EREV onboard diagnostics for enhanced troubleshooting

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EREV OBD Background and Objectives

Extended Range Electric Vehicles (EREVs) have emerged as a promising solution to address the range anxiety associated with pure electric vehicles while maintaining the benefits of electric propulsion. As the automotive industry continues to evolve towards electrification, the need for advanced onboard diagnostics (OBD) systems in EREVs has become increasingly critical. This report aims to explore the background and objectives of EREV onboard diagnostics for enhanced troubleshooting.

The development of EREV technology can be traced back to the early 2000s when major automakers began exploring hybrid powertrains as a bridge between conventional internal combustion engines and fully electric vehicles. EREVs, also known as series plug-in hybrids, utilize an electric motor as the primary propulsion system, with a small internal combustion engine serving as a range extender. This configuration allows for extended driving range while maintaining the benefits of electric propulsion for shorter trips.

As EREV technology has matured, the complexity of these vehicles has increased significantly, incorporating advanced power electronics, battery management systems, and sophisticated control algorithms. This complexity has necessitated the development of more advanced onboard diagnostic systems to ensure optimal performance, reliability, and safety of EREVs.

The primary objective of EREV onboard diagnostics for enhanced troubleshooting is to provide real-time monitoring and analysis of the vehicle's various subsystems, enabling early detection of potential issues and facilitating efficient maintenance and repair processes. This includes monitoring the health of the battery pack, assessing the performance of the electric motor and power electronics, and evaluating the operation of the range-extending internal combustion engine.

Another key objective is to improve the overall reliability and longevity of EREV systems by enabling predictive maintenance. By continuously analyzing vehicle data and identifying trends, OBD systems can alert drivers and technicians to potential issues before they lead to component failure or vehicle breakdown. This proactive approach not only enhances the user experience but also reduces maintenance costs and extends the lifespan of EREV components.

Furthermore, EREV onboard diagnostics aim to optimize vehicle performance and energy efficiency. By providing detailed insights into the vehicle's energy consumption patterns and powertrain efficiency, OBD systems can help drivers and fleet managers make informed decisions about vehicle usage and charging strategies. This data can also be leveraged by manufacturers to refine their EREV designs and control algorithms, leading to continuous improvements in vehicle performance and efficiency.

In the context of regulatory compliance, EREV onboard diagnostics play a crucial role in meeting increasingly stringent emissions and safety standards. Advanced OBD systems ensure that EREVs operate within specified parameters, monitoring emissions from the range-extending engine and verifying the proper functioning of safety-critical systems.

The development of EREV technology can be traced back to the early 2000s when major automakers began exploring hybrid powertrains as a bridge between conventional internal combustion engines and fully electric vehicles. EREVs, also known as series plug-in hybrids, utilize an electric motor as the primary propulsion system, with a small internal combustion engine serving as a range extender. This configuration allows for extended driving range while maintaining the benefits of electric propulsion for shorter trips.

As EREV technology has matured, the complexity of these vehicles has increased significantly, incorporating advanced power electronics, battery management systems, and sophisticated control algorithms. This complexity has necessitated the development of more advanced onboard diagnostic systems to ensure optimal performance, reliability, and safety of EREVs.

The primary objective of EREV onboard diagnostics for enhanced troubleshooting is to provide real-time monitoring and analysis of the vehicle's various subsystems, enabling early detection of potential issues and facilitating efficient maintenance and repair processes. This includes monitoring the health of the battery pack, assessing the performance of the electric motor and power electronics, and evaluating the operation of the range-extending internal combustion engine.

Another key objective is to improve the overall reliability and longevity of EREV systems by enabling predictive maintenance. By continuously analyzing vehicle data and identifying trends, OBD systems can alert drivers and technicians to potential issues before they lead to component failure or vehicle breakdown. This proactive approach not only enhances the user experience but also reduces maintenance costs and extends the lifespan of EREV components.

Furthermore, EREV onboard diagnostics aim to optimize vehicle performance and energy efficiency. By providing detailed insights into the vehicle's energy consumption patterns and powertrain efficiency, OBD systems can help drivers and fleet managers make informed decisions about vehicle usage and charging strategies. This data can also be leveraged by manufacturers to refine their EREV designs and control algorithms, leading to continuous improvements in vehicle performance and efficiency.

In the context of regulatory compliance, EREV onboard diagnostics play a crucial role in meeting increasingly stringent emissions and safety standards. Advanced OBD systems ensure that EREVs operate within specified parameters, monitoring emissions from the range-extending engine and verifying the proper functioning of safety-critical systems.

Market Demand for Advanced EREV Diagnostics

The market demand for advanced Extended Range Electric Vehicle (EREV) diagnostics is experiencing significant growth, driven by the increasing adoption of EREVs and the need for more sophisticated troubleshooting capabilities. As EREVs become more prevalent in the automotive market, there is a growing requirement for enhanced onboard diagnostic systems that can effectively identify and resolve issues specific to these complex hybrid powertrains.

The primary market drivers for advanced EREV diagnostics include the rising consumer expectations for vehicle reliability and performance, stringent environmental regulations, and the automotive industry's push towards electrification. Fleet operators and individual owners alike are seeking more efficient and accurate diagnostic tools to minimize downtime and reduce maintenance costs associated with EREVs.

One of the key market demands is for real-time monitoring and predictive maintenance capabilities. Advanced diagnostic systems that can continuously analyze vehicle performance data and predict potential failures before they occur are highly sought after. This proactive approach to vehicle maintenance can significantly reduce unexpected breakdowns and improve overall vehicle uptime.

Another important market requirement is the integration of artificial intelligence and machine learning algorithms into EREV diagnostic systems. These technologies can enhance the accuracy of fault detection and provide more precise recommendations for repairs. The ability to learn from historical data and adapt to new failure modes is particularly valuable in the rapidly evolving EREV technology landscape.

There is also a growing demand for remote diagnostic capabilities, allowing technicians to access vehicle data and perform initial troubleshooting without physical access to the vehicle. This feature is especially valuable for fleet management and can lead to faster resolution of issues and reduced service costs.

The market is also seeing increased interest in diagnostic systems that can provide detailed insights into battery health and performance. As the battery is a critical and expensive component of EREVs, tools that can accurately assess battery condition and predict remaining lifespan are highly valued by both vehicle owners and manufacturers.

Furthermore, there is a rising demand for diagnostic systems that can interface with a wide range of third-party tools and software platforms. This interoperability is crucial for streamlining maintenance processes and enabling more comprehensive vehicle health management.

As the EREV market continues to expand, the demand for advanced diagnostic solutions is expected to grow proportionally. Manufacturers and aftermarket suppliers that can deliver robust, user-friendly, and feature-rich diagnostic systems are likely to gain a significant competitive advantage in this evolving market segment.

The primary market drivers for advanced EREV diagnostics include the rising consumer expectations for vehicle reliability and performance, stringent environmental regulations, and the automotive industry's push towards electrification. Fleet operators and individual owners alike are seeking more efficient and accurate diagnostic tools to minimize downtime and reduce maintenance costs associated with EREVs.

One of the key market demands is for real-time monitoring and predictive maintenance capabilities. Advanced diagnostic systems that can continuously analyze vehicle performance data and predict potential failures before they occur are highly sought after. This proactive approach to vehicle maintenance can significantly reduce unexpected breakdowns and improve overall vehicle uptime.

Another important market requirement is the integration of artificial intelligence and machine learning algorithms into EREV diagnostic systems. These technologies can enhance the accuracy of fault detection and provide more precise recommendations for repairs. The ability to learn from historical data and adapt to new failure modes is particularly valuable in the rapidly evolving EREV technology landscape.

There is also a growing demand for remote diagnostic capabilities, allowing technicians to access vehicle data and perform initial troubleshooting without physical access to the vehicle. This feature is especially valuable for fleet management and can lead to faster resolution of issues and reduced service costs.

The market is also seeing increased interest in diagnostic systems that can provide detailed insights into battery health and performance. As the battery is a critical and expensive component of EREVs, tools that can accurately assess battery condition and predict remaining lifespan are highly valued by both vehicle owners and manufacturers.

Furthermore, there is a rising demand for diagnostic systems that can interface with a wide range of third-party tools and software platforms. This interoperability is crucial for streamlining maintenance processes and enabling more comprehensive vehicle health management.

As the EREV market continues to expand, the demand for advanced diagnostic solutions is expected to grow proportionally. Manufacturers and aftermarket suppliers that can deliver robust, user-friendly, and feature-rich diagnostic systems are likely to gain a significant competitive advantage in this evolving market segment.

Current OBD Challenges in EREV Systems

Extended Range Electric Vehicles (EREVs) represent a significant advancement in automotive technology, combining the benefits of electric propulsion with the range assurance of a combustion engine. However, the complexity of these hybrid systems presents unique challenges for onboard diagnostics (OBD) systems, which are crucial for troubleshooting and maintaining vehicle performance.

One of the primary challenges in EREV OBD systems is the integration of multiple powertrain components. The presence of both electric and combustion systems requires a sophisticated diagnostic approach that can accurately identify and differentiate between issues in either system. This complexity often leads to difficulties in pinpointing the root cause of performance problems, as symptoms may manifest similarly across different subsystems.

Another significant challenge is the need for real-time monitoring and analysis of a vast array of sensors and data points. EREVs generate an enormous amount of data from various components, including battery management systems, electric motors, generators, and internal combustion engines. Processing this data efficiently and accurately to detect anomalies and potential failures poses a substantial technical hurdle for current OBD systems.

The dynamic nature of EREV operation further complicates diagnostic processes. As these vehicles frequently switch between electric and combustion modes, OBD systems must be capable of adapting their diagnostic strategies in real-time. This requirement for flexibility often strains the computational resources of onboard systems and can lead to delayed or inaccurate fault detection.

Battery health monitoring presents another unique challenge for EREV OBD systems. Accurately assessing the state of health and predicting the remaining useful life of high-voltage batteries is critical for vehicle performance and safety. However, current OBD technologies often struggle to provide precise and reliable battery diagnostics, particularly as batteries age and degrade over time.

Electromagnetic interference (EMI) from high-voltage components in EREVs can also impact the reliability of OBD systems. The presence of strong electromagnetic fields can disrupt sensor readings and communication between various electronic control units, leading to false positives or missed diagnoses.

Lastly, the regulatory landscape for EREV OBD systems is still evolving. As emissions regulations become more stringent, OBD systems must adapt to monitor and report on an expanding set of parameters related to both electric and combustion systems. This regulatory complexity adds another layer of challenge to the development and implementation of effective OBD solutions for EREVs.

One of the primary challenges in EREV OBD systems is the integration of multiple powertrain components. The presence of both electric and combustion systems requires a sophisticated diagnostic approach that can accurately identify and differentiate between issues in either system. This complexity often leads to difficulties in pinpointing the root cause of performance problems, as symptoms may manifest similarly across different subsystems.

Another significant challenge is the need for real-time monitoring and analysis of a vast array of sensors and data points. EREVs generate an enormous amount of data from various components, including battery management systems, electric motors, generators, and internal combustion engines. Processing this data efficiently and accurately to detect anomalies and potential failures poses a substantial technical hurdle for current OBD systems.

The dynamic nature of EREV operation further complicates diagnostic processes. As these vehicles frequently switch between electric and combustion modes, OBD systems must be capable of adapting their diagnostic strategies in real-time. This requirement for flexibility often strains the computational resources of onboard systems and can lead to delayed or inaccurate fault detection.

Battery health monitoring presents another unique challenge for EREV OBD systems. Accurately assessing the state of health and predicting the remaining useful life of high-voltage batteries is critical for vehicle performance and safety. However, current OBD technologies often struggle to provide precise and reliable battery diagnostics, particularly as batteries age and degrade over time.

Electromagnetic interference (EMI) from high-voltage components in EREVs can also impact the reliability of OBD systems. The presence of strong electromagnetic fields can disrupt sensor readings and communication between various electronic control units, leading to false positives or missed diagnoses.

Lastly, the regulatory landscape for EREV OBD systems is still evolving. As emissions regulations become more stringent, OBD systems must adapt to monitor and report on an expanding set of parameters related to both electric and combustion systems. This regulatory complexity adds another layer of challenge to the development and implementation of effective OBD solutions for EREVs.

Existing EREV OBD Solutions

01 Remote diagnostics and troubleshooting for EREV systems

Remote diagnostic systems allow for real-time monitoring and troubleshooting of Extended Range Electric Vehicles (EREVs). These systems can collect and analyze vehicle data, identify potential issues, and provide remote assistance to drivers or technicians. This approach enhances the efficiency of diagnostics and reduces downtime for EREV vehicles.- Remote diagnostics and troubleshooting: Remote diagnostics and troubleshooting systems for EREVs allow for real-time monitoring and analysis of vehicle performance. These systems enable remote access to onboard diagnostic data, facilitating quick identification and resolution of issues without physical presence at the vehicle location. This approach improves efficiency in maintenance and reduces downtime for EREV vehicles.

- Onboard diagnostic system integration: Integration of advanced onboard diagnostic systems in EREVs enhances the vehicle's ability to self-diagnose and report issues. These systems continuously monitor various components and subsystems, providing detailed information about the vehicle's status. This integration allows for early detection of potential problems and facilitates proactive maintenance strategies.

- Machine learning in diagnostics: Implementing machine learning algorithms in EREV onboard diagnostics systems improves the accuracy and efficiency of troubleshooting processes. These algorithms can analyze patterns in diagnostic data, predict potential failures, and suggest optimal solutions. This approach enhances the overall reliability and performance of EREV systems.

- User interface for diagnostic information: Developing user-friendly interfaces for displaying diagnostic information enhances the accessibility of troubleshooting data for both drivers and technicians. These interfaces can provide clear, actionable insights into the vehicle's status, making it easier to understand and address issues promptly. This improvement in communication between the vehicle and its users contributes to more effective maintenance and problem-solving.

- Diagnostic data management and analysis: Efficient management and analysis of diagnostic data from EREVs are crucial for effective troubleshooting. This involves collecting, storing, and processing large volumes of data from multiple vehicles. Advanced data management systems can identify trends, correlate issues across vehicle fleets, and provide valuable insights for improving EREV design and maintenance procedures.

02 On-board diagnostic system for EREV performance optimization

Advanced on-board diagnostic systems in EREVs can continuously monitor vehicle performance, battery health, and powertrain efficiency. These systems use sophisticated algorithms to detect anomalies, predict potential failures, and optimize vehicle performance in real-time. This proactive approach helps maintain optimal EREV operation and extends vehicle lifespan.Expand Specific Solutions03 Machine learning-based diagnostics for EREV systems

Incorporating machine learning algorithms into EREV diagnostic systems enables more accurate fault detection and predictive maintenance. These AI-powered systems can learn from historical data, recognize patterns, and improve their diagnostic capabilities over time. This results in more precise troubleshooting and reduced false positives in EREV diagnostics.Expand Specific Solutions04 Integration of EREV diagnostics with cloud-based platforms

Cloud-based diagnostic platforms for EREVs allow for centralized data storage, analysis, and sharing of diagnostic information. This integration enables fleet-wide monitoring, over-the-air updates, and collaborative troubleshooting among service centers. It also facilitates the development of more comprehensive diagnostic databases and improved troubleshooting methodologies.Expand Specific Solutions05 User-friendly interfaces for EREV diagnostic information

Developing intuitive user interfaces for EREV diagnostic systems helps drivers and technicians easily access and interpret diagnostic information. These interfaces can include visual representations of vehicle systems, clear error messages, and step-by-step troubleshooting guides. This approach improves the overall user experience and enables more efficient problem resolution for EREV-related issues.Expand Specific Solutions

Key Players in EREV OBD Industry

The EREV onboard diagnostics market for enhanced troubleshooting is in a growth phase, driven by increasing demand for advanced vehicle diagnostics and the shift towards electrification. The market size is expanding as more automotive manufacturers integrate EREV technology into their vehicles. Technologically, the field is rapidly evolving, with companies like Bosch, Continental, and Huawei leading innovation. Established automakers such as BMW, Mercedes-Benz, and Volkswagen are also investing heavily in this area, while specialized diagnostic equipment manufacturers like Launch Tech and Autel Intelligent are developing sophisticated tools. The competition is intensifying as both traditional automotive players and tech companies vie for market share in this emerging sector.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has developed an AI-powered EREV onboard diagnostics system that leverages its expertise in 5G and IoT technologies. The system utilizes edge computing to process vast amounts of sensor data in real-time, enabling rapid fault detection and diagnosis[2]. Huawei's solution incorporates a distributed architecture that allows for scalable deployment across various vehicle models and fleet sizes. The system employs advanced natural language processing to provide intuitive, voice-activated diagnostics and troubleshooting guidance. Additionally, Huawei's platform integrates with their smart city infrastructure, enabling vehicles to share diagnostic data with traffic management systems for improved urban mobility[4].

Strengths: Advanced AI capabilities, seamless integration with smart city infrastructure, and scalable architecture. Weaknesses: Potential concerns over data privacy and security due to Huawei's global position.

Robert Bosch GmbH

Technical Solution: Bosch has developed an advanced EREV onboard diagnostics system that integrates machine learning algorithms for enhanced troubleshooting. The system utilizes a combination of sensor data, historical fault information, and real-time vehicle performance metrics to provide accurate and timely diagnostics[1]. It employs a cloud-connected architecture that allows for continuous updates and improvements to the diagnostic algorithms. The system can predict potential failures before they occur, reducing downtime and maintenance costs. Bosch's solution also incorporates a user-friendly interface that provides clear, actionable insights to both technicians and drivers, improving overall vehicle reliability and performance[3].

Strengths: Comprehensive data integration, predictive maintenance capabilities, and user-friendly interface. Weaknesses: Reliance on cloud connectivity may pose challenges in areas with poor network coverage.

Core Innovations in EREV Diagnostics

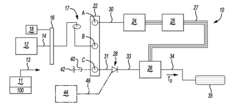

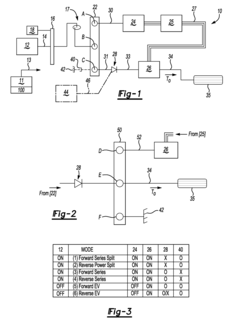

Low content extended-range electric vehicle powertrain

PatentInactiveUS8196687B2

Innovation

- The extended-range electric vehicle design incorporates a direct mechanical path between the engine and drive wheels through a series mode, utilizing two electric machines, a one-way clutch, and an auxiliary starter motor, enabling efficient power transmission and operation in various modes, including electric-only and power-split modes.

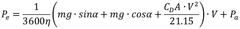

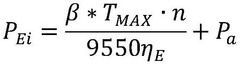

Extended-range automobile energy management method combining working condition recognition and driving style

PatentPendingCN119408525A

Innovation

- Using an energy management method combining working condition recognition and driving style, the working condition and driving style are identified and classified through the LSTM neural network and deep learning neural network model, dynamically adjust the start and output power of the range extender to achieve the optimal energy Management strategy.

Regulatory Framework for EREV OBD Systems

The regulatory framework for Extended Range Electric Vehicle (EREV) On-Board Diagnostics (OBD) systems is a complex and evolving landscape that plays a crucial role in ensuring the safety, efficiency, and environmental compliance of these advanced hybrid vehicles. At the forefront of this regulatory environment are the stringent emissions standards set by various governmental bodies, such as the Environmental Protection Agency (EPA) in the United States and the European Commission in the European Union.

These regulations typically mandate that EREV OBD systems must continuously monitor the performance of emission-related components and alert drivers when malfunctions occur. The California Air Resources Board (CARB) has been particularly influential in shaping OBD requirements, with many other jurisdictions adopting similar standards. CARB's OBD II regulations, which apply to EREVs, require monitoring of the powertrain, fuel system, and emission control devices.

For EREVs specifically, the regulatory framework addresses the unique challenges posed by their dual powertrain architecture. OBD systems must be capable of monitoring both the electric drive components and the internal combustion engine, ensuring seamless integration and accurate diagnostics across both systems. This includes monitoring battery health, electric motor performance, and the efficiency of the energy recovery systems.

International standards, such as those developed by the Society of Automotive Engineers (SAE), provide guidelines for the implementation of OBD systems in EREVs. These standards ensure interoperability and consistency in diagnostic protocols across different vehicle manufacturers and models. The SAE J1979 standard, for instance, defines the diagnostic test modes and parameter IDs used in OBD communications.

Regulatory bodies also specify the types of diagnostic trouble codes (DTCs) that EREV OBD systems must be capable of generating and storing. These codes are standardized to facilitate easier troubleshooting and repair processes. Additionally, regulations often mandate the use of a standardized data link connector (DLC) for accessing OBD information, ensuring that diagnostic tools can interface with vehicles from different manufacturers.

As EREV technology continues to advance, regulatory frameworks are evolving to keep pace. There is an increasing focus on cybersecurity in OBD systems, with regulations beginning to address the potential vulnerabilities associated with connected vehicle diagnostics. Furthermore, as the emphasis on reducing greenhouse gas emissions grows, regulations are expanding to include more comprehensive monitoring of energy efficiency and overall vehicle performance in EREVs.

These regulations typically mandate that EREV OBD systems must continuously monitor the performance of emission-related components and alert drivers when malfunctions occur. The California Air Resources Board (CARB) has been particularly influential in shaping OBD requirements, with many other jurisdictions adopting similar standards. CARB's OBD II regulations, which apply to EREVs, require monitoring of the powertrain, fuel system, and emission control devices.

For EREVs specifically, the regulatory framework addresses the unique challenges posed by their dual powertrain architecture. OBD systems must be capable of monitoring both the electric drive components and the internal combustion engine, ensuring seamless integration and accurate diagnostics across both systems. This includes monitoring battery health, electric motor performance, and the efficiency of the energy recovery systems.

International standards, such as those developed by the Society of Automotive Engineers (SAE), provide guidelines for the implementation of OBD systems in EREVs. These standards ensure interoperability and consistency in diagnostic protocols across different vehicle manufacturers and models. The SAE J1979 standard, for instance, defines the diagnostic test modes and parameter IDs used in OBD communications.

Regulatory bodies also specify the types of diagnostic trouble codes (DTCs) that EREV OBD systems must be capable of generating and storing. These codes are standardized to facilitate easier troubleshooting and repair processes. Additionally, regulations often mandate the use of a standardized data link connector (DLC) for accessing OBD information, ensuring that diagnostic tools can interface with vehicles from different manufacturers.

As EREV technology continues to advance, regulatory frameworks are evolving to keep pace. There is an increasing focus on cybersecurity in OBD systems, with regulations beginning to address the potential vulnerabilities associated with connected vehicle diagnostics. Furthermore, as the emphasis on reducing greenhouse gas emissions grows, regulations are expanding to include more comprehensive monitoring of energy efficiency and overall vehicle performance in EREVs.

Cybersecurity in EREV Diagnostics

Cybersecurity in EREV diagnostics has become a critical concern as Extended Range Electric Vehicles (EREVs) increasingly rely on sophisticated onboard diagnostic systems. These systems, while essential for enhanced troubleshooting and vehicle performance optimization, also present potential vulnerabilities that could be exploited by malicious actors.

The interconnected nature of EREV systems, including the onboard diagnostics, powertrain control, and communication networks, creates a complex attack surface. Cybersecurity threats to EREV diagnostics can range from unauthorized access to sensitive vehicle data to more severe scenarios such as remote manipulation of vehicle functions.

One of the primary challenges in securing EREV diagnostics is maintaining a balance between accessibility for legitimate diagnostic purposes and robust protection against cyber threats. Manufacturers and cybersecurity experts are developing multi-layered security approaches to address these concerns.

Encryption plays a crucial role in protecting diagnostic data both at rest and in transit. Advanced encryption algorithms are being implemented to secure communication channels between the vehicle's onboard systems and external diagnostic tools. This helps prevent eavesdropping and man-in-the-middle attacks that could compromise sensitive vehicle information.

Authentication mechanisms are another key component of EREV diagnostic cybersecurity. Secure authentication protocols ensure that only authorized personnel and devices can access the vehicle's diagnostic systems. This may include multi-factor authentication, digital certificates, and secure key management systems.

Intrusion detection and prevention systems (IDPS) are being integrated into EREV diagnostic architectures to monitor for suspicious activities and potential cyber attacks in real-time. These systems can detect anomalies in data patterns or communication protocols that may indicate a security breach.

Regular security updates and patches are essential to address newly discovered vulnerabilities in EREV diagnostic systems. Over-the-air (OTA) update capabilities are becoming increasingly common, allowing manufacturers to quickly deploy security fixes without requiring physical access to the vehicle.

As the automotive industry continues to evolve, standardization efforts are underway to establish common cybersecurity frameworks for EREV diagnostics. These standards aim to provide a consistent approach to security across different vehicle models and manufacturers, enhancing overall resilience against cyber threats.

The interconnected nature of EREV systems, including the onboard diagnostics, powertrain control, and communication networks, creates a complex attack surface. Cybersecurity threats to EREV diagnostics can range from unauthorized access to sensitive vehicle data to more severe scenarios such as remote manipulation of vehicle functions.

One of the primary challenges in securing EREV diagnostics is maintaining a balance between accessibility for legitimate diagnostic purposes and robust protection against cyber threats. Manufacturers and cybersecurity experts are developing multi-layered security approaches to address these concerns.

Encryption plays a crucial role in protecting diagnostic data both at rest and in transit. Advanced encryption algorithms are being implemented to secure communication channels between the vehicle's onboard systems and external diagnostic tools. This helps prevent eavesdropping and man-in-the-middle attacks that could compromise sensitive vehicle information.

Authentication mechanisms are another key component of EREV diagnostic cybersecurity. Secure authentication protocols ensure that only authorized personnel and devices can access the vehicle's diagnostic systems. This may include multi-factor authentication, digital certificates, and secure key management systems.

Intrusion detection and prevention systems (IDPS) are being integrated into EREV diagnostic architectures to monitor for suspicious activities and potential cyber attacks in real-time. These systems can detect anomalies in data patterns or communication protocols that may indicate a security breach.

Regular security updates and patches are essential to address newly discovered vulnerabilities in EREV diagnostic systems. Over-the-air (OTA) update capabilities are becoming increasingly common, allowing manufacturers to quickly deploy security fixes without requiring physical access to the vehicle.

As the automotive industry continues to evolve, standardization efforts are underway to establish common cybersecurity frameworks for EREV diagnostics. These standards aim to provide a consistent approach to security across different vehicle models and manufacturers, enhancing overall resilience against cyber threats.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!