Safety analysis of EREV powertrains

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EREV Powertrain Evolution

The evolution of Extended Range Electric Vehicle (EREV) powertrains represents a significant milestone in the automotive industry's transition towards more sustainable and efficient transportation solutions. This technological progression can be traced through several key stages, each marked by notable advancements in powertrain design and performance.

In the early 2000s, the concept of EREV powertrains began to take shape as automakers sought to address the limitations of pure electric vehicles, particularly range anxiety. The initial designs featured a small internal combustion engine (ICE) acting primarily as a generator to charge the battery pack, with the electric motor providing the main propulsion.

The first commercially successful EREV, the Chevrolet Volt, was introduced in 2010. Its powertrain incorporated a 1.4-liter gasoline engine and a 16 kWh lithium-ion battery pack, offering an electric range of approximately 35 miles before the ICE engaged. This marked a significant step forward in combining the benefits of electric driving with the extended range capabilities of conventional vehicles.

As battery technology improved, subsequent generations of EREV powertrains saw increases in electric range and overall efficiency. By the mid-2010s, models like the second-generation Volt offered electric ranges of up to 53 miles, demonstrating the rapid pace of technological advancement in this field.

A key development in EREV powertrain evolution has been the refinement of power management systems. These sophisticated control units optimize the interplay between the electric motor, battery, and ICE, maximizing efficiency and performance. Advanced algorithms have been developed to seamlessly transition between electric and hybrid modes, enhancing the driving experience and energy utilization.

More recent iterations of EREV powertrains have focused on reducing the size and weight of components while increasing power output. This has been achieved through the use of more energy-dense batteries, more efficient electric motors, and smaller, highly optimized ICEs. Some manufacturers have also explored the use of alternative fuels for the range extender, such as hydrogen fuel cells, to further reduce emissions.

The integration of regenerative braking systems has become increasingly sophisticated in EREV powertrains. These systems not only recover energy during deceleration but also contribute to improved vehicle handling and brake wear reduction. The latest designs can capture and store a significant portion of the vehicle's kinetic energy, further extending the electric range.

Looking towards the future, EREV powertrain evolution is likely to continue with a focus on increased electrification. This may include the development of plug-in hybrid systems with larger battery capacities and more powerful electric motors, potentially relegating the ICE to an even more limited role as a range extender. The ongoing advancements in battery technology, particularly in energy density and charging speeds, will play a crucial role in shaping the next generation of EREV powertrains.

In the early 2000s, the concept of EREV powertrains began to take shape as automakers sought to address the limitations of pure electric vehicles, particularly range anxiety. The initial designs featured a small internal combustion engine (ICE) acting primarily as a generator to charge the battery pack, with the electric motor providing the main propulsion.

The first commercially successful EREV, the Chevrolet Volt, was introduced in 2010. Its powertrain incorporated a 1.4-liter gasoline engine and a 16 kWh lithium-ion battery pack, offering an electric range of approximately 35 miles before the ICE engaged. This marked a significant step forward in combining the benefits of electric driving with the extended range capabilities of conventional vehicles.

As battery technology improved, subsequent generations of EREV powertrains saw increases in electric range and overall efficiency. By the mid-2010s, models like the second-generation Volt offered electric ranges of up to 53 miles, demonstrating the rapid pace of technological advancement in this field.

A key development in EREV powertrain evolution has been the refinement of power management systems. These sophisticated control units optimize the interplay between the electric motor, battery, and ICE, maximizing efficiency and performance. Advanced algorithms have been developed to seamlessly transition between electric and hybrid modes, enhancing the driving experience and energy utilization.

More recent iterations of EREV powertrains have focused on reducing the size and weight of components while increasing power output. This has been achieved through the use of more energy-dense batteries, more efficient electric motors, and smaller, highly optimized ICEs. Some manufacturers have also explored the use of alternative fuels for the range extender, such as hydrogen fuel cells, to further reduce emissions.

The integration of regenerative braking systems has become increasingly sophisticated in EREV powertrains. These systems not only recover energy during deceleration but also contribute to improved vehicle handling and brake wear reduction. The latest designs can capture and store a significant portion of the vehicle's kinetic energy, further extending the electric range.

Looking towards the future, EREV powertrain evolution is likely to continue with a focus on increased electrification. This may include the development of plug-in hybrid systems with larger battery capacities and more powerful electric motors, potentially relegating the ICE to an even more limited role as a range extender. The ongoing advancements in battery technology, particularly in energy density and charging speeds, will play a crucial role in shaping the next generation of EREV powertrains.

Market Demand for EREV

The market demand for Extended Range Electric Vehicles (EREVs) has been steadily growing in recent years, driven by increasing environmental concerns and the need for more sustainable transportation solutions. EREVs offer a unique combination of electric vehicle benefits and the convenience of longer-range travel, making them an attractive option for consumers who want to reduce their carbon footprint without sacrificing mobility.

In the automotive industry, EREVs are positioned as a transitional technology between conventional internal combustion engine vehicles and fully electric vehicles. This positioning has created a significant market niche, particularly in regions where charging infrastructure is still developing. The demand for EREVs is especially strong in urban and suburban areas, where consumers often need to make longer trips but also want to take advantage of electric-only driving for daily commutes.

Several factors contribute to the increasing market demand for EREVs. Firstly, government regulations and incentives aimed at reducing carbon emissions have created a favorable environment for EREV adoption. Many countries offer tax credits, rebates, and other financial incentives to encourage consumers to purchase these vehicles. Secondly, advancements in battery technology have improved the electric-only range of EREVs, making them more practical for a wider range of consumers.

The market for EREVs is also being driven by consumer awareness of environmental issues and a growing desire for more sustainable transportation options. As more consumers become educated about the benefits of electric vehicles, the demand for EREVs as a compromise between traditional and fully electric vehicles continues to rise.

From an industry perspective, major automakers are investing heavily in EREV technology, recognizing its potential as a bridge technology in the transition to fully electric vehicles. This investment is leading to a wider range of EREV models available to consumers, further stimulating market demand.

However, the EREV market is not without challenges. The higher initial cost of these vehicles compared to conventional internal combustion engine vehicles remains a barrier for some consumers. Additionally, the complexity of EREV powertrains raises concerns about long-term reliability and maintenance costs, which can impact consumer confidence and market demand.

Despite these challenges, market analysts predict continued growth in the EREV sector. The global EREV market is expected to expand significantly over the next decade, with particularly strong growth in regions with supportive government policies and developing charging infrastructure. As battery technology continues to improve and production costs decrease, EREVs are likely to become an increasingly attractive option for a broader range of consumers, further driving market demand.

In the automotive industry, EREVs are positioned as a transitional technology between conventional internal combustion engine vehicles and fully electric vehicles. This positioning has created a significant market niche, particularly in regions where charging infrastructure is still developing. The demand for EREVs is especially strong in urban and suburban areas, where consumers often need to make longer trips but also want to take advantage of electric-only driving for daily commutes.

Several factors contribute to the increasing market demand for EREVs. Firstly, government regulations and incentives aimed at reducing carbon emissions have created a favorable environment for EREV adoption. Many countries offer tax credits, rebates, and other financial incentives to encourage consumers to purchase these vehicles. Secondly, advancements in battery technology have improved the electric-only range of EREVs, making them more practical for a wider range of consumers.

The market for EREVs is also being driven by consumer awareness of environmental issues and a growing desire for more sustainable transportation options. As more consumers become educated about the benefits of electric vehicles, the demand for EREVs as a compromise between traditional and fully electric vehicles continues to rise.

From an industry perspective, major automakers are investing heavily in EREV technology, recognizing its potential as a bridge technology in the transition to fully electric vehicles. This investment is leading to a wider range of EREV models available to consumers, further stimulating market demand.

However, the EREV market is not without challenges. The higher initial cost of these vehicles compared to conventional internal combustion engine vehicles remains a barrier for some consumers. Additionally, the complexity of EREV powertrains raises concerns about long-term reliability and maintenance costs, which can impact consumer confidence and market demand.

Despite these challenges, market analysts predict continued growth in the EREV sector. The global EREV market is expected to expand significantly over the next decade, with particularly strong growth in regions with supportive government policies and developing charging infrastructure. As battery technology continues to improve and production costs decrease, EREVs are likely to become an increasingly attractive option for a broader range of consumers, further driving market demand.

EREV Safety Challenges

Extended Range Electric Vehicles (EREVs) represent a significant advancement in automotive technology, combining the benefits of electric propulsion with the range assurance of a combustion engine. However, this hybrid powertrain configuration introduces unique safety challenges that require careful analysis and mitigation strategies.

One of the primary safety concerns in EREV powertrains is the integration of high-voltage electrical systems with traditional combustion engine components. This combination creates potential risks for electrical fires, short circuits, and electromagnetic interference. The presence of large battery packs, often operating at voltages exceeding 400V, necessitates robust insulation and protection systems to prevent electrical hazards during normal operation, charging, and in the event of a collision.

Thermal management is another critical safety aspect of EREV powertrains. The heat generated by both the electric drivetrain and the internal combustion engine must be effectively dissipated to prevent overheating, which could lead to battery degradation, system failures, or even thermal runaway in extreme cases. Sophisticated cooling systems and thermal barriers are essential to maintain safe operating temperatures across all powertrain components.

The complexity of EREV control systems presents additional safety challenges. The seamless coordination between electric and combustion power sources requires advanced software and hardware integration. Any malfunction in these control systems could result in unexpected vehicle behavior, potentially compromising safety. Robust fail-safe mechanisms and redundant systems are necessary to ensure vehicle stability and predictable performance under all operating conditions.

Crash safety is a paramount concern for EREV powertrains. The placement of battery packs and high-voltage components within the vehicle structure must be carefully engineered to maintain integrity during collisions. Designers must consider the potential for battery puncture, electrolyte leakage, and the risk of electrical fires in the aftermath of an accident. Advanced structural designs and materials are required to protect these critical components while maintaining overall vehicle crashworthiness.

The presence of both electric and combustion systems in EREVs also introduces unique challenges for first responders and rescue operations. Emergency personnel must be trained to handle potential electrical hazards, as well as the risks associated with traditional fuel systems. Clear labeling, easily accessible power disconnects, and standardized safety protocols are essential to ensure swift and safe responses to EREV-related incidents.

Electromagnetic compatibility (EMC) is another significant safety consideration for EREV powertrains. The high-power electrical systems can generate electromagnetic interference that may affect other vehicle systems or external devices. Stringent EMC testing and shielding measures are necessary to prevent interference with critical vehicle functions, such as braking systems, steering controls, and communication devices.

One of the primary safety concerns in EREV powertrains is the integration of high-voltage electrical systems with traditional combustion engine components. This combination creates potential risks for electrical fires, short circuits, and electromagnetic interference. The presence of large battery packs, often operating at voltages exceeding 400V, necessitates robust insulation and protection systems to prevent electrical hazards during normal operation, charging, and in the event of a collision.

Thermal management is another critical safety aspect of EREV powertrains. The heat generated by both the electric drivetrain and the internal combustion engine must be effectively dissipated to prevent overheating, which could lead to battery degradation, system failures, or even thermal runaway in extreme cases. Sophisticated cooling systems and thermal barriers are essential to maintain safe operating temperatures across all powertrain components.

The complexity of EREV control systems presents additional safety challenges. The seamless coordination between electric and combustion power sources requires advanced software and hardware integration. Any malfunction in these control systems could result in unexpected vehicle behavior, potentially compromising safety. Robust fail-safe mechanisms and redundant systems are necessary to ensure vehicle stability and predictable performance under all operating conditions.

Crash safety is a paramount concern for EREV powertrains. The placement of battery packs and high-voltage components within the vehicle structure must be carefully engineered to maintain integrity during collisions. Designers must consider the potential for battery puncture, electrolyte leakage, and the risk of electrical fires in the aftermath of an accident. Advanced structural designs and materials are required to protect these critical components while maintaining overall vehicle crashworthiness.

The presence of both electric and combustion systems in EREVs also introduces unique challenges for first responders and rescue operations. Emergency personnel must be trained to handle potential electrical hazards, as well as the risks associated with traditional fuel systems. Clear labeling, easily accessible power disconnects, and standardized safety protocols are essential to ensure swift and safe responses to EREV-related incidents.

Electromagnetic compatibility (EMC) is another significant safety consideration for EREV powertrains. The high-power electrical systems can generate electromagnetic interference that may affect other vehicle systems or external devices. Stringent EMC testing and shielding measures are necessary to prevent interference with critical vehicle functions, such as braking systems, steering controls, and communication devices.

Current EREV Safety Solutions

01 Safety systems for EREV powertrains

Extended Range Electric Vehicle (EREV) powertrains incorporate various safety systems to ensure optimal performance and protect occupants. These systems may include advanced driver assistance features, collision avoidance technologies, and battery management systems to monitor and control the electric powertrain components.- Safety systems for EREV powertrains: Extended Range Electric Vehicle (EREV) powertrains incorporate various safety systems to ensure optimal performance and protect occupants. These systems may include advanced driver assistance features, collision avoidance technologies, and battery management systems to monitor and control the electric powertrain components.

- Thermal management in EREV powertrains: Effective thermal management is crucial for the safety and efficiency of EREV powertrains. This involves cooling systems for batteries, electric motors, and power electronics to prevent overheating and maintain optimal operating temperatures. Advanced thermal management strategies may include liquid cooling, heat exchangers, and intelligent temperature control algorithms.

- Battery safety and protection in EREVs: Battery safety is a critical aspect of EREV powertrain design. This includes measures to prevent thermal runaway, short circuits, and physical damage to battery packs. Advanced battery management systems monitor cell voltages, temperatures, and state of charge to ensure safe operation and longevity of the battery system.

- Regenerative braking and energy recovery: EREV powertrains utilize regenerative braking systems to recover kinetic energy during deceleration and braking. This not only improves energy efficiency but also contributes to vehicle safety by providing additional braking force. Advanced control systems ensure smooth integration between regenerative and friction braking for optimal safety and performance.

- Fail-safe mechanisms and redundancy: EREV powertrains incorporate fail-safe mechanisms and redundancy in critical systems to ensure safety in case of component failures. This may include backup power systems, redundant sensors, and fault detection algorithms. These features help maintain vehicle control and minimize safety risks in the event of system malfunctions.

02 Thermal management in EREV powertrains

Effective thermal management is crucial for the safety and efficiency of EREV powertrains. This involves cooling systems for batteries, electric motors, and power electronics to prevent overheating and maintain optimal operating temperatures. Advanced thermal management strategies may include liquid cooling, heat exchangers, and intelligent temperature control algorithms.Expand Specific Solutions03 Battery safety and protection in EREVs

Battery safety is a critical aspect of EREV powertrain design. This includes measures to prevent thermal runaway, short circuits, and physical damage to battery packs. Advanced battery management systems monitor cell voltages, temperatures, and state of charge to ensure safe operation and longevity of the battery system.Expand Specific Solutions04 Regenerative braking and energy recovery

EREV powertrains utilize regenerative braking systems to recover kinetic energy during deceleration and braking. This not only improves energy efficiency but also contributes to vehicle safety by providing additional braking force. Advanced control systems ensure smooth integration of regenerative and friction braking for optimal safety and performance.Expand Specific Solutions05 Fail-safe mechanisms and redundancy

EREV powertrains incorporate fail-safe mechanisms and redundancy in critical systems to ensure safety in case of component failures. This may include backup power systems, redundant sensors, and fault detection algorithms. These features help maintain vehicle control and minimize safety risks in the event of system malfunctions.Expand Specific Solutions

Key EREV Manufacturers

The safety analysis of Extended Range Electric Vehicle (EREV) powertrains is currently in a growth phase, with increasing market demand and technological advancements. The global EREV market is expanding, driven by environmental concerns and government incentives. Technologically, EREV powertrains are maturing, with major players like GM Global Technology Operations, Robert Bosch GmbH, and FCA US LLC leading innovation. Companies such as Cummins, Inc. and Continental Automotive Systems are also contributing to the field's development. The competitive landscape is diverse, including traditional automakers, technology firms, and specialized electric vehicle manufacturers, indicating a dynamic and evolving market with significant potential for further growth and technological refinement.

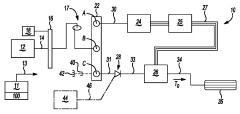

GM Global Technology Operations LLC

Technical Solution: GM's safety analysis of EREV powertrains focuses on a comprehensive approach, integrating advanced simulation tools and real-world testing. They employ a multi-layered safety strategy, including fault detection algorithms, redundant systems, and intelligent power management[1]. Their EREV architecture incorporates a sophisticated Battery Management System (BMS) that continuously monitors cell voltages, temperatures, and state of charge to prevent thermal runaway and ensure optimal performance[3]. GM also utilizes predictive modeling to anticipate potential failure modes and implement preventive measures. Their safety protocols extend to the vehicle's high-voltage isolation system, employing multiple layers of protection against electrical hazards[5]. Additionally, GM has developed a unique thermal management system for the battery pack, which helps maintain safe operating temperatures across various driving conditions and charging scenarios[7].

Strengths: Comprehensive safety approach, advanced BMS, predictive modeling capabilities. Weaknesses: Complexity may lead to higher costs, potential for software vulnerabilities in interconnected systems.

Robert Bosch GmbH

Technical Solution: Bosch's approach to EREV powertrain safety analysis involves a holistic system integration perspective. They have developed a suite of sensors and control units specifically designed for hybrid and electric powertrains, which work in concert to ensure safe operation[2]. Bosch's safety strategy includes real-time monitoring of power electronics, battery systems, and electric motors. Their innovative iBooster electromechanical brake system provides enhanced regenerative braking capabilities while maintaining fail-safe operation[4]. Bosch also emphasizes cybersecurity in their EREV systems, implementing secure gateway solutions to protect against potential hacking attempts. Their safety analysis extends to the charging infrastructure, with intelligent charging systems that monitor for potential faults or anomalies during the charging process[6]. Furthermore, Bosch has developed advanced driver assistance systems tailored for EREVs, which take into account the unique characteristics of electric powertrains in safety-critical situations[8].

Strengths: Comprehensive system integration, focus on cybersecurity, advanced driver assistance systems. Weaknesses: Dependence on complex electronic systems may increase maintenance challenges.

EREV Safety Innovations

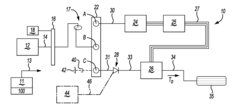

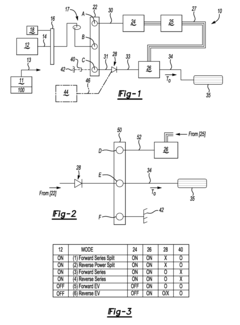

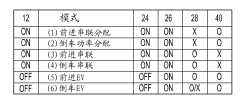

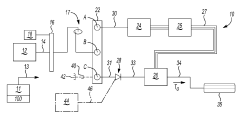

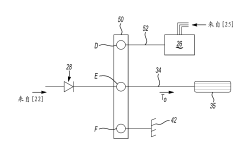

Low content extended-range electric vehicle powertrain

PatentInactiveUS20110297466A1

Innovation

- The EREV design incorporates a direct mechanical path between the engine and drive wheels through a series mode, utilizing two electric machines, a one-way clutch, and an auxiliary starter motor, allowing for efficient operation in various modes including electric-only, power-split, and series modes, with a planetary gear set and controller algorithm to manage these modes.

Low Fuel Consumption Extended Range Electric Vehicle Powertrain

PatentInactiveCN102275518A

Innovation

- An extended-range electric vehicle is designed, which uses an engine with direct mechanical lines to connect to the driving wheels. It realizes forward and reverse pure electric modes and series modes through two motors and one-way clutches, and uses a passive rectifier bypass device and an auxiliary starting motor. Optimize power delivery, reduce motor size and improve fuel efficiency.

EREV Safety Regulations

Extended Range Electric Vehicles (EREVs) are subject to a complex set of safety regulations that encompass both electric vehicle (EV) and internal combustion engine (ICE) vehicle standards. These regulations are designed to ensure the safety of occupants, pedestrians, and emergency responders in various scenarios.

At the international level, the United Nations Economic Commission for Europe (UNECE) has developed regulations specifically addressing EREV safety. Regulation No. 100 covers battery electric vehicle safety, including requirements for protection against electric shock, battery safety, and functional safety. Regulation No. 136 addresses specific safety provisions for electric power train vehicles.

In the United States, the National Highway Traffic Safety Administration (NHTSA) has established Federal Motor Vehicle Safety Standards (FMVSS) that apply to EREVs. FMVSS No. 305 specifically addresses electric-powered vehicles, covering aspects such as electrolyte spillage, battery retention, and electrical isolation during and after crash tests.

The European Union has implemented similar regulations through the General Safety Regulation (GSR) and the Pedestrian Safety Regulation. These regulations cover a wide range of safety aspects, including advanced driver assistance systems, crash protection, and pedestrian impact mitigation.

China, as a major automotive market, has also developed its own set of regulations for new energy vehicles, including EREVs. The GB/T 18384 series of standards covers electric vehicle safety requirements, while GB/T 31498 specifically addresses the safety requirements for EREVs.

One of the key focus areas in EREV safety regulations is the prevention of thermal runaway in battery systems. Regulations typically require manufacturers to implement robust battery management systems, thermal management solutions, and protective enclosures to minimize the risk of fire or explosion.

Another critical aspect addressed by safety regulations is the isolation of high-voltage components. Standards mandate proper insulation, shielding, and labeling of high-voltage systems to prevent electric shock hazards during normal operation, maintenance, and in post-crash scenarios.

EREV safety regulations also address the unique challenges posed by the presence of both electric and combustion powertrains. This includes requirements for fuel system integrity, exhaust emissions control, and the safe integration of the two power sources.

As EREV technology continues to evolve, regulatory bodies are working to update and refine safety standards. Emerging areas of focus include cybersecurity measures to protect against potential hacking of vehicle systems, as well as regulations addressing the safety implications of advanced driver assistance systems and autonomous driving features in EREVs.

At the international level, the United Nations Economic Commission for Europe (UNECE) has developed regulations specifically addressing EREV safety. Regulation No. 100 covers battery electric vehicle safety, including requirements for protection against electric shock, battery safety, and functional safety. Regulation No. 136 addresses specific safety provisions for electric power train vehicles.

In the United States, the National Highway Traffic Safety Administration (NHTSA) has established Federal Motor Vehicle Safety Standards (FMVSS) that apply to EREVs. FMVSS No. 305 specifically addresses electric-powered vehicles, covering aspects such as electrolyte spillage, battery retention, and electrical isolation during and after crash tests.

The European Union has implemented similar regulations through the General Safety Regulation (GSR) and the Pedestrian Safety Regulation. These regulations cover a wide range of safety aspects, including advanced driver assistance systems, crash protection, and pedestrian impact mitigation.

China, as a major automotive market, has also developed its own set of regulations for new energy vehicles, including EREVs. The GB/T 18384 series of standards covers electric vehicle safety requirements, while GB/T 31498 specifically addresses the safety requirements for EREVs.

One of the key focus areas in EREV safety regulations is the prevention of thermal runaway in battery systems. Regulations typically require manufacturers to implement robust battery management systems, thermal management solutions, and protective enclosures to minimize the risk of fire or explosion.

Another critical aspect addressed by safety regulations is the isolation of high-voltage components. Standards mandate proper insulation, shielding, and labeling of high-voltage systems to prevent electric shock hazards during normal operation, maintenance, and in post-crash scenarios.

EREV safety regulations also address the unique challenges posed by the presence of both electric and combustion powertrains. This includes requirements for fuel system integrity, exhaust emissions control, and the safe integration of the two power sources.

As EREV technology continues to evolve, regulatory bodies are working to update and refine safety standards. Emerging areas of focus include cybersecurity measures to protect against potential hacking of vehicle systems, as well as regulations addressing the safety implications of advanced driver assistance systems and autonomous driving features in EREVs.

EREV Environmental Impact

Extended Range Electric Vehicles (EREVs) have emerged as a promising solution to address environmental concerns associated with traditional internal combustion engine vehicles. The environmental impact of EREVs is multifaceted, encompassing various aspects of their lifecycle from production to end-of-life disposal.

One of the primary environmental benefits of EREVs is their potential to significantly reduce greenhouse gas emissions. By utilizing electric power for a substantial portion of their operation, EREVs can dramatically decrease tailpipe emissions compared to conventional vehicles. This reduction is particularly notable in urban environments, where air quality improvements can have a direct positive impact on public health.

However, the environmental impact of EREVs extends beyond operational emissions. The production phase of these vehicles, particularly battery manufacturing, can have significant environmental implications. The extraction and processing of raw materials for batteries, such as lithium, cobalt, and nickel, can lead to habitat disruption and water pollution in mining regions. Additionally, the energy-intensive battery production process contributes to the overall carbon footprint of EREVs.

The source of electricity used to charge EREVs plays a crucial role in determining their overall environmental impact. In regions where electricity is predominantly generated from renewable sources, the environmental benefits of EREVs are maximized. Conversely, in areas heavily reliant on fossil fuels for electricity generation, the indirect emissions associated with charging can partially offset the benefits of reduced tailpipe emissions.

End-of-life considerations for EREVs also factor into their environmental impact. The recycling and disposal of batteries present both challenges and opportunities. Proper recycling processes can recover valuable materials and reduce the need for new raw material extraction. However, the complexity of battery compositions and the lack of standardized recycling infrastructure in many regions pose ongoing challenges.

The overall lifecycle assessment of EREVs indicates a generally positive environmental impact compared to conventional vehicles, particularly in terms of reducing local air pollution and greenhouse gas emissions. However, continued efforts are needed to address the environmental concerns associated with battery production and end-of-life management to further enhance the sustainability of EREV technology.

One of the primary environmental benefits of EREVs is their potential to significantly reduce greenhouse gas emissions. By utilizing electric power for a substantial portion of their operation, EREVs can dramatically decrease tailpipe emissions compared to conventional vehicles. This reduction is particularly notable in urban environments, where air quality improvements can have a direct positive impact on public health.

However, the environmental impact of EREVs extends beyond operational emissions. The production phase of these vehicles, particularly battery manufacturing, can have significant environmental implications. The extraction and processing of raw materials for batteries, such as lithium, cobalt, and nickel, can lead to habitat disruption and water pollution in mining regions. Additionally, the energy-intensive battery production process contributes to the overall carbon footprint of EREVs.

The source of electricity used to charge EREVs plays a crucial role in determining their overall environmental impact. In regions where electricity is predominantly generated from renewable sources, the environmental benefits of EREVs are maximized. Conversely, in areas heavily reliant on fossil fuels for electricity generation, the indirect emissions associated with charging can partially offset the benefits of reduced tailpipe emissions.

End-of-life considerations for EREVs also factor into their environmental impact. The recycling and disposal of batteries present both challenges and opportunities. Proper recycling processes can recover valuable materials and reduce the need for new raw material extraction. However, the complexity of battery compositions and the lack of standardized recycling infrastructure in many regions pose ongoing challenges.

The overall lifecycle assessment of EREVs indicates a generally positive environmental impact compared to conventional vehicles, particularly in terms of reducing local air pollution and greenhouse gas emissions. However, continued efforts are needed to address the environmental concerns associated with battery production and end-of-life management to further enhance the sustainability of EREV technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!