How to Facilitate Knowledge Sharing in PLA Production?

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PLA Production Knowledge Sharing Background and Objectives

Polylactic acid (PLA) production has gained significant attention in recent years due to its biodegradable and renewable nature. As the demand for sustainable materials continues to grow, the PLA industry faces challenges in optimizing production processes and maintaining consistent quality. Knowledge sharing within PLA production has become a critical factor in addressing these challenges and driving innovation in the field.

The evolution of PLA production technology has been marked by continuous improvements in fermentation processes, polymer synthesis, and material properties. From its initial discovery in the 1930s to its commercial production in the 1990s, PLA has undergone substantial advancements. However, the complexity of PLA production, involving multiple stages from raw material selection to final product formulation, necessitates a comprehensive understanding of various technical aspects.

The primary objective of facilitating knowledge sharing in PLA production is to enhance overall efficiency, reduce production costs, and improve product quality. By promoting the exchange of information and best practices among researchers, engineers, and production personnel, organizations can accelerate problem-solving, minimize errors, and foster innovation. This collaborative approach is essential for addressing the technical challenges associated with PLA production, such as controlling molecular weight distribution, optimizing catalyst systems, and enhancing thermal stability.

Another crucial goal of knowledge sharing in PLA production is to standardize processes and quality control measures across different production facilities. As the PLA market expands globally, maintaining consistency in product specifications and performance becomes increasingly important. Effective knowledge sharing can help establish industry-wide standards, ensuring that PLA products meet the diverse requirements of various applications, from packaging to medical devices.

Furthermore, knowledge sharing plays a vital role in driving sustainable practices within the PLA industry. By disseminating information on eco-friendly production methods, energy-efficient processes, and waste reduction strategies, companies can collectively work towards minimizing the environmental impact of PLA production. This aligns with the broader sustainability goals that have fueled the growth of the bioplastics sector.

The technological landscape of PLA production is rapidly evolving, with emerging trends in areas such as nanotechnology, process intensification, and circular economy principles. Knowledge sharing is crucial for staying abreast of these developments and integrating cutting-edge technologies into existing production systems. By fostering a culture of open communication and collaboration, the PLA industry can leverage collective expertise to overcome technical barriers and push the boundaries of what is possible in sustainable polymer production.

The evolution of PLA production technology has been marked by continuous improvements in fermentation processes, polymer synthesis, and material properties. From its initial discovery in the 1930s to its commercial production in the 1990s, PLA has undergone substantial advancements. However, the complexity of PLA production, involving multiple stages from raw material selection to final product formulation, necessitates a comprehensive understanding of various technical aspects.

The primary objective of facilitating knowledge sharing in PLA production is to enhance overall efficiency, reduce production costs, and improve product quality. By promoting the exchange of information and best practices among researchers, engineers, and production personnel, organizations can accelerate problem-solving, minimize errors, and foster innovation. This collaborative approach is essential for addressing the technical challenges associated with PLA production, such as controlling molecular weight distribution, optimizing catalyst systems, and enhancing thermal stability.

Another crucial goal of knowledge sharing in PLA production is to standardize processes and quality control measures across different production facilities. As the PLA market expands globally, maintaining consistency in product specifications and performance becomes increasingly important. Effective knowledge sharing can help establish industry-wide standards, ensuring that PLA products meet the diverse requirements of various applications, from packaging to medical devices.

Furthermore, knowledge sharing plays a vital role in driving sustainable practices within the PLA industry. By disseminating information on eco-friendly production methods, energy-efficient processes, and waste reduction strategies, companies can collectively work towards minimizing the environmental impact of PLA production. This aligns with the broader sustainability goals that have fueled the growth of the bioplastics sector.

The technological landscape of PLA production is rapidly evolving, with emerging trends in areas such as nanotechnology, process intensification, and circular economy principles. Knowledge sharing is crucial for staying abreast of these developments and integrating cutting-edge technologies into existing production systems. By fostering a culture of open communication and collaboration, the PLA industry can leverage collective expertise to overcome technical barriers and push the boundaries of what is possible in sustainable polymer production.

Market Analysis for PLA Production Knowledge Management

The market for knowledge management systems in PLA (Polylactic Acid) production is experiencing significant growth, driven by the increasing complexity of manufacturing processes and the need for efficient information sharing. As the global demand for biodegradable plastics continues to rise, PLA producers are seeking innovative solutions to streamline their operations and maintain a competitive edge.

The PLA production industry faces unique challenges in knowledge management due to the specialized nature of the manufacturing process. These challenges include the need to capture and disseminate best practices, maintain consistent quality across production batches, and ensure compliance with evolving environmental regulations. As a result, there is a growing demand for tailored knowledge management solutions that can address these specific requirements.

Market research indicates that the global PLA market is expected to grow at a compound annual growth rate (CAGR) of over 15% in the coming years. This growth is primarily fueled by increasing environmental concerns and the shift towards sustainable packaging solutions across various industries. As production scales up to meet this demand, the need for effective knowledge sharing becomes even more critical.

Key market segments for PLA production knowledge management systems include large-scale manufacturers, research institutions, and small to medium-sized enterprises entering the biodegradable plastics market. Large manufacturers are particularly interested in enterprise-wide solutions that can integrate with existing production systems and provide real-time data analytics. Research institutions are seeking platforms that facilitate collaboration and the exchange of scientific findings, while smaller producers are looking for cost-effective solutions that can help them optimize their processes and compete with larger players.

The market for knowledge management in PLA production is also being shaped by technological advancements such as artificial intelligence, machine learning, and the Internet of Things (IoT). These technologies are enabling more sophisticated data analysis, predictive maintenance, and automated knowledge capture, creating new opportunities for software providers and consultancy firms specializing in this niche.

Geographically, the market for PLA production knowledge management is most developed in regions with established bioplastics industries, such as North America, Europe, and parts of Asia. However, emerging markets in South America and Southeast Asia are showing increasing interest as they expand their PLA production capabilities.

In terms of market dynamics, there is a trend towards integrated solutions that combine knowledge management with other aspects of production management, such as supply chain optimization and quality control. This integration is driving partnerships between software providers, equipment manufacturers, and PLA producers to create comprehensive platforms that address multiple aspects of the production process.

The PLA production industry faces unique challenges in knowledge management due to the specialized nature of the manufacturing process. These challenges include the need to capture and disseminate best practices, maintain consistent quality across production batches, and ensure compliance with evolving environmental regulations. As a result, there is a growing demand for tailored knowledge management solutions that can address these specific requirements.

Market research indicates that the global PLA market is expected to grow at a compound annual growth rate (CAGR) of over 15% in the coming years. This growth is primarily fueled by increasing environmental concerns and the shift towards sustainable packaging solutions across various industries. As production scales up to meet this demand, the need for effective knowledge sharing becomes even more critical.

Key market segments for PLA production knowledge management systems include large-scale manufacturers, research institutions, and small to medium-sized enterprises entering the biodegradable plastics market. Large manufacturers are particularly interested in enterprise-wide solutions that can integrate with existing production systems and provide real-time data analytics. Research institutions are seeking platforms that facilitate collaboration and the exchange of scientific findings, while smaller producers are looking for cost-effective solutions that can help them optimize their processes and compete with larger players.

The market for knowledge management in PLA production is also being shaped by technological advancements such as artificial intelligence, machine learning, and the Internet of Things (IoT). These technologies are enabling more sophisticated data analysis, predictive maintenance, and automated knowledge capture, creating new opportunities for software providers and consultancy firms specializing in this niche.

Geographically, the market for PLA production knowledge management is most developed in regions with established bioplastics industries, such as North America, Europe, and parts of Asia. However, emerging markets in South America and Southeast Asia are showing increasing interest as they expand their PLA production capabilities.

In terms of market dynamics, there is a trend towards integrated solutions that combine knowledge management with other aspects of production management, such as supply chain optimization and quality control. This integration is driving partnerships between software providers, equipment manufacturers, and PLA producers to create comprehensive platforms that address multiple aspects of the production process.

Current Challenges in PLA Production Knowledge Sharing

Knowledge sharing in PLA (Polylactic Acid) production faces several significant challenges that hinder the efficient dissemination of information and best practices across the industry. One of the primary obstacles is the proprietary nature of production processes and technologies. Many companies in the PLA sector guard their intellectual property closely, limiting the exchange of valuable insights and innovations.

The rapid pace of technological advancements in PLA production further complicates knowledge sharing efforts. As new production methods, catalysts, and processing techniques emerge, keeping all stakeholders informed and up-to-date becomes increasingly difficult. This knowledge gap can lead to inefficiencies and missed opportunities for improvement across the industry.

Another challenge lies in the diverse range of applications for PLA, from packaging to medical devices. This diversity results in a fragmented knowledge base, with expertise scattered across different sectors and specializations. Bridging these knowledge silos and facilitating cross-sector learning presents a significant hurdle.

The global nature of PLA production adds another layer of complexity to knowledge sharing. Language barriers, cultural differences, and varying regulatory environments across different regions can impede the smooth flow of information and best practices. This geographical dispersion of knowledge makes it challenging to establish a unified platform for information exchange.

Furthermore, the lack of standardized terminology and metrics in PLA production can lead to misunderstandings and miscommunications. Without a common language and agreed-upon benchmarks, comparing processes, results, and innovations becomes problematic, hindering effective knowledge transfer.

The competitive landscape of the PLA industry also poses a challenge to open knowledge sharing. Companies may be reluctant to share information that could potentially benefit their competitors, leading to a culture of secrecy that stifles innovation and industry-wide progress.

Lastly, the absence of a centralized, industry-wide platform for knowledge sharing in PLA production exacerbates these challenges. Without a dedicated forum or database for exchanging information, valuable insights often remain siloed within individual organizations or research institutions, limiting the potential for collaborative problem-solving and innovation.

Addressing these challenges requires a multifaceted approach that balances the need for intellectual property protection with the benefits of collaborative knowledge sharing. Developing strategies to overcome these obstacles will be crucial for advancing the PLA industry as a whole and accelerating the adoption of sustainable bioplastic solutions.

The rapid pace of technological advancements in PLA production further complicates knowledge sharing efforts. As new production methods, catalysts, and processing techniques emerge, keeping all stakeholders informed and up-to-date becomes increasingly difficult. This knowledge gap can lead to inefficiencies and missed opportunities for improvement across the industry.

Another challenge lies in the diverse range of applications for PLA, from packaging to medical devices. This diversity results in a fragmented knowledge base, with expertise scattered across different sectors and specializations. Bridging these knowledge silos and facilitating cross-sector learning presents a significant hurdle.

The global nature of PLA production adds another layer of complexity to knowledge sharing. Language barriers, cultural differences, and varying regulatory environments across different regions can impede the smooth flow of information and best practices. This geographical dispersion of knowledge makes it challenging to establish a unified platform for information exchange.

Furthermore, the lack of standardized terminology and metrics in PLA production can lead to misunderstandings and miscommunications. Without a common language and agreed-upon benchmarks, comparing processes, results, and innovations becomes problematic, hindering effective knowledge transfer.

The competitive landscape of the PLA industry also poses a challenge to open knowledge sharing. Companies may be reluctant to share information that could potentially benefit their competitors, leading to a culture of secrecy that stifles innovation and industry-wide progress.

Lastly, the absence of a centralized, industry-wide platform for knowledge sharing in PLA production exacerbates these challenges. Without a dedicated forum or database for exchanging information, valuable insights often remain siloed within individual organizations or research institutions, limiting the potential for collaborative problem-solving and innovation.

Addressing these challenges requires a multifaceted approach that balances the need for intellectual property protection with the benefits of collaborative knowledge sharing. Developing strategies to overcome these obstacles will be crucial for advancing the PLA industry as a whole and accelerating the adoption of sustainable bioplastic solutions.

Existing Knowledge Sharing Solutions in PLA Industry

01 Knowledge management systems for PLA production

Implementing knowledge management systems to capture, organize, and share information related to PLA production processes. These systems facilitate the exchange of best practices, troubleshooting techniques, and process improvements among team members, enhancing overall production efficiency and quality.- Knowledge management systems for PLA production: Implementing knowledge management systems to capture, organize, and share information related to PLA production processes. These systems facilitate the exchange of best practices, troubleshooting techniques, and process improvements among team members, leading to increased efficiency and innovation in PLA manufacturing.

- Collaborative platforms for PLA production expertise: Developing collaborative platforms that enable PLA production experts to share their knowledge, experiences, and insights. These platforms may include features such as discussion forums, wikis, and project spaces, fostering a community of practice and facilitating cross-functional learning in PLA manufacturing.

- Training and skill development programs for PLA production: Establishing comprehensive training and skill development programs focused on PLA production techniques. These programs may include e-learning modules, hands-on workshops, and mentorship opportunities to enhance the expertise of production staff and ensure consistent knowledge transfer across the organization.

- Data-driven knowledge sharing in PLA production: Leveraging data analytics and machine learning techniques to extract insights from PLA production processes and share them across the organization. This approach involves collecting and analyzing production data to identify patterns, optimize processes, and disseminate valuable knowledge to improve overall manufacturing efficiency.

- Cross-functional knowledge exchange for PLA innovation: Facilitating cross-functional knowledge exchange between different departments involved in PLA production, such as R&D, manufacturing, and quality control. This approach promotes innovation by combining diverse expertise and perspectives to address challenges and improve PLA production processes.

02 Collaborative platforms for PLA production expertise

Developing collaborative platforms that enable PLA production experts to share their knowledge, experiences, and insights. These platforms may include features such as discussion forums, wikis, and project spaces, fostering a culture of continuous learning and innovation in PLA manufacturing.Expand Specific Solutions03 Data-driven knowledge sharing in PLA production

Utilizing data analytics and machine learning techniques to extract valuable insights from PLA production data. This approach enables the identification of patterns, trends, and correlations that can be shared across the organization to optimize production processes and improve product quality.Expand Specific Solutions04 Training and skill development for PLA production

Implementing comprehensive training programs and skill development initiatives to enhance the knowledge and expertise of PLA production personnel. This may include e-learning modules, virtual reality simulations, and hands-on workshops to ensure effective knowledge transfer and skill acquisition.Expand Specific Solutions05 Cross-functional knowledge sharing in PLA production

Promoting cross-functional collaboration and knowledge sharing among different departments involved in PLA production, such as R&D, manufacturing, quality control, and supply chain. This approach ensures a holistic understanding of the production process and facilitates the development of innovative solutions to complex challenges.Expand Specific Solutions

Key Players in PLA Production and Knowledge Management

The knowledge sharing landscape in PLA production is evolving rapidly, with the industry in a growth phase characterized by increasing market size and technological advancements. Key players like LG Chem, Total Research Corp, and Stora Enso are driving innovation in this field. The technology's maturity is progressing, with companies such as COFCO Nutrition & Health Research Institute and HI-TECH Biobased Materials Engineering & Technology contributing to its development. Academic institutions like Nanjing Forestry University and Donghua University are also playing crucial roles in research and development. As the market expands, collaborations between industry leaders and research institutions are becoming increasingly important for facilitating effective knowledge sharing and advancing PLA production technologies.

International Business Machines Corp.

Technical Solution: IBM has developed a blockchain-based solution for facilitating knowledge sharing in PLA production. This system creates a secure, transparent, and immutable ledger of all production processes, research findings, and quality control data. It allows for real-time sharing of information across the supply chain, from raw material suppliers to end-product manufacturers. The platform incorporates smart contracts to automate data validation and sharing protocols, ensuring that only authorized parties can access sensitive information. Additionally, IBM's AI capabilities are integrated to analyze the shared data, providing insights for process optimization and quality improvement.

Strengths: Robust security, transparency, and traceability. Seamless integration with existing ERP systems. AI-powered analytics for continuous improvement. Weaknesses: High initial implementation cost. Requires buy-in from all stakeholders in the supply chain.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has implemented an IoT-driven knowledge sharing platform for PLA production. This system utilizes a network of smart sensors and devices throughout the production line to collect real-time data on various parameters such as temperature, pressure, and material flow. The collected data is then processed using edge computing technology, allowing for immediate analysis and decision-making at the production site. The platform also incorporates augmented reality (AR) interfaces, enabling workers to access relevant information and expert knowledge in real-time while performing their tasks. Machine learning algorithms are employed to identify patterns and anomalies in the production process, facilitating predictive maintenance and quality control.

Strengths: Real-time data collection and analysis. Enhanced worker efficiency through AR interfaces. Predictive maintenance capabilities. Weaknesses: Potential cybersecurity risks due to increased connectivity. High hardware and infrastructure requirements.

Innovative Approaches to PLA Production Knowledge Transfer

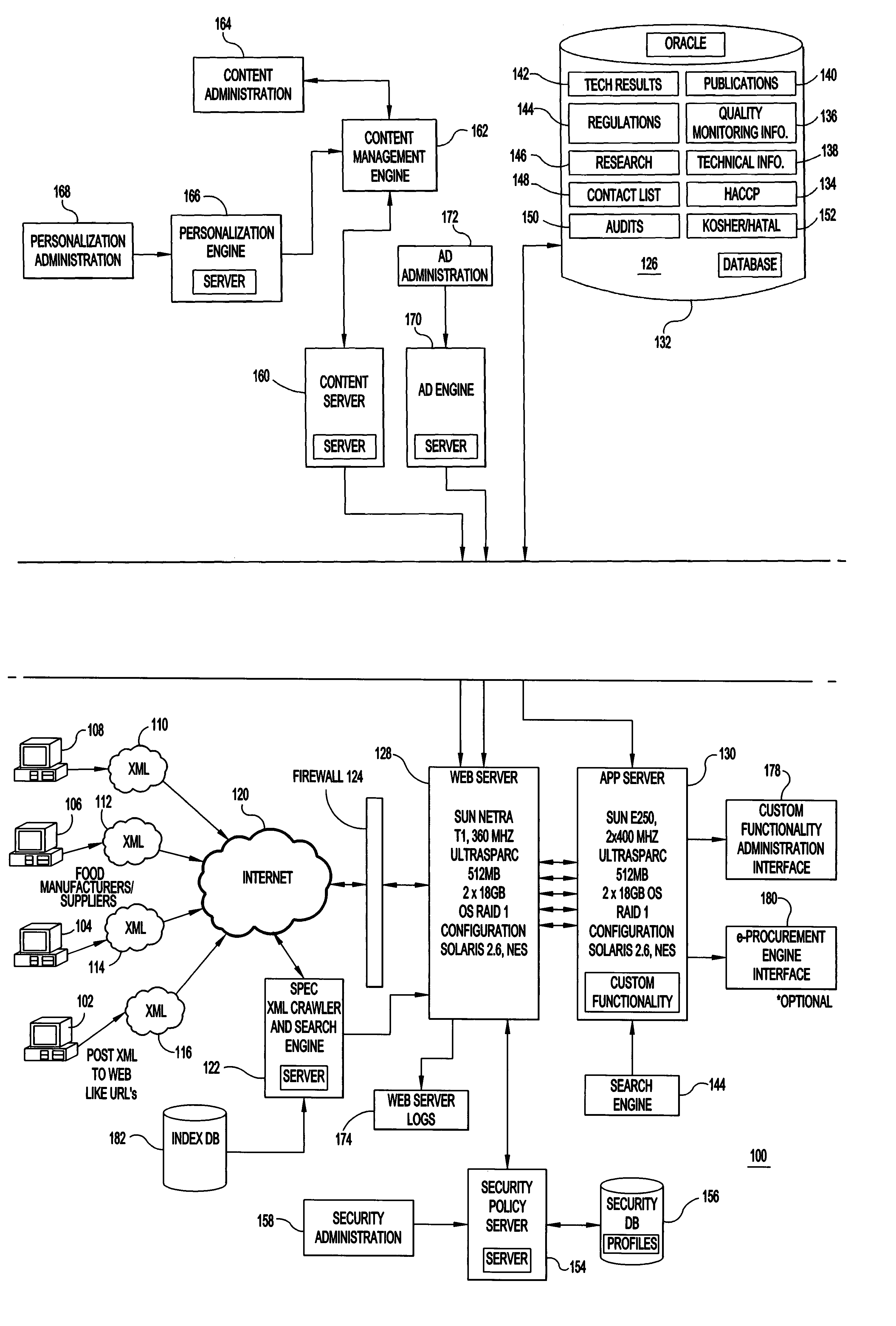

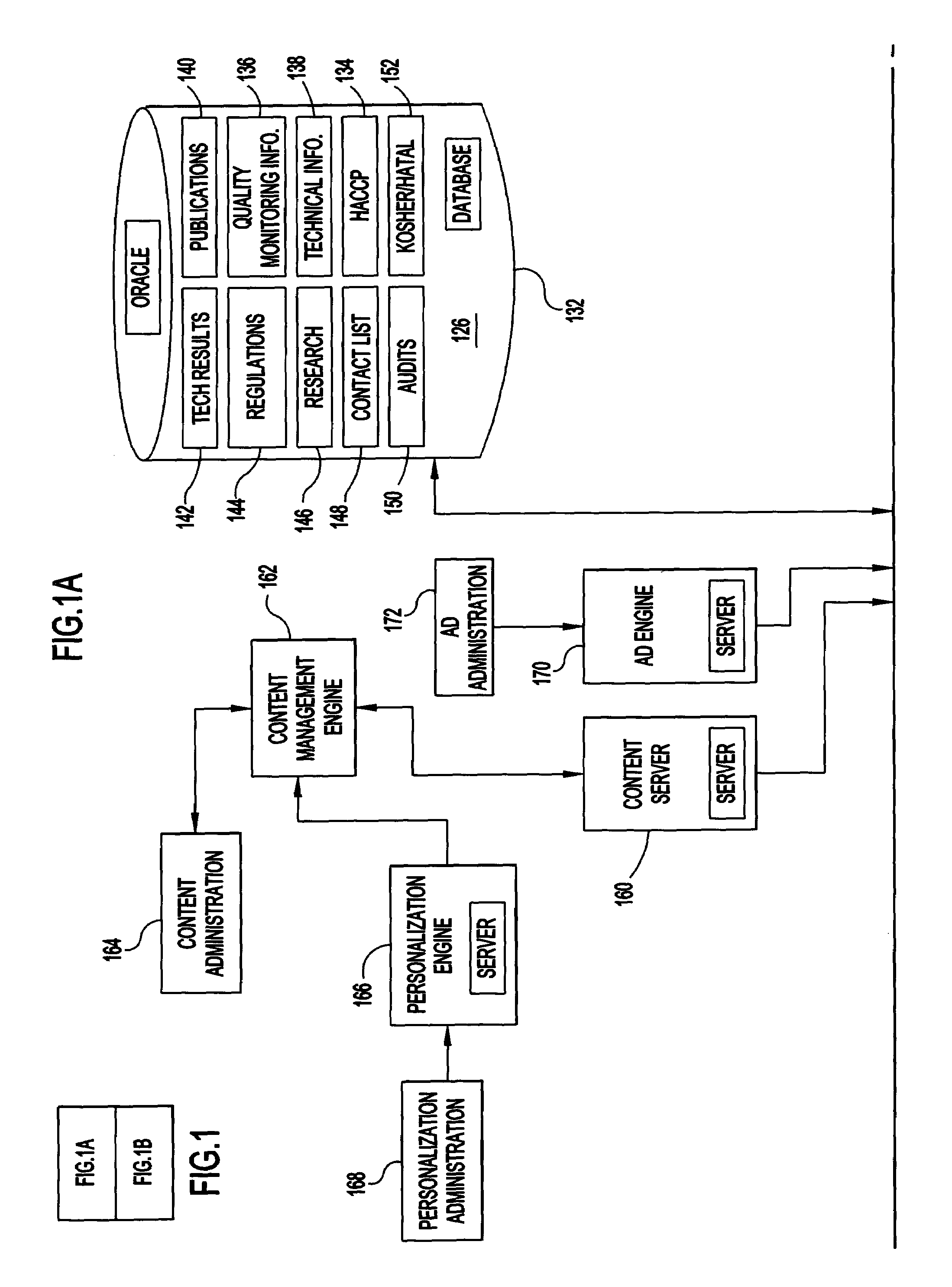

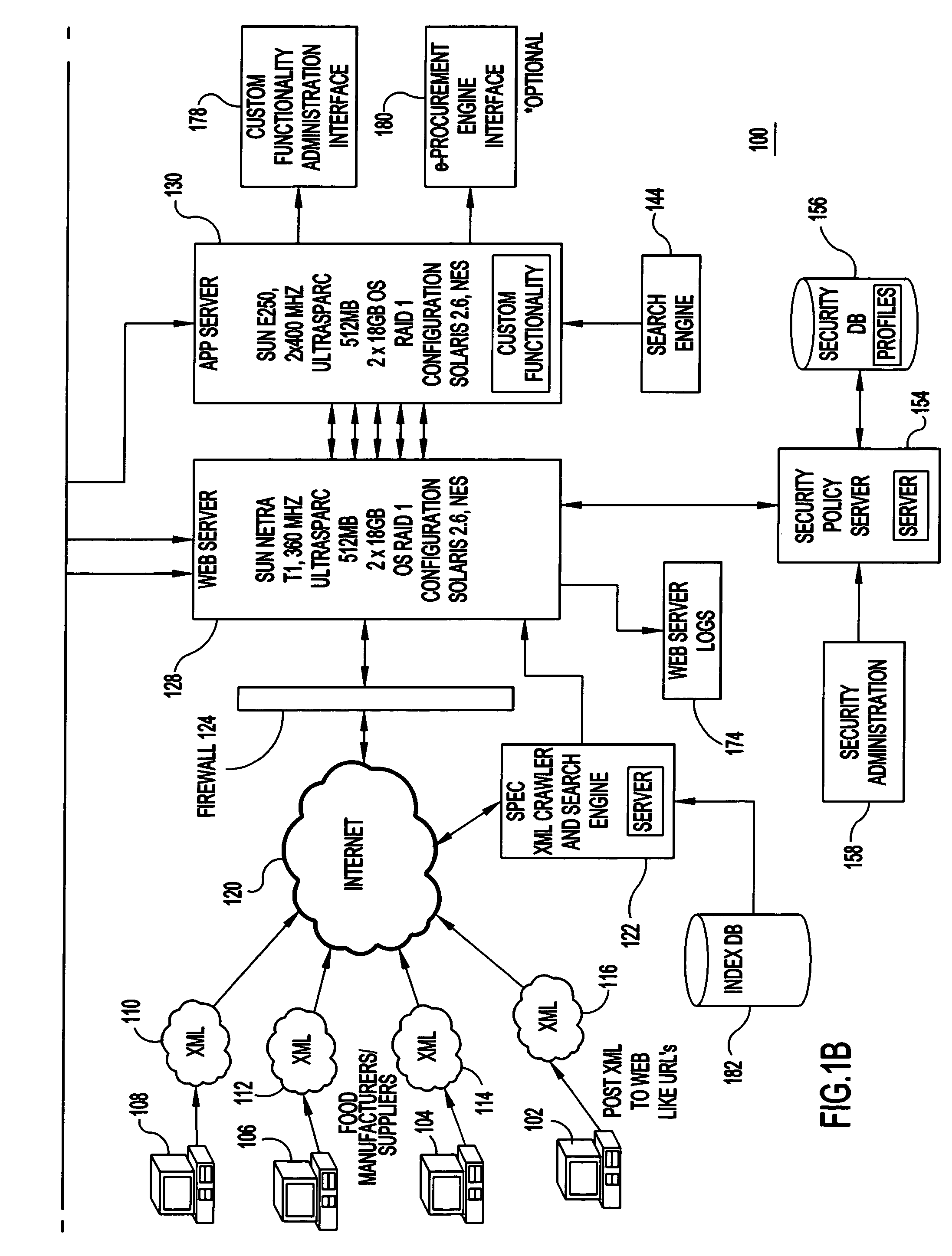

System, method and program product for sharing information

PatentInactiveUS7024391B2

Innovation

- A member-accessible information system that allows suppliers, manufacturers, and customers to share and manage product information in a standardized format through a networked platform, utilizing a central database for storage, security policies for access control, and personalization for user experience, enabling collaborative problem-solving and reducing audit costs.

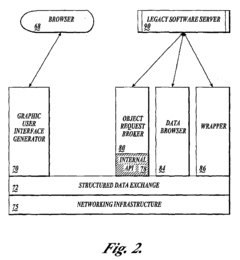

Browser-based information sharing within a manufacturing facility

PatentInactiveEP1304615A3

Innovation

- A high-level meta-layer software system with a graphic user interface and structured data exchange, using software wrappers and a browser interface to integrate communications across multiple software servers, allowing for bi-directional access to manufacturing data and automating processes like tool management and task tracking.

Regulatory Considerations for PLA Production Information

In the context of facilitating knowledge sharing in PLA (Polylactic Acid) production, regulatory considerations play a crucial role in shaping the industry's information exchange practices. The production of PLA, a biodegradable polymer derived from renewable resources, is subject to various regulations that impact the sharing of production-related information.

One of the primary regulatory considerations is the protection of intellectual property rights. Companies involved in PLA production often possess proprietary technologies and processes that give them a competitive edge. Regulatory frameworks, such as patent laws and trade secret protections, govern how this information can be shared or protected. These regulations may limit the extent of knowledge sharing between different entities in the PLA production chain.

Environmental regulations also significantly influence information sharing in PLA production. As a biodegradable material, PLA is subject to stringent environmental standards. Producers must comply with regulations regarding emissions, waste management, and the overall environmental impact of their production processes. This necessitates the sharing of environmental performance data and best practices among industry players to ensure compliance and promote sustainable production methods.

Safety regulations form another critical aspect of regulatory considerations in PLA production. These regulations often mandate the sharing of safety-related information, such as material safety data sheets (MSDS) and handling protocols. Producers must ensure that all parties involved in the PLA supply chain have access to this crucial safety information to maintain compliance and protect worker health.

Data privacy regulations also impact knowledge sharing in PLA production. With the increasing digitization of manufacturing processes, producers must navigate complex data protection laws when sharing production data or collaborating on research and development initiatives. This includes considerations for cross-border data transfers and the protection of sensitive business information.

Standardization and quality control regulations play a vital role in facilitating knowledge sharing. Industry standards for PLA production, such as those set by organizations like ASTM International or ISO, provide a common language and set of benchmarks for producers. These standards often require the sharing of certain production parameters and quality control data, fostering a more transparent and collaborative industry environment.

Regulatory bodies also influence knowledge sharing through reporting requirements. Producers may be obligated to report certain production data, environmental metrics, or safety incidents to regulatory agencies. While this information is primarily for compliance purposes, it can also contribute to industry-wide knowledge sharing and improvement initiatives.

One of the primary regulatory considerations is the protection of intellectual property rights. Companies involved in PLA production often possess proprietary technologies and processes that give them a competitive edge. Regulatory frameworks, such as patent laws and trade secret protections, govern how this information can be shared or protected. These regulations may limit the extent of knowledge sharing between different entities in the PLA production chain.

Environmental regulations also significantly influence information sharing in PLA production. As a biodegradable material, PLA is subject to stringent environmental standards. Producers must comply with regulations regarding emissions, waste management, and the overall environmental impact of their production processes. This necessitates the sharing of environmental performance data and best practices among industry players to ensure compliance and promote sustainable production methods.

Safety regulations form another critical aspect of regulatory considerations in PLA production. These regulations often mandate the sharing of safety-related information, such as material safety data sheets (MSDS) and handling protocols. Producers must ensure that all parties involved in the PLA supply chain have access to this crucial safety information to maintain compliance and protect worker health.

Data privacy regulations also impact knowledge sharing in PLA production. With the increasing digitization of manufacturing processes, producers must navigate complex data protection laws when sharing production data or collaborating on research and development initiatives. This includes considerations for cross-border data transfers and the protection of sensitive business information.

Standardization and quality control regulations play a vital role in facilitating knowledge sharing. Industry standards for PLA production, such as those set by organizations like ASTM International or ISO, provide a common language and set of benchmarks for producers. These standards often require the sharing of certain production parameters and quality control data, fostering a more transparent and collaborative industry environment.

Regulatory bodies also influence knowledge sharing through reporting requirements. Producers may be obligated to report certain production data, environmental metrics, or safety incidents to regulatory agencies. While this information is primarily for compliance purposes, it can also contribute to industry-wide knowledge sharing and improvement initiatives.

Environmental Impact of Improved PLA Production Knowledge

Improved knowledge sharing in PLA (Polylactic Acid) production can have significant environmental impacts, primarily through enhanced efficiency and reduced waste in the manufacturing process. By facilitating better communication and information exchange among researchers, engineers, and production staff, companies can optimize their PLA production methods, leading to a reduction in energy consumption and raw material usage.

One of the key environmental benefits of improved knowledge sharing is the potential for developing more sustainable production techniques. As information about innovative processes and technologies is disseminated more effectively, manufacturers can implement cleaner production methods that minimize the use of harmful chemicals and reduce emissions. This can lead to a decrease in the overall carbon footprint of PLA production, aligning with global efforts to combat climate change.

Furthermore, enhanced knowledge sharing can accelerate the development of PLA grades with improved biodegradability and compostability characteristics. By pooling research findings and practical experiences, scientists and engineers can work towards creating PLA formulations that break down more efficiently in various environmental conditions. This advancement could significantly reduce the long-term environmental impact of PLA products, addressing concerns about plastic pollution in ecosystems.

Improved knowledge sharing also has the potential to optimize the sourcing and utilization of renewable feedstocks for PLA production. By exchanging information on sustainable farming practices and efficient biomass conversion techniques, the industry can reduce the environmental impact associated with raw material procurement. This could lead to decreased land use, water consumption, and the use of agricultural inputs, thereby minimizing the ecological footprint of PLA production from cradle to grave.

Additionally, better knowledge sharing can foster the development of more efficient recycling and end-of-life management strategies for PLA products. As information about the most effective recycling methods and technologies becomes more widely available, waste management facilities can implement more sustainable practices. This could result in higher recycling rates for PLA materials, reducing the amount of plastic waste that ends up in landfills or the environment.

Lastly, improved knowledge sharing in PLA production can contribute to the development of more environmentally friendly additives and processing aids. By collaborating on research and sharing findings, chemists and material scientists can create bio-based alternatives to traditional petroleum-derived additives, further enhancing the overall sustainability of PLA products. This shift towards greener additives can reduce the release of potentially harmful substances into the environment during the product's lifecycle.

One of the key environmental benefits of improved knowledge sharing is the potential for developing more sustainable production techniques. As information about innovative processes and technologies is disseminated more effectively, manufacturers can implement cleaner production methods that minimize the use of harmful chemicals and reduce emissions. This can lead to a decrease in the overall carbon footprint of PLA production, aligning with global efforts to combat climate change.

Furthermore, enhanced knowledge sharing can accelerate the development of PLA grades with improved biodegradability and compostability characteristics. By pooling research findings and practical experiences, scientists and engineers can work towards creating PLA formulations that break down more efficiently in various environmental conditions. This advancement could significantly reduce the long-term environmental impact of PLA products, addressing concerns about plastic pollution in ecosystems.

Improved knowledge sharing also has the potential to optimize the sourcing and utilization of renewable feedstocks for PLA production. By exchanging information on sustainable farming practices and efficient biomass conversion techniques, the industry can reduce the environmental impact associated with raw material procurement. This could lead to decreased land use, water consumption, and the use of agricultural inputs, thereby minimizing the ecological footprint of PLA production from cradle to grave.

Additionally, better knowledge sharing can foster the development of more efficient recycling and end-of-life management strategies for PLA products. As information about the most effective recycling methods and technologies becomes more widely available, waste management facilities can implement more sustainable practices. This could result in higher recycling rates for PLA materials, reducing the amount of plastic waste that ends up in landfills or the environment.

Lastly, improved knowledge sharing in PLA production can contribute to the development of more environmentally friendly additives and processing aids. By collaborating on research and sharing findings, chemists and material scientists can create bio-based alternatives to traditional petroleum-derived additives, further enhancing the overall sustainability of PLA products. This shift towards greener additives can reduce the release of potentially harmful substances into the environment during the product's lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!