EREV efficiency benchmarking across different model types

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EREV Technology Overview and Objectives

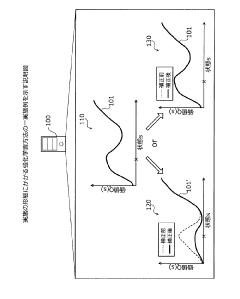

Extended Range Electric Vehicles (EREVs) represent a significant advancement in automotive technology, combining the benefits of electric propulsion with the range assurance of internal combustion engines. This hybrid approach has evolved over the past two decades, driven by the need for more sustainable transportation solutions and the limitations of pure battery electric vehicles.

The primary objective of EREV technology is to maximize overall vehicle efficiency while minimizing emissions and fuel consumption. This is achieved through a complex interplay of electric motors, batteries, and internal combustion engines, all managed by sophisticated control systems. The evolution of EREV technology has been marked by continuous improvements in battery capacity, electric motor efficiency, and powertrain integration.

Market trends indicate a growing demand for vehicles that offer both zero-emission capability for daily commutes and long-range flexibility for occasional trips. EREVs address this need by providing an electric-only range sufficient for most daily driving, with the added security of a range extender for longer journeys. This dual-mode operation has positioned EREVs as a transitional technology in the automotive industry's shift towards full electrification.

The technical challenges facing EREV development are multifaceted. Engineers must optimize the balance between electric and combustion power sources, manage thermal systems across multiple propulsion components, and develop control strategies that seamlessly integrate these diverse systems. Additionally, weight management and packaging constraints present ongoing challenges as manufacturers strive to incorporate larger battery packs without compromising vehicle dynamics or interior space.

Recent advancements in EREV technology have focused on increasing the electric-only range, improving the efficiency of range extender engines, and enhancing overall system integration. Innovations in battery chemistry, such as the adoption of lithium-ion technologies with higher energy densities, have played a crucial role in extending electric range capabilities.

The goal of efficiency benchmarking across different EREV model types is to establish industry standards, identify best practices, and drive continuous improvement in vehicle performance. This process involves comprehensive analysis of various EREV architectures, comparing factors such as energy consumption, emissions, and overall drivetrain efficiency under diverse operating conditions.

By systematically evaluating different EREV models, researchers and manufacturers can gain insights into the most effective powertrain configurations, control strategies, and component selections. This knowledge is essential for guiding future development efforts and informing strategic decisions in product planning and technology investment.

The primary objective of EREV technology is to maximize overall vehicle efficiency while minimizing emissions and fuel consumption. This is achieved through a complex interplay of electric motors, batteries, and internal combustion engines, all managed by sophisticated control systems. The evolution of EREV technology has been marked by continuous improvements in battery capacity, electric motor efficiency, and powertrain integration.

Market trends indicate a growing demand for vehicles that offer both zero-emission capability for daily commutes and long-range flexibility for occasional trips. EREVs address this need by providing an electric-only range sufficient for most daily driving, with the added security of a range extender for longer journeys. This dual-mode operation has positioned EREVs as a transitional technology in the automotive industry's shift towards full electrification.

The technical challenges facing EREV development are multifaceted. Engineers must optimize the balance between electric and combustion power sources, manage thermal systems across multiple propulsion components, and develop control strategies that seamlessly integrate these diverse systems. Additionally, weight management and packaging constraints present ongoing challenges as manufacturers strive to incorporate larger battery packs without compromising vehicle dynamics or interior space.

Recent advancements in EREV technology have focused on increasing the electric-only range, improving the efficiency of range extender engines, and enhancing overall system integration. Innovations in battery chemistry, such as the adoption of lithium-ion technologies with higher energy densities, have played a crucial role in extending electric range capabilities.

The goal of efficiency benchmarking across different EREV model types is to establish industry standards, identify best practices, and drive continuous improvement in vehicle performance. This process involves comprehensive analysis of various EREV architectures, comparing factors such as energy consumption, emissions, and overall drivetrain efficiency under diverse operating conditions.

By systematically evaluating different EREV models, researchers and manufacturers can gain insights into the most effective powertrain configurations, control strategies, and component selections. This knowledge is essential for guiding future development efforts and informing strategic decisions in product planning and technology investment.

Market Analysis for EREV Models

The market for Extended Range Electric Vehicles (EREVs) has shown significant growth potential in recent years, driven by increasing environmental concerns and the need for more versatile electric vehicle options. EREVs offer a unique value proposition by combining the benefits of electric vehicles with the extended range capabilities provided by a small internal combustion engine.

Market demand for EREVs has been steadily increasing, particularly in regions with developing charging infrastructure. Consumers are attracted to the flexibility of EREVs, which alleviate range anxiety while still providing substantial electric-only driving capabilities. This has led to a growing market share for EREV models, especially in urban and suburban areas where daily commutes can be completed on electric power alone.

The EREV market is currently dominated by a few key players, with major automotive manufacturers investing heavily in EREV technology. These companies are continuously improving their EREV offerings, focusing on enhancing efficiency, extending electric range, and reducing overall vehicle costs. The competition in this space is driving innovation and pushing the boundaries of EREV technology.

Market trends indicate a shift towards more efficient and powerful electric drivetrains in EREVs, with manufacturers striving to increase the electric-only range while minimizing the size and weight of the range extender. This trend aligns with consumer preferences for vehicles that can operate primarily on electric power while retaining the ability to undertake longer journeys without the need for frequent charging stops.

The EREV market is also influenced by government policies and regulations aimed at reducing carbon emissions. Many countries have implemented incentives for the purchase of electric and hybrid vehicles, including EREVs, which has further stimulated market growth. These incentives, coupled with stricter emissions standards, are expected to continue driving EREV adoption in the coming years.

As the automotive industry transitions towards electrification, EREVs are positioned as an important bridge technology. They offer a practical solution for consumers who are interested in electric vehicles but are not yet ready to commit to a fully electric model due to range limitations or charging infrastructure concerns. This positioning has created a distinct market segment for EREVs, with potential for further expansion as technology improves and consumer awareness grows.

The market analysis for EREV models reveals a complex landscape shaped by technological advancements, consumer preferences, and regulatory pressures. As efficiency benchmarking across different EREV model types becomes increasingly important, manufacturers are likely to focus on optimizing their designs to achieve the best balance between electric range, fuel efficiency, and overall performance. This ongoing development is expected to further enhance the appeal of EREVs and solidify their position in the evolving automotive market.

Market demand for EREVs has been steadily increasing, particularly in regions with developing charging infrastructure. Consumers are attracted to the flexibility of EREVs, which alleviate range anxiety while still providing substantial electric-only driving capabilities. This has led to a growing market share for EREV models, especially in urban and suburban areas where daily commutes can be completed on electric power alone.

The EREV market is currently dominated by a few key players, with major automotive manufacturers investing heavily in EREV technology. These companies are continuously improving their EREV offerings, focusing on enhancing efficiency, extending electric range, and reducing overall vehicle costs. The competition in this space is driving innovation and pushing the boundaries of EREV technology.

Market trends indicate a shift towards more efficient and powerful electric drivetrains in EREVs, with manufacturers striving to increase the electric-only range while minimizing the size and weight of the range extender. This trend aligns with consumer preferences for vehicles that can operate primarily on electric power while retaining the ability to undertake longer journeys without the need for frequent charging stops.

The EREV market is also influenced by government policies and regulations aimed at reducing carbon emissions. Many countries have implemented incentives for the purchase of electric and hybrid vehicles, including EREVs, which has further stimulated market growth. These incentives, coupled with stricter emissions standards, are expected to continue driving EREV adoption in the coming years.

As the automotive industry transitions towards electrification, EREVs are positioned as an important bridge technology. They offer a practical solution for consumers who are interested in electric vehicles but are not yet ready to commit to a fully electric model due to range limitations or charging infrastructure concerns. This positioning has created a distinct market segment for EREVs, with potential for further expansion as technology improves and consumer awareness grows.

The market analysis for EREV models reveals a complex landscape shaped by technological advancements, consumer preferences, and regulatory pressures. As efficiency benchmarking across different EREV model types becomes increasingly important, manufacturers are likely to focus on optimizing their designs to achieve the best balance between electric range, fuel efficiency, and overall performance. This ongoing development is expected to further enhance the appeal of EREVs and solidify their position in the evolving automotive market.

Current EREV Efficiency Challenges

Extended Range Electric Vehicles (EREVs) face several efficiency challenges that hinder their widespread adoption and optimal performance. One of the primary issues is the complexity of integrating two distinct power sources - an electric motor and an internal combustion engine. This integration often leads to increased vehicle weight and reduced overall efficiency compared to pure electric vehicles.

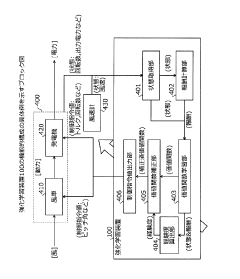

The battery management system (BMS) in EREVs presents another significant challenge. Optimizing the balance between battery usage and engine operation to maximize efficiency across various driving conditions remains a complex task. The BMS must account for factors such as battery state of charge, driving patterns, and energy recuperation opportunities, all of which can vary greatly between different EREV models.

Thermal management is a critical aspect that affects EREV efficiency. The need to cool both the electric components and the internal combustion engine creates additional energy demands, potentially reducing the overall efficiency of the vehicle. Different EREV models employ various thermal management strategies, making it difficult to establish a standardized approach for efficiency benchmarking.

The regenerative braking systems in EREVs also present efficiency challenges. While these systems can recover energy during deceleration, their effectiveness varies significantly across different models. Factors such as vehicle weight, brake system design, and control algorithms all influence the amount of energy that can be recaptured and stored in the battery.

Drivetrain efficiency is another area where EREVs face challenges. The need to transmit power from both the electric motor and the internal combustion engine to the wheels can result in energy losses. Different EREV models employ various transmission systems and power-split devices, each with its own efficiency characteristics, making it challenging to compare performance across models.

The efficiency of the internal combustion engine itself is a crucial factor in EREV performance. As these engines often operate in a series hybrid configuration, optimizing their operation for maximum efficiency while minimizing emissions is a complex task. Different EREV models may use engines with varying displacements, fuel types, and operating strategies, further complicating efficiency benchmarking efforts.

Lastly, the control strategies employed in EREVs to manage power flow between the electric and combustion components significantly impact overall efficiency. These strategies must balance factors such as battery life, fuel consumption, and performance requirements. The diversity of control approaches across different EREV models makes it challenging to establish standardized efficiency metrics for comparison.

The battery management system (BMS) in EREVs presents another significant challenge. Optimizing the balance between battery usage and engine operation to maximize efficiency across various driving conditions remains a complex task. The BMS must account for factors such as battery state of charge, driving patterns, and energy recuperation opportunities, all of which can vary greatly between different EREV models.

Thermal management is a critical aspect that affects EREV efficiency. The need to cool both the electric components and the internal combustion engine creates additional energy demands, potentially reducing the overall efficiency of the vehicle. Different EREV models employ various thermal management strategies, making it difficult to establish a standardized approach for efficiency benchmarking.

The regenerative braking systems in EREVs also present efficiency challenges. While these systems can recover energy during deceleration, their effectiveness varies significantly across different models. Factors such as vehicle weight, brake system design, and control algorithms all influence the amount of energy that can be recaptured and stored in the battery.

Drivetrain efficiency is another area where EREVs face challenges. The need to transmit power from both the electric motor and the internal combustion engine to the wheels can result in energy losses. Different EREV models employ various transmission systems and power-split devices, each with its own efficiency characteristics, making it challenging to compare performance across models.

The efficiency of the internal combustion engine itself is a crucial factor in EREV performance. As these engines often operate in a series hybrid configuration, optimizing their operation for maximum efficiency while minimizing emissions is a complex task. Different EREV models may use engines with varying displacements, fuel types, and operating strategies, further complicating efficiency benchmarking efforts.

Lastly, the control strategies employed in EREVs to manage power flow between the electric and combustion components significantly impact overall efficiency. These strategies must balance factors such as battery life, fuel consumption, and performance requirements. The diversity of control approaches across different EREV models makes it challenging to establish standardized efficiency metrics for comparison.

Existing EREV Efficiency Solutions

01 Powertrain optimization for EREV efficiency

Optimizing the powertrain configuration in Extended Range Electric Vehicles (EREVs) is crucial for improving overall efficiency. This includes advanced control strategies for the engine, electric motor, and battery management system to ensure optimal power distribution and energy recovery. Techniques such as regenerative braking, intelligent power splitting, and adaptive driving mode selection contribute to maximizing the vehicle's range and energy efficiency.- Powertrain optimization for EREV efficiency: Optimizing the powertrain configuration in Extended Range Electric Vehicles (EREVs) is crucial for improving overall efficiency. This includes advanced control strategies for the engine, electric motor, and battery management system to ensure optimal power distribution and energy recovery. Techniques such as regenerative braking, intelligent power splitting, and adaptive driving modes contribute to maximizing the vehicle's range and efficiency.

- Battery management and energy storage improvements: Enhancing battery management systems and energy storage technologies is key to increasing EREV efficiency. This involves developing high-capacity batteries with improved energy density, implementing smart charging algorithms, and utilizing advanced thermal management systems. These improvements lead to extended electric-only range, faster charging times, and better overall energy utilization in EREVs.

- Lightweight materials and aerodynamic design: Incorporating lightweight materials in vehicle construction and improving aerodynamic design significantly contribute to EREV efficiency. The use of advanced composites, high-strength alloys, and innovative manufacturing techniques reduces overall vehicle weight. Coupled with aerodynamic optimizations, these improvements lead to reduced energy consumption and increased range for EREVs.

- Intelligent energy management systems: Developing sophisticated energy management systems that utilize artificial intelligence and machine learning algorithms enhances EREV efficiency. These systems can predict energy demands, optimize power distribution between the electric motor and range extender, and adapt to various driving conditions and user preferences. This results in improved overall energy efficiency and extended vehicle range.

- Integration of renewable energy sources: Incorporating renewable energy sources into EREV charging infrastructure improves overall efficiency and reduces environmental impact. This includes the development of solar-powered charging stations, integration of wind energy systems, and implementation of smart grid technologies. These innovations contribute to a more sustainable and efficient ecosystem for EREVs.

02 Battery management and charging systems

Efficient battery management and charging systems play a vital role in EREV performance. Advanced battery technologies, smart charging algorithms, and thermal management systems are employed to extend battery life, improve charging efficiency, and optimize energy storage. This includes the development of fast-charging capabilities and intelligent battery state-of-charge monitoring to enhance the vehicle's electric range and overall efficiency.Expand Specific Solutions03 Aerodynamic design and lightweight materials

Improving the aerodynamic design of EREVs and utilizing lightweight materials contribute significantly to vehicle efficiency. Advanced computational fluid dynamics simulations are used to optimize body shapes, reducing drag and improving energy consumption. The use of lightweight materials such as carbon fiber composites and high-strength alloys in vehicle construction helps reduce overall weight, leading to improved range and performance.Expand Specific Solutions04 Energy recovery and regenerative systems

Implementing advanced energy recovery and regenerative systems enhances EREV efficiency. This includes regenerative braking technologies that capture kinetic energy during deceleration and convert it into electrical energy for battery recharging. Additionally, waste heat recovery systems and thermoelectric generators are utilized to convert thermal energy from the engine and other components into usable electrical power, further improving overall vehicle efficiency.Expand Specific Solutions05 Intelligent energy management and predictive control

Developing intelligent energy management systems and predictive control algorithms significantly improves EREV efficiency. These systems utilize real-time data, GPS information, and machine learning techniques to optimize power distribution between the electric motor and internal combustion engine. Predictive control strategies anticipate driving conditions and adjust powertrain parameters accordingly, maximizing energy efficiency and extending the vehicle's range.Expand Specific Solutions

Key EREV Manufacturers and Competitors

The EREV efficiency benchmarking across different model types is currently in a growth phase, with increasing market size and technological advancements. The competitive landscape is characterized by a mix of established automakers and emerging players, reflecting the industry's transition towards electrification. Companies like GM Global Technology Operations, Dongfeng Motor Group, and Changan Automobile are actively developing EREV technologies, while Toyota Motor Corp. and Guangzhou Automobile Group are also making strides in this field. The involvement of research institutions such as Tsinghua University and Zhejiang University indicates ongoing efforts to improve EREV efficiency. As the technology matures, we can expect increased competition and innovation in this sector.

GM Global Technology Operations LLC

Technical Solution: GM has developed a sophisticated EREV (Extended Range Electric Vehicle) system, exemplified by the Chevrolet Volt. Their approach focuses on optimizing the interplay between electric and gasoline power sources. The system utilizes a large battery pack for pure electric driving and a gasoline engine that primarily functions as a generator. GM's EREV technology incorporates advanced power electronics and thermal management systems to maximize efficiency across various driving conditions. The company has implemented a split-power transmission that allows for multiple power flow paths, enhancing overall system efficiency[1]. GM's latest EREV models have shown improvements in electric range and fuel economy, with some versions achieving over 50 miles of all-electric range and a combined fuel economy of over 100 MPGe[2].

Strengths: Long electric range, seamless transition between electric and gasoline power, reduced range anxiety. Weaknesses: Higher initial cost compared to conventional hybrids, complexity of dual powertrain system.

Dongfeng Motor Group Co., Ltd.

Technical Solution: Dongfeng has been actively developing EREV technology as part of its electrification strategy. The company's approach focuses on adapting EREV systems for the Chinese market, with an emphasis on cost-effectiveness and practicality. Dongfeng's EREV models typically feature a combination of electric motors and small-displacement gasoline engines optimized for efficiency. The company has invested in developing advanced battery management systems and power electronics to enhance the overall efficiency of their EREV powertrains. Dongfeng's EREV technology has shown improvements in recent years, with some models achieving electric ranges of up to 80 kilometers and significant reductions in fuel consumption compared to conventional vehicles[5]. The company has also focused on integrating EREV technology into a variety of vehicle types, including sedans and SUVs, to cater to different market segments[6].

Strengths: Cost-effective solutions tailored for the Chinese market, diverse vehicle applications. Weaknesses: Less advanced technology compared to some global competitors, limited international presence.

Core EREV Efficiency Innovations

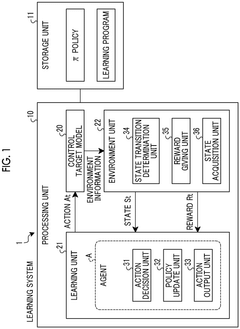

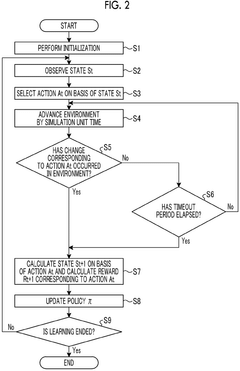

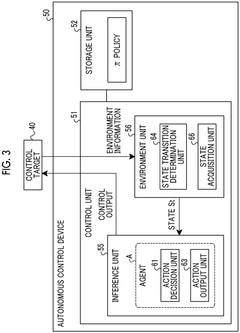

Training system, training method, training program, and autonomous control device

PatentPendingEP4528603A1

Innovation

- An event-driven approach is adopted, where the evaluation step is updated based on transitions from a first environment state to a second state when a predetermined action is executed by the agent, with a timeout period set to handle actions that take longer to complete, allowing for efficient reinforcement learning.

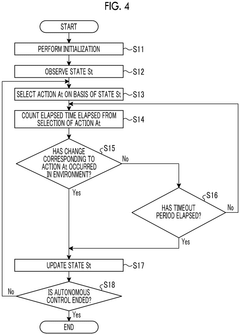

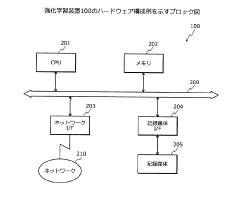

Reinforcement learning method, reinforcement learning program, and reinforcement learning apparatus

PatentActiveJP2020119139A

Innovation

- A reinforcement learning method that calculates the contribution of states or actions using basis functions and determines whether to update the value function based on monotonicity, ensuring accurate updates and reducing processing time.

EREV Environmental Impact Assessment

The environmental impact assessment of Extended Range Electric Vehicles (EREVs) is a critical aspect of evaluating their overall efficiency and sustainability across different model types. EREVs, which combine electric and internal combustion engine technologies, present a unique set of environmental considerations that must be carefully analyzed.

One of the primary environmental benefits of EREVs is their potential to significantly reduce greenhouse gas emissions compared to conventional internal combustion engine vehicles. By operating primarily on electric power for short to medium-range trips, EREVs can substantially decrease tailpipe emissions in urban areas, contributing to improved air quality and reduced carbon footprint. However, the extent of these benefits varies depending on the specific EREV model and its electric range capability.

The production phase of EREVs also warrants consideration in environmental impact assessments. The manufacturing of battery packs and electric powertrains involves energy-intensive processes and the use of rare earth materials. This can lead to higher initial environmental costs compared to conventional vehicles. However, these impacts are often offset over the vehicle's lifetime through reduced operational emissions.

Energy source mix plays a crucial role in determining the overall environmental impact of EREVs. In regions with a high proportion of renewable energy in the electricity grid, EREVs can achieve significantly lower lifecycle emissions. Conversely, in areas heavily reliant on fossil fuels for electricity generation, the environmental advantages of EREVs may be less pronounced.

The end-of-life phase for EREVs presents both challenges and opportunities. The recycling and disposal of battery packs require specialized processes to minimize environmental harm and recover valuable materials. Advancements in battery recycling technologies are essential to enhance the overall sustainability of EREV models.

When comparing different EREV models, factors such as battery size, electric range, and overall vehicle efficiency must be considered. Models with larger battery capacities may offer extended electric-only driving ranges, potentially reducing reliance on the internal combustion engine and lowering emissions. However, this must be balanced against the increased environmental impact of larger battery production.

The integration of smart charging technologies and vehicle-to-grid (V2G) capabilities in some EREV models can further enhance their environmental benefits. By optimizing charging times to align with periods of high renewable energy availability, these features can maximize the use of clean energy and potentially support grid stability.

In conclusion, the environmental impact assessment of EREVs across different model types reveals a complex interplay of factors. While these vehicles offer significant potential for reducing emissions and improving urban air quality, their overall environmental performance depends on a range of variables including energy source, manufacturing processes, and end-of-life management. Continued research and development in battery technology, recycling processes, and smart charging systems will be crucial in maximizing the environmental benefits of EREV technology.

One of the primary environmental benefits of EREVs is their potential to significantly reduce greenhouse gas emissions compared to conventional internal combustion engine vehicles. By operating primarily on electric power for short to medium-range trips, EREVs can substantially decrease tailpipe emissions in urban areas, contributing to improved air quality and reduced carbon footprint. However, the extent of these benefits varies depending on the specific EREV model and its electric range capability.

The production phase of EREVs also warrants consideration in environmental impact assessments. The manufacturing of battery packs and electric powertrains involves energy-intensive processes and the use of rare earth materials. This can lead to higher initial environmental costs compared to conventional vehicles. However, these impacts are often offset over the vehicle's lifetime through reduced operational emissions.

Energy source mix plays a crucial role in determining the overall environmental impact of EREVs. In regions with a high proportion of renewable energy in the electricity grid, EREVs can achieve significantly lower lifecycle emissions. Conversely, in areas heavily reliant on fossil fuels for electricity generation, the environmental advantages of EREVs may be less pronounced.

The end-of-life phase for EREVs presents both challenges and opportunities. The recycling and disposal of battery packs require specialized processes to minimize environmental harm and recover valuable materials. Advancements in battery recycling technologies are essential to enhance the overall sustainability of EREV models.

When comparing different EREV models, factors such as battery size, electric range, and overall vehicle efficiency must be considered. Models with larger battery capacities may offer extended electric-only driving ranges, potentially reducing reliance on the internal combustion engine and lowering emissions. However, this must be balanced against the increased environmental impact of larger battery production.

The integration of smart charging technologies and vehicle-to-grid (V2G) capabilities in some EREV models can further enhance their environmental benefits. By optimizing charging times to align with periods of high renewable energy availability, these features can maximize the use of clean energy and potentially support grid stability.

In conclusion, the environmental impact assessment of EREVs across different model types reveals a complex interplay of factors. While these vehicles offer significant potential for reducing emissions and improving urban air quality, their overall environmental performance depends on a range of variables including energy source, manufacturing processes, and end-of-life management. Continued research and development in battery technology, recycling processes, and smart charging systems will be crucial in maximizing the environmental benefits of EREV technology.

EREV Regulatory Compliance Standards

Regulatory compliance standards for Extended Range Electric Vehicles (EREVs) play a crucial role in shaping the development and adoption of these vehicles across different markets. These standards are designed to ensure that EREVs meet specific performance, safety, and environmental criteria while providing a framework for manufacturers to benchmark their models against industry norms.

In the United States, the Environmental Protection Agency (EPA) and the National Highway Traffic Safety Administration (NHTSA) jointly establish fuel economy and emissions standards for EREVs. These regulations are part of the Corporate Average Fuel Economy (CAFE) standards, which set specific targets for manufacturers to achieve across their vehicle fleets. For EREVs, the EPA employs a utility factor approach to calculate the overall fuel economy, taking into account both electric and gasoline operation modes.

The European Union has implemented the Worldwide Harmonized Light Vehicles Test Procedure (WLTP) for measuring CO2 emissions and fuel consumption of EREVs. This test cycle provides a more realistic assessment of vehicle performance compared to its predecessor, the New European Driving Cycle (NEDC). Additionally, the EU has set stringent CO2 emission targets for new passenger cars, which directly impact EREV development and market positioning.

China, as a major player in the electric vehicle market, has established its own set of standards for EREVs through the Ministry of Industry and Information Technology (MIIT). These regulations focus on energy consumption, electric range, and emissions performance. The New Energy Vehicle (NEV) credit system in China also incentivizes manufacturers to produce and sell more efficient EREVs.

Globally, the United Nations Economic Commission for Europe (UNECE) has developed regulations under the World Forum for Harmonization of Vehicle Regulations (WP.29) that address various aspects of EREV performance and safety. These regulations aim to facilitate international harmonization of standards and reduce barriers to trade in the automotive sector.

To benchmark EREV efficiency across different model types, manufacturers must adhere to these regulatory standards while also considering market-specific requirements. This process involves comprehensive testing procedures, data collection, and analysis to ensure compliance and optimize vehicle performance. As regulatory landscapes continue to evolve, EREV manufacturers must remain agile in adapting their technologies and strategies to meet increasingly stringent efficiency and emissions targets across global markets.

In the United States, the Environmental Protection Agency (EPA) and the National Highway Traffic Safety Administration (NHTSA) jointly establish fuel economy and emissions standards for EREVs. These regulations are part of the Corporate Average Fuel Economy (CAFE) standards, which set specific targets for manufacturers to achieve across their vehicle fleets. For EREVs, the EPA employs a utility factor approach to calculate the overall fuel economy, taking into account both electric and gasoline operation modes.

The European Union has implemented the Worldwide Harmonized Light Vehicles Test Procedure (WLTP) for measuring CO2 emissions and fuel consumption of EREVs. This test cycle provides a more realistic assessment of vehicle performance compared to its predecessor, the New European Driving Cycle (NEDC). Additionally, the EU has set stringent CO2 emission targets for new passenger cars, which directly impact EREV development and market positioning.

China, as a major player in the electric vehicle market, has established its own set of standards for EREVs through the Ministry of Industry and Information Technology (MIIT). These regulations focus on energy consumption, electric range, and emissions performance. The New Energy Vehicle (NEV) credit system in China also incentivizes manufacturers to produce and sell more efficient EREVs.

Globally, the United Nations Economic Commission for Europe (UNECE) has developed regulations under the World Forum for Harmonization of Vehicle Regulations (WP.29) that address various aspects of EREV performance and safety. These regulations aim to facilitate international harmonization of standards and reduce barriers to trade in the automotive sector.

To benchmark EREV efficiency across different model types, manufacturers must adhere to these regulatory standards while also considering market-specific requirements. This process involves comprehensive testing procedures, data collection, and analysis to ensure compliance and optimize vehicle performance. As regulatory landscapes continue to evolve, EREV manufacturers must remain agile in adapting their technologies and strategies to meet increasingly stringent efficiency and emissions targets across global markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!