Thin Film Deposition for Wear Resistant Coatings in Tooling Applications

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thin Film Coating Technology Evolution and Objectives

Thin film deposition technologies for wear-resistant coatings have evolved significantly over the past century, transforming from rudimentary thermal evaporation methods to sophisticated atomic-level engineering processes. The journey began in the early 20th century with simple vacuum metallization techniques, primarily used for decorative purposes rather than functional applications. By the 1950s, the development of vacuum-based Physical Vapor Deposition (PVD) marked a significant milestone, enabling the creation of thin metallic films with improved adhesion and uniformity.

The 1970s witnessed a revolutionary advancement with the introduction of Chemical Vapor Deposition (CVD) techniques, allowing for the deposition of complex compounds and ceramics at elevated temperatures. This period also saw the emergence of ion-assisted deposition methods, which significantly enhanced coating adhesion and density. The subsequent decade brought forth the development of plasma-enhanced processes, reducing operating temperatures and expanding the range of applicable substrate materials.

A paradigm shift occurred in the 1980s and 1990s with the commercialization of magnetron sputtering technology, which dramatically improved deposition rates and coating quality. Concurrently, the introduction of arc evaporation techniques enabled the creation of exceptionally hard nitride coatings, particularly titanium nitride (TiN), which became the industry standard for cutting tools.

The early 2000s marked the beginning of the nanostructured coating era, with multilayer and nanocomposite architectures demonstrating unprecedented combinations of hardness, toughness, and wear resistance. These advanced structures effectively addressed the traditional trade-off between hardness and brittleness that had limited earlier coating generations. Recent developments have focused on self-lubricating coatings and adaptive surfaces that can respond to changing operational conditions.

The primary objective of modern thin film deposition for tooling applications is to extend tool life while maintaining or improving cutting performance. This involves developing coatings with optimal combinations of hardness, toughness, thermal stability, and chemical inertness. Additional goals include reducing friction coefficients to minimize heat generation and energy consumption during machining operations.

Current research aims to create environmentally friendly deposition processes that eliminate toxic precursors and reduce energy consumption. There is also significant interest in developing coatings capable of operating under extreme conditions, such as high-temperature machining of difficult-to-cut materials like nickel-based superalloys and titanium alloys. The ultimate vision is to create "smart" coatings with self-healing capabilities and integrated sensors for real-time monitoring of tool condition, representing the next frontier in this rapidly evolving technological landscape.

The 1970s witnessed a revolutionary advancement with the introduction of Chemical Vapor Deposition (CVD) techniques, allowing for the deposition of complex compounds and ceramics at elevated temperatures. This period also saw the emergence of ion-assisted deposition methods, which significantly enhanced coating adhesion and density. The subsequent decade brought forth the development of plasma-enhanced processes, reducing operating temperatures and expanding the range of applicable substrate materials.

A paradigm shift occurred in the 1980s and 1990s with the commercialization of magnetron sputtering technology, which dramatically improved deposition rates and coating quality. Concurrently, the introduction of arc evaporation techniques enabled the creation of exceptionally hard nitride coatings, particularly titanium nitride (TiN), which became the industry standard for cutting tools.

The early 2000s marked the beginning of the nanostructured coating era, with multilayer and nanocomposite architectures demonstrating unprecedented combinations of hardness, toughness, and wear resistance. These advanced structures effectively addressed the traditional trade-off between hardness and brittleness that had limited earlier coating generations. Recent developments have focused on self-lubricating coatings and adaptive surfaces that can respond to changing operational conditions.

The primary objective of modern thin film deposition for tooling applications is to extend tool life while maintaining or improving cutting performance. This involves developing coatings with optimal combinations of hardness, toughness, thermal stability, and chemical inertness. Additional goals include reducing friction coefficients to minimize heat generation and energy consumption during machining operations.

Current research aims to create environmentally friendly deposition processes that eliminate toxic precursors and reduce energy consumption. There is also significant interest in developing coatings capable of operating under extreme conditions, such as high-temperature machining of difficult-to-cut materials like nickel-based superalloys and titanium alloys. The ultimate vision is to create "smart" coatings with self-healing capabilities and integrated sensors for real-time monitoring of tool condition, representing the next frontier in this rapidly evolving technological landscape.

Market Analysis for Wear Resistant Tool Coatings

The global market for wear resistant tool coatings has experienced significant growth over the past decade, driven by increasing demands for improved tool performance and longevity across multiple industries. Currently valued at approximately 7.2 billion USD, this market is projected to reach 11.5 billion USD by 2028, representing a compound annual growth rate of 8.3% during the forecast period.

The automotive manufacturing sector remains the largest consumer of coated tooling, accounting for roughly 32% of the total market share. This dominance is attributed to the industry's continuous pursuit of higher production efficiency and reduced maintenance costs. The aerospace industry follows closely at 24%, where extreme operating conditions necessitate superior tool performance and durability.

General manufacturing and electronics sectors collectively represent another 30% of the market, with the remaining share distributed among various industries including medical device manufacturing, energy, and defense. Regionally, Asia-Pacific leads the market with 38% share, followed by North America (27%) and Europe (25%), with the rest of the world accounting for 10%.

Customer demand patterns reveal a clear shift toward multi-functional coatings that offer not just wear resistance but also additional properties such as thermal stability, chemical inertness, and reduced friction. This trend is particularly evident in high-precision manufacturing segments where tool performance directly impacts product quality and production costs.

Price sensitivity varies significantly across market segments. While mass production industries remain highly cost-conscious, high-value manufacturing sectors demonstrate willingness to invest in premium coating solutions that deliver demonstrable performance advantages and extended tool life. The average return on investment for advanced wear resistant coatings ranges between 3-5 times the initial coating cost through extended tool life and reduced downtime.

Market research indicates that end-users increasingly prioritize total cost of ownership over initial acquisition costs, creating opportunities for suppliers of higher-performance coating technologies. Additionally, environmental regulations are driving demand for coatings that eliminate hazardous materials and reduce environmental impact during both application and disposal phases.

Emerging market trends include growing interest in nanoscale coatings, hybrid coating systems that combine multiple deposition technologies, and customized coating solutions for specific applications. The service aspect of the coating business is also expanding, with coating providers increasingly offering comprehensive tool life management services rather than simply selling coating applications.

The automotive manufacturing sector remains the largest consumer of coated tooling, accounting for roughly 32% of the total market share. This dominance is attributed to the industry's continuous pursuit of higher production efficiency and reduced maintenance costs. The aerospace industry follows closely at 24%, where extreme operating conditions necessitate superior tool performance and durability.

General manufacturing and electronics sectors collectively represent another 30% of the market, with the remaining share distributed among various industries including medical device manufacturing, energy, and defense. Regionally, Asia-Pacific leads the market with 38% share, followed by North America (27%) and Europe (25%), with the rest of the world accounting for 10%.

Customer demand patterns reveal a clear shift toward multi-functional coatings that offer not just wear resistance but also additional properties such as thermal stability, chemical inertness, and reduced friction. This trend is particularly evident in high-precision manufacturing segments where tool performance directly impacts product quality and production costs.

Price sensitivity varies significantly across market segments. While mass production industries remain highly cost-conscious, high-value manufacturing sectors demonstrate willingness to invest in premium coating solutions that deliver demonstrable performance advantages and extended tool life. The average return on investment for advanced wear resistant coatings ranges between 3-5 times the initial coating cost through extended tool life and reduced downtime.

Market research indicates that end-users increasingly prioritize total cost of ownership over initial acquisition costs, creating opportunities for suppliers of higher-performance coating technologies. Additionally, environmental regulations are driving demand for coatings that eliminate hazardous materials and reduce environmental impact during both application and disposal phases.

Emerging market trends include growing interest in nanoscale coatings, hybrid coating systems that combine multiple deposition technologies, and customized coating solutions for specific applications. The service aspect of the coating business is also expanding, with coating providers increasingly offering comprehensive tool life management services rather than simply selling coating applications.

Current Deposition Technologies and Barriers

The current landscape of thin film deposition technologies for wear-resistant coatings in tooling applications is dominated by several established methods, each with distinct advantages and limitations. Physical Vapor Deposition (PVD) techniques, including magnetron sputtering, arc evaporation, and electron beam evaporation, represent the most widely adopted approaches. These methods offer excellent adhesion properties and can produce dense, uniform coatings with thicknesses ranging from nanometers to several micrometers. Magnetron sputtering, in particular, provides precise control over coating composition and structure, making it ideal for complex multi-component films.

Chemical Vapor Deposition (CVD) processes, including plasma-enhanced CVD and thermal CVD, constitute another significant category. These technologies enable the deposition of highly conformal coatings with superior step coverage compared to PVD methods, allowing for more uniform protection of complex tool geometries. CVD processes typically operate at higher temperatures (400-1000°C), which can limit substrate material selection but often result in excellent coating-substrate adhesion.

Atomic Layer Deposition (ALD) has emerged as a specialized technique offering unprecedented control over film thickness at the atomic level. While slower than conventional methods, ALD produces exceptionally uniform and conformal coatings, even on high-aspect-ratio features common in modern cutting tools and forming dies.

Despite these advancements, significant barriers persist in current deposition technologies. Temperature constraints represent a major limitation, as many high-performance substrates cannot withstand the elevated processing temperatures required for optimal coating formation. This is particularly problematic for precision tools with tight dimensional tolerances that can be compromised by thermal expansion and contraction cycles.

Adhesion failures remain a persistent challenge, especially in applications involving severe mechanical stresses or thermal cycling. The interface between coating and substrate often becomes the weak point in the system, leading to premature coating delamination and subsequent tool failure. Current surface preparation and interlayer technologies provide only partial solutions to this fundamental problem.

Scaling limitations also hinder industrial implementation, as many advanced deposition techniques struggle to maintain coating uniformity and quality across large batch sizes or complex geometries. This creates a significant cost barrier for widespread adoption in mass production tooling applications.

Process control and reproducibility present additional challenges, with many deposition systems exhibiting sensitivity to minor variations in process parameters. This results in batch-to-batch inconsistencies that compromise quality control in industrial settings. Furthermore, the high capital equipment costs and specialized expertise required for advanced deposition systems restrict their accessibility to smaller manufacturers and limit broader market penetration.

Chemical Vapor Deposition (CVD) processes, including plasma-enhanced CVD and thermal CVD, constitute another significant category. These technologies enable the deposition of highly conformal coatings with superior step coverage compared to PVD methods, allowing for more uniform protection of complex tool geometries. CVD processes typically operate at higher temperatures (400-1000°C), which can limit substrate material selection but often result in excellent coating-substrate adhesion.

Atomic Layer Deposition (ALD) has emerged as a specialized technique offering unprecedented control over film thickness at the atomic level. While slower than conventional methods, ALD produces exceptionally uniform and conformal coatings, even on high-aspect-ratio features common in modern cutting tools and forming dies.

Despite these advancements, significant barriers persist in current deposition technologies. Temperature constraints represent a major limitation, as many high-performance substrates cannot withstand the elevated processing temperatures required for optimal coating formation. This is particularly problematic for precision tools with tight dimensional tolerances that can be compromised by thermal expansion and contraction cycles.

Adhesion failures remain a persistent challenge, especially in applications involving severe mechanical stresses or thermal cycling. The interface between coating and substrate often becomes the weak point in the system, leading to premature coating delamination and subsequent tool failure. Current surface preparation and interlayer technologies provide only partial solutions to this fundamental problem.

Scaling limitations also hinder industrial implementation, as many advanced deposition techniques struggle to maintain coating uniformity and quality across large batch sizes or complex geometries. This creates a significant cost barrier for widespread adoption in mass production tooling applications.

Process control and reproducibility present additional challenges, with many deposition systems exhibiting sensitivity to minor variations in process parameters. This results in batch-to-batch inconsistencies that compromise quality control in industrial settings. Furthermore, the high capital equipment costs and specialized expertise required for advanced deposition systems restrict their accessibility to smaller manufacturers and limit broader market penetration.

Prevalent Deposition Methods for Tool Applications

01 Physical Vapor Deposition (PVD) techniques for wear resistance

Physical Vapor Deposition techniques such as sputtering and evaporation are used to create thin films with enhanced wear resistance properties. These processes involve the deposition of material atoms onto a substrate in a vacuum environment, resulting in dense, uniform coatings that significantly improve surface hardness and durability. The controlled deposition parameters allow for customization of film properties to meet specific wear resistance requirements in various applications.- Physical Vapor Deposition (PVD) techniques for wear-resistant coatings: Physical Vapor Deposition techniques such as sputtering and evaporation are used to create thin films with enhanced wear resistance properties. These processes involve the deposition of material atoms onto a substrate in a vacuum environment, resulting in dense, uniform coatings with excellent adhesion. PVD coatings can significantly improve the surface hardness and wear resistance of various components, extending their service life in high-friction applications.

- Chemical Vapor Deposition (CVD) methods for wear-resistant films: Chemical Vapor Deposition processes involve chemical reactions of precursor gases at elevated temperatures to form thin films with superior wear resistance. CVD methods allow for the deposition of various materials including diamond-like carbon, carbides, and nitrides that provide exceptional hardness and tribological properties. These techniques enable the creation of conformal coatings even on complex geometries, making them suitable for components subjected to severe wear conditions.

- Multi-layer and composite thin film structures for enhanced wear resistance: Multi-layer and composite thin film structures combine different materials to achieve superior wear resistance properties. By alternating layers of hard and tough materials or creating nanocomposite structures, these films can provide an optimal balance of hardness, toughness, and adhesion. The interfaces between layers can effectively block crack propagation, while the combination of different materials can address multiple wear mechanisms simultaneously, resulting in significantly improved component durability.

- Doping and alloying techniques for improved thin film wear properties: Incorporating dopants or alloying elements into thin films can significantly enhance their wear resistance characteristics. By carefully selecting and controlling the concentration of these additional elements, the microstructure and mechanical properties of the films can be tailored for specific applications. These modifications can improve hardness, reduce friction coefficients, enhance thermal stability, and increase resistance to various wear mechanisms, resulting in coatings with superior performance in demanding environments.

- Surface preparation and post-deposition treatments for wear-resistant films: Proper surface preparation before deposition and post-deposition treatments are crucial for optimizing the wear resistance of thin films. Surface cleaning, etching, and activation processes ensure strong adhesion between the substrate and coating. Post-deposition treatments such as annealing, ion bombardment, or laser processing can modify the film structure, reduce internal stresses, improve crystallinity, and enhance interfacial bonding. These processes significantly contribute to the overall performance and durability of wear-resistant coatings in practical applications.

02 Chemical Vapor Deposition (CVD) methods for protective coatings

Chemical Vapor Deposition methods involve chemical reactions of precursor gases to form thin films with excellent wear resistance. These processes typically operate at higher temperatures than PVD and create films with strong adhesion to the substrate. CVD techniques can produce conformal coatings on complex geometries and are particularly effective for creating hard, wear-resistant layers such as diamond-like carbon, silicon carbide, and various metal carbides that significantly extend component lifetimes in high-wear applications.Expand Specific Solutions03 Multi-layer thin film structures for enhanced durability

Multi-layer thin film structures combine different materials in alternating layers to achieve superior wear resistance properties. This approach allows for the optimization of various properties such as hardness, toughness, and adhesion by leveraging the advantages of different materials. The interfaces between layers can act as barriers to crack propagation, enhancing overall durability. These multi-layer systems often incorporate transition layers to manage stress and improve adhesion between dissimilar materials, resulting in coatings with significantly improved wear life.Expand Specific Solutions04 Nanocomposite thin films for extreme wear conditions

Nanocomposite thin films incorporate nanoscale particles or structures within a matrix material to achieve exceptional wear resistance. These films combine the hardness of ceramic components with the toughness of metallic or polymer matrices. The nanoscale features disrupt dislocation movement and crack propagation, resulting in materials with superior mechanical properties. Nanocomposite coatings can be tailored for specific wear mechanisms such as abrasion, erosion, or fretting, making them ideal for extreme operating conditions in industrial, automotive, and aerospace applications.Expand Specific Solutions05 Surface treatment and post-deposition processes for wear optimization

Various surface treatment and post-deposition processes are employed to optimize the wear resistance of thin films. These include thermal annealing to relieve stress and improve crystallinity, ion implantation to modify surface properties, and polishing to reduce surface roughness. Post-deposition treatments can significantly enhance film adhesion, hardness, and tribological performance. Additionally, surface texturing techniques can be applied to create controlled patterns that reduce friction and wear by improving lubrication retention and reducing contact area in sliding applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The thin film deposition market for wear-resistant coatings in tooling applications is in a growth phase, characterized by increasing demand across manufacturing sectors. The market is estimated to reach several billion dollars by 2025, driven by the need for enhanced tool performance and longevity. Technologically, the field shows moderate maturity with ongoing innovation. Leading players include Sandvik Intellectual Property AB and Kennametal, who focus on premium coating solutions for industrial applications; Oerlikon Surface Solutions and Balzers, specializing in PVD/CVD technologies; and tool manufacturers like Walter AG, SECO TOOLS, and Sumitomo Electric Hardmetal. Research-oriented companies such as Applied Materials and Micron Technology are advancing deposition techniques, while materials specialists like BASF and Wacker Chemie are developing novel coating compositions, creating a competitive landscape balanced between established players and innovative entrants.

Sandvik Intellectual Property AB

Technical Solution: Sandvik has developed sophisticated thin film deposition technologies for wear-resistant coatings in tooling applications. Their InveioTM technology represents a breakthrough in coating microstructure control, featuring a unique unidirectional crystal orientation that significantly enhances wear resistance. This proprietary PVD (Physical Vapor Deposition) process creates aluminum oxide (Al2O3) coatings with aligned crystal growth, resulting in exceptional thermal barriers and wear resistance at cutting temperatures exceeding 900°C. The coating thickness typically ranges from 2-7 μm with hardness values above 3000 HV. Sandvik also utilizes advanced CVD (Chemical Vapor Deposition) technology to create multilayer coatings combining TiCN, Al2O3, and TiN layers, each optimized for specific functions such as adhesion, wear resistance, and friction reduction. Their Zertivo™ technology incorporates post-deposition treatments that enhance coating adhesion and toughness through controlled residual stress management. For specialized applications, Sandvik has developed nanocomposite PVD coatings with grain sizes below 10 nm, achieving hardness values exceeding 40 GPa while maintaining adequate toughness for interrupted cutting operations. Recent innovations include self-lubricating coatings that incorporate solid lubricants within the coating architecture, reducing friction coefficients to as low as 0.15 under dry machining conditions.

Strengths: Unique InveioTM technology provides superior wear resistance through controlled crystal orientation; comprehensive coating portfolio covering both PVD and CVD technologies; excellent coating adhesion through proprietary surface preparation techniques. Weaknesses: Some coating processes require specialized equipment and expertise; higher cost compared to conventional coatings; certain high-performance coatings have limited application ranges due to specific operating requirements.

SECO TOOLS AB

Technical Solution: Seco Tools has developed advanced thin film deposition technologies specifically tailored for cutting tool applications. Their Duratomic® coating technology represents a significant innovation in the field, utilizing a proprietary process that arranges aluminum and titanium atoms in an optimized crystal structure at the atomic level. This technology enables the creation of Al2O3 coatings with controlled crystallographic orientation, resulting in exceptional wear resistance and thermal stability. The coatings typically range from 2-15 μm in thickness and are applied using modified CVD (Chemical Vapor Deposition) processes at temperatures between 700-1000°C. For applications requiring lower deposition temperatures, Seco has developed specialized PVD (Physical Vapor Deposition) processes to create nanostructured TiAlN and AlCrN coatings with hardness values exceeding 3000 HV. Their multilayer coating architectures feature alternating hard and tough nanolayers, typically 5-25 nm thick, which effectively interrupt crack propagation while maintaining overall coating hardness. Recent innovations include their X-treme coating series, which incorporates post-deposition treatments to enhance surface smoothness and reduce friction coefficients to below 0.2 even under dry machining conditions.

Strengths: Proprietary Duratomic technology provides exceptional control over coating microstructure; comprehensive range of coating solutions for different machining applications; excellent thermal stability for high-speed machining. Weaknesses: Some CVD coatings require high deposition temperatures that can affect certain tool substrates; complex coating processes can result in higher production costs; limited flexibility in coating thickness for certain applications.

Critical Patents in Wear Resistant Coating Technology

A thin layer for cutting tools and a coating materialsused thereof

PatentInactiveKR1020030052468A

Innovation

- A titanium carbonitride (TiCN) thin film is modified by doping a small amount of boron (B) to form a TiBCN thin film, which is coated using a medium temperature chemical vapor deposition method, minimizing eta phase formation and enhancing hardness and wear resistance.

Wear resistant thin film coating and combination

PatentInactiveUS5798182A

Innovation

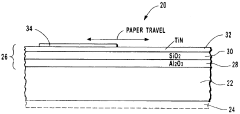

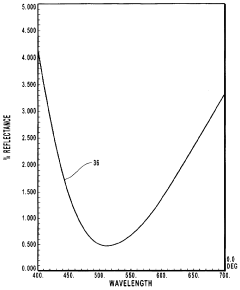

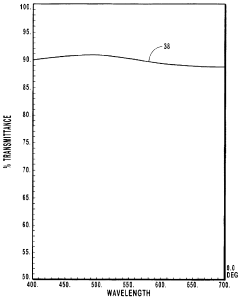

- A thin film composite comprising a thick aluminum oxide layer over a glass substrate, a thick silicon oxide layer over the aluminum oxide, and a thin titanium nitride layer over the silicon oxide, providing enhanced abrasion resistance, low reflectance, and static charge control.

Environmental Impact and Sustainability Considerations

The environmental impact of thin film deposition processes for wear-resistant coatings in tooling applications has become increasingly significant as industries strive for sustainable manufacturing practices. Traditional coating methods such as Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) often involve energy-intensive processes and hazardous materials that pose environmental concerns. These processes typically require high temperatures and vacuum conditions, resulting in substantial energy consumption and associated carbon emissions.

Many conventional coating materials contain toxic elements like chromium, cadmium, and lead, which present serious environmental and health risks throughout their lifecycle. The disposal of spent tools with these coatings can lead to soil and water contamination if not properly managed. Additionally, the precursor chemicals used in CVD processes often include volatile organic compounds (VOCs) and other environmentally harmful substances that contribute to air pollution and potential worker exposure.

Recent advancements have focused on developing more environmentally friendly alternatives. Water-based coating systems and powder coating technologies have emerged as lower-impact options, significantly reducing VOC emissions compared to solvent-based systems. The industry has also witnessed a shift toward using more benign materials such as titanium aluminum nitride (TiAlN) and diamond-like carbon (DLC) coatings, which offer excellent wear resistance without the environmental liabilities of traditional materials.

Energy efficiency improvements represent another critical area of progress. Modern thin film deposition equipment increasingly incorporates energy recovery systems, more efficient heating elements, and optimized process cycles that reduce overall energy consumption. Some manufacturers have reported energy savings of up to 30% through these technological improvements, directly translating to reduced carbon footprints.

Life cycle assessment (LCA) studies have become essential tools for evaluating the environmental impact of different coating technologies. These assessments consider the entire lifecycle from raw material extraction through manufacturing, use, and end-of-life disposal. Recent LCA data indicates that despite the energy-intensive nature of some advanced coating processes, the extended tool life they provide often results in net environmental benefits through reduced material consumption and waste generation.

Regulatory frameworks worldwide are increasingly influencing coating technology development. The European Union's REACH regulations, RoHS directive, and similar legislation in other regions have accelerated the transition away from hazardous substances in coating formulations. Companies investing in compliant technologies not only mitigate environmental risks but also gain competitive advantages in markets with stringent environmental standards.

Looking forward, circular economy principles are being applied to tooling applications through coating technologies that enable easier remanufacturing and recycling. Developments in coating removal techniques and substrate recovery processes are making it more feasible to reclaim valuable materials from end-of-life tools, further reducing the environmental footprint of industrial tooling operations.

Many conventional coating materials contain toxic elements like chromium, cadmium, and lead, which present serious environmental and health risks throughout their lifecycle. The disposal of spent tools with these coatings can lead to soil and water contamination if not properly managed. Additionally, the precursor chemicals used in CVD processes often include volatile organic compounds (VOCs) and other environmentally harmful substances that contribute to air pollution and potential worker exposure.

Recent advancements have focused on developing more environmentally friendly alternatives. Water-based coating systems and powder coating technologies have emerged as lower-impact options, significantly reducing VOC emissions compared to solvent-based systems. The industry has also witnessed a shift toward using more benign materials such as titanium aluminum nitride (TiAlN) and diamond-like carbon (DLC) coatings, which offer excellent wear resistance without the environmental liabilities of traditional materials.

Energy efficiency improvements represent another critical area of progress. Modern thin film deposition equipment increasingly incorporates energy recovery systems, more efficient heating elements, and optimized process cycles that reduce overall energy consumption. Some manufacturers have reported energy savings of up to 30% through these technological improvements, directly translating to reduced carbon footprints.

Life cycle assessment (LCA) studies have become essential tools for evaluating the environmental impact of different coating technologies. These assessments consider the entire lifecycle from raw material extraction through manufacturing, use, and end-of-life disposal. Recent LCA data indicates that despite the energy-intensive nature of some advanced coating processes, the extended tool life they provide often results in net environmental benefits through reduced material consumption and waste generation.

Regulatory frameworks worldwide are increasingly influencing coating technology development. The European Union's REACH regulations, RoHS directive, and similar legislation in other regions have accelerated the transition away from hazardous substances in coating formulations. Companies investing in compliant technologies not only mitigate environmental risks but also gain competitive advantages in markets with stringent environmental standards.

Looking forward, circular economy principles are being applied to tooling applications through coating technologies that enable easier remanufacturing and recycling. Developments in coating removal techniques and substrate recovery processes are making it more feasible to reclaim valuable materials from end-of-life tools, further reducing the environmental footprint of industrial tooling operations.

Performance Testing and Quality Control Standards

Performance testing and quality control standards for wear-resistant coatings in tooling applications are critical for ensuring consistent product performance and reliability. The evaluation of thin film coatings requires comprehensive testing protocols that simulate real-world conditions while providing quantifiable metrics for quality assurance.

Standardized wear testing methodologies such as pin-on-disk, ball-on-disk, and scratch tests form the foundation of performance evaluation. These tests measure critical parameters including coefficient of friction, wear rate, and critical load for coating failure. The ASTM G99 standard for wear testing and ISO 20502 for scratch resistance testing have become industry benchmarks that enable consistent comparison across different coating solutions.

Adhesion testing represents another crucial aspect of quality control, typically conducted through methods like the Rockwell indentation test (VDI 3198) and tape test (ASTM D3359). These tests evaluate the coating's ability to remain bonded to the substrate under mechanical stress, which directly correlates with service life in high-wear applications.

Hardness measurement techniques including nanoindentation (ISO 14577) and microhardness testing provide essential data on coating resistance to plastic deformation. Modern quality control protocols often specify minimum hardness values based on application requirements, with HV values exceeding 2000 becoming standard for premium tooling applications.

Coating thickness uniformity, measured through techniques like calotest or SEM cross-sectional analysis, must adhere to tight tolerances—typically ±10% of the target thickness. This parameter significantly impacts both wear resistance and dimensional precision of the coated tool.

Surface roughness evaluation using profilometry or atomic force microscopy ensures that the coating maintains or improves the substrate's surface finish. For precision tooling applications, Ra values below 0.2 μm are often specified to minimize friction and wear during operation.

Chemical composition verification through techniques such as XPS, EDX, or SIMS analysis confirms the stoichiometry and purity of deposited films. This verification is particularly important for multi-component coatings like TiAlN or CrAlSiN, where slight compositional variations can significantly alter performance characteristics.

Accelerated environmental testing, including salt spray exposure (ASTM B117) and thermal cycling tests, evaluates coating durability under extreme conditions. These tests help predict long-term performance and identify potential failure modes before field deployment.

Industry certification systems like ISO 9001 and specific automotive or aerospace standards provide frameworks for implementing these testing protocols within comprehensive quality management systems, ensuring consistent production quality and traceability.

Standardized wear testing methodologies such as pin-on-disk, ball-on-disk, and scratch tests form the foundation of performance evaluation. These tests measure critical parameters including coefficient of friction, wear rate, and critical load for coating failure. The ASTM G99 standard for wear testing and ISO 20502 for scratch resistance testing have become industry benchmarks that enable consistent comparison across different coating solutions.

Adhesion testing represents another crucial aspect of quality control, typically conducted through methods like the Rockwell indentation test (VDI 3198) and tape test (ASTM D3359). These tests evaluate the coating's ability to remain bonded to the substrate under mechanical stress, which directly correlates with service life in high-wear applications.

Hardness measurement techniques including nanoindentation (ISO 14577) and microhardness testing provide essential data on coating resistance to plastic deformation. Modern quality control protocols often specify minimum hardness values based on application requirements, with HV values exceeding 2000 becoming standard for premium tooling applications.

Coating thickness uniformity, measured through techniques like calotest or SEM cross-sectional analysis, must adhere to tight tolerances—typically ±10% of the target thickness. This parameter significantly impacts both wear resistance and dimensional precision of the coated tool.

Surface roughness evaluation using profilometry or atomic force microscopy ensures that the coating maintains or improves the substrate's surface finish. For precision tooling applications, Ra values below 0.2 μm are often specified to minimize friction and wear during operation.

Chemical composition verification through techniques such as XPS, EDX, or SIMS analysis confirms the stoichiometry and purity of deposited films. This verification is particularly important for multi-component coatings like TiAlN or CrAlSiN, where slight compositional variations can significantly alter performance characteristics.

Accelerated environmental testing, including salt spray exposure (ASTM B117) and thermal cycling tests, evaluates coating durability under extreme conditions. These tests help predict long-term performance and identify potential failure modes before field deployment.

Industry certification systems like ISO 9001 and specific automotive or aerospace standards provide frameworks for implementing these testing protocols within comprehensive quality management systems, ensuring consistent production quality and traceability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!