EREV supply chain sustainability impacts

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EREV Tech Background

Extended Range Electric Vehicles (EREVs) represent a significant advancement in automotive technology, combining the benefits of electric propulsion with the range assurance of internal combustion engines. This hybrid approach emerged as a solution to address the limitations of pure electric vehicles, particularly range anxiety and charging infrastructure constraints.

The development of EREVs can be traced back to the early 2000s, with pioneering concepts like the Chevrolet Volt. These vehicles utilize a small internal combustion engine as a generator to extend the range of the electric powertrain, offering a compromise between all-electric and traditional hybrid vehicles.

EREVs have evolved to incorporate more sophisticated power management systems and improved battery technologies. The integration of lithium-ion batteries has been crucial, enabling higher energy density and longer electric-only driving ranges. Advancements in power electronics and control systems have further optimized the interaction between electric motors and range-extending engines.

The technology behind EREVs continues to progress, with a focus on increasing electric range, improving overall efficiency, and reducing reliance on fossil fuels. Recent developments include the use of more compact and efficient range extenders, such as rotary engines or hydrogen fuel cells, to further enhance sustainability.

In the context of supply chain sustainability, EREVs present both opportunities and challenges. The complex nature of EREV powertrains requires a diverse supply chain, encompassing traditional automotive components, advanced electronics, and battery technologies. This complexity necessitates careful consideration of material sourcing, manufacturing processes, and end-of-life recycling.

The sustainability impacts of EREV supply chains are multifaceted. On one hand, the increased use of electric propulsion reduces direct emissions during vehicle operation. However, the production of batteries and electronic components can have significant environmental implications, including resource extraction and energy-intensive manufacturing processes.

As the automotive industry transitions towards electrification, EREV technology serves as a bridge, allowing for gradual infrastructure development and consumer adaptation. This transitional role influences supply chain dynamics, requiring flexibility and innovation from suppliers to meet evolving demands.

Looking forward, the EREV supply chain is expected to evolve alongside advancements in battery technology, renewable energy integration, and circular economy principles. The focus is shifting towards more sustainable material sourcing, improved manufacturing efficiency, and enhanced recyclability of components, particularly batteries.

The development of EREVs can be traced back to the early 2000s, with pioneering concepts like the Chevrolet Volt. These vehicles utilize a small internal combustion engine as a generator to extend the range of the electric powertrain, offering a compromise between all-electric and traditional hybrid vehicles.

EREVs have evolved to incorporate more sophisticated power management systems and improved battery technologies. The integration of lithium-ion batteries has been crucial, enabling higher energy density and longer electric-only driving ranges. Advancements in power electronics and control systems have further optimized the interaction between electric motors and range-extending engines.

The technology behind EREVs continues to progress, with a focus on increasing electric range, improving overall efficiency, and reducing reliance on fossil fuels. Recent developments include the use of more compact and efficient range extenders, such as rotary engines or hydrogen fuel cells, to further enhance sustainability.

In the context of supply chain sustainability, EREVs present both opportunities and challenges. The complex nature of EREV powertrains requires a diverse supply chain, encompassing traditional automotive components, advanced electronics, and battery technologies. This complexity necessitates careful consideration of material sourcing, manufacturing processes, and end-of-life recycling.

The sustainability impacts of EREV supply chains are multifaceted. On one hand, the increased use of electric propulsion reduces direct emissions during vehicle operation. However, the production of batteries and electronic components can have significant environmental implications, including resource extraction and energy-intensive manufacturing processes.

As the automotive industry transitions towards electrification, EREV technology serves as a bridge, allowing for gradual infrastructure development and consumer adaptation. This transitional role influences supply chain dynamics, requiring flexibility and innovation from suppliers to meet evolving demands.

Looking forward, the EREV supply chain is expected to evolve alongside advancements in battery technology, renewable energy integration, and circular economy principles. The focus is shifting towards more sustainable material sourcing, improved manufacturing efficiency, and enhanced recyclability of components, particularly batteries.

EREV Market Analysis

The EREV (Extended Range Electric Vehicle) market has been experiencing significant growth in recent years, driven by increasing environmental concerns and the push for sustainable transportation solutions. As a bridge between conventional hybrid vehicles and fully electric vehicles, EREVs offer a unique value proposition that addresses range anxiety while still providing substantial environmental benefits.

Market demand for EREVs has been steadily increasing, with sales figures showing double-digit growth rates in key markets such as China, Europe, and North America. This trend is expected to continue as consumers become more environmentally conscious and governments implement stricter emissions regulations. The global EREV market size is projected to expand at a compound annual growth rate (CAGR) of over 10% in the coming years.

Several factors are contributing to the growing demand for EREVs. Firstly, the improved battery technology and charging infrastructure have made these vehicles more practical for everyday use. Secondly, the lower total cost of ownership compared to traditional internal combustion engine vehicles is attracting cost-conscious consumers. Lastly, the flexibility offered by EREVs in terms of range and charging options appeals to a wide range of users, from urban commuters to long-distance travelers.

The EREV market is characterized by intense competition among established automakers and new entrants. Major players in this space include General Motors, BMW, Toyota, and BYD, each with their own unique EREV offerings. These companies are investing heavily in research and development to improve battery technology, extend electric range, and enhance overall vehicle performance.

Industry trends indicate a shift towards more efficient and sustainable supply chain practices in EREV production. Manufacturers are increasingly focusing on reducing the environmental impact of their supply chains, from raw material sourcing to end-of-life vehicle recycling. This includes efforts to use recycled materials, optimize production processes, and implement circular economy principles.

The sustainability impacts of the EREV supply chain are becoming a crucial factor in market dynamics. Consumers are showing a growing preference for vehicles with lower carbon footprints, not just in terms of tailpipe emissions but also in their production and lifecycle. This has led to increased transparency in supply chain practices and a push for more sustainable sourcing of critical components, particularly batteries.

Looking ahead, the EREV market is poised for further growth and innovation. Advancements in battery technology are expected to increase electric range and reduce costs, making EREVs even more attractive to consumers. Additionally, the integration of smart grid technologies and vehicle-to-grid capabilities could position EREVs as key components in future energy systems, further driving market demand and sustainability benefits.

Market demand for EREVs has been steadily increasing, with sales figures showing double-digit growth rates in key markets such as China, Europe, and North America. This trend is expected to continue as consumers become more environmentally conscious and governments implement stricter emissions regulations. The global EREV market size is projected to expand at a compound annual growth rate (CAGR) of over 10% in the coming years.

Several factors are contributing to the growing demand for EREVs. Firstly, the improved battery technology and charging infrastructure have made these vehicles more practical for everyday use. Secondly, the lower total cost of ownership compared to traditional internal combustion engine vehicles is attracting cost-conscious consumers. Lastly, the flexibility offered by EREVs in terms of range and charging options appeals to a wide range of users, from urban commuters to long-distance travelers.

The EREV market is characterized by intense competition among established automakers and new entrants. Major players in this space include General Motors, BMW, Toyota, and BYD, each with their own unique EREV offerings. These companies are investing heavily in research and development to improve battery technology, extend electric range, and enhance overall vehicle performance.

Industry trends indicate a shift towards more efficient and sustainable supply chain practices in EREV production. Manufacturers are increasingly focusing on reducing the environmental impact of their supply chains, from raw material sourcing to end-of-life vehicle recycling. This includes efforts to use recycled materials, optimize production processes, and implement circular economy principles.

The sustainability impacts of the EREV supply chain are becoming a crucial factor in market dynamics. Consumers are showing a growing preference for vehicles with lower carbon footprints, not just in terms of tailpipe emissions but also in their production and lifecycle. This has led to increased transparency in supply chain practices and a push for more sustainable sourcing of critical components, particularly batteries.

Looking ahead, the EREV market is poised for further growth and innovation. Advancements in battery technology are expected to increase electric range and reduce costs, making EREVs even more attractive to consumers. Additionally, the integration of smart grid technologies and vehicle-to-grid capabilities could position EREVs as key components in future energy systems, further driving market demand and sustainability benefits.

Supply Chain Challenges

The supply chain for Extended Range Electric Vehicles (EREVs) faces numerous challenges that impact sustainability efforts. One of the primary issues is the complex and globally distributed nature of EREV component sourcing. Critical components such as batteries, electric motors, and power electronics often involve multiple tiers of suppliers across different countries, making it difficult to ensure consistent sustainability standards throughout the chain.

Raw material sourcing presents another significant challenge. The production of lithium-ion batteries, a key component in EREVs, requires materials like lithium, cobalt, and nickel. These materials are often mined in regions with less stringent environmental regulations or unstable political situations, raising concerns about environmental degradation and human rights issues. The limited availability of these resources also poses risks to long-term supply chain stability and sustainability.

Manufacturing processes for EREV components can be energy-intensive and potentially polluting. The production of battery cells and the assembly of battery packs, in particular, require substantial energy inputs and can generate hazardous waste. Ensuring that these processes are as clean and efficient as possible across all suppliers is a major challenge for EREV manufacturers.

Transportation and logistics within the EREV supply chain also contribute to sustainability concerns. The global nature of the supply chain often necessitates long-distance shipping of components and finished vehicles, resulting in significant carbon emissions. Optimizing transportation routes and modes to minimize environmental impact while maintaining cost-effectiveness and timely delivery is a complex balancing act.

End-of-life considerations for EREV components, especially batteries, present unique challenges. The recycling and disposal of lithium-ion batteries require specialized processes to recover valuable materials and prevent environmental contamination. Developing efficient, widespread recycling infrastructure and ensuring that all supply chain partners adhere to responsible end-of-life practices is crucial for long-term sustainability.

Transparency and traceability throughout the supply chain are essential for addressing sustainability impacts but can be challenging to achieve. Many EREV manufacturers struggle to gain full visibility into their entire supply chain, particularly beyond tier-one suppliers. This lack of transparency makes it difficult to identify and address sustainability issues effectively.

Lastly, the rapid evolution of EREV technology poses challenges for supply chain sustainability. As new battery chemistries and electric powertrain technologies emerge, supply chains must adapt quickly. This constant change can disrupt established sustainability practices and require continuous reassessment of environmental impacts throughout the supply chain.

Raw material sourcing presents another significant challenge. The production of lithium-ion batteries, a key component in EREVs, requires materials like lithium, cobalt, and nickel. These materials are often mined in regions with less stringent environmental regulations or unstable political situations, raising concerns about environmental degradation and human rights issues. The limited availability of these resources also poses risks to long-term supply chain stability and sustainability.

Manufacturing processes for EREV components can be energy-intensive and potentially polluting. The production of battery cells and the assembly of battery packs, in particular, require substantial energy inputs and can generate hazardous waste. Ensuring that these processes are as clean and efficient as possible across all suppliers is a major challenge for EREV manufacturers.

Transportation and logistics within the EREV supply chain also contribute to sustainability concerns. The global nature of the supply chain often necessitates long-distance shipping of components and finished vehicles, resulting in significant carbon emissions. Optimizing transportation routes and modes to minimize environmental impact while maintaining cost-effectiveness and timely delivery is a complex balancing act.

End-of-life considerations for EREV components, especially batteries, present unique challenges. The recycling and disposal of lithium-ion batteries require specialized processes to recover valuable materials and prevent environmental contamination. Developing efficient, widespread recycling infrastructure and ensuring that all supply chain partners adhere to responsible end-of-life practices is crucial for long-term sustainability.

Transparency and traceability throughout the supply chain are essential for addressing sustainability impacts but can be challenging to achieve. Many EREV manufacturers struggle to gain full visibility into their entire supply chain, particularly beyond tier-one suppliers. This lack of transparency makes it difficult to identify and address sustainability issues effectively.

Lastly, the rapid evolution of EREV technology poses challenges for supply chain sustainability. As new battery chemistries and electric powertrain technologies emerge, supply chains must adapt quickly. This constant change can disrupt established sustainability practices and require continuous reassessment of environmental impacts throughout the supply chain.

Current Supply Solutions

01 Sustainable supply chain management for EREVs

Implementing sustainable practices in the supply chain of Extended Range Electric Vehicles (EREVs) to reduce environmental impact and improve efficiency. This includes optimizing logistics, reducing waste, and using eco-friendly materials throughout the production and distribution process.- Sustainable supply chain management for EREVs: Implementing sustainable practices in the supply chain management of Extended Range Electric Vehicles (EREVs) to reduce environmental impact and improve efficiency. This includes optimizing logistics, reducing waste, and incorporating eco-friendly materials and processes throughout the supply chain.

- Battery lifecycle management in EREV supply chains: Developing strategies for efficient battery lifecycle management within EREV supply chains, including production, use, recycling, and disposal. This focuses on minimizing environmental impact, extending battery life, and implementing effective recycling processes to support sustainability goals.

- Green energy integration in EREV manufacturing: Incorporating renewable energy sources and energy-efficient technologies in EREV manufacturing processes and supply chain operations. This includes the use of solar, wind, and other clean energy sources to power production facilities and reduce the carbon footprint of EREV supply chains.

- Sustainable sourcing of materials for EREV components: Implementing sustainable sourcing practices for raw materials and components used in EREV production. This involves selecting environmentally friendly materials, ensuring ethical sourcing, and developing partnerships with suppliers committed to sustainability principles.

- Digital technologies for EREV supply chain sustainability: Leveraging digital technologies such as AI, IoT, and blockchain to enhance sustainability in EREV supply chains. These technologies can improve traceability, optimize resource allocation, reduce waste, and enable more efficient and sustainable supply chain management practices.

02 Battery lifecycle management in EREV supply chains

Developing strategies for the sustainable production, use, and recycling of batteries in EREVs. This involves improving battery longevity, implementing efficient recycling processes, and exploring second-life applications for used batteries to minimize environmental impact and resource consumption.Expand Specific Solutions03 Green energy integration in EREV manufacturing

Incorporating renewable energy sources into the EREV manufacturing process and supply chain operations. This includes using solar, wind, or other clean energy sources to power production facilities and charging infrastructure, reducing the carbon footprint of EREV production and use.Expand Specific Solutions04 Circular economy principles in EREV supply chains

Applying circular economy concepts to EREV supply chains, focusing on resource efficiency, waste reduction, and material reuse. This involves designing components for easy disassembly and recycling, implementing take-back programs, and creating closed-loop systems for materials and components.Expand Specific Solutions05 Sustainable sourcing and supplier management for EREVs

Developing and implementing sustainable sourcing strategies for EREV components and materials. This includes establishing sustainability criteria for suppliers, conducting regular audits, and collaborating with partners to improve environmental and social performance throughout the supply chain.Expand Specific Solutions

Key EREV Manufacturers

The EREV supply chain sustainability impacts market is in a growth phase, driven by increasing environmental concerns and regulatory pressures. The market size is expanding as more automotive manufacturers invest in extended-range electric vehicle technologies. Technical maturity varies across companies, with established players like GM Global Technology Operations LLC and Cummins, Inc. leading in EREV powertrain development. Emerging players such as Aizen Global Co. Ltd. and Nextracker LLC are focusing on innovative energy management and tracking solutions. Academic institutions like North China Electric Power University and École Polytechnique Fédérale de Lausanne are contributing to research and development, while energy companies like State Grid Corp. of China are exploring grid integration aspects. The competitive landscape is diverse, with collaborations between automotive, technology, and energy sectors becoming increasingly common to address sustainability challenges in the EREV supply chain.

GM Global Technology Operations LLC

Technical Solution: GM has developed a comprehensive approach to EREV supply chain sustainability. They focus on reducing environmental impact through advanced battery technology and efficient powertrain systems. GM's Ultium battery platform is designed for scalability and sustainability, using less cobalt and incorporating recycled materials[1]. Their EREV systems integrate regenerative braking and intelligent power management to maximize energy efficiency. GM also implements a circular economy approach, aiming to reuse or recycle up to 100% of battery components[2]. They've established partnerships with suppliers to ensure responsible sourcing of raw materials, including initiatives to trace cobalt and lithium throughout the supply chain[3].

Strengths: Innovative battery technology, strong supplier partnerships, commitment to circular economy. Weaknesses: Dependency on rare earth materials, potential supply chain disruptions in emerging markets.

Cummins, Inc.

Technical Solution: Cummins has developed a multi-faceted approach to EREV supply chain sustainability. Their strategy includes the development of advanced power systems that combine electric and diesel technologies for improved efficiency and reduced emissions. Cummins' PowerDrive system integrates high-capacity batteries with efficient engines, optimizing performance and reducing environmental impact[4]. They've also invested in hydrogen fuel cell technology as a complementary solution for long-range applications. Cummins emphasizes responsible sourcing, working closely with suppliers to ensure ethical practices and reduce the carbon footprint of their supply chain. They've implemented a comprehensive Life Cycle Assessment (LCA) approach to evaluate and minimize environmental impacts across the entire product lifecycle[5].

Strengths: Diverse powertrain solutions, strong focus on LCA, established global supply chain. Weaknesses: Transition challenges from traditional diesel technology, potential higher costs in short term.

Sustainable Innovations

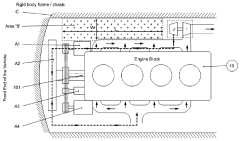

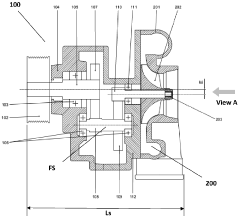

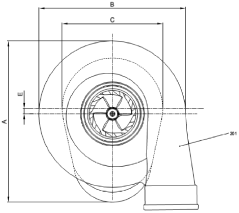

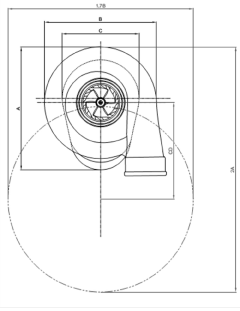

A compact centrifugal supercharger and a method thereof

PatentPendingIN202141050707A

Innovation

- A compact mechanical centrifugal supercharger with a high-speed two-stage helical gearbox providing a high step-up ratio, designed for easy adaptability and retrofitability, which enhances air boost during torque dips and low engine speeds, reducing emissions and improving fuel efficiency.

Environmental Regulations

Environmental regulations play a crucial role in shaping the sustainability impacts of Extended Range Electric Vehicle (EREV) supply chains. These regulations are designed to mitigate the environmental footprint of automotive manufacturing and operation, with a particular focus on reducing greenhouse gas emissions and promoting energy efficiency.

At the global level, the Paris Agreement sets the overarching framework for climate action, influencing national policies that affect EREV production and adoption. Many countries have implemented stringent emissions standards for vehicles, such as the Corporate Average Fuel Economy (CAFE) standards in the United States and the European Union's CO2 emissions targets. These regulations incentivize automakers to invest in EREV technology as a means to comply with increasingly strict environmental requirements.

In the context of EREV supply chains, environmental regulations extend beyond vehicle emissions to encompass the entire lifecycle of components and materials. For instance, the European Union's End-of-Life Vehicles (ELV) Directive mandates the recycling and recovery of vehicle components, including batteries. This directive has significant implications for EREV manufacturers, as it necessitates the development of sustainable practices for battery disposal and recycling.

The sourcing of raw materials for EREV components, particularly batteries, is also subject to environmental regulations. The EU's Conflict Minerals Regulation and similar laws in other jurisdictions aim to ensure responsible sourcing of materials like cobalt and lithium, which are essential for EREV battery production. These regulations require companies to conduct due diligence on their supply chains to prevent environmental degradation and human rights abuses associated with mineral extraction.

Environmental regulations also influence the energy sources used in EREV manufacturing and charging infrastructure. Many countries have implemented renewable energy targets and carbon pricing mechanisms, which indirectly affect the sustainability of EREV supply chains by promoting cleaner energy production. For example, China's New Energy Vehicle (NEV) policy not only encourages EREV adoption but also emphasizes the use of renewable energy in vehicle charging networks.

As environmental regulations continue to evolve, EREV manufacturers must adapt their supply chains to ensure compliance and maintain competitiveness. This may involve investing in cleaner production technologies, developing more efficient recycling processes, and collaborating with suppliers to improve sustainability throughout the value chain. The regulatory landscape is likely to become more stringent in the coming years, driven by global efforts to combat climate change and promote sustainable transportation solutions.

At the global level, the Paris Agreement sets the overarching framework for climate action, influencing national policies that affect EREV production and adoption. Many countries have implemented stringent emissions standards for vehicles, such as the Corporate Average Fuel Economy (CAFE) standards in the United States and the European Union's CO2 emissions targets. These regulations incentivize automakers to invest in EREV technology as a means to comply with increasingly strict environmental requirements.

In the context of EREV supply chains, environmental regulations extend beyond vehicle emissions to encompass the entire lifecycle of components and materials. For instance, the European Union's End-of-Life Vehicles (ELV) Directive mandates the recycling and recovery of vehicle components, including batteries. This directive has significant implications for EREV manufacturers, as it necessitates the development of sustainable practices for battery disposal and recycling.

The sourcing of raw materials for EREV components, particularly batteries, is also subject to environmental regulations. The EU's Conflict Minerals Regulation and similar laws in other jurisdictions aim to ensure responsible sourcing of materials like cobalt and lithium, which are essential for EREV battery production. These regulations require companies to conduct due diligence on their supply chains to prevent environmental degradation and human rights abuses associated with mineral extraction.

Environmental regulations also influence the energy sources used in EREV manufacturing and charging infrastructure. Many countries have implemented renewable energy targets and carbon pricing mechanisms, which indirectly affect the sustainability of EREV supply chains by promoting cleaner energy production. For example, China's New Energy Vehicle (NEV) policy not only encourages EREV adoption but also emphasizes the use of renewable energy in vehicle charging networks.

As environmental regulations continue to evolve, EREV manufacturers must adapt their supply chains to ensure compliance and maintain competitiveness. This may involve investing in cleaner production technologies, developing more efficient recycling processes, and collaborating with suppliers to improve sustainability throughout the value chain. The regulatory landscape is likely to become more stringent in the coming years, driven by global efforts to combat climate change and promote sustainable transportation solutions.

Circular Economy Impact

The circular economy impact of Extended Range Electric Vehicles (EREVs) on supply chain sustainability is multifaceted and significant. EREVs, by their design, incorporate principles of circular economy through the use of rechargeable batteries and the potential for battery second life applications. This approach extends the lifecycle of critical components, reducing waste and resource consumption.

In the context of supply chain sustainability, EREVs contribute to the circular economy by promoting the reuse and recycling of battery materials. As battery technology advances, the potential for recycling and repurposing end-of-life batteries increases, creating new value streams within the automotive industry. This circular approach not only reduces the environmental impact of battery production but also mitigates the strain on raw material supply chains, particularly for critical minerals used in battery manufacturing.

The adoption of EREVs also encourages the development of more sustainable manufacturing processes. Manufacturers are incentivized to design vehicles with end-of-life considerations in mind, promoting easier disassembly and material recovery. This shift towards design for circularity has ripple effects throughout the supply chain, encouraging suppliers to adopt more sustainable practices and materials.

Furthermore, the extended range capabilities of EREVs contribute to the circular economy by optimizing the use of existing infrastructure. By reducing range anxiety and allowing for longer trips, EREVs can potentially decrease the need for rapid expansion of charging infrastructure, leading to more efficient use of resources and energy in the broader transportation ecosystem.

The circular economy impact extends to the energy sector as well. EREVs can play a role in vehicle-to-grid (V2G) systems, where vehicle batteries serve as distributed energy storage units. This integration into the smart grid enhances energy efficiency and promotes the use of renewable energy sources, further contributing to the circular economy principles in the energy sector.

However, the full realization of these circular economy benefits depends on the development of robust reverse logistics systems and recycling infrastructure. The automotive industry must collaborate with recycling companies and policymakers to establish efficient collection, sorting, and processing systems for end-of-life vehicles and components, particularly batteries.

In the context of supply chain sustainability, EREVs contribute to the circular economy by promoting the reuse and recycling of battery materials. As battery technology advances, the potential for recycling and repurposing end-of-life batteries increases, creating new value streams within the automotive industry. This circular approach not only reduces the environmental impact of battery production but also mitigates the strain on raw material supply chains, particularly for critical minerals used in battery manufacturing.

The adoption of EREVs also encourages the development of more sustainable manufacturing processes. Manufacturers are incentivized to design vehicles with end-of-life considerations in mind, promoting easier disassembly and material recovery. This shift towards design for circularity has ripple effects throughout the supply chain, encouraging suppliers to adopt more sustainable practices and materials.

Furthermore, the extended range capabilities of EREVs contribute to the circular economy by optimizing the use of existing infrastructure. By reducing range anxiety and allowing for longer trips, EREVs can potentially decrease the need for rapid expansion of charging infrastructure, leading to more efficient use of resources and energy in the broader transportation ecosystem.

The circular economy impact extends to the energy sector as well. EREVs can play a role in vehicle-to-grid (V2G) systems, where vehicle batteries serve as distributed energy storage units. This integration into the smart grid enhances energy efficiency and promotes the use of renewable energy sources, further contributing to the circular economy principles in the energy sector.

However, the full realization of these circular economy benefits depends on the development of robust reverse logistics systems and recycling infrastructure. The automotive industry must collaborate with recycling companies and policymakers to establish efficient collection, sorting, and processing systems for end-of-life vehicles and components, particularly batteries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!