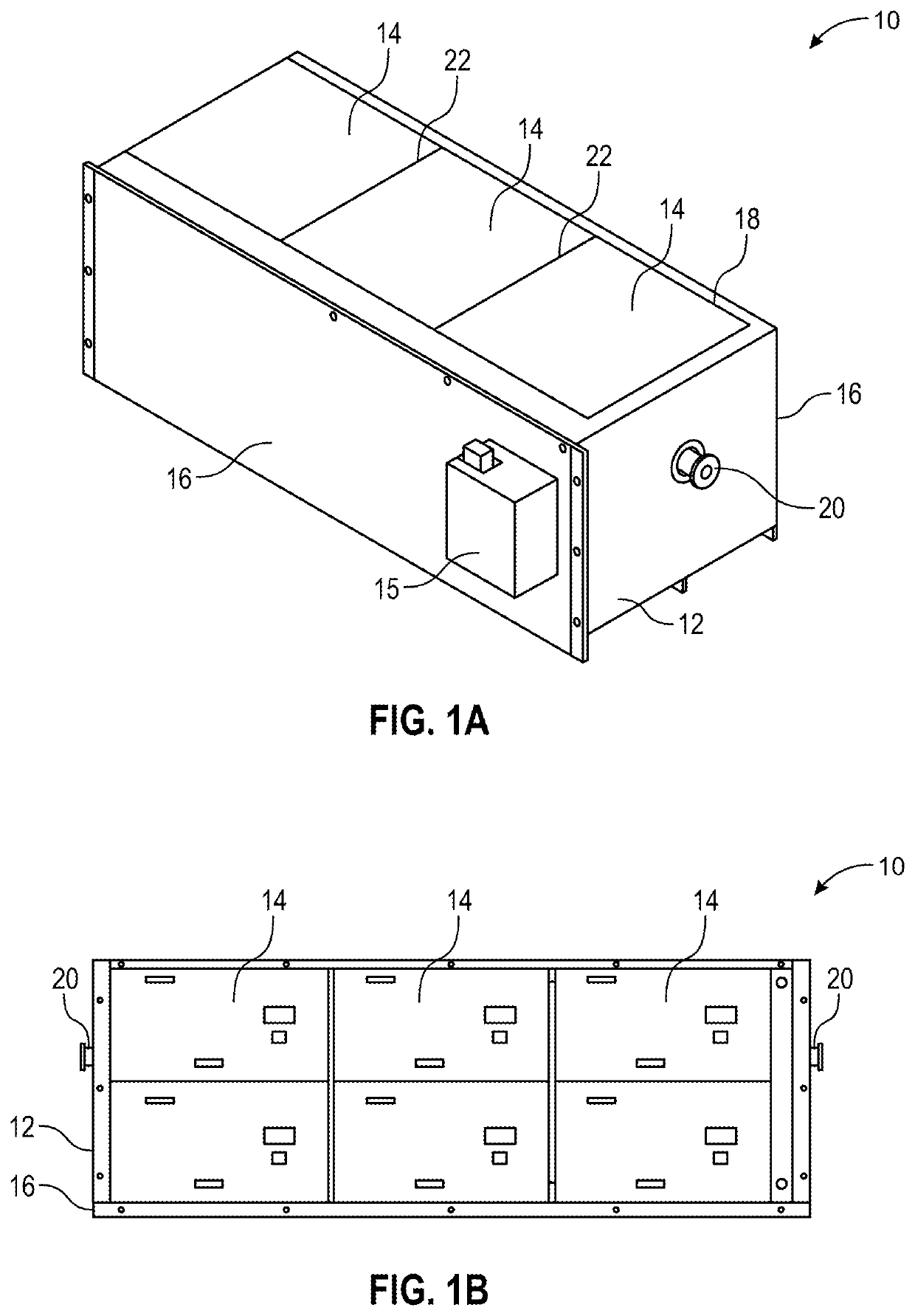

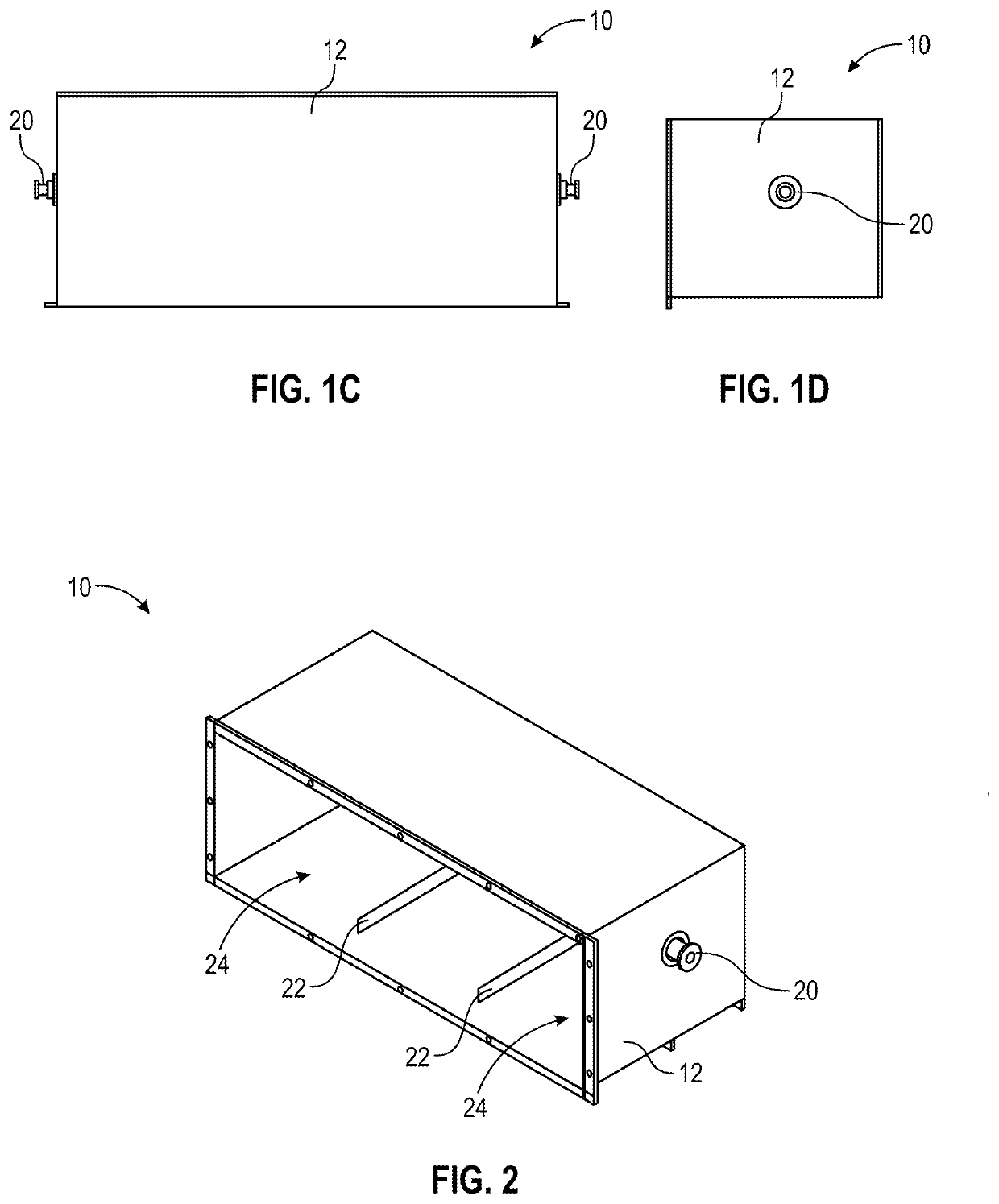

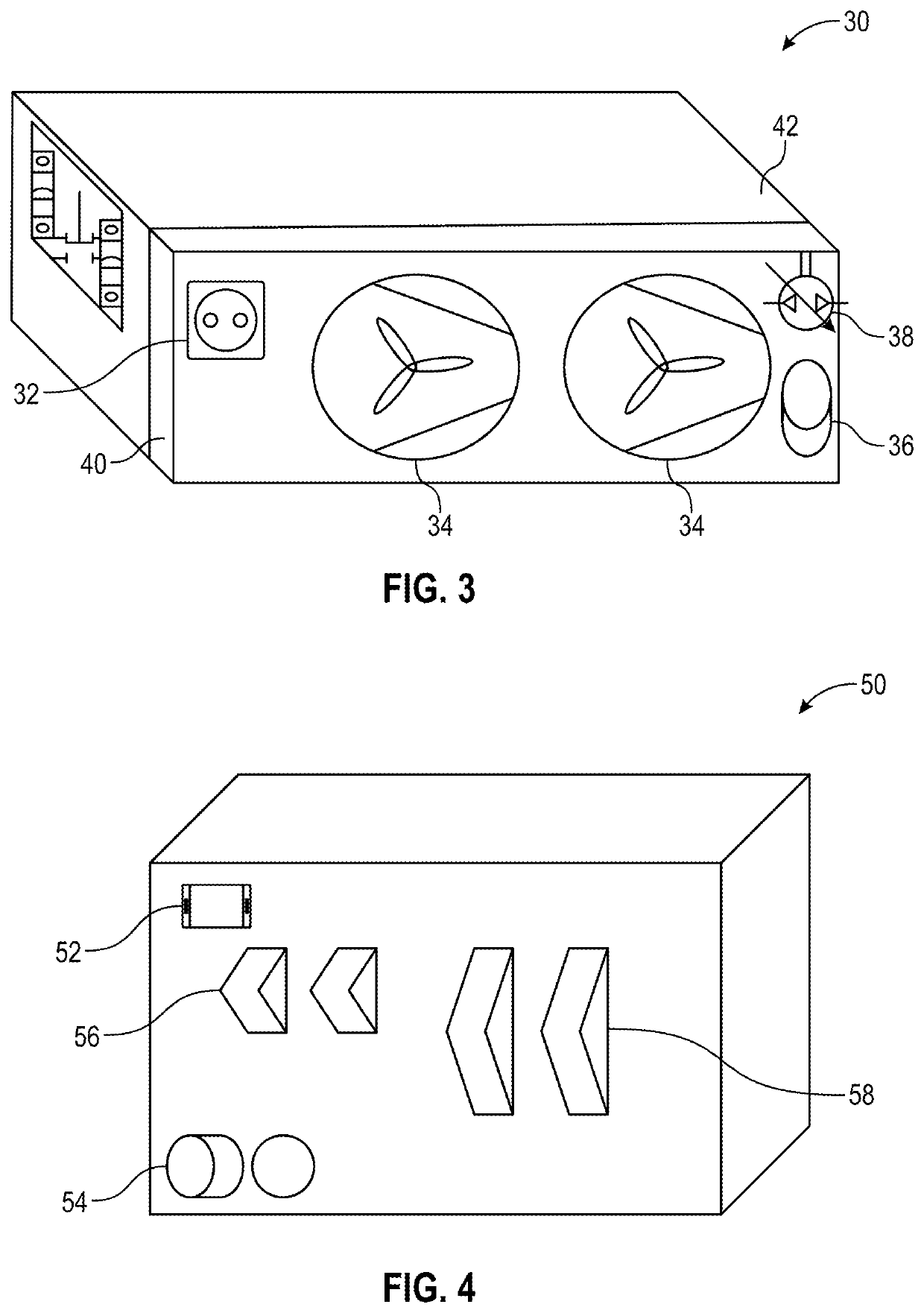

Universal battery pack, electric vehicle powertrain design and battery swapping network with battery health management

PatentPendingUS20220289067A1

Innovation

- A modular electric vehicle battery pack with an intelligent wireless management system, closed-loop cooling, and bidirectional AC/DC charger, integrated with a swappable platform and battery sharing network that optimizes battery swapping, charging, and energy storage, allowing for efficient energy sharing and grid integration.

Environmental Regulations

Environmental regulations play a crucial role in shaping the future of Extended Range Electric Vehicles (EREVs) in global logistics chains. As governments worldwide intensify efforts to combat climate change and reduce greenhouse gas emissions, the transportation sector faces increasing pressure to adopt cleaner technologies. EREVs, with their ability to operate on both electric power and conventional fuel, are positioned as a potential solution to meet these stringent environmental standards.

Many countries have implemented or announced plans for stricter emission regulations, particularly targeting commercial vehicles. The European Union, for instance, has set ambitious targets to reduce CO2 emissions from new heavy-duty vehicles by 15% by 2025 and 30% by 2030, compared to 2019 levels. Similarly, California's Advanced Clean Trucks regulation mandates increasing sales of zero-emission trucks starting from 2024. These regulations create a favorable environment for EREV adoption in logistics operations.

The impact of environmental regulations extends beyond emission standards to include low-emission zones in urban areas. Cities like London, Paris, and Amsterdam have implemented or plan to introduce ultra-low emission zones, restricting access for high-polluting vehicles. This trend is likely to accelerate, making EREVs an attractive option for logistics companies operating in urban environments, as they can switch to electric mode in restricted areas while maintaining long-range capabilities for intercity transport.

Carbon pricing mechanisms, such as carbon taxes and cap-and-trade systems, are becoming more prevalent globally. These policies increase the cost of operating conventional fossil fuel-powered vehicles, thereby improving the economic competitiveness of EREVs. As carbon pricing schemes mature and expand, the total cost of ownership for EREVs is expected to become increasingly favorable compared to traditional diesel trucks.

Environmental regulations also influence the development of charging infrastructure, which is critical for EREV adoption in logistics chains. Many governments are implementing policies to support the expansion of charging networks, including financial incentives for infrastructure development and mandates for charging stations at key locations such as highways and logistics hubs. This regulatory support is essential for addressing range anxiety and ensuring the viability of EREVs in long-haul logistics operations.

Furthermore, regulations promoting renewable energy integration in the power grid indirectly benefit EREV adoption. As grids become cleaner, the environmental benefits of electric vehicles, including EREVs, increase. This synergy between clean energy policies and electric vehicle regulations creates a positive feedback loop, further driving the transition towards sustainable logistics solutions.

Many countries have implemented or announced plans for stricter emission regulations, particularly targeting commercial vehicles. The European Union, for instance, has set ambitious targets to reduce CO2 emissions from new heavy-duty vehicles by 15% by 2025 and 30% by 2030, compared to 2019 levels. Similarly, California's Advanced Clean Trucks regulation mandates increasing sales of zero-emission trucks starting from 2024. These regulations create a favorable environment for EREV adoption in logistics operations.

The impact of environmental regulations extends beyond emission standards to include low-emission zones in urban areas. Cities like London, Paris, and Amsterdam have implemented or plan to introduce ultra-low emission zones, restricting access for high-polluting vehicles. This trend is likely to accelerate, making EREVs an attractive option for logistics companies operating in urban environments, as they can switch to electric mode in restricted areas while maintaining long-range capabilities for intercity transport.

Carbon pricing mechanisms, such as carbon taxes and cap-and-trade systems, are becoming more prevalent globally. These policies increase the cost of operating conventional fossil fuel-powered vehicles, thereby improving the economic competitiveness of EREVs. As carbon pricing schemes mature and expand, the total cost of ownership for EREVs is expected to become increasingly favorable compared to traditional diesel trucks.

Environmental regulations also influence the development of charging infrastructure, which is critical for EREV adoption in logistics chains. Many governments are implementing policies to support the expansion of charging networks, including financial incentives for infrastructure development and mandates for charging stations at key locations such as highways and logistics hubs. This regulatory support is essential for addressing range anxiety and ensuring the viability of EREVs in long-haul logistics operations.

Furthermore, regulations promoting renewable energy integration in the power grid indirectly benefit EREV adoption. As grids become cleaner, the environmental benefits of electric vehicles, including EREVs, increase. This synergy between clean energy policies and electric vehicle regulations creates a positive feedback loop, further driving the transition towards sustainable logistics solutions.

EREV Infrastructure Needs

The successful integration of Extended Range Electric Vehicles (EREVs) into global logistics chains hinges on the development of robust infrastructure to support their operation. A comprehensive network of charging stations is paramount, with a focus on strategic placement along major transportation routes and at key logistics hubs. These stations must offer rapid charging capabilities to minimize downtime and maintain operational efficiency. Additionally, the infrastructure should include battery swap stations, allowing for quick energy replenishment during long-haul journeys.

To accommodate the unique power requirements of EREVs, upgrades to the electrical grid are necessary. This involves enhancing power distribution systems and implementing smart grid technologies to manage the increased demand and ensure stable energy supply. The infrastructure must also incorporate advanced energy management systems to optimize charging schedules, reduce peak load, and integrate renewable energy sources.

Maintenance and service facilities specialized in EREV technology are crucial components of the infrastructure ecosystem. These centers should be equipped with diagnostic tools, spare parts inventories, and trained technicians capable of addressing the specific needs of electric powertrains and range extenders. The establishment of a robust supply chain for EREV components and batteries is essential to support maintenance operations and minimize vehicle downtime.

Data infrastructure plays a vital role in EREV logistics operations. A network of sensors, communication systems, and data centers is required to collect, process, and analyze vehicle performance data, charging patterns, and route optimization information. This data infrastructure enables predictive maintenance, efficient fleet management, and continuous improvement of EREV technology.

The development of standardized protocols for charging interfaces, communication systems, and data exchange is critical for ensuring interoperability across different EREV models and charging networks. This standardization facilitates seamless integration of EREVs into existing logistics systems and promotes widespread adoption.

Lastly, the infrastructure needs extend to the development of specialized training programs and certification systems for EREV operators, maintenance personnel, and emergency responders. This human infrastructure is essential for the safe and efficient operation of EREVs in global logistics chains, ensuring that the workforce is equipped to handle the unique challenges and opportunities presented by this technology.

To accommodate the unique power requirements of EREVs, upgrades to the electrical grid are necessary. This involves enhancing power distribution systems and implementing smart grid technologies to manage the increased demand and ensure stable energy supply. The infrastructure must also incorporate advanced energy management systems to optimize charging schedules, reduce peak load, and integrate renewable energy sources.

Maintenance and service facilities specialized in EREV technology are crucial components of the infrastructure ecosystem. These centers should be equipped with diagnostic tools, spare parts inventories, and trained technicians capable of addressing the specific needs of electric powertrains and range extenders. The establishment of a robust supply chain for EREV components and batteries is essential to support maintenance operations and minimize vehicle downtime.

Data infrastructure plays a vital role in EREV logistics operations. A network of sensors, communication systems, and data centers is required to collect, process, and analyze vehicle performance data, charging patterns, and route optimization information. This data infrastructure enables predictive maintenance, efficient fleet management, and continuous improvement of EREV technology.

The development of standardized protocols for charging interfaces, communication systems, and data exchange is critical for ensuring interoperability across different EREV models and charging networks. This standardization facilitates seamless integration of EREVs into existing logistics systems and promotes widespread adoption.

Lastly, the infrastructure needs extend to the development of specialized training programs and certification systems for EREV operators, maintenance personnel, and emergency responders. This human infrastructure is essential for the safe and efficient operation of EREVs in global logistics chains, ensuring that the workforce is equipped to handle the unique challenges and opportunities presented by this technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!