How EREV supports circular economy initiatives

AUG 14, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EREV Circular Economy Background

Extended Range Electric Vehicles (EREVs) have emerged as a promising technology in the automotive industry, bridging the gap between conventional internal combustion engine vehicles and fully electric vehicles. As the world grapples with the challenges of climate change and resource depletion, the concept of a circular economy has gained significant traction. The circular economy model aims to minimize waste and maximize resource efficiency by promoting the reuse, refurbishment, and recycling of materials and products.

In the context of the automotive sector, EREVs present a unique opportunity to support circular economy initiatives. These vehicles combine the benefits of electric propulsion with the extended range capabilities provided by a small internal combustion engine, which acts as a generator to charge the battery when needed. This hybrid approach allows for a more gradual transition towards fully electric mobility while addressing some of the key challenges associated with battery electric vehicles, such as range anxiety and charging infrastructure limitations.

The circular economy potential of EREVs lies in several key areas. Firstly, the battery systems in EREVs are typically smaller than those in fully electric vehicles, reducing the overall demand for critical battery materials. This aligns with circular economy principles by minimizing resource extraction and promoting more efficient use of materials. Additionally, the dual powertrain system in EREVs allows for modular design approaches, facilitating easier maintenance, repair, and component replacement, which are essential aspects of a circular economy model.

Furthermore, EREVs can play a crucial role in the development of vehicle-to-grid (V2G) technologies. By leveraging their battery capacity and the ability to generate electricity on-board, EREVs can potentially serve as mobile energy storage units, contributing to grid stability and enabling more efficient integration of renewable energy sources. This capability aligns with the circular economy's emphasis on maximizing the utility and value of assets throughout their lifecycle.

The extended range capabilities of EREVs also support circular economy initiatives by potentially reducing the need for extensive charging infrastructure development. This can lead to more efficient use of resources and urban space, as well as reduced environmental impact associated with infrastructure construction and maintenance. Moreover, the flexibility offered by EREVs in terms of powertrain options can contribute to the longevity of vehicles, allowing for adaptations to evolving energy landscapes and technological advancements.

As the automotive industry continues to evolve, EREVs represent a transitional technology that can facilitate the shift towards more sustainable and circular mobility solutions. By addressing some of the limitations of current electric vehicle technologies while incorporating principles of modularity, resource efficiency, and extended product life cycles, EREVs are well-positioned to support and accelerate the implementation of circular economy initiatives in the transportation sector.

In the context of the automotive sector, EREVs present a unique opportunity to support circular economy initiatives. These vehicles combine the benefits of electric propulsion with the extended range capabilities provided by a small internal combustion engine, which acts as a generator to charge the battery when needed. This hybrid approach allows for a more gradual transition towards fully electric mobility while addressing some of the key challenges associated with battery electric vehicles, such as range anxiety and charging infrastructure limitations.

The circular economy potential of EREVs lies in several key areas. Firstly, the battery systems in EREVs are typically smaller than those in fully electric vehicles, reducing the overall demand for critical battery materials. This aligns with circular economy principles by minimizing resource extraction and promoting more efficient use of materials. Additionally, the dual powertrain system in EREVs allows for modular design approaches, facilitating easier maintenance, repair, and component replacement, which are essential aspects of a circular economy model.

Furthermore, EREVs can play a crucial role in the development of vehicle-to-grid (V2G) technologies. By leveraging their battery capacity and the ability to generate electricity on-board, EREVs can potentially serve as mobile energy storage units, contributing to grid stability and enabling more efficient integration of renewable energy sources. This capability aligns with the circular economy's emphasis on maximizing the utility and value of assets throughout their lifecycle.

The extended range capabilities of EREVs also support circular economy initiatives by potentially reducing the need for extensive charging infrastructure development. This can lead to more efficient use of resources and urban space, as well as reduced environmental impact associated with infrastructure construction and maintenance. Moreover, the flexibility offered by EREVs in terms of powertrain options can contribute to the longevity of vehicles, allowing for adaptations to evolving energy landscapes and technological advancements.

As the automotive industry continues to evolve, EREVs represent a transitional technology that can facilitate the shift towards more sustainable and circular mobility solutions. By addressing some of the limitations of current electric vehicle technologies while incorporating principles of modularity, resource efficiency, and extended product life cycles, EREVs are well-positioned to support and accelerate the implementation of circular economy initiatives in the transportation sector.

Market Demand for Sustainable Mobility

The market demand for sustainable mobility solutions has been steadily increasing in recent years, driven by growing environmental concerns, stricter regulations, and changing consumer preferences. Extended Range Electric Vehicles (EREVs) have emerged as a promising technology that aligns with circular economy principles and addresses the need for more sustainable transportation options.

Consumer awareness of environmental issues and the desire for eco-friendly products have significantly influenced the automotive market. A survey conducted by Deloitte found that over 60% of consumers in major automotive markets consider sustainability as an important factor in their vehicle purchasing decisions. This shift in consumer sentiment has created a strong demand for vehicles that offer reduced emissions and improved fuel efficiency.

Governments worldwide have implemented stringent emissions regulations and incentives to promote the adoption of low-emission vehicles. For instance, the European Union has set a target to reduce CO2 emissions from new cars by 37.5% by 2030 compared to 2021 levels. These regulatory pressures have compelled automakers to invest in technologies like EREVs to meet compliance requirements and avoid potential penalties.

The global market for electric vehicles, including EREVs, has experienced remarkable growth. According to the International Energy Agency, electric car sales reached 6.6 million units in 2021, more than doubling from the previous year. This rapid expansion demonstrates the increasing market acceptance and demand for electrified mobility solutions.

EREVs offer a unique value proposition in the sustainable mobility landscape by addressing range anxiety, a common concern among potential electric vehicle buyers. By combining the benefits of electric propulsion with the flexibility of an internal combustion engine, EREVs provide a transitional technology that appeals to consumers who are hesitant to switch to fully electric vehicles due to charging infrastructure limitations or long-distance travel needs.

The circular economy aspect of EREVs further enhances their market appeal. As businesses and consumers become more conscious of resource efficiency and waste reduction, vehicles designed with circular economy principles in mind gain a competitive edge. EREVs support these initiatives through their potential for extended lifespan, modular design for easier repair and refurbishment, and the use of recyclable materials in their construction.

Fleet operators and businesses are also driving demand for sustainable mobility solutions like EREVs. Companies are increasingly incorporating sustainability goals into their corporate strategies, leading to a growing interest in greening their vehicle fleets. EREVs offer these organizations a practical solution to reduce their carbon footprint while maintaining operational flexibility.

The market demand for sustainable mobility solutions, including EREVs, is expected to continue its upward trajectory. As technology advances and economies of scale are achieved, the cost-competitiveness of these vehicles will improve, further accelerating their adoption. The integration of EREVs into circular economy initiatives presents a compelling opportunity for automakers to meet evolving market demands while contributing to broader sustainability goals.

Consumer awareness of environmental issues and the desire for eco-friendly products have significantly influenced the automotive market. A survey conducted by Deloitte found that over 60% of consumers in major automotive markets consider sustainability as an important factor in their vehicle purchasing decisions. This shift in consumer sentiment has created a strong demand for vehicles that offer reduced emissions and improved fuel efficiency.

Governments worldwide have implemented stringent emissions regulations and incentives to promote the adoption of low-emission vehicles. For instance, the European Union has set a target to reduce CO2 emissions from new cars by 37.5% by 2030 compared to 2021 levels. These regulatory pressures have compelled automakers to invest in technologies like EREVs to meet compliance requirements and avoid potential penalties.

The global market for electric vehicles, including EREVs, has experienced remarkable growth. According to the International Energy Agency, electric car sales reached 6.6 million units in 2021, more than doubling from the previous year. This rapid expansion demonstrates the increasing market acceptance and demand for electrified mobility solutions.

EREVs offer a unique value proposition in the sustainable mobility landscape by addressing range anxiety, a common concern among potential electric vehicle buyers. By combining the benefits of electric propulsion with the flexibility of an internal combustion engine, EREVs provide a transitional technology that appeals to consumers who are hesitant to switch to fully electric vehicles due to charging infrastructure limitations or long-distance travel needs.

The circular economy aspect of EREVs further enhances their market appeal. As businesses and consumers become more conscious of resource efficiency and waste reduction, vehicles designed with circular economy principles in mind gain a competitive edge. EREVs support these initiatives through their potential for extended lifespan, modular design for easier repair and refurbishment, and the use of recyclable materials in their construction.

Fleet operators and businesses are also driving demand for sustainable mobility solutions like EREVs. Companies are increasingly incorporating sustainability goals into their corporate strategies, leading to a growing interest in greening their vehicle fleets. EREVs offer these organizations a practical solution to reduce their carbon footprint while maintaining operational flexibility.

The market demand for sustainable mobility solutions, including EREVs, is expected to continue its upward trajectory. As technology advances and economies of scale are achieved, the cost-competitiveness of these vehicles will improve, further accelerating their adoption. The integration of EREVs into circular economy initiatives presents a compelling opportunity for automakers to meet evolving market demands while contributing to broader sustainability goals.

EREV Technology Status and Challenges

Extended Range Electric Vehicles (EREVs) have emerged as a promising technology in the automotive industry, offering a potential solution to address environmental concerns and support circular economy initiatives. The current status of EREV technology demonstrates significant advancements in battery capacity, electric motor efficiency, and overall vehicle performance. However, several challenges remain in fully realizing the potential of EREVs in supporting circular economy principles.

One of the primary technological advancements in EREVs is the improvement in battery technology. Lithium-ion batteries have become the standard, with energy densities increasing substantially over the past decade. This has led to extended electric-only driving ranges, typically ranging from 40 to 80 miles, before the internal combustion engine engages. However, the production and disposal of these batteries present significant environmental challenges, hindering the full realization of circular economy goals.

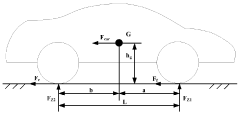

The integration of regenerative braking systems has greatly enhanced the energy efficiency of EREVs. These systems capture kinetic energy during deceleration and convert it into electrical energy, which is then stored in the battery for later use. While this technology has improved significantly, there is still room for optimization to maximize energy recovery and further support circular economy initiatives.

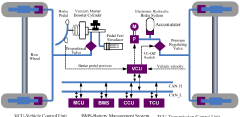

A major challenge facing EREV technology is the complexity of the dual powertrain system. The combination of an electric motor and an internal combustion engine requires sophisticated control systems to manage power distribution and optimize efficiency. This complexity can lead to increased manufacturing costs and potential reliability issues, which may hinder widespread adoption and the establishment of a circular economy ecosystem for EREVs.

The development of lightweight materials for EREV construction has progressed, with advanced composites and high-strength alloys being increasingly utilized. These materials contribute to improved energy efficiency and extended electric range. However, the recyclability and end-of-life management of these advanced materials pose challenges in aligning with circular economy principles.

Another significant hurdle is the charging infrastructure for EREVs. While the extended range provided by the internal combustion engine alleviates some concerns, the availability of charging stations remains a limiting factor in many regions. This infrastructure gap needs to be addressed to fully support the transition to EREVs and create a sustainable, circular ecosystem.

The current state of EREV technology also faces challenges in terms of standardization. Different manufacturers employ varying approaches to powertrain design, battery management, and charging systems. This lack of standardization complicates maintenance, repair, and recycling processes, potentially impeding the development of a circular economy for EREVs.

In conclusion, while EREV technology has made significant strides in supporting circular economy initiatives, several technological and infrastructural challenges remain. Addressing these issues will be crucial in fully realizing the potential of EREVs as a sustainable transportation solution aligned with circular economy principles.

One of the primary technological advancements in EREVs is the improvement in battery technology. Lithium-ion batteries have become the standard, with energy densities increasing substantially over the past decade. This has led to extended electric-only driving ranges, typically ranging from 40 to 80 miles, before the internal combustion engine engages. However, the production and disposal of these batteries present significant environmental challenges, hindering the full realization of circular economy goals.

The integration of regenerative braking systems has greatly enhanced the energy efficiency of EREVs. These systems capture kinetic energy during deceleration and convert it into electrical energy, which is then stored in the battery for later use. While this technology has improved significantly, there is still room for optimization to maximize energy recovery and further support circular economy initiatives.

A major challenge facing EREV technology is the complexity of the dual powertrain system. The combination of an electric motor and an internal combustion engine requires sophisticated control systems to manage power distribution and optimize efficiency. This complexity can lead to increased manufacturing costs and potential reliability issues, which may hinder widespread adoption and the establishment of a circular economy ecosystem for EREVs.

The development of lightweight materials for EREV construction has progressed, with advanced composites and high-strength alloys being increasingly utilized. These materials contribute to improved energy efficiency and extended electric range. However, the recyclability and end-of-life management of these advanced materials pose challenges in aligning with circular economy principles.

Another significant hurdle is the charging infrastructure for EREVs. While the extended range provided by the internal combustion engine alleviates some concerns, the availability of charging stations remains a limiting factor in many regions. This infrastructure gap needs to be addressed to fully support the transition to EREVs and create a sustainable, circular ecosystem.

The current state of EREV technology also faces challenges in terms of standardization. Different manufacturers employ varying approaches to powertrain design, battery management, and charging systems. This lack of standardization complicates maintenance, repair, and recycling processes, potentially impeding the development of a circular economy for EREVs.

In conclusion, while EREV technology has made significant strides in supporting circular economy initiatives, several technological and infrastructural challenges remain. Addressing these issues will be crucial in fully realizing the potential of EREVs as a sustainable transportation solution aligned with circular economy principles.

Current EREV Circular Economy Solutions

01 Battery recycling and reuse systems for EREVs

Implementing circular economy principles in EREV battery management through recycling and reuse systems. This includes developing efficient battery collection processes, refurbishing methods for second-life applications, and recycling technologies to recover valuable materials from end-of-life batteries.- Battery recycling and reuse systems for EREVs: Implementing circular economy principles in EREV battery management through recycling and reuse systems. This includes developing efficient battery collection processes, refurbishing methods for second-life applications, and recycling technologies to recover valuable materials from end-of-life batteries.

- Modular design for easy maintenance and upgrades: Designing EREVs with modular components to facilitate easy maintenance, repair, and upgrades. This approach extends the vehicle's lifespan, reduces waste, and allows for the integration of newer technologies as they become available, supporting circular economy principles.

- Renewable energy integration for EREV charging: Developing systems to integrate renewable energy sources into EREV charging infrastructure. This includes smart charging stations that prioritize renewable energy use, vehicle-to-grid (V2G) technologies, and energy storage solutions to maximize the use of clean energy in EREV operations.

- Sustainable material selection and manufacturing processes: Incorporating sustainable and recyclable materials in EREV production, along with eco-friendly manufacturing processes. This includes using bio-based materials, recycled content, and designing components for easy disassembly and recycling at the end of the vehicle's life.

- Digital twin technology for lifecycle management: Utilizing digital twin technology to monitor and optimize the entire lifecycle of EREVs. This involves creating virtual models of vehicles to track performance, predict maintenance needs, and improve overall efficiency, supporting circular economy principles through data-driven lifecycle management.

02 Modular design for easy maintenance and upgrades

Designing EREVs with modular components to facilitate easy maintenance, repairs, and upgrades. This approach extends the vehicle's lifespan, reduces waste, and allows for the integration of newer technologies as they become available, supporting circular economy principles.Expand Specific Solutions03 Renewable energy integration for EREV charging

Developing systems to integrate renewable energy sources for EREV charging infrastructure. This includes smart grid technologies, solar-powered charging stations, and energy storage solutions to maximize the use of clean energy and reduce the overall environmental impact of EREVs.Expand Specific Solutions04 Advanced powertrain optimization for efficiency

Implementing advanced powertrain optimization techniques to improve the overall efficiency of EREVs. This includes developing intelligent energy management systems, regenerative braking technologies, and lightweight materials to extend the vehicle's range and reduce resource consumption.Expand Specific Solutions05 End-of-life vehicle recycling and material recovery

Establishing comprehensive end-of-life vehicle recycling processes for EREVs, focusing on efficient disassembly techniques, material sorting, and recovery of valuable components. This approach aims to maximize resource utilization and minimize waste in the EREV lifecycle.Expand Specific Solutions

Key Players in EREV and Circular Economy

The competition landscape for Extended Range Electric Vehicles (EREVs) supporting circular economy initiatives is evolving rapidly. The market is in an early growth stage, with increasing adoption as automakers expand EREV offerings. Major players like GM, Hyundai, and Kia are investing heavily in EREV technology development. The market size is projected to grow significantly in the coming years as consumers seek more sustainable transportation options. While the technology is maturing, there is still room for innovation, particularly in areas like battery recycling and sustainable materials. Companies like Cummins and Accenture are also contributing expertise in powertrain electrification and sustainability consulting to advance EREV circular economy applications.

GM Global Technology Operations LLC

Technical Solution: GM's EREV technology, exemplified by the Chevrolet Volt platform, supports circular economy initiatives through its advanced battery management and recycling programs. The company's EREV system utilizes a lithium-ion battery pack coupled with a small gasoline engine, maximizing electric driving while providing extended range capabilities[4]. GM has implemented a comprehensive battery recycling strategy, partnering with specialized firms to recover up to 95% of battery materials for reuse in new batteries or other applications[5]. Furthermore, GM's EREV vehicles incorporate smart charging technologies that optimize grid interaction, potentially supporting renewable energy integration and reducing overall carbon footprint[6].

Strengths: Established EREV technology, comprehensive battery recycling program, and smart grid integration. Weaknesses: Continued dependence on gasoline for range extension, potential complexity in recycling mixed material batteries.

Cummins, Inc.

Technical Solution: Cummins' EREV technology supports circular economy initiatives through its focus on sustainable power solutions and modular design. The company's EREV systems integrate advanced electric drivetrains with efficient range-extending engines, optimized for various vehicle applications[10]. Cummins has developed a scalable battery pack architecture that allows for easy maintenance, repair, and eventual recycling of components. Their EREV powertrains incorporate regenerative braking systems and intelligent power management to maximize energy efficiency. Furthermore, Cummins has invested in second-life battery applications, repurposing EV batteries for stationary energy storage, thus extending the useful life of these components and reducing waste[11].

Strengths: Scalable and modular powertrain design, expertise in efficient engine technology, and investment in battery second-life applications. Weaknesses: Primary focus on commercial and industrial applications may limit consumer market penetration.

Innovations in EREV Sustainability

Intelligent autonomous braking control strategy of e-vehicle based on driving intention recognition

PatentPendingIN202341007949A

Innovation

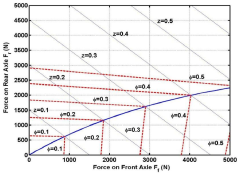

- A fuzzy logic-based braking control strategy integrated with series regenerative braking is developed to optimize energy recovery and distribute braking forces between front and rear wheels, utilizing a Sugeno-type fuzzy logic controller with inputs from driver's braking force, vehicle speed, battery SOC, and temperature to manage regenerative and friction braking forces effectively.

Intelligent autonomous braking control strategy of e-vehicle based on driving intention recognition

PatentPendingIN202341007949A

Innovation

- A fuzzy logic-based braking control strategy integrated with series regenerative braking is developed to optimize energy recovery and distribute braking forces between front and rear wheels, utilizing a Sugeno-type fuzzy logic controller with inputs from driver's braking force, vehicle speed, battery SOC, and temperature to manage regenerative and friction braking forces effectively.

Policy and Regulatory Framework

The policy and regulatory framework surrounding Extended Range Electric Vehicles (EREVs) plays a crucial role in supporting circular economy initiatives. Governments worldwide are increasingly recognizing the potential of EREVs to contribute to sustainability goals and are implementing policies to encourage their adoption and integration into circular economy practices.

One key aspect of the regulatory framework is the establishment of emissions standards and fuel efficiency requirements. Many countries have introduced stringent regulations that favor low-emission vehicles, including EREVs. These policies create incentives for manufacturers to invest in EREV technology and promote their use, aligning with circular economy principles of resource efficiency and waste reduction.

Financial incentives form another important pillar of the policy framework. Governments offer various subsidies, tax credits, and grants to both consumers and manufacturers to stimulate EREV adoption. These incentives not only make EREVs more affordable but also encourage the development of supporting infrastructure, such as charging stations and battery recycling facilities, which are essential for a circular economy approach.

Regulations regarding end-of-life vehicle management and battery recycling are particularly relevant to circular economy initiatives. Many jurisdictions have implemented extended producer responsibility (EPR) policies, requiring manufacturers to take responsibility for the entire lifecycle of their products, including disposal and recycling. These policies promote the design of EREVs with recyclability and reusability in mind, supporting the circular economy concept.

Infrastructure development policies also play a crucial role. Governments are investing in and incentivizing the construction of charging networks, which is essential for widespread EREV adoption. Additionally, policies supporting smart grid integration and vehicle-to-grid (V2G) technology enable EREVs to contribute to grid stability and energy storage, further enhancing their role in a circular economy.

Research and development support is another key policy area. Many governments provide funding and incentives for EREV-related research, focusing on areas such as battery technology, lightweight materials, and recycling processes. These initiatives drive innovation in circular design principles and help overcome technical barriers to implementing circular economy practices in the EREV sector.

Standardization and interoperability regulations are also crucial. Governments and industry bodies are working to establish common standards for EREV components, charging interfaces, and data protocols. These standards facilitate the reuse and recycling of components across different manufacturers and models, supporting the circular economy's principles of resource efficiency and waste reduction.

One key aspect of the regulatory framework is the establishment of emissions standards and fuel efficiency requirements. Many countries have introduced stringent regulations that favor low-emission vehicles, including EREVs. These policies create incentives for manufacturers to invest in EREV technology and promote their use, aligning with circular economy principles of resource efficiency and waste reduction.

Financial incentives form another important pillar of the policy framework. Governments offer various subsidies, tax credits, and grants to both consumers and manufacturers to stimulate EREV adoption. These incentives not only make EREVs more affordable but also encourage the development of supporting infrastructure, such as charging stations and battery recycling facilities, which are essential for a circular economy approach.

Regulations regarding end-of-life vehicle management and battery recycling are particularly relevant to circular economy initiatives. Many jurisdictions have implemented extended producer responsibility (EPR) policies, requiring manufacturers to take responsibility for the entire lifecycle of their products, including disposal and recycling. These policies promote the design of EREVs with recyclability and reusability in mind, supporting the circular economy concept.

Infrastructure development policies also play a crucial role. Governments are investing in and incentivizing the construction of charging networks, which is essential for widespread EREV adoption. Additionally, policies supporting smart grid integration and vehicle-to-grid (V2G) technology enable EREVs to contribute to grid stability and energy storage, further enhancing their role in a circular economy.

Research and development support is another key policy area. Many governments provide funding and incentives for EREV-related research, focusing on areas such as battery technology, lightweight materials, and recycling processes. These initiatives drive innovation in circular design principles and help overcome technical barriers to implementing circular economy practices in the EREV sector.

Standardization and interoperability regulations are also crucial. Governments and industry bodies are working to establish common standards for EREV components, charging interfaces, and data protocols. These standards facilitate the reuse and recycling of components across different manufacturers and models, supporting the circular economy's principles of resource efficiency and waste reduction.

Environmental Impact Assessment

The environmental impact assessment of Extended Range Electric Vehicles (EREVs) in supporting circular economy initiatives reveals both positive and negative effects. On the positive side, EREVs contribute significantly to reducing greenhouse gas emissions and air pollution compared to conventional internal combustion engine vehicles. By utilizing electric power for a substantial portion of their operation, EREVs decrease reliance on fossil fuels and minimize tailpipe emissions, particularly in urban areas where air quality is a critical concern.

Furthermore, the integration of EREVs into circular economy models promotes the development of more sustainable battery technologies and recycling processes. As battery production and disposal are key environmental concerns for electric vehicles, the circular economy approach encourages innovative solutions for battery life extension, repurposing, and efficient recycling. This not only reduces the environmental impact of battery production but also minimizes waste and conserves valuable resources.

However, the environmental impact of EREVs is not entirely positive. The production of batteries and electric components still involves energy-intensive processes and the extraction of rare earth elements, which can have significant environmental consequences. Mining activities for these materials can lead to habitat destruction, water pollution, and soil degradation in resource-rich regions.

Additionally, the environmental benefits of EREVs are heavily dependent on the source of electricity used for charging. In regions where electricity generation relies heavily on fossil fuels, the overall environmental impact of EREVs may be less favorable. This underscores the importance of transitioning to renewable energy sources in parallel with the adoption of electric vehicle technologies.

The lifecycle assessment of EREVs also reveals potential challenges in terms of vehicle longevity and maintenance. While electric drivetrains generally have fewer moving parts and require less maintenance than traditional engines, the complexity of hybrid systems in EREVs may lead to increased resource consumption for repairs and replacements over the vehicle's lifespan.

In conclusion, while EREVs offer significant environmental benefits in terms of emissions reduction and support for circular economy initiatives, their overall environmental impact is complex and multifaceted. To maximize the positive effects and mitigate negative consequences, a holistic approach is necessary, encompassing sustainable production methods, clean energy sources, and effective end-of-life management strategies for vehicles and their components.

Furthermore, the integration of EREVs into circular economy models promotes the development of more sustainable battery technologies and recycling processes. As battery production and disposal are key environmental concerns for electric vehicles, the circular economy approach encourages innovative solutions for battery life extension, repurposing, and efficient recycling. This not only reduces the environmental impact of battery production but also minimizes waste and conserves valuable resources.

However, the environmental impact of EREVs is not entirely positive. The production of batteries and electric components still involves energy-intensive processes and the extraction of rare earth elements, which can have significant environmental consequences. Mining activities for these materials can lead to habitat destruction, water pollution, and soil degradation in resource-rich regions.

Additionally, the environmental benefits of EREVs are heavily dependent on the source of electricity used for charging. In regions where electricity generation relies heavily on fossil fuels, the overall environmental impact of EREVs may be less favorable. This underscores the importance of transitioning to renewable energy sources in parallel with the adoption of electric vehicle technologies.

The lifecycle assessment of EREVs also reveals potential challenges in terms of vehicle longevity and maintenance. While electric drivetrains generally have fewer moving parts and require less maintenance than traditional engines, the complexity of hybrid systems in EREVs may lead to increased resource consumption for repairs and replacements over the vehicle's lifespan.

In conclusion, while EREVs offer significant environmental benefits in terms of emissions reduction and support for circular economy initiatives, their overall environmental impact is complex and multifaceted. To maximize the positive effects and mitigate negative consequences, a holistic approach is necessary, encompassing sustainable production methods, clean energy sources, and effective end-of-life management strategies for vehicles and their components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!