Impact of lightweight materials on EREV efficiency

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EREV Efficiency Goals

Extended Range Electric Vehicles (EREVs) have emerged as a promising solution to address the limitations of traditional electric vehicles, particularly in terms of range anxiety. As the automotive industry continues to evolve, setting ambitious efficiency goals for EREVs has become crucial for their widespread adoption and long-term success. These goals are primarily focused on maximizing the vehicle's overall energy efficiency, extending its electric-only range, and reducing its environmental impact.

One of the key EREV efficiency goals is to increase the electric-only range, allowing drivers to complete most of their daily commutes without relying on the internal combustion engine. This objective requires advancements in battery technology, including improvements in energy density, charging speed, and overall capacity. Manufacturers are targeting electric ranges of 100 miles or more for future EREV models, a significant increase from the current industry standards.

Another critical efficiency goal for EREVs is to optimize the integration between the electric drivetrain and the internal combustion engine. This involves developing sophisticated control systems that can seamlessly switch between power sources, maximizing the use of electric power while minimizing fuel consumption. The aim is to achieve a combined fuel economy of over 100 miles per gallon equivalent (MPGe) for next-generation EREVs.

Reducing the overall weight of EREVs is also a paramount efficiency goal. Lightweight materials play a crucial role in achieving this objective, as they directly impact the vehicle's energy consumption and performance. By incorporating advanced materials such as high-strength steel, aluminum alloys, and carbon fiber composites, manufacturers aim to reduce vehicle weight by up to 30% compared to conventional models. This weight reduction translates into improved acceleration, handling, and most importantly, increased energy efficiency.

EREV efficiency goals also extend to the vehicle's aerodynamics. Engineers are working on designing more streamlined body shapes and incorporating active aerodynamic features to minimize drag coefficients. The target is to achieve drag coefficients below 0.25, which would significantly reduce energy consumption at highway speeds and extend the vehicle's range.

Furthermore, EREV manufacturers are setting ambitious goals for regenerative braking systems. By capturing and converting a higher percentage of kinetic energy into electrical energy during deceleration, these systems can contribute to extending the electric range. The industry is aiming for regenerative braking systems that can recover up to 70% of the vehicle's kinetic energy, a substantial improvement over current technologies.

Lastly, EREV efficiency goals include reducing the environmental impact of vehicle production and end-of-life disposal. This involves developing more sustainable manufacturing processes, increasing the use of recycled materials, and designing vehicles for easier disassembly and recycling at the end of their lifecycle. The ultimate goal is to create EREVs with a significantly lower carbon footprint throughout their entire lifecycle, from production to disposal.

One of the key EREV efficiency goals is to increase the electric-only range, allowing drivers to complete most of their daily commutes without relying on the internal combustion engine. This objective requires advancements in battery technology, including improvements in energy density, charging speed, and overall capacity. Manufacturers are targeting electric ranges of 100 miles or more for future EREV models, a significant increase from the current industry standards.

Another critical efficiency goal for EREVs is to optimize the integration between the electric drivetrain and the internal combustion engine. This involves developing sophisticated control systems that can seamlessly switch between power sources, maximizing the use of electric power while minimizing fuel consumption. The aim is to achieve a combined fuel economy of over 100 miles per gallon equivalent (MPGe) for next-generation EREVs.

Reducing the overall weight of EREVs is also a paramount efficiency goal. Lightweight materials play a crucial role in achieving this objective, as they directly impact the vehicle's energy consumption and performance. By incorporating advanced materials such as high-strength steel, aluminum alloys, and carbon fiber composites, manufacturers aim to reduce vehicle weight by up to 30% compared to conventional models. This weight reduction translates into improved acceleration, handling, and most importantly, increased energy efficiency.

EREV efficiency goals also extend to the vehicle's aerodynamics. Engineers are working on designing more streamlined body shapes and incorporating active aerodynamic features to minimize drag coefficients. The target is to achieve drag coefficients below 0.25, which would significantly reduce energy consumption at highway speeds and extend the vehicle's range.

Furthermore, EREV manufacturers are setting ambitious goals for regenerative braking systems. By capturing and converting a higher percentage of kinetic energy into electrical energy during deceleration, these systems can contribute to extending the electric range. The industry is aiming for regenerative braking systems that can recover up to 70% of the vehicle's kinetic energy, a substantial improvement over current technologies.

Lastly, EREV efficiency goals include reducing the environmental impact of vehicle production and end-of-life disposal. This involves developing more sustainable manufacturing processes, increasing the use of recycled materials, and designing vehicles for easier disassembly and recycling at the end of their lifecycle. The ultimate goal is to create EREVs with a significantly lower carbon footprint throughout their entire lifecycle, from production to disposal.

Market Demand Analysis

The market demand for lightweight materials in Extended Range Electric Vehicles (EREVs) has been steadily increasing due to the growing emphasis on energy efficiency and environmental sustainability in the automotive industry. As governments worldwide implement stricter emissions regulations and fuel economy standards, automakers are increasingly turning to lightweight materials to improve the overall efficiency of EREVs.

The primary driver for this demand is the direct correlation between vehicle weight reduction and improved energy efficiency. Lightweight materials, such as advanced high-strength steels, aluminum alloys, carbon fiber reinforced polymers, and magnesium alloys, can significantly reduce the overall weight of EREVs. This weight reduction translates into improved range, acceleration, and overall performance, addressing key consumer concerns about electric vehicles.

In the EREV market, the demand for lightweight materials is particularly pronounced due to the unique challenges these vehicles face. EREVs must balance the weight of both electric and combustion powertrains, making weight reduction even more critical. The use of lightweight materials in EREVs can help offset the additional weight of batteries and range-extending engines, maintaining or even improving vehicle performance and efficiency.

The market for lightweight materials in EREVs is expected to grow substantially in the coming years. This growth is driven by several factors, including increasing consumer demand for more efficient and environmentally friendly vehicles, advancements in material science and manufacturing technologies, and the ongoing electrification of the automotive industry.

Automotive OEMs and suppliers are investing heavily in research and development of lightweight materials and their applications in EREVs. This investment is not only focused on material development but also on innovative design and manufacturing processes that can effectively integrate these materials into vehicle structures while maintaining safety standards and cost-effectiveness.

The demand for lightweight materials in EREVs is also influenced by regional market dynamics. In regions with stringent emissions regulations, such as Europe and parts of Asia, the adoption of lightweight materials in EREVs is likely to be more rapid. In contrast, markets with less stringent regulations may see a more gradual adoption curve, driven primarily by consumer demand for improved fuel efficiency and performance.

As the EREV market continues to evolve, the demand for lightweight materials is expected to expand beyond traditional automotive applications. This includes the development of new lightweight battery enclosures, innovative chassis designs, and advanced interior components. The integration of these materials across various vehicle systems will play a crucial role in maximizing the efficiency gains in EREVs.

The primary driver for this demand is the direct correlation between vehicle weight reduction and improved energy efficiency. Lightweight materials, such as advanced high-strength steels, aluminum alloys, carbon fiber reinforced polymers, and magnesium alloys, can significantly reduce the overall weight of EREVs. This weight reduction translates into improved range, acceleration, and overall performance, addressing key consumer concerns about electric vehicles.

In the EREV market, the demand for lightweight materials is particularly pronounced due to the unique challenges these vehicles face. EREVs must balance the weight of both electric and combustion powertrains, making weight reduction even more critical. The use of lightweight materials in EREVs can help offset the additional weight of batteries and range-extending engines, maintaining or even improving vehicle performance and efficiency.

The market for lightweight materials in EREVs is expected to grow substantially in the coming years. This growth is driven by several factors, including increasing consumer demand for more efficient and environmentally friendly vehicles, advancements in material science and manufacturing technologies, and the ongoing electrification of the automotive industry.

Automotive OEMs and suppliers are investing heavily in research and development of lightweight materials and their applications in EREVs. This investment is not only focused on material development but also on innovative design and manufacturing processes that can effectively integrate these materials into vehicle structures while maintaining safety standards and cost-effectiveness.

The demand for lightweight materials in EREVs is also influenced by regional market dynamics. In regions with stringent emissions regulations, such as Europe and parts of Asia, the adoption of lightweight materials in EREVs is likely to be more rapid. In contrast, markets with less stringent regulations may see a more gradual adoption curve, driven primarily by consumer demand for improved fuel efficiency and performance.

As the EREV market continues to evolve, the demand for lightweight materials is expected to expand beyond traditional automotive applications. This includes the development of new lightweight battery enclosures, innovative chassis designs, and advanced interior components. The integration of these materials across various vehicle systems will play a crucial role in maximizing the efficiency gains in EREVs.

Lightweight Materials

Lightweight materials have emerged as a critical factor in enhancing the efficiency of Extended Range Electric Vehicles (EREVs). These materials, primarily including advanced high-strength steels, aluminum alloys, magnesium alloys, and carbon fiber reinforced polymers, offer significant weight reduction potential without compromising structural integrity or safety standards.

The adoption of lightweight materials in EREV design directly impacts vehicle efficiency through several mechanisms. Firstly, reduced vehicle mass decreases the energy required for acceleration and deceleration, leading to improved overall energy efficiency. This is particularly beneficial in urban driving scenarios with frequent stops and starts. Additionally, lighter vehicles require less energy to maintain cruising speeds, further contributing to extended electric range.

In the context of EREVs, the weight reduction achieved through lightweight materials allows for potential downsizing of the battery pack without sacrificing range. This creates a positive feedback loop, as a smaller battery further reduces the vehicle's overall weight. The cumulative effect is a significant improvement in the vehicle's energy efficiency and range performance.

Moreover, lightweight materials enable more efficient packaging of powertrain components. This allows for optimized weight distribution and improved vehicle dynamics, which in turn can lead to reduced energy consumption during cornering and maneuvering. The use of these materials also contributes to enhanced thermal management of battery systems, as reduced mass allows for more effective cooling strategies.

From a manufacturing perspective, the integration of lightweight materials in EREV production presents both challenges and opportunities. While some materials, such as advanced high-strength steels, can be incorporated using existing manufacturing processes, others like carbon fiber composites require new production techniques. This necessitates significant investment in research and development, as well as retooling of production facilities.

The impact of lightweight materials extends beyond immediate efficiency gains. By enabling longer electric ranges and improved performance, these materials contribute to the broader adoption of EREVs. This, in turn, supports the transition towards more sustainable transportation solutions and helps meet increasingly stringent emissions regulations.

However, the implementation of lightweight materials in EREVs is not without challenges. Cost remains a significant barrier, particularly for advanced composites. Balancing the trade-offs between material cost, weight reduction, and performance improvement is a key consideration for EREV manufacturers. Additionally, the lifecycle environmental impact of these materials, including production energy intensity and recyclability, must be carefully evaluated to ensure a net positive effect on sustainability.

The adoption of lightweight materials in EREV design directly impacts vehicle efficiency through several mechanisms. Firstly, reduced vehicle mass decreases the energy required for acceleration and deceleration, leading to improved overall energy efficiency. This is particularly beneficial in urban driving scenarios with frequent stops and starts. Additionally, lighter vehicles require less energy to maintain cruising speeds, further contributing to extended electric range.

In the context of EREVs, the weight reduction achieved through lightweight materials allows for potential downsizing of the battery pack without sacrificing range. This creates a positive feedback loop, as a smaller battery further reduces the vehicle's overall weight. The cumulative effect is a significant improvement in the vehicle's energy efficiency and range performance.

Moreover, lightweight materials enable more efficient packaging of powertrain components. This allows for optimized weight distribution and improved vehicle dynamics, which in turn can lead to reduced energy consumption during cornering and maneuvering. The use of these materials also contributes to enhanced thermal management of battery systems, as reduced mass allows for more effective cooling strategies.

From a manufacturing perspective, the integration of lightweight materials in EREV production presents both challenges and opportunities. While some materials, such as advanced high-strength steels, can be incorporated using existing manufacturing processes, others like carbon fiber composites require new production techniques. This necessitates significant investment in research and development, as well as retooling of production facilities.

The impact of lightweight materials extends beyond immediate efficiency gains. By enabling longer electric ranges and improved performance, these materials contribute to the broader adoption of EREVs. This, in turn, supports the transition towards more sustainable transportation solutions and helps meet increasingly stringent emissions regulations.

However, the implementation of lightweight materials in EREVs is not without challenges. Cost remains a significant barrier, particularly for advanced composites. Balancing the trade-offs between material cost, weight reduction, and performance improvement is a key consideration for EREV manufacturers. Additionally, the lifecycle environmental impact of these materials, including production energy intensity and recyclability, must be carefully evaluated to ensure a net positive effect on sustainability.

Current Lightweight

01 Composite materials for lightweight efficiency

Composite materials are used to create lightweight structures with improved efficiency. These materials combine different components to achieve optimal strength-to-weight ratios, enhancing overall performance while reducing mass. Advanced composites can be tailored for specific applications, offering superior mechanical properties and durability compared to traditional materials.- Composite materials for lightweight efficiency: Composite materials are utilized to achieve lightweight efficiency in various applications. These materials combine different components to create structures with high strength-to-weight ratios, improving overall performance and energy efficiency. Composites often incorporate fibers, resins, and other reinforcing materials to optimize mechanical properties while minimizing weight.

- Lightweight alloys and metal foams: Lightweight alloys, such as aluminum and magnesium alloys, and metal foams are developed to reduce weight while maintaining structural integrity. These materials offer significant weight savings compared to traditional metals, making them ideal for automotive, aerospace, and other industries where weight reduction is crucial for improved efficiency and performance.

- Advanced manufacturing techniques for lightweight structures: Innovative manufacturing processes, such as additive manufacturing and advanced forming techniques, are employed to create lightweight structures with complex geometries. These methods allow for the optimization of material distribution, resulting in parts that are both lightweight and structurally efficient. Such techniques enable the production of components with intricate internal structures or topology-optimized designs.

- Nanomaterials for weight reduction: Nanomaterials, including carbon nanotubes and graphene, are incorporated into various materials to enhance strength and reduce weight. These nanoscale additives can significantly improve the mechanical properties of polymers, metals, and composites without adding substantial mass, leading to more efficient lightweight materials for diverse applications.

- Lightweight materials in energy storage and conversion: Lightweight materials are crucial in the development of efficient energy storage and conversion devices. This includes the use of advanced materials in batteries, fuel cells, and solar panels to improve energy density and overall system efficiency while reducing weight. Such advancements are particularly important for portable electronics and electric vehicles.

02 Lightweight alloys for improved efficiency

Lightweight alloys, particularly those based on aluminum, magnesium, or titanium, are developed to increase efficiency in various applications. These alloys offer reduced weight while maintaining necessary strength and durability. Advanced processing techniques and alloying elements are used to enhance their properties, making them suitable for automotive, aerospace, and other industries where weight reduction is crucial.Expand Specific Solutions03 Innovative design techniques for lightweight structures

Novel design approaches are employed to create lightweight yet efficient structures. These techniques include topology optimization, generative design, and biomimicry. By optimizing material distribution and structural geometry, engineers can significantly reduce weight while maintaining or improving performance. Such designs often incorporate complex shapes that are enabled by advanced manufacturing methods like 3D printing.Expand Specific Solutions04 Nanotechnology for enhanced material efficiency

Nanotechnology is utilized to develop lightweight materials with improved efficiency. By manipulating materials at the nanoscale, researchers can create nanocomposites, nanostructured coatings, and other advanced materials with exceptional strength-to-weight ratios. These nanomaterials often exhibit unique properties that contribute to increased durability, thermal management, and overall performance in lightweight applications.Expand Specific Solutions05 Manufacturing processes for lightweight efficient components

Advanced manufacturing techniques are developed to produce lightweight, efficient components. These processes include additive manufacturing, advanced forming techniques, and novel joining methods. By optimizing manufacturing processes, it's possible to create complex geometries, reduce material waste, and integrate multiple functions into single components, all contributing to improved lightweight efficiency.Expand Specific Solutions

Key EREV Manufacturers

The impact of lightweight materials on EREV efficiency is a rapidly evolving field within the automotive industry. The market is in a growth phase, with increasing demand for more efficient and environmentally friendly vehicles driving innovation. The global market for lightweight materials in EVs is projected to expand significantly in the coming years. Technologically, the field is advancing quickly, with companies like BASF Corp., LG Chem Ltd., and Sumitomo Chemical Co., Ltd. leading the way in developing advanced lightweight materials. These companies are investing heavily in R&D to create new composites and alloys that can significantly reduce vehicle weight while maintaining structural integrity and safety standards. The competition is fierce, with both established automotive suppliers and new entrants vying for market share in this promising sector.

BASF Corp.

Technical Solution: BASF has developed innovative lightweight materials for EREVs, focusing on high-performance plastics and composites. Their Ultramid® Advanced N polyamide has been used to create lightweight structural components, reducing vehicle weight by up to 50% compared to metal parts[1]. They have also introduced Elastolit®, a polyurethane system for producing lightweight roof modules, which can reduce weight by up to 30%[2]. BASF's Elastoflex® E semi-rigid polyurethane foam is used for noise and vibration damping, contributing to improved energy efficiency[3]. These materials collectively contribute to increased EREV efficiency by reducing overall vehicle weight and improving aerodynamics.

Strengths: Wide range of lightweight materials, significant weight reduction potential, improved energy efficiency. Weaknesses: Higher initial costs compared to traditional materials, potential challenges in recycling composite materials.

LG Chem Ltd.

Technical Solution: LG Chem has focused on developing advanced battery technologies and lightweight materials for EREVs. They have introduced a new generation of lithium-ion batteries with higher energy density and lower weight, improving the overall efficiency of EREVs[4]. Their carbon nanotube (CNT) technology has been applied to create lightweight, high-strength components for vehicle bodies, reducing weight by up to 30% compared to steel[5]. LG Chem has also developed lightweight thermoplastic olefins (TPOs) for interior and exterior automotive applications, further contributing to weight reduction[6]. These innovations collectively enhance EREV efficiency by reducing vehicle weight and improving energy storage capacity.

Strengths: Integrated approach combining battery technology and lightweight materials, significant weight reduction and energy density improvements. Weaknesses: High research and development costs, potential supply chain challenges for specialized materials.

Innovative Lightweight

Range-extended electric vehicles having lithium titanate oxide (LTO) battery with super high charge and discharge rates

PatentActiveUS11152614B2

Innovation

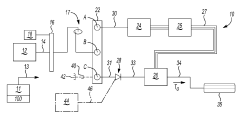

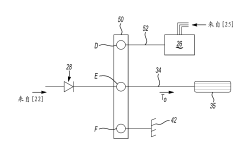

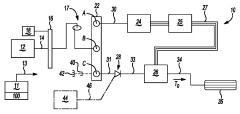

- A range-extended electric vehicle equipped with a lithium titanate oxide (LTO) battery pack that offers high charge and discharge rates, enhanced safety, and improved low-temperature performance, combined with a range extender that can operate in multiple states to optimize power delivery and charging, using LTO battery cells with Li4Ti5O12 composition and nanocrystals for increased surface area and efficiency.

Low Fuel Consumption Extended Range Electric Vehicle Powertrain

PatentInactiveCN102275518A

Innovation

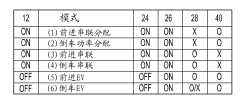

- An extended-range electric vehicle is designed, which uses an engine with direct mechanical lines to connect to the driving wheels. It realizes forward and reverse pure electric modes and series modes through two motors and one-way clutches, and uses a passive rectifier bypass device and an auxiliary starting motor. Optimize power delivery, reduce motor size and improve fuel efficiency.

Environmental Impact

The use of lightweight materials in Extended Range Electric Vehicles (EREVs) has significant environmental implications, both positive and negative. On the positive side, the reduction in vehicle weight leads to improved energy efficiency, which translates to lower energy consumption and reduced greenhouse gas emissions during the vehicle's operational life. This efficiency gain is particularly important for EREVs, as it extends the electric-only range and reduces the frequency of engaging the internal combustion engine, further minimizing emissions.

Moreover, the use of lightweight materials often results in a decrease in the overall amount of raw materials required for vehicle production. This reduction in material usage can lead to lower energy consumption and emissions during the manufacturing process, as well as reduced waste generation at the end of the vehicle's life cycle. Additionally, some lightweight materials, such as advanced high-strength steels and aluminum alloys, are highly recyclable, contributing to a more circular economy in the automotive industry.

However, the environmental impact of lightweight materials is not entirely positive. The production of certain lightweight materials, such as carbon fiber composites, can be energy-intensive and may involve the use of toxic chemicals. This could potentially offset some of the environmental benefits gained during the vehicle's operational life. Furthermore, the complexity of some lightweight material structures may pose challenges for recycling and end-of-life vehicle management.

The shift towards lightweight materials also has implications for the broader automotive supply chain. As demand for these materials increases, there may be environmental consequences associated with their extraction, processing, and transportation. For instance, increased aluminum production could lead to higher bauxite mining activities, which have their own set of environmental challenges.

It is crucial to consider the entire life cycle of lightweight materials when assessing their environmental impact on EREV efficiency. This includes evaluating the environmental costs of material production, the benefits during vehicle operation, and the implications for end-of-life recycling and disposal. As technology advances, the development of more environmentally friendly production methods for lightweight materials and improved recycling techniques will be essential to maximize the positive environmental impact of their use in EREVs.

In conclusion, while lightweight materials generally contribute positively to EREV efficiency and environmental performance, a holistic approach is necessary to fully understand and optimize their environmental impact across the entire vehicle life cycle.

Moreover, the use of lightweight materials often results in a decrease in the overall amount of raw materials required for vehicle production. This reduction in material usage can lead to lower energy consumption and emissions during the manufacturing process, as well as reduced waste generation at the end of the vehicle's life cycle. Additionally, some lightweight materials, such as advanced high-strength steels and aluminum alloys, are highly recyclable, contributing to a more circular economy in the automotive industry.

However, the environmental impact of lightweight materials is not entirely positive. The production of certain lightweight materials, such as carbon fiber composites, can be energy-intensive and may involve the use of toxic chemicals. This could potentially offset some of the environmental benefits gained during the vehicle's operational life. Furthermore, the complexity of some lightweight material structures may pose challenges for recycling and end-of-life vehicle management.

The shift towards lightweight materials also has implications for the broader automotive supply chain. As demand for these materials increases, there may be environmental consequences associated with their extraction, processing, and transportation. For instance, increased aluminum production could lead to higher bauxite mining activities, which have their own set of environmental challenges.

It is crucial to consider the entire life cycle of lightweight materials when assessing their environmental impact on EREV efficiency. This includes evaluating the environmental costs of material production, the benefits during vehicle operation, and the implications for end-of-life recycling and disposal. As technology advances, the development of more environmentally friendly production methods for lightweight materials and improved recycling techniques will be essential to maximize the positive environmental impact of their use in EREVs.

In conclusion, while lightweight materials generally contribute positively to EREV efficiency and environmental performance, a holistic approach is necessary to fully understand and optimize their environmental impact across the entire vehicle life cycle.

Cost-Benefit Analysis

The cost-benefit analysis of implementing lightweight materials in Extended Range Electric Vehicles (EREVs) reveals a complex interplay of factors that impact both the initial investment and long-term operational efficiency. The primary benefit of using lightweight materials, such as advanced composites, high-strength steel, and aluminum alloys, is the significant reduction in vehicle weight. This weight reduction directly translates to improved energy efficiency, as less energy is required to propel the vehicle, thereby extending the electric range and reducing the frequency of charging or fuel consumption in the range extender.

However, the initial costs associated with lightweight materials can be substantial. Advanced composites and specialized alloys often come with higher material costs and may require new manufacturing processes, tooling, and workforce training. This increased upfront investment must be carefully weighed against the long-term benefits of improved vehicle efficiency and performance.

From an operational perspective, the use of lightweight materials can lead to reduced energy consumption, which translates to lower operating costs for the end-user. This is particularly significant for fleet operators and high-mileage users, where even small improvements in efficiency can result in substantial cost savings over the vehicle's lifetime. Additionally, the extended range capability may reduce the need for frequent charging infrastructure, potentially offsetting some of the initial investment costs.

The environmental impact of lightweight materials in EREVs should also be considered in the cost-benefit analysis. While the production of some lightweight materials may have a higher carbon footprint initially, the reduced emissions during the vehicle's operational life can often offset this. The overall lifecycle assessment typically favors lightweight materials, especially as the energy grid becomes cleaner and more renewable energy sources are utilized.

Durability and maintenance costs are crucial factors in the long-term cost-benefit equation. While some lightweight materials may offer improved corrosion resistance and fatigue strength, others might require more frequent inspections or specialized repair techniques. The potential for reduced wear on components due to lower vehicle weight should be balanced against any increased maintenance requirements specific to the new materials.

In conclusion, the cost-benefit analysis of lightweight materials in EREVs indicates a generally positive outlook, with the long-term operational benefits often outweighing the initial investment costs. However, the specific balance will depend on factors such as production volume, energy prices, and technological advancements in material science and manufacturing processes. As economies of scale improve and material technologies mature, the cost-benefit ratio is expected to become increasingly favorable for lightweight materials in EREV applications.

However, the initial costs associated with lightweight materials can be substantial. Advanced composites and specialized alloys often come with higher material costs and may require new manufacturing processes, tooling, and workforce training. This increased upfront investment must be carefully weighed against the long-term benefits of improved vehicle efficiency and performance.

From an operational perspective, the use of lightweight materials can lead to reduced energy consumption, which translates to lower operating costs for the end-user. This is particularly significant for fleet operators and high-mileage users, where even small improvements in efficiency can result in substantial cost savings over the vehicle's lifetime. Additionally, the extended range capability may reduce the need for frequent charging infrastructure, potentially offsetting some of the initial investment costs.

The environmental impact of lightweight materials in EREVs should also be considered in the cost-benefit analysis. While the production of some lightweight materials may have a higher carbon footprint initially, the reduced emissions during the vehicle's operational life can often offset this. The overall lifecycle assessment typically favors lightweight materials, especially as the energy grid becomes cleaner and more renewable energy sources are utilized.

Durability and maintenance costs are crucial factors in the long-term cost-benefit equation. While some lightweight materials may offer improved corrosion resistance and fatigue strength, others might require more frequent inspections or specialized repair techniques. The potential for reduced wear on components due to lower vehicle weight should be balanced against any increased maintenance requirements specific to the new materials.

In conclusion, the cost-benefit analysis of lightweight materials in EREVs indicates a generally positive outlook, with the long-term operational benefits often outweighing the initial investment costs. However, the specific balance will depend on factors such as production volume, energy prices, and technological advancements in material science and manufacturing processes. As economies of scale improve and material technologies mature, the cost-benefit ratio is expected to become increasingly favorable for lightweight materials in EREV applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!