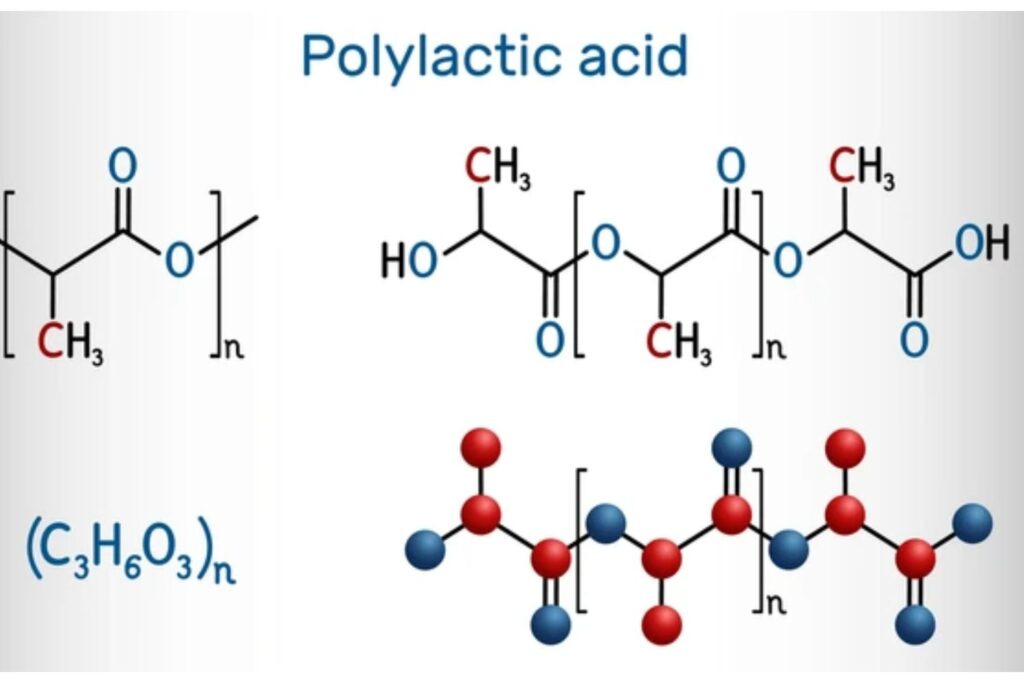

Polylactic Acid (PLA) is a biodegradable thermoplastic derived from renewable sources such as corn starch or sugarcane. With growing pressure to reduce petroleum-based plastic waste and carbon emissions, industries seek bio-based alternatives that deliver performance without compromising sustainability. PLA has rapidly emerged as a preferred material across packaging, 3D printing, textiles, and biomedical fields. This article unpacks PLA’s composition and key properties, maps its multi-industry applications, weighs its advantages and limitations, and highlights future innovation frontiers—backed by analysis from PatSnap Eureka AI Agent.

Material Composition & Key Properties

- PLA is typically synthesized from fermented plant sugars, forming lactic acid monomers that are polymerized into high-molecular-weight chains.

- Common synthesis techniques include ring-opening polymerization and direct condensation polymerization.

- Key properties include:

● High biodegradability under industrial composting

● Good mechanical strength and dimensional stability

● Ease of processing into films, fibers, and filaments

● Low toxicity, making it suitable for medical and food-contact applications

● Thermoplastic nature, enabling molding and 3D printing

Application Domains

3D Printing & Prototyping

Demand for user-friendly, low-warp materials in additive manufacturing has made PLA a top choice. It prints at low temperatures, offers high precision, and is widely available in filament form.

Research Frontlines: Enhancements focus on mechanical durability, heat resistance, and faster printing.

Related Reports:

- PLA in 3D Printing: Innovations and Future Trends

- PLA Filament for Eco-Friendly 3D Printing: Benefits and Drawbacks

- How to Minimize Warping in PLA 3D Printing Projects?

- How to Achieve High-Quality Finishes with PLA in 3D Printing?

- PLA Filament Innovations: Next‑Gen Materials for 3D Printing

- How to Enhance PLA Print Speed without Sacrificing Quality?

- How to Overcome Common Challenges with PLA 3D Printing?

Sustainable Packaging

Single-use plastics in packaging drive environmental concerns. PLA offers a biodegradable alternative that meets both regulatory and consumer sustainability expectations.

Research Frontlines: Focus on barrier properties, compostability, and blending with additives.

Related Reports:

- How to Maximize PLA’s Biodegradability in Packaging?

- Exploring PLA’s Potential in Food Packaging Solutions

- PLA for Home Use: Safe and Effective Applications

- PLA in Consumer Packaging: Market Trends and Projections

- How to Expand Commercial Use of PLA for Packaging?

- How to Leverage PLA’s Eco‑Friendly Messaging?

- PLA and Its Contribution to Low Carbon Footprint Products

Biomedical Applications

PLA’s biocompatibility and degradation profile make it ideal for temporary implants, drug delivery systems, and tissue scaffolds.

Research Frontlines: Focused on tuning molecular weight, blending for mechanical resilience, and sterilization compatibility.

Related Reports:

- Future of PLA in Medical Manufacturing: Biocompatibility and Uses

- Discovering PLA’s Full Potential in Biomedical Devices

- Advances in PLA‑Based Smart Materials

- How to Enhance Biodegradability Rate of PLA in Landfills?

- PLA in Educational Tools and Prototypes: A Growing Field

- The Science Behind PLA’s Biodegradability

- PLA for Electronics: Insulation and Eco-Friendly Solutions

Circular Economy & Recycling

As circular design becomes a policy and brand imperative, PLA’s compostability and recyclability provide material circularity.

Research Frontlines: Focus on enzymatic breakdown, chemical recycling, and reprocessing efficiency.

Related Reports:

- PLA’s Role in Circular Economy: Strategies and Solutions

- How to Recycle PLA Products Effectively: Techniques and Challenges?

- How to Effectively Process Post‑Consumer PLA Materials?

- Recycling Mechanisms for PLA: A Technical Overview

- How to Implement PLA Solutions in Waste Management?

- How to Conduct Efficient Recycling of PLA Materials?

- How to Optimize Resource Use in PLA Manufacturing?

Smart Composites & Advanced Materials

PLA is being hybridized with carbon fibers, nanoparticles, and functional additives to improve properties for high-performance applications.

Research Frontlines: Research targets improved flexibility, UV resistance, and integration into electronics and high-tech consumer goods.

Related Reports:

- PLA Blends for Improved Performance: A Comprehensive Guide

- Innovations in PLA Compounding for Enhanced Flexibility

- How to Improve PLA’s UV Resistance for Outdoor Applications?

- How to Strengthen PLA Composites for Industrial Uses?

- PLA Compatibility with Additives for Custom Properties

- Advances in PLA Chemical Structure for Enhanced Properties

- Cutting‑edge Research on PLA Polymer Enhancements

Comparative Advantages & Limitations

Advantages:

● Derived from renewable biomass, reducing fossil fuel dependence

● Biodegradable under industrial composting

● Safe for food and biomedical use

● Good printability and moldability for custom parts

● Lower greenhouse gas emissions during production

Limitations:

● Limited thermal resistance compared to PET or ABS

● Brittle unless modified with additives

● Degradation depends on controlled composting conditions

● Higher cost than conventional plastics in some markets

● Recycling infrastructure still under development globally

Future Outlook & Research Frontiers

In the next decade, PLA is expected to expand its role in:

- Biodegradable consumer electronics

- Flexible and printed electronics

- losed-loop packaging systems

- Next-gen medical devices and drug carriers

- Lightweight, high-strength composite structures

Eureka trends indicate accelerating investment in PLA modifications, especially for thermal resistance, recyclability, and smart functionality.

Conclusion & Strategic Takeaways

PLA offers a compelling blend of sustainability, versatility, and market readiness. Its bio-based origin, safe degradation profile, and broad adaptability position it as a cornerstone material in the green transition. With ongoing innovations in formulation and processing, PLA will continue to gain traction in packaging, healthcare, and high-performance manufacturing.

Accelerate Innovation with PatSnap Eureka AI Agent

The PLA innovation landscape is evolving fast—with scattered data, patent battles, and new entrants making it harder to keep up. PatSnap Eureka AI Agent helps you:

- Map global patent and technology trends in PLA

- Benchmark competitors and collaboration networks

- Discover material gaps and white space innovation zones

👉 Explore PLA’s emerging potential with Eureka-powered insights.