PLA Blends for Improved Performance: A Comprehensive Guide

JUN 25, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PLA Blends Background

Polylactic acid (PLA) has emerged as a promising biodegradable polymer in recent years, gaining significant attention due to its renewable sourcing and eco-friendly characteristics. However, despite its numerous advantages, PLA faces limitations in terms of mechanical properties and thermal stability, which restrict its widespread adoption in various applications.

To address these challenges, researchers and industry professionals have been exploring PLA blends as a viable solution to enhance the overall performance of PLA-based materials. PLA blends involve combining PLA with other polymers or additives to create composite materials that exhibit improved properties while maintaining biodegradability.

The development of PLA blends has been driven by the growing demand for sustainable materials across multiple sectors, including packaging, automotive, and consumer goods. By carefully selecting blend components and optimizing processing conditions, researchers aim to overcome the inherent limitations of pure PLA while preserving its environmentally friendly attributes.

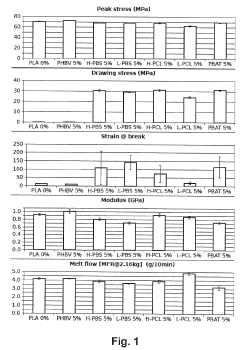

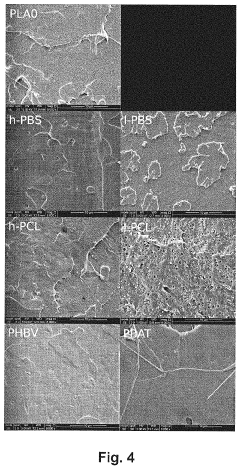

One of the primary objectives of PLA blending is to enhance mechanical properties such as tensile strength, impact resistance, and elongation at break. This is particularly crucial for applications that require durability and toughness. Additionally, improving the thermal stability of PLA is essential for expanding its use in high-temperature applications and extending its shelf life.

The history of PLA blends can be traced back to the early 2000s when researchers began experimenting with various polymer combinations to enhance PLA's performance. Since then, significant progress has been made in understanding the complex interactions between PLA and other materials, leading to the development of novel blend formulations and processing techniques.

Recent advancements in PLA blends have focused on incorporating natural fibers, nanoparticles, and other biodegradable polymers to create high-performance composites. These innovations have opened up new possibilities for PLA-based materials in industries such as 3D printing, biomedical engineering, and sustainable packaging.

As the field of PLA blends continues to evolve, researchers are exploring new avenues for improvement, including the development of compatibilizers to enhance blend miscibility, the use of reactive extrusion techniques for better property control, and the integration of smart materials for advanced functionalities.

To address these challenges, researchers and industry professionals have been exploring PLA blends as a viable solution to enhance the overall performance of PLA-based materials. PLA blends involve combining PLA with other polymers or additives to create composite materials that exhibit improved properties while maintaining biodegradability.

The development of PLA blends has been driven by the growing demand for sustainable materials across multiple sectors, including packaging, automotive, and consumer goods. By carefully selecting blend components and optimizing processing conditions, researchers aim to overcome the inherent limitations of pure PLA while preserving its environmentally friendly attributes.

One of the primary objectives of PLA blending is to enhance mechanical properties such as tensile strength, impact resistance, and elongation at break. This is particularly crucial for applications that require durability and toughness. Additionally, improving the thermal stability of PLA is essential for expanding its use in high-temperature applications and extending its shelf life.

The history of PLA blends can be traced back to the early 2000s when researchers began experimenting with various polymer combinations to enhance PLA's performance. Since then, significant progress has been made in understanding the complex interactions between PLA and other materials, leading to the development of novel blend formulations and processing techniques.

Recent advancements in PLA blends have focused on incorporating natural fibers, nanoparticles, and other biodegradable polymers to create high-performance composites. These innovations have opened up new possibilities for PLA-based materials in industries such as 3D printing, biomedical engineering, and sustainable packaging.

As the field of PLA blends continues to evolve, researchers are exploring new avenues for improvement, including the development of compatibilizers to enhance blend miscibility, the use of reactive extrusion techniques for better property control, and the integration of smart materials for advanced functionalities.

Market Analysis

The market for PLA blends has experienced significant growth in recent years, driven by increasing environmental concerns and the push for sustainable materials across various industries. The global PLA market size was valued at approximately $698 million in 2020 and is projected to reach $2.9 billion by 2028, growing at a CAGR of 19.5% from 2021 to 2028. This robust growth is primarily attributed to the rising demand for biodegradable plastics and the expanding applications of PLA blends in packaging, automotive, and consumer goods sectors.

The packaging industry remains the largest consumer of PLA blends, accounting for over 60% of the market share. This dominance is expected to continue due to the increasing adoption of eco-friendly packaging solutions by major food and beverage companies. The automotive sector is emerging as a promising market for PLA blends, with manufacturers exploring lightweight and sustainable materials to improve fuel efficiency and reduce carbon emissions.

Geographically, North America and Europe are the leading markets for PLA blends, collectively accounting for over 70% of the global market share. This is largely due to stringent environmental regulations and consumer awareness regarding sustainable products. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing disposable income, and growing environmental consciousness in countries like China and India.

The market for PLA blends is characterized by intense competition and continuous innovation. Key players in the industry are focusing on developing advanced PLA blends with enhanced properties to expand their application scope. For instance, blends of PLA with other biopolymers or synthetic polymers are being developed to improve mechanical strength, thermal stability, and barrier properties.

Despite the positive outlook, the PLA blends market faces challenges such as higher production costs compared to conventional plastics and limited waste management infrastructure for biodegradable materials. However, ongoing research and development efforts, coupled with supportive government policies promoting bio-based materials, are expected to address these challenges and drive market growth.

Consumer preferences are shifting towards sustainable and eco-friendly products, creating a favorable environment for PLA blends. This trend is particularly evident in the packaging and consumer goods sectors, where brands are increasingly adopting biodegradable materials to appeal to environmentally conscious consumers. The food packaging segment, in particular, is witnessing rapid adoption of PLA blends due to their biodegradability and food contact safety.

The packaging industry remains the largest consumer of PLA blends, accounting for over 60% of the market share. This dominance is expected to continue due to the increasing adoption of eco-friendly packaging solutions by major food and beverage companies. The automotive sector is emerging as a promising market for PLA blends, with manufacturers exploring lightweight and sustainable materials to improve fuel efficiency and reduce carbon emissions.

Geographically, North America and Europe are the leading markets for PLA blends, collectively accounting for over 70% of the global market share. This is largely due to stringent environmental regulations and consumer awareness regarding sustainable products. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing disposable income, and growing environmental consciousness in countries like China and India.

The market for PLA blends is characterized by intense competition and continuous innovation. Key players in the industry are focusing on developing advanced PLA blends with enhanced properties to expand their application scope. For instance, blends of PLA with other biopolymers or synthetic polymers are being developed to improve mechanical strength, thermal stability, and barrier properties.

Despite the positive outlook, the PLA blends market faces challenges such as higher production costs compared to conventional plastics and limited waste management infrastructure for biodegradable materials. However, ongoing research and development efforts, coupled with supportive government policies promoting bio-based materials, are expected to address these challenges and drive market growth.

Consumer preferences are shifting towards sustainable and eco-friendly products, creating a favorable environment for PLA blends. This trend is particularly evident in the packaging and consumer goods sectors, where brands are increasingly adopting biodegradable materials to appeal to environmentally conscious consumers. The food packaging segment, in particular, is witnessing rapid adoption of PLA blends due to their biodegradability and food contact safety.

Technical Challenges

Despite the numerous advantages of PLA as a biodegradable and renewable polymer, several technical challenges persist in its widespread adoption and application. One of the primary issues is the inherent brittleness of PLA, which limits its use in applications requiring high impact strength or flexibility. This characteristic makes PLA unsuitable for many durable goods and packaging applications without modification.

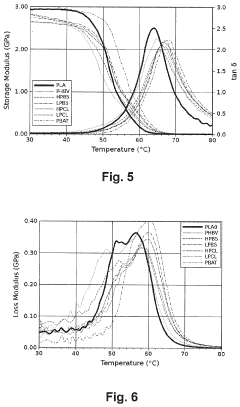

Another significant challenge is PLA's low heat deflection temperature, typically around 55-60°C for amorphous PLA. This thermal instability restricts its use in high-temperature applications and can lead to deformation during transportation or storage in warm environments. The low crystallization rate of PLA also contributes to its thermal instability and limits its processability in certain manufacturing techniques.

PLA's hydrolytic degradation presents a double-edged sword. While beneficial for biodegradability, it can lead to premature degradation during use, especially in high-humidity environments or applications involving contact with water. This susceptibility to hydrolysis can result in a loss of mechanical properties over time, limiting PLA's long-term durability.

The relatively high cost of PLA production compared to conventional petroleum-based plastics remains a significant barrier to its widespread adoption. The complex fermentation and polymerization processes required for PLA synthesis contribute to its higher price point, making it less competitive in price-sensitive markets.

PLA's limited gas barrier properties, particularly its high oxygen permeability, pose challenges in food packaging applications. This characteristic can lead to reduced shelf life for packaged products and necessitates additional barrier layers or treatments, increasing complexity and cost.

The narrow processing window of PLA during manufacturing presents difficulties in achieving consistent product quality. PLA's sensitivity to processing conditions, such as temperature and shear, can lead to thermal degradation or inconsistent material properties if not carefully controlled.

Lastly, the end-of-life management of PLA products faces challenges. While PLA is compostable under industrial conditions, it requires specific temperature and humidity levels not typically found in home composting systems or natural environments. This discrepancy between theoretical biodegradability and practical disposal options can lead to misconceptions and improper waste management.

Addressing these technical challenges is crucial for expanding PLA's application range and market penetration. Ongoing research and development efforts focus on overcoming these limitations through various strategies, including blending with other polymers, incorporating additives, and developing novel processing techniques.

Another significant challenge is PLA's low heat deflection temperature, typically around 55-60°C for amorphous PLA. This thermal instability restricts its use in high-temperature applications and can lead to deformation during transportation or storage in warm environments. The low crystallization rate of PLA also contributes to its thermal instability and limits its processability in certain manufacturing techniques.

PLA's hydrolytic degradation presents a double-edged sword. While beneficial for biodegradability, it can lead to premature degradation during use, especially in high-humidity environments or applications involving contact with water. This susceptibility to hydrolysis can result in a loss of mechanical properties over time, limiting PLA's long-term durability.

The relatively high cost of PLA production compared to conventional petroleum-based plastics remains a significant barrier to its widespread adoption. The complex fermentation and polymerization processes required for PLA synthesis contribute to its higher price point, making it less competitive in price-sensitive markets.

PLA's limited gas barrier properties, particularly its high oxygen permeability, pose challenges in food packaging applications. This characteristic can lead to reduced shelf life for packaged products and necessitates additional barrier layers or treatments, increasing complexity and cost.

The narrow processing window of PLA during manufacturing presents difficulties in achieving consistent product quality. PLA's sensitivity to processing conditions, such as temperature and shear, can lead to thermal degradation or inconsistent material properties if not carefully controlled.

Lastly, the end-of-life management of PLA products faces challenges. While PLA is compostable under industrial conditions, it requires specific temperature and humidity levels not typically found in home composting systems or natural environments. This discrepancy between theoretical biodegradability and practical disposal options can lead to misconceptions and improper waste management.

Addressing these technical challenges is crucial for expanding PLA's application range and market penetration. Ongoing research and development efforts focus on overcoming these limitations through various strategies, including blending with other polymers, incorporating additives, and developing novel processing techniques.

Current PLA Solutions

01 Improved mechanical properties of PLA blends

PLA blends can be formulated to enhance mechanical properties such as tensile strength, impact resistance, and flexibility. This is often achieved by blending PLA with other polymers or additives that complement its characteristics, resulting in a material with superior performance for various applications.- Improved mechanical properties of PLA blends: PLA blends can be formulated to enhance mechanical properties such as tensile strength, impact resistance, and flexibility. This is often achieved by blending PLA with other polymers or additives that complement its characteristics, resulting in a material with superior performance for various applications.

- Enhanced thermal stability of PLA composites: The thermal stability of PLA can be improved through the creation of blends or composites. This involves incorporating heat-resistant additives or other polymers that increase the material's resistance to degradation at higher temperatures, expanding its potential uses in various industries.

- Biodegradability and compostability of PLA blends: PLA blends can be designed to maintain or enhance biodegradability and compostability while improving other performance aspects. This is crucial for developing environmentally friendly materials that meet both performance requirements and end-of-life sustainability goals.

- Processing improvements for PLA blends: Techniques to enhance the processability of PLA blends, such as improved melt strength, reduced cycle times, and better flow properties, can be developed. These advancements allow for more efficient manufacturing processes and broader application possibilities for PLA-based materials.

- Functional properties of PLA blends: PLA blends can be formulated to exhibit specific functional properties such as improved barrier characteristics, antimicrobial activity, or flame retardancy. These enhancements expand the potential applications of PLA-based materials in packaging, medical, and consumer goods industries.

02 Thermal stability enhancement of PLA blends

The thermal stability of PLA blends can be improved through the incorporation of specific additives or by blending with thermally resistant polymers. This enhancement allows for better processing and wider temperature range applications, expanding the potential uses of PLA-based materials.Expand Specific Solutions03 Biodegradability and compostability of PLA blends

PLA blends can be designed to maintain or improve biodegradability and compostability while enhancing other performance aspects. This is crucial for environmentally friendly applications and end-of-life considerations, making PLA blends attractive for sustainable product development.Expand Specific Solutions04 Barrier properties of PLA blends

The barrier properties of PLA blends, such as gas and moisture permeability, can be enhanced through specific formulations. This improvement is particularly important for packaging applications, where protection against environmental factors is crucial for product preservation.Expand Specific Solutions05 Processing improvements for PLA blends

Various techniques and additives can be employed to improve the processing characteristics of PLA blends. These enhancements can include better melt strength, reduced cycle times, and improved compatibility between blend components, leading to more efficient manufacturing processes and higher quality end products.Expand Specific Solutions

Key Industry Players

The market for PLA blends is in a growth phase, driven by increasing demand for sustainable materials. The global market size for PLA and its blends is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, PLA blends are advancing, with companies like BASF Corp., LG Chem Ltd., and Arkema France SA leading innovation. Universities such as Sichuan University and South China University of Technology are contributing to research and development. The technology's maturity varies across applications, with some sectors seeing commercial adoption while others remain in developmental stages. Companies like Tepha, Inc. and Floreon Technology Ltd. are focusing on specialized applications, indicating a diversifying market landscape.

Arctic Biomaterials Oy

Technical Solution: Arctic Biomaterials has developed a unique approach to PLA blends by incorporating their proprietary mineral-based additive technology. Their ABM™ (Arctic Biomaterials) compounds combine PLA with mineral fibers to significantly improve mechanical properties, particularly heat resistance and impact strength. The company has also focused on developing PLA blends with enhanced biodegradability in various environments. Their technology allows for the creation of PLA-based materials suitable for more demanding applications, such as automotive parts and durable consumer goods.

Strengths: Significantly improved heat resistance and mechanical properties, unique mineral-based technology. Weaknesses: Potentially higher costs due to specialized additives, limited global market presence compared to larger corporations.

LG Chem Ltd.

Technical Solution: LG Chem has developed a series of PLA compounds and blends under their BIOMASS™ product line. Their approach involves blending PLA with various bio-based and petroleum-based polymers to enhance properties such as impact strength, heat resistance, and flexibility. LG Chem has also focused on developing PLA blends with improved processability for injection molding and extrusion applications. The company has invested in research to optimize crystallization behavior and melt strength of PLA blends for foaming and thermoforming processes.

Strengths: Improved thermal and mechanical properties, wide range of applications from packaging to automotive. Weaknesses: Complexity in formulation, potential for inconsistent biodegradation rates in blends.

Innovative PLA Blends

Biodegradable polymer blend

PatentPendingUS20210246303A1

Innovation

- A biodegradable polyester blend comprising predominantly PLA, poly-LD-lactide, poly-D-lactide, and other biodegradable polyesters, with a nucleating agent to enhance crystallization and impact strength, and a low molecular weight polyester for improved flow rates, eliminating the need for non-degradable additives and secondary processing steps.

Toughened polylactic acid polymers and copolymers

PatentInactiveUS20160355677A1

Innovation

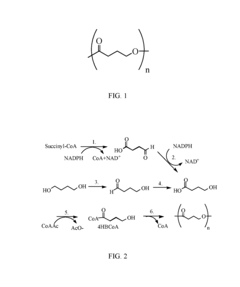

- Blending PLA and its copolymers with poly-4-hydroxybutyrate (P4HB) and its copolymers to create compositions with improved toughness and reduced stiffness, achieved through specific ratios and processing techniques such as twin screw extrusion and subsequent pelletization.

Environmental Impact

The environmental impact of PLA blends is a critical consideration in the development and application of these materials. PLA, or polylactic acid, is inherently biodegradable and derived from renewable resources, making it an attractive option for environmentally conscious applications. However, the blending of PLA with other materials to improve its performance characteristics can significantly alter its environmental profile.

When assessing the environmental impact of PLA blends, it is essential to consider the entire lifecycle of the material, from production to disposal. The production of PLA itself is generally considered to have a lower carbon footprint compared to traditional petroleum-based plastics. However, the energy requirements and emissions associated with the production of blending components must be taken into account.

The biodegradability of PLA blends can vary greatly depending on the nature and proportion of the blending materials. While pure PLA can biodegrade under specific conditions, the addition of non-biodegradable components may significantly reduce or eliminate this property. This alteration in biodegradability can have implications for waste management and end-of-life scenarios.

The recyclability of PLA blends is another crucial factor in their environmental impact. Some blends may be more challenging to recycle than pure PLA, potentially leading to increased waste if appropriate recycling infrastructure is not in place. On the other hand, certain blends may offer improved recyclability compared to traditional plastics, providing a potential environmental benefit.

The use phase of PLA blends can also contribute to their environmental impact. Improved performance characteristics, such as enhanced durability or heat resistance, may lead to longer product lifespans and reduced waste generation. However, these benefits must be weighed against any potential increase in environmental burden during production or end-of-life processing.

Water consumption and pollution are additional environmental concerns associated with PLA blend production and use. The cultivation of crops for PLA production, as well as the manufacturing processes for blending components, may have significant water requirements and potential for water pollution. Careful management of these aspects is necessary to minimize negative environmental impacts.

In conclusion, while PLA blends offer potential environmental benefits, their overall impact is complex and multifaceted. A comprehensive life cycle assessment is necessary to fully understand and optimize the environmental performance of these materials. As research and development in this field continue, there is potential for further improvements in the environmental profile of PLA blends, aligning with the growing demand for sustainable materials in various industries.

When assessing the environmental impact of PLA blends, it is essential to consider the entire lifecycle of the material, from production to disposal. The production of PLA itself is generally considered to have a lower carbon footprint compared to traditional petroleum-based plastics. However, the energy requirements and emissions associated with the production of blending components must be taken into account.

The biodegradability of PLA blends can vary greatly depending on the nature and proportion of the blending materials. While pure PLA can biodegrade under specific conditions, the addition of non-biodegradable components may significantly reduce or eliminate this property. This alteration in biodegradability can have implications for waste management and end-of-life scenarios.

The recyclability of PLA blends is another crucial factor in their environmental impact. Some blends may be more challenging to recycle than pure PLA, potentially leading to increased waste if appropriate recycling infrastructure is not in place. On the other hand, certain blends may offer improved recyclability compared to traditional plastics, providing a potential environmental benefit.

The use phase of PLA blends can also contribute to their environmental impact. Improved performance characteristics, such as enhanced durability or heat resistance, may lead to longer product lifespans and reduced waste generation. However, these benefits must be weighed against any potential increase in environmental burden during production or end-of-life processing.

Water consumption and pollution are additional environmental concerns associated with PLA blend production and use. The cultivation of crops for PLA production, as well as the manufacturing processes for blending components, may have significant water requirements and potential for water pollution. Careful management of these aspects is necessary to minimize negative environmental impacts.

In conclusion, while PLA blends offer potential environmental benefits, their overall impact is complex and multifaceted. A comprehensive life cycle assessment is necessary to fully understand and optimize the environmental performance of these materials. As research and development in this field continue, there is potential for further improvements in the environmental profile of PLA blends, aligning with the growing demand for sustainable materials in various industries.

Regulatory Framework

The regulatory framework surrounding PLA blends is a critical aspect for manufacturers and researchers to consider. Regulations vary across different regions and countries, with some areas having more stringent requirements than others. In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating PLA blends, especially when used in food contact applications or medical devices.

For food contact materials, PLA blends must comply with FDA regulations outlined in 21 CFR 177.1630, which specifies the conditions under which PLA can be safely used in contact with food. The European Union has its own set of regulations, including Regulation (EC) No 1935/2004 on materials and articles intended to come into contact with food. Manufacturers must ensure their PLA blends meet these standards to gain market access.

In the medical field, PLA blends used in implants or drug delivery systems are subject to rigorous regulatory scrutiny. The FDA classifies these as medical devices, requiring premarket approval or 510(k) clearance depending on the specific application. Similarly, in the EU, the Medical Device Regulation (MDR) governs the use of PLA blends in medical applications, emphasizing safety and performance.

Environmental regulations also impact PLA blends, particularly in terms of biodegradability claims. The Federal Trade Commission (FTC) in the US and similar bodies in other countries have guidelines on environmental marketing claims. Manufacturers must provide scientific evidence to support biodegradability assertions for their PLA blends.

Standardization bodies such as ASTM International and ISO have developed specific standards for testing and characterizing bioplastics, including PLA blends. These standards help ensure consistency in product quality and performance across the industry. For instance, ASTM D6400 sets the specifications for compostable plastics, which many PLA blends aim to meet.

As sustainability becomes increasingly important, new regulations are emerging. The EU's Single-Use Plastics Directive, for example, impacts the use of certain plastic products, potentially creating opportunities for PLA blends as alternatives. However, it also sets stringent requirements for biodegradability and compostability.

Compliance with these diverse regulatory frameworks requires ongoing vigilance and adaptation from manufacturers. As PLA blends continue to evolve and find new applications, it is crucial for companies to stay informed about regulatory changes and proactively engage with regulatory bodies to ensure their products meet all necessary requirements.

For food contact materials, PLA blends must comply with FDA regulations outlined in 21 CFR 177.1630, which specifies the conditions under which PLA can be safely used in contact with food. The European Union has its own set of regulations, including Regulation (EC) No 1935/2004 on materials and articles intended to come into contact with food. Manufacturers must ensure their PLA blends meet these standards to gain market access.

In the medical field, PLA blends used in implants or drug delivery systems are subject to rigorous regulatory scrutiny. The FDA classifies these as medical devices, requiring premarket approval or 510(k) clearance depending on the specific application. Similarly, in the EU, the Medical Device Regulation (MDR) governs the use of PLA blends in medical applications, emphasizing safety and performance.

Environmental regulations also impact PLA blends, particularly in terms of biodegradability claims. The Federal Trade Commission (FTC) in the US and similar bodies in other countries have guidelines on environmental marketing claims. Manufacturers must provide scientific evidence to support biodegradability assertions for their PLA blends.

Standardization bodies such as ASTM International and ISO have developed specific standards for testing and characterizing bioplastics, including PLA blends. These standards help ensure consistency in product quality and performance across the industry. For instance, ASTM D6400 sets the specifications for compostable plastics, which many PLA blends aim to meet.

As sustainability becomes increasingly important, new regulations are emerging. The EU's Single-Use Plastics Directive, for example, impacts the use of certain plastic products, potentially creating opportunities for PLA blends as alternatives. However, it also sets stringent requirements for biodegradability and compostability.

Compliance with these diverse regulatory frameworks requires ongoing vigilance and adaptation from manufacturers. As PLA blends continue to evolve and find new applications, it is crucial for companies to stay informed about regulatory changes and proactively engage with regulatory bodies to ensure their products meet all necessary requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!