ULED's Contribution to Sustainable Electronics Design

JUN 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ULED Technology Background and Objectives

Ultra-Low Energy Devices (ULEDs) represent a groundbreaking technological advancement in the field of sustainable electronics design. This innovative approach to electronic component development aims to drastically reduce energy consumption while maintaining or even enhancing device performance. The evolution of ULED technology can be traced back to the early 2000s when the need for more energy-efficient electronics became increasingly apparent due to growing environmental concerns and the proliferation of portable devices.

The primary objective of ULED technology is to minimize power consumption in electronic devices without compromising functionality. This goal aligns with the broader industry trend towards sustainability and energy conservation. By focusing on ultra-low energy consumption, ULED technology addresses several critical challenges facing the electronics industry, including battery life extension, heat dissipation reduction, and overall environmental impact mitigation.

ULED technology builds upon the principles of low-power electronics but takes energy efficiency to unprecedented levels. It incorporates advanced materials science, innovative circuit design techniques, and cutting-edge manufacturing processes to achieve remarkable reductions in power requirements. The development of ULED technology has been driven by a combination of academic research, industry initiatives, and government-sponsored programs aimed at promoting sustainable technology solutions.

One of the key technological trends in ULED development is the exploration of novel semiconductor materials and structures. Researchers are investigating materials with unique electronic properties that can operate at extremely low voltages, such as carbon nanotubes, graphene, and other two-dimensional materials. These materials offer the potential for creating electronic components that consume orders of magnitude less power than conventional silicon-based devices.

Another significant aspect of ULED technology is the integration of energy harvesting capabilities. By incorporating miniature energy harvesting systems, ULEDs can potentially operate autonomously, drawing power from ambient sources such as light, heat, or vibrations. This self-powering capability opens up new possibilities for long-term deployment of sensors and other electronic devices in remote or inaccessible locations.

The evolution of ULED technology is closely tied to advancements in nanotechnology and quantum physics. As our understanding of quantum-scale phenomena improves, new opportunities emerge for designing electronic components that operate at the limits of energy efficiency. Quantum tunneling transistors and single-electron devices are examples of technologies being explored in the context of ULED development.

Looking ahead, the objectives for ULED technology include achieving sub-picowatt power consumption for basic logic operations, developing self-powered sensor networks for Internet of Things (IoT) applications, and creating ultra-efficient display technologies. These ambitious goals reflect the transformative potential of ULED technology in reshaping the landscape of sustainable electronics design and contributing to a more energy-efficient future.

The primary objective of ULED technology is to minimize power consumption in electronic devices without compromising functionality. This goal aligns with the broader industry trend towards sustainability and energy conservation. By focusing on ultra-low energy consumption, ULED technology addresses several critical challenges facing the electronics industry, including battery life extension, heat dissipation reduction, and overall environmental impact mitigation.

ULED technology builds upon the principles of low-power electronics but takes energy efficiency to unprecedented levels. It incorporates advanced materials science, innovative circuit design techniques, and cutting-edge manufacturing processes to achieve remarkable reductions in power requirements. The development of ULED technology has been driven by a combination of academic research, industry initiatives, and government-sponsored programs aimed at promoting sustainable technology solutions.

One of the key technological trends in ULED development is the exploration of novel semiconductor materials and structures. Researchers are investigating materials with unique electronic properties that can operate at extremely low voltages, such as carbon nanotubes, graphene, and other two-dimensional materials. These materials offer the potential for creating electronic components that consume orders of magnitude less power than conventional silicon-based devices.

Another significant aspect of ULED technology is the integration of energy harvesting capabilities. By incorporating miniature energy harvesting systems, ULEDs can potentially operate autonomously, drawing power from ambient sources such as light, heat, or vibrations. This self-powering capability opens up new possibilities for long-term deployment of sensors and other electronic devices in remote or inaccessible locations.

The evolution of ULED technology is closely tied to advancements in nanotechnology and quantum physics. As our understanding of quantum-scale phenomena improves, new opportunities emerge for designing electronic components that operate at the limits of energy efficiency. Quantum tunneling transistors and single-electron devices are examples of technologies being explored in the context of ULED development.

Looking ahead, the objectives for ULED technology include achieving sub-picowatt power consumption for basic logic operations, developing self-powered sensor networks for Internet of Things (IoT) applications, and creating ultra-efficient display technologies. These ambitious goals reflect the transformative potential of ULED technology in reshaping the landscape of sustainable electronics design and contributing to a more energy-efficient future.

Market Demand for Sustainable Electronics

The market demand for sustainable electronics has been steadily growing in recent years, driven by increasing environmental awareness and regulatory pressures. Consumers are becoming more conscious of the environmental impact of their electronic devices, leading to a shift in purchasing behavior towards more sustainable options. This trend is particularly evident in developed markets such as North America and Europe, where consumers are willing to pay a premium for eco-friendly electronics.

The global sustainable electronics market is expected to experience significant growth in the coming years. Factors contributing to this growth include the rising adoption of renewable energy sources, the implementation of stringent environmental regulations, and the increasing focus on circular economy principles. Companies are responding to this demand by developing products with improved energy efficiency, longer lifespans, and enhanced recyclability.

One of the key drivers of market demand is the growing concern over electronic waste (e-waste). As the volume of e-waste continues to increase globally, there is a pressing need for electronics that are designed with end-of-life considerations in mind. This has led to a surge in demand for products that are easily repairable, upgradeable, and recyclable, aligning with the principles of sustainable design.

The corporate sector is also playing a significant role in driving demand for sustainable electronics. Many businesses are setting ambitious sustainability goals and are actively seeking ways to reduce their environmental footprint. This includes the procurement of energy-efficient and environmentally friendly electronic equipment for their operations, creating a substantial B2B market for sustainable electronics.

In the consumer electronics segment, there is a growing demand for products that not only offer advanced features but also demonstrate a commitment to sustainability. This includes smartphones, laptops, and home appliances that are manufactured using recycled materials, consume less energy, and have extended lifespans. Manufacturers are responding by incorporating sustainable design principles into their product development processes and highlighting these features in their marketing efforts.

The automotive industry is another significant driver of demand for sustainable electronics. With the rapid growth of electric vehicles and the increasing integration of advanced electronics in automobiles, there is a growing need for sustainable electronic components that can withstand the rigors of automotive use while minimizing environmental impact. This includes everything from battery management systems to in-vehicle infotainment systems.

As the market for sustainable electronics continues to expand, there is also an increasing demand for transparency and standardization in sustainability claims. Consumers and businesses alike are seeking clear, verifiable information about the environmental impact of electronic products throughout their lifecycle. This has led to the development of various sustainability certifications and standards, which are becoming important factors in purchasing decisions.

The global sustainable electronics market is expected to experience significant growth in the coming years. Factors contributing to this growth include the rising adoption of renewable energy sources, the implementation of stringent environmental regulations, and the increasing focus on circular economy principles. Companies are responding to this demand by developing products with improved energy efficiency, longer lifespans, and enhanced recyclability.

One of the key drivers of market demand is the growing concern over electronic waste (e-waste). As the volume of e-waste continues to increase globally, there is a pressing need for electronics that are designed with end-of-life considerations in mind. This has led to a surge in demand for products that are easily repairable, upgradeable, and recyclable, aligning with the principles of sustainable design.

The corporate sector is also playing a significant role in driving demand for sustainable electronics. Many businesses are setting ambitious sustainability goals and are actively seeking ways to reduce their environmental footprint. This includes the procurement of energy-efficient and environmentally friendly electronic equipment for their operations, creating a substantial B2B market for sustainable electronics.

In the consumer electronics segment, there is a growing demand for products that not only offer advanced features but also demonstrate a commitment to sustainability. This includes smartphones, laptops, and home appliances that are manufactured using recycled materials, consume less energy, and have extended lifespans. Manufacturers are responding by incorporating sustainable design principles into their product development processes and highlighting these features in their marketing efforts.

The automotive industry is another significant driver of demand for sustainable electronics. With the rapid growth of electric vehicles and the increasing integration of advanced electronics in automobiles, there is a growing need for sustainable electronic components that can withstand the rigors of automotive use while minimizing environmental impact. This includes everything from battery management systems to in-vehicle infotainment systems.

As the market for sustainable electronics continues to expand, there is also an increasing demand for transparency and standardization in sustainability claims. Consumers and businesses alike are seeking clear, verifiable information about the environmental impact of electronic products throughout their lifecycle. This has led to the development of various sustainability certifications and standards, which are becoming important factors in purchasing decisions.

ULED Technical Challenges and Limitations

Despite the promising potential of Ultra-Low Energy Devices (ULEDs) in sustainable electronics design, several technical challenges and limitations need to be addressed for widespread adoption and optimal performance.

One of the primary challenges is the trade-off between energy efficiency and device performance. While ULEDs aim to minimize power consumption, this often comes at the cost of reduced processing speed, memory capacity, or functionality. Striking the right balance between energy savings and maintaining adequate performance levels remains a significant hurdle for researchers and engineers.

Another critical limitation is the scalability of ULED technologies. Many ultra-low energy solutions that work well in small-scale laboratory settings face difficulties when scaled up for mass production. Issues such as manufacturing consistency, yield rates, and cost-effectiveness need to be resolved to make ULEDs commercially viable for large-scale implementation in consumer electronics.

The integration of ULEDs with existing electronic systems and infrastructures poses another set of challenges. Compatibility issues may arise when incorporating ultra-low energy components into conventional electronic designs, requiring significant modifications to system architectures and communication protocols. This integration complexity can slow down the adoption of ULED technologies in established product lines.

Material constraints also present limitations for ULED development. The quest for materials that can operate efficiently at ultra-low energy levels while maintaining durability and reliability is ongoing. Some promising materials may have limited availability or high production costs, hindering their widespread use in consumer electronics.

Power management and energy harvesting techniques for ULEDs face their own set of challenges. Efficiently capturing and utilizing ambient energy sources, such as light, heat, or vibrations, to power ULEDs requires sophisticated energy harvesting systems. These systems must be compact, cost-effective, and capable of providing stable power output under varying environmental conditions.

The reliability and longevity of ULEDs in real-world applications remain concerns. Ultra-low energy operation may impact the lifespan of electronic components, potentially leading to premature failure or degradation of performance over time. Ensuring long-term stability and reliability of ULEDs under various operating conditions is crucial for their adoption in critical applications.

Lastly, the development of standardized testing and benchmarking methodologies for ULEDs presents a challenge. Accurately measuring and comparing the energy efficiency and performance of different ULED technologies requires consistent and widely accepted evaluation methods. The lack of standardized metrics can hinder the assessment of ULED advancements and their potential impact on sustainable electronics design.

One of the primary challenges is the trade-off between energy efficiency and device performance. While ULEDs aim to minimize power consumption, this often comes at the cost of reduced processing speed, memory capacity, or functionality. Striking the right balance between energy savings and maintaining adequate performance levels remains a significant hurdle for researchers and engineers.

Another critical limitation is the scalability of ULED technologies. Many ultra-low energy solutions that work well in small-scale laboratory settings face difficulties when scaled up for mass production. Issues such as manufacturing consistency, yield rates, and cost-effectiveness need to be resolved to make ULEDs commercially viable for large-scale implementation in consumer electronics.

The integration of ULEDs with existing electronic systems and infrastructures poses another set of challenges. Compatibility issues may arise when incorporating ultra-low energy components into conventional electronic designs, requiring significant modifications to system architectures and communication protocols. This integration complexity can slow down the adoption of ULED technologies in established product lines.

Material constraints also present limitations for ULED development. The quest for materials that can operate efficiently at ultra-low energy levels while maintaining durability and reliability is ongoing. Some promising materials may have limited availability or high production costs, hindering their widespread use in consumer electronics.

Power management and energy harvesting techniques for ULEDs face their own set of challenges. Efficiently capturing and utilizing ambient energy sources, such as light, heat, or vibrations, to power ULEDs requires sophisticated energy harvesting systems. These systems must be compact, cost-effective, and capable of providing stable power output under varying environmental conditions.

The reliability and longevity of ULEDs in real-world applications remain concerns. Ultra-low energy operation may impact the lifespan of electronic components, potentially leading to premature failure or degradation of performance over time. Ensuring long-term stability and reliability of ULEDs under various operating conditions is crucial for their adoption in critical applications.

Lastly, the development of standardized testing and benchmarking methodologies for ULEDs presents a challenge. Accurately measuring and comparing the energy efficiency and performance of different ULED technologies requires consistent and widely accepted evaluation methods. The lack of standardized metrics can hinder the assessment of ULED advancements and their potential impact on sustainable electronics design.

Current ULED Sustainability Solutions

01 Energy efficiency and power management in ULED systems

ULED (Ultra Light Emitting Diode) systems are designed with advanced energy efficiency features and power management techniques. These systems optimize power consumption, reduce heat generation, and extend the lifespan of the LEDs. Implementations may include intelligent dimming, adaptive brightness control, and power-saving modes to minimize energy usage while maintaining performance.- Energy efficiency and power management in ULED systems: ULED (Ultra Light Emitting Diode) systems are designed with advanced energy efficiency features and power management techniques. These include optimized power consumption, intelligent dimming capabilities, and adaptive brightness control based on ambient conditions. Such features contribute to reduced energy usage and extended lifespan of ULED devices, enhancing their overall sustainability.

- Sustainable materials and manufacturing processes for ULED: The sustainability of ULED technology is improved through the use of eco-friendly materials and manufacturing processes. This includes the development of recyclable components, reduction of harmful substances, and implementation of energy-efficient production methods. These approaches minimize the environmental impact of ULED production and disposal.

- ULED integration with smart systems for sustainability: ULED technology is increasingly integrated with smart systems and IoT devices to enhance sustainability. This integration allows for automated control, remote management, and data-driven optimization of lighting systems. Such smart ULED systems can adapt to user behavior and environmental conditions, further reducing energy consumption and improving efficiency.

- Longevity and durability of ULED technology: ULED systems are designed for extended operational lifespans and improved durability. This is achieved through advanced thermal management, robust component design, and protective technologies that guard against environmental factors. The increased longevity of ULED products reduces the frequency of replacements, contributing to sustainability by minimizing waste and resource consumption.

- Circular economy approaches in ULED lifecycle: Sustainability in ULED technology is enhanced through circular economy principles. This includes designing products for easy disassembly and recycling, implementing take-back programs for end-of-life products, and exploring ways to repurpose or upcycle ULED components. These approaches aim to minimize waste and maximize resource efficiency throughout the ULED lifecycle.

02 Sustainable materials and manufacturing processes for ULED

The production of ULED devices incorporates sustainable materials and eco-friendly manufacturing processes. This includes the use of recyclable components, reduction of hazardous substances, and implementation of energy-efficient production techniques. The focus is on minimizing environmental impact throughout the product lifecycle, from raw material sourcing to end-of-life disposal.Expand Specific Solutions03 ULED integration with smart and sustainable building systems

ULED technology is being integrated into smart building systems to enhance overall sustainability. This includes incorporation with daylight harvesting systems, occupancy sensors, and building management systems. The integration allows for optimized lighting control, reduced energy consumption, and improved occupant comfort in sustainable building designs.Expand Specific Solutions04 Longevity and durability of ULED systems

ULED systems are designed for extended operational lifespans and increased durability. This is achieved through advanced thermal management, robust component selection, and protective designs. The long-lasting nature of ULED systems contributes to sustainability by reducing the frequency of replacements and associated waste generation.Expand Specific Solutions05 Recycling and circular economy approaches for ULED products

Sustainability initiatives for ULED products include the development of recycling programs and adoption of circular economy principles. This involves designing products for easy disassembly, using recyclable materials, and establishing take-back programs. The aim is to minimize waste, recover valuable materials, and reduce the environmental footprint of ULED technology throughout its lifecycle.Expand Specific Solutions

Key Players in ULED Industry

The ULED (Ultra-Light Emitting Diode) technology for sustainable electronics design is in its early growth stage, with a rapidly expanding market driven by increasing demand for energy-efficient and environmentally friendly display solutions. The global ULED market is projected to grow significantly in the coming years, fueled by advancements in materials science and manufacturing processes. Companies like Samsung Electronics, BOE Technology Group, and ams-Osram International GmbH are at the forefront of ULED development, investing heavily in R&D to improve efficiency, color accuracy, and longevity. While the technology is still evolving, recent breakthroughs by research institutions such as Industrial Technology Research Institute and Ghent University are accelerating its maturation, promising a more sustainable future for the electronics industry.

Lumileds LLC

Technical Solution: Lumileds has developed advanced ULED (Ultra-Light Emitting Diode) technology that significantly contributes to sustainable electronics design. Their ULED solutions incorporate high-efficiency phosphor materials and innovative chip designs to maximize light output while minimizing energy consumption. The company's ULEDs feature a unique micro-lens array structure that enhances light extraction and reduces internal reflections, resulting in improved overall efficiency. Additionally, Lumileds has implemented a proprietary thermal management system in their ULEDs, which extends the lifespan of the devices and reduces the need for frequent replacements.

Strengths: High energy efficiency, extended lifespan, and reduced material waste. Weaknesses: Potentially higher initial cost compared to traditional LEDs and limited color options in some ULED product lines.

Xiamen San'an Optoelectronics Co., Ltd.

Technical Solution: San'an Optoelectronics has developed a cutting-edge ULED technology that focuses on miniaturization and energy efficiency. Their ULED chips utilize advanced epitaxial growth techniques and novel substrate materials to achieve ultra-high luminous efficacy. The company has also implemented a proprietary quantum dot conversion layer in their ULEDs, which allows for precise color tuning and enhanced color gamut. San'an's ULEDs incorporate a unique heat dissipation structure that effectively manages thermal issues, leading to improved reliability and longevity. Furthermore, their manufacturing process emphasizes the reduction of harmful materials and the use of recyclable components, aligning with sustainable electronics design principles.

Strengths: High luminous efficacy, excellent color performance, and eco-friendly manufacturing process. Weaknesses: Relatively high production costs and potential supply chain constraints for some specialized materials.

Core Innovations in ULED Sustainability

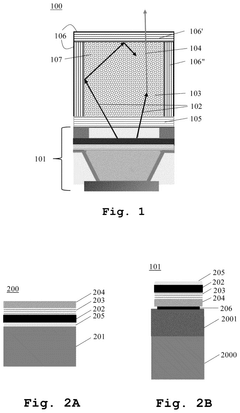

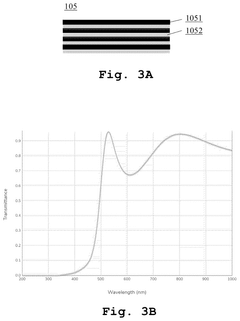

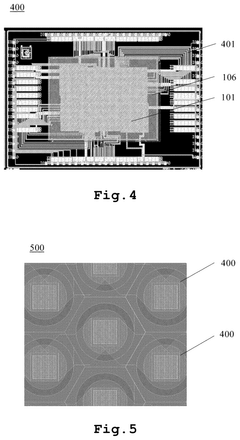

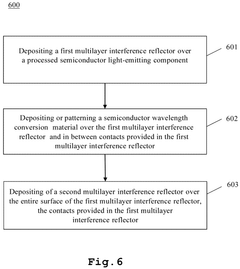

An optoelectronic device with color conversion and with conformal DBR and an associated fabrication method

PatentPendingUS20250151479A1

Innovation

- The proposed optoelectronic device incorporates a semiconductor light-emitting component with a cavity filled with wavelength conversion material, surrounded by multilayer interference reflectors that enhance light conversion and isolation, allowing for improved light emission efficiency and longer device lifetime.

ULED/OLED integrated light emitting body for display

PatentActiveCN108039359A

Innovation

- Using ULED and OLED combined light emitters, by forming an epitaxial barrier crystal film layer and pixel points on the substrate, using micro ULED and OLED to connect in parallel respectively, controlling the combination of micro inorganic light-emitting diodes and organic light-emitting diodes, and using gallium nitride materials to improve Light efficiency, and achieve efficient electrical connection through the electrical interface matrix layer and LED controller.

Environmental Impact Assessment of ULED

The environmental impact assessment of ULED (Ultra-Low Energy Display) technology reveals significant potential for sustainable electronics design. ULEDs offer substantial energy efficiency improvements compared to traditional display technologies, potentially reducing power consumption by up to 90%. This dramatic reduction in energy usage translates to lower greenhouse gas emissions throughout the product lifecycle, from manufacturing to end-user operation.

ULED technology also addresses the issue of electronic waste (e-waste) by extending the lifespan of display devices. The improved durability and longevity of ULED panels mean fewer replacements are needed over time, reducing the overall volume of discarded electronics. Additionally, the materials used in ULED production are often more environmentally friendly, with reduced reliance on rare earth elements and toxic substances commonly found in conventional displays.

The manufacturing process for ULEDs has been optimized to minimize resource consumption and waste generation. Advanced production techniques, such as roll-to-roll printing, allow for more efficient use of materials and energy during fabrication. This not only reduces the environmental footprint of the manufacturing phase but also contributes to lower production costs, making sustainable display technology more accessible to consumers.

Water usage in ULED production is significantly lower compared to traditional LCD manufacturing, addressing concerns about water scarcity and pollution. The reduction in water consumption not only conserves this vital resource but also minimizes the release of potentially harmful chemicals into local ecosystems.

The lightweight nature of ULED panels contributes to reduced transportation emissions when shipping finished products. This factor, combined with the technology's energy efficiency, results in a lower carbon footprint throughout the supply chain and distribution network.

End-of-life considerations for ULEDs are also promising from an environmental perspective. The simplified structure and reduced use of hazardous materials make ULED panels easier to recycle and less harmful when disposed of. Manufacturers are increasingly designing ULED products with modularity in mind, facilitating easier repair and component replacement, which further extends product lifespans and reduces waste.

As ULED technology continues to evolve, ongoing research focuses on further improving its environmental performance. This includes exploring bio-based materials for ULED substrates, enhancing energy harvesting capabilities to reduce reliance on external power sources, and developing advanced recycling techniques specific to ULED components.

ULED technology also addresses the issue of electronic waste (e-waste) by extending the lifespan of display devices. The improved durability and longevity of ULED panels mean fewer replacements are needed over time, reducing the overall volume of discarded electronics. Additionally, the materials used in ULED production are often more environmentally friendly, with reduced reliance on rare earth elements and toxic substances commonly found in conventional displays.

The manufacturing process for ULEDs has been optimized to minimize resource consumption and waste generation. Advanced production techniques, such as roll-to-roll printing, allow for more efficient use of materials and energy during fabrication. This not only reduces the environmental footprint of the manufacturing phase but also contributes to lower production costs, making sustainable display technology more accessible to consumers.

Water usage in ULED production is significantly lower compared to traditional LCD manufacturing, addressing concerns about water scarcity and pollution. The reduction in water consumption not only conserves this vital resource but also minimizes the release of potentially harmful chemicals into local ecosystems.

The lightweight nature of ULED panels contributes to reduced transportation emissions when shipping finished products. This factor, combined with the technology's energy efficiency, results in a lower carbon footprint throughout the supply chain and distribution network.

End-of-life considerations for ULEDs are also promising from an environmental perspective. The simplified structure and reduced use of hazardous materials make ULED panels easier to recycle and less harmful when disposed of. Manufacturers are increasingly designing ULED products with modularity in mind, facilitating easier repair and component replacement, which further extends product lifespans and reduces waste.

As ULED technology continues to evolve, ongoing research focuses on further improving its environmental performance. This includes exploring bio-based materials for ULED substrates, enhancing energy harvesting capabilities to reduce reliance on external power sources, and developing advanced recycling techniques specific to ULED components.

Regulatory Framework for Green Electronics

The regulatory framework for green electronics plays a crucial role in shaping the landscape of sustainable electronics design, including ULED (Ultra-Low Energy Devices) technology. This framework encompasses a wide range of policies, standards, and guidelines aimed at promoting environmentally friendly practices in the electronics industry.

At the international level, organizations such as the United Nations Environment Programme (UNEP) and the International Electrotechnical Commission (IEC) have established guidelines and standards for sustainable electronics. These include the Sustainable Development Goals (SDGs) and the IEC 62474 standard for material declaration in products of the electrotechnical industry.

In the European Union, the Restriction of Hazardous Substances (RoHS) Directive and the Waste Electrical and Electronic Equipment (WEEE) Directive form the cornerstone of green electronics regulations. These directives restrict the use of certain hazardous substances in electrical and electronic equipment and promote the collection and recycling of e-waste, respectively.

The United States has implemented similar regulations, such as the Electronic Product Environmental Assessment Tool (EPEAT) and the Energy Star program. These initiatives encourage the design and production of energy-efficient and environmentally friendly electronic devices.

In the context of ULED technology, these regulatory frameworks have a significant impact on design and manufacturing processes. Manufacturers must ensure compliance with energy efficiency standards, material restrictions, and end-of-life management requirements. This has led to innovations in low-power circuit design, the use of sustainable materials, and improved recyclability of ULED devices.

Furthermore, emerging regulations are focusing on the circular economy concept, promoting design for repairability, upgradability, and recyclability. This shift is driving ULED manufacturers to adopt modular designs and explore new business models that extend product lifespans and reduce electronic waste.

The regulatory landscape also influences research and development priorities in the ULED sector. Funding programs and incentives are increasingly aligned with sustainability goals, encouraging innovation in areas such as energy harvesting, biodegradable electronics, and advanced recycling technologies.

As the field of sustainable electronics continues to evolve, it is expected that regulatory frameworks will become more stringent and comprehensive. This will likely lead to further advancements in ULED technology, pushing the boundaries of energy efficiency and environmental sustainability in electronic devices.

At the international level, organizations such as the United Nations Environment Programme (UNEP) and the International Electrotechnical Commission (IEC) have established guidelines and standards for sustainable electronics. These include the Sustainable Development Goals (SDGs) and the IEC 62474 standard for material declaration in products of the electrotechnical industry.

In the European Union, the Restriction of Hazardous Substances (RoHS) Directive and the Waste Electrical and Electronic Equipment (WEEE) Directive form the cornerstone of green electronics regulations. These directives restrict the use of certain hazardous substances in electrical and electronic equipment and promote the collection and recycling of e-waste, respectively.

The United States has implemented similar regulations, such as the Electronic Product Environmental Assessment Tool (EPEAT) and the Energy Star program. These initiatives encourage the design and production of energy-efficient and environmentally friendly electronic devices.

In the context of ULED technology, these regulatory frameworks have a significant impact on design and manufacturing processes. Manufacturers must ensure compliance with energy efficiency standards, material restrictions, and end-of-life management requirements. This has led to innovations in low-power circuit design, the use of sustainable materials, and improved recyclability of ULED devices.

Furthermore, emerging regulations are focusing on the circular economy concept, promoting design for repairability, upgradability, and recyclability. This shift is driving ULED manufacturers to adopt modular designs and explore new business models that extend product lifespans and reduce electronic waste.

The regulatory landscape also influences research and development priorities in the ULED sector. Funding programs and incentives are increasingly aligned with sustainability goals, encouraging innovation in areas such as energy harvesting, biodegradable electronics, and advanced recycling technologies.

As the field of sustainable electronics continues to evolve, it is expected that regulatory frameworks will become more stringent and comprehensive. This will likely lead to further advancements in ULED technology, pushing the boundaries of energy efficiency and environmental sustainability in electronic devices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!