How to Enhance PLA's Mechanical Properties for Better Durability?

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PLA Enhancement Goals

Polylactic acid (PLA) has gained significant attention in various industries due to its biodegradability and renewable sourcing. However, its mechanical properties often fall short of requirements for durable applications. The primary goal of enhancing PLA's mechanical properties is to expand its potential uses and increase its competitiveness against traditional petroleum-based plastics.

One key objective is to improve PLA's tensile strength and modulus. Current PLA formulations typically exhibit tensile strengths ranging from 50 to 70 MPa, which is insufficient for many high-stress applications. Researchers aim to increase this to at least 100 MPa while maintaining or improving elongation at break. This would enable PLA to compete with engineering plastics like ABS or nylon in automotive and consumer electronics sectors.

Another critical goal is enhancing PLA's impact resistance. The inherent brittleness of PLA limits its use in applications requiring toughness. Improving impact strength to levels comparable with polypropylene (notched Izod impact strength of 50-100 J/m) would significantly broaden PLA's applicability in packaging and consumer goods.

Thermal stability is another area targeted for improvement. PLA's low heat deflection temperature (around 55°C) restricts its use in high-temperature environments. Researchers are working to increase this to at least 100°C, which would open up new possibilities in automotive interiors, appliances, and hot-fill packaging applications.

Long-term durability under various environmental conditions is also a key focus. Enhancing PLA's resistance to hydrolysis and UV degradation would extend its service life in outdoor applications. The goal is to achieve a lifespan of 5-10 years in exterior uses without significant property loss, comparable to conventional plastics.

Dimensional stability is another property slated for improvement. PLA's tendency to warp and shrink during processing can lead to inconsistencies in final products. Reducing these effects would improve manufacturing efficiency and product quality, particularly in 3D printing and injection molding applications.

Lastly, researchers aim to enhance PLA's barrier properties, particularly its oxygen and moisture vapor transmission rates. Improving these characteristics would expand PLA's use in food packaging and medical applications, where maintaining product freshness and sterility is crucial.

These enhancement goals are driven by the need to position PLA as a viable, sustainable alternative to petroleum-based plastics across a broader range of applications. Success in these areas would not only improve PLA's performance but also contribute to reducing plastic waste and dependence on fossil resources.

One key objective is to improve PLA's tensile strength and modulus. Current PLA formulations typically exhibit tensile strengths ranging from 50 to 70 MPa, which is insufficient for many high-stress applications. Researchers aim to increase this to at least 100 MPa while maintaining or improving elongation at break. This would enable PLA to compete with engineering plastics like ABS or nylon in automotive and consumer electronics sectors.

Another critical goal is enhancing PLA's impact resistance. The inherent brittleness of PLA limits its use in applications requiring toughness. Improving impact strength to levels comparable with polypropylene (notched Izod impact strength of 50-100 J/m) would significantly broaden PLA's applicability in packaging and consumer goods.

Thermal stability is another area targeted for improvement. PLA's low heat deflection temperature (around 55°C) restricts its use in high-temperature environments. Researchers are working to increase this to at least 100°C, which would open up new possibilities in automotive interiors, appliances, and hot-fill packaging applications.

Long-term durability under various environmental conditions is also a key focus. Enhancing PLA's resistance to hydrolysis and UV degradation would extend its service life in outdoor applications. The goal is to achieve a lifespan of 5-10 years in exterior uses without significant property loss, comparable to conventional plastics.

Dimensional stability is another property slated for improvement. PLA's tendency to warp and shrink during processing can lead to inconsistencies in final products. Reducing these effects would improve manufacturing efficiency and product quality, particularly in 3D printing and injection molding applications.

Lastly, researchers aim to enhance PLA's barrier properties, particularly its oxygen and moisture vapor transmission rates. Improving these characteristics would expand PLA's use in food packaging and medical applications, where maintaining product freshness and sterility is crucial.

These enhancement goals are driven by the need to position PLA as a viable, sustainable alternative to petroleum-based plastics across a broader range of applications. Success in these areas would not only improve PLA's performance but also contribute to reducing plastic waste and dependence on fossil resources.

Market Demand Analysis

The market demand for enhanced PLA (Polylactic Acid) with improved mechanical properties and durability has been steadily growing across various industries. This surge in demand is primarily driven by the increasing focus on sustainable and biodegradable materials in response to environmental concerns and regulatory pressures.

In the packaging industry, there is a significant push towards replacing conventional plastics with biodegradable alternatives. Enhanced PLA, with its improved durability, presents a viable solution for food packaging, disposable cutlery, and beverage containers. The global bioplastics market, of which PLA is a key component, is expected to experience substantial growth in the coming years.

The automotive sector is another major driver for enhanced PLA demand. As automakers strive to reduce vehicle weight and improve fuel efficiency, they are increasingly looking towards bio-based materials. PLA with enhanced mechanical properties could potentially replace certain plastic components in car interiors, contributing to weight reduction while maintaining the required durability and performance standards.

In the medical field, there is a growing interest in biodegradable implants and drug delivery systems. Enhanced PLA, with its biocompatibility and improved mechanical strength, could find extensive applications in orthopedic implants, sutures, and controlled release drug delivery devices. The biomedical market for PLA is projected to expand significantly as research in this area progresses.

The 3D printing industry is also showing increased demand for enhanced PLA filaments. As 3D printing technology advances and finds more applications in prototyping and small-scale manufacturing, there is a need for stronger and more durable printing materials. PLA with improved mechanical properties could meet this demand, expanding its use in functional prototypes and end-use parts.

Consumer goods manufacturers are exploring enhanced PLA for durable goods such as electronics casings, toys, and household items. The improved mechanical properties could allow PLA to compete with conventional plastics in these applications, offering a more environmentally friendly alternative without compromising on performance.

The textile industry is another potential growth area for enhanced PLA. Durable PLA fibers could be used in clothing, upholstery, and technical textiles, offering a biodegradable alternative to synthetic fibers. This aligns with the growing trend of sustainable fashion and eco-friendly textiles.

Overall, the market demand for enhanced PLA is driven by a combination of environmental consciousness, regulatory support for sustainable materials, and the need for high-performance biodegradable alternatives across multiple industries. As research and development in PLA enhancement continue, the market is expected to expand further, potentially disrupting traditional plastic markets and creating new opportunities in various sectors.

In the packaging industry, there is a significant push towards replacing conventional plastics with biodegradable alternatives. Enhanced PLA, with its improved durability, presents a viable solution for food packaging, disposable cutlery, and beverage containers. The global bioplastics market, of which PLA is a key component, is expected to experience substantial growth in the coming years.

The automotive sector is another major driver for enhanced PLA demand. As automakers strive to reduce vehicle weight and improve fuel efficiency, they are increasingly looking towards bio-based materials. PLA with enhanced mechanical properties could potentially replace certain plastic components in car interiors, contributing to weight reduction while maintaining the required durability and performance standards.

In the medical field, there is a growing interest in biodegradable implants and drug delivery systems. Enhanced PLA, with its biocompatibility and improved mechanical strength, could find extensive applications in orthopedic implants, sutures, and controlled release drug delivery devices. The biomedical market for PLA is projected to expand significantly as research in this area progresses.

The 3D printing industry is also showing increased demand for enhanced PLA filaments. As 3D printing technology advances and finds more applications in prototyping and small-scale manufacturing, there is a need for stronger and more durable printing materials. PLA with improved mechanical properties could meet this demand, expanding its use in functional prototypes and end-use parts.

Consumer goods manufacturers are exploring enhanced PLA for durable goods such as electronics casings, toys, and household items. The improved mechanical properties could allow PLA to compete with conventional plastics in these applications, offering a more environmentally friendly alternative without compromising on performance.

The textile industry is another potential growth area for enhanced PLA. Durable PLA fibers could be used in clothing, upholstery, and technical textiles, offering a biodegradable alternative to synthetic fibers. This aligns with the growing trend of sustainable fashion and eco-friendly textiles.

Overall, the market demand for enhanced PLA is driven by a combination of environmental consciousness, regulatory support for sustainable materials, and the need for high-performance biodegradable alternatives across multiple industries. As research and development in PLA enhancement continue, the market is expected to expand further, potentially disrupting traditional plastic markets and creating new opportunities in various sectors.

PLA Limitations

Polylactic acid (PLA) has gained significant attention as a biodegradable and renewable alternative to traditional petroleum-based plastics. However, its widespread adoption in various applications is hindered by several inherent limitations, particularly in terms of mechanical properties and durability.

One of the primary limitations of PLA is its brittleness and low impact strength. This characteristic makes PLA susceptible to fracture under sudden impacts or stress, limiting its use in applications that require high toughness or impact resistance. The low elongation at break further contributes to its brittle nature, restricting its ability to withstand deformation without failure.

PLA also exhibits poor heat resistance compared to many conventional plastics. Its low glass transition temperature (around 60°C) and low heat deflection temperature make it unsuitable for high-temperature applications or products that may be exposed to elevated temperatures during use or storage. This thermal instability can lead to deformation, warping, or loss of structural integrity in PLA-based products.

Another significant limitation is PLA's susceptibility to hydrolysis, especially in humid environments or when exposed to moisture. This characteristic leads to a gradual degradation of the polymer chains, resulting in a decrease in mechanical properties over time. The hydrolytic degradation can cause premature failure of PLA products, limiting their long-term durability and shelf life.

PLA's low barrier properties, particularly its high gas permeability, pose challenges in packaging applications. This limitation restricts its use in food packaging or other applications where maintaining a controlled atmosphere is crucial. The high oxygen transmission rate can lead to reduced shelf life for packaged products and potential quality issues.

Furthermore, PLA exhibits poor weatherability and UV resistance. Prolonged exposure to sunlight and outdoor conditions can cause rapid degradation, leading to discoloration, embrittlement, and loss of mechanical properties. This limitation restricts PLA's use in outdoor applications or products that require long-term exposure to environmental elements.

The relatively low melt strength of PLA presents challenges in processing techniques such as blow molding or foam extrusion. This limitation narrows the range of manufacturing processes that can be effectively used with PLA, potentially increasing production costs or limiting design flexibility.

Lastly, PLA's slow crystallization rate can result in products with lower crystallinity, which in turn affects mechanical properties and heat resistance. Achieving high crystallinity in PLA often requires additional processing steps or the use of nucleating agents, adding complexity and cost to the manufacturing process.

One of the primary limitations of PLA is its brittleness and low impact strength. This characteristic makes PLA susceptible to fracture under sudden impacts or stress, limiting its use in applications that require high toughness or impact resistance. The low elongation at break further contributes to its brittle nature, restricting its ability to withstand deformation without failure.

PLA also exhibits poor heat resistance compared to many conventional plastics. Its low glass transition temperature (around 60°C) and low heat deflection temperature make it unsuitable for high-temperature applications or products that may be exposed to elevated temperatures during use or storage. This thermal instability can lead to deformation, warping, or loss of structural integrity in PLA-based products.

Another significant limitation is PLA's susceptibility to hydrolysis, especially in humid environments or when exposed to moisture. This characteristic leads to a gradual degradation of the polymer chains, resulting in a decrease in mechanical properties over time. The hydrolytic degradation can cause premature failure of PLA products, limiting their long-term durability and shelf life.

PLA's low barrier properties, particularly its high gas permeability, pose challenges in packaging applications. This limitation restricts its use in food packaging or other applications where maintaining a controlled atmosphere is crucial. The high oxygen transmission rate can lead to reduced shelf life for packaged products and potential quality issues.

Furthermore, PLA exhibits poor weatherability and UV resistance. Prolonged exposure to sunlight and outdoor conditions can cause rapid degradation, leading to discoloration, embrittlement, and loss of mechanical properties. This limitation restricts PLA's use in outdoor applications or products that require long-term exposure to environmental elements.

The relatively low melt strength of PLA presents challenges in processing techniques such as blow molding or foam extrusion. This limitation narrows the range of manufacturing processes that can be effectively used with PLA, potentially increasing production costs or limiting design flexibility.

Lastly, PLA's slow crystallization rate can result in products with lower crystallinity, which in turn affects mechanical properties and heat resistance. Achieving high crystallinity in PLA often requires additional processing steps or the use of nucleating agents, adding complexity and cost to the manufacturing process.

Current PLA Solutions

01 Improving mechanical properties of PLA

Various methods are employed to enhance the mechanical properties of PLA, including blending with other polymers, adding reinforcing agents, and modifying the molecular structure. These techniques aim to improve strength, toughness, and flexibility of PLA-based materials for diverse applications.- Improving mechanical properties of PLA: Various methods are employed to enhance the mechanical properties of PLA, including blending with other polymers, adding reinforcing agents, and modifying the molecular structure. These techniques aim to improve strength, toughness, and flexibility of PLA-based materials for diverse applications.

- PLA composites and nanocomposites: PLA is often combined with other materials to form composites and nanocomposites. These combinations can significantly enhance mechanical properties such as tensile strength, impact resistance, and thermal stability. Common additives include natural fibers, nanoparticles, and other biodegradable polymers.

- Processing techniques for PLA: Various processing techniques are used to manipulate the mechanical properties of PLA. These include extrusion, injection molding, and 3D printing. The processing conditions, such as temperature and pressure, can significantly affect the final mechanical properties of PLA products.

- Crystallization and thermal treatment of PLA: The degree of crystallinity in PLA greatly influences its mechanical properties. Techniques such as annealing, tempering, and controlled cooling are used to manipulate the crystalline structure of PLA, thereby enhancing its strength, stiffness, and heat resistance.

- Surface modification and functionalization of PLA: Surface treatments and functionalization techniques are applied to PLA to improve its mechanical properties, especially in composite materials. These methods can enhance interfacial adhesion, impact resistance, and overall mechanical performance of PLA-based products.

02 PLA composites and nanocomposites

PLA composites and nanocomposites are developed by incorporating fillers, fibers, or nanoparticles to enhance mechanical properties. These additives can significantly improve tensile strength, impact resistance, and thermal stability of PLA-based materials.Expand Specific Solutions03 Biodegradable PLA blends

Blending PLA with other biodegradable polymers or natural materials is explored to create materials with improved mechanical properties while maintaining biodegradability. These blends often exhibit enhanced flexibility, toughness, and processability compared to pure PLA.Expand Specific Solutions04 PLA crystallization and thermal properties

Controlling the crystallization behavior and thermal properties of PLA is crucial for improving its mechanical performance. Techniques such as annealing, nucleation, and plasticization are used to optimize crystallinity and enhance mechanical strength and heat resistance.Expand Specific Solutions05 Surface modification of PLA

Surface modification techniques are applied to PLA to improve its mechanical properties, especially in terms of adhesion and interfacial compatibility. These methods include plasma treatment, grafting, and coating, which can enhance the material's performance in composite applications and improve its overall mechanical characteristics.Expand Specific Solutions

Key PLA Manufacturers

The market for enhancing PLA's mechanical properties is in a growth phase, driven by increasing demand for sustainable and durable materials. The global bioplastics market, including PLA, is projected to reach $19.93 billion by 2026, with a CAGR of 13.8%. Technologically, the field is advancing rapidly, with various approaches being explored. Key players like Sichuan University, 3M Innovative Properties Co., and LG Chem Ltd. are at the forefront of research, focusing on techniques such as blending, copolymerization, and nanocomposite formation. Other significant contributors include Donghua University and South China University of Technology, who are developing novel methods to improve PLA's durability. The technology's maturity varies, with some solutions nearing commercialization while others remain in early research stages.

3M Innovative Properties Co.

Technical Solution: 3M has developed a proprietary technology called "Nanostructured PLA" to enhance the mechanical properties of PLA. This technology involves incorporating nanoscale reinforcements, such as nanocellulose or nanoclays, into the PLA matrix. The nanoparticles are uniformly dispersed throughout the polymer, creating a network that significantly improves the material's strength, stiffness, and impact resistance. Additionally, 3M has implemented a unique processing technique that optimizes the crystallization of PLA, further enhancing its durability and heat resistance.

Strengths: Significantly improved mechanical properties, enhanced heat resistance, and potential for biodegradability. Weaknesses: Potentially higher production costs and challenges in maintaining uniform dispersion of nanoparticles at large scales.

LG Chem Ltd.

Technical Solution: LG Chem has developed a novel approach to enhance PLA's mechanical properties through a combination of stereocomplex formation and reactive extrusion. Their process involves blending high-molecular-weight PLLA (poly-L-lactic acid) with PDLA (poly-D-lactic acid) to create stereocomplex crystals. During the reactive extrusion process, they introduce a multifunctional epoxy-based chain extender, which not only increases the molecular weight but also creates branched structures. This dual approach results in a PLA material with significantly improved tensile strength, impact resistance, and heat deflection temperature.

Strengths: Substantial improvement in mechanical and thermal properties, potential for use in high-performance applications. Weaknesses: Complex processing requirements, potentially higher raw material costs due to the use of both PLLA and PDLA.

PLA Innovations

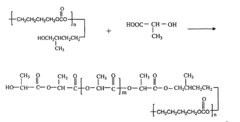

Producing method for polylactic acid-based copolymer

PatentActiveEP2184307A1

Innovation

- A method for preparing poly (lactic acid)-based copolymers by introducing flexible chain segments through copolymerization with polycaprolactone and aliphatic polycarbonate diols, enhancing molecular weight and mechanical properties, and incorporating chain extension processes to improve toughness, elasticity, and biodegradability.

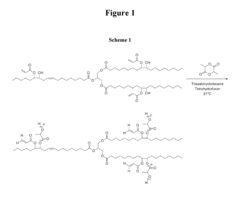

Biorenewable blends of polylactide and acrylated epoxidized soybean oil compatibilized by a polylactide star polymer

PatentActiveUS20190010326A1

Innovation

- A biorenewable thermoplastic additive blend comprising up to 99% of a modified natural oil, such as acrylated epoxidized soybean oil (AESO), an unmodified natural oil, and a compatibilizer like a PLA star polymer, which enhances interfacial adhesion and reduces blend interfacial tension, resulting in improved tensile properties and toughness.

Environmental Impact

The environmental impact of enhancing PLA's mechanical properties for better durability is a critical consideration in the development and application of this biodegradable polymer. PLA (Polylactic Acid) is widely recognized for its eco-friendly attributes, being derived from renewable resources and biodegradable under specific conditions. However, efforts to improve its durability may have both positive and negative environmental implications.

Enhancing PLA's mechanical properties often involves the incorporation of additives, fillers, or the modification of its molecular structure. These processes can potentially alter the material's biodegradability and end-of-life characteristics. While improved durability may lead to longer-lasting products, reducing the need for frequent replacements and thereby decreasing overall waste, it could also extend the time required for the material to decompose in natural environments.

The production of more durable PLA may require additional energy and resources, potentially increasing the carbon footprint of the manufacturing process. However, this initial environmental cost could be offset by the reduced need for replacement products over time. The balance between improved durability and maintained biodegradability is crucial to ensure that PLA retains its environmental advantages.

Another important aspect to consider is the impact on recycling systems. Enhanced PLA with improved mechanical properties may require specialized recycling processes, potentially complicating existing waste management infrastructures. On the other hand, more durable PLA products could lead to increased recycling rates due to their longer lifespan and potentially higher value in recycling streams.

The use of bio-based additives or reinforcements to enhance PLA's properties could maintain or even improve its overall environmental profile. For instance, incorporating natural fibers or other biodegradable materials may enhance durability while preserving the polymer's compostability. This approach aligns with circular economy principles and could lead to more sustainable product lifecycles.

It's also worth noting that improved durability in PLA could expand its applications, potentially replacing less environmentally friendly materials in various industries. This substitution effect could lead to broader positive environmental impacts, such as reduced reliance on petroleum-based plastics and decreased plastic pollution in ecosystems.

In conclusion, while enhancing PLA's mechanical properties for better durability presents some environmental challenges, it also offers significant opportunities for sustainable material development. The key lies in balancing improved performance with maintained or enhanced eco-friendly characteristics, ensuring that the environmental benefits of PLA are preserved or amplified throughout its lifecycle.

Enhancing PLA's mechanical properties often involves the incorporation of additives, fillers, or the modification of its molecular structure. These processes can potentially alter the material's biodegradability and end-of-life characteristics. While improved durability may lead to longer-lasting products, reducing the need for frequent replacements and thereby decreasing overall waste, it could also extend the time required for the material to decompose in natural environments.

The production of more durable PLA may require additional energy and resources, potentially increasing the carbon footprint of the manufacturing process. However, this initial environmental cost could be offset by the reduced need for replacement products over time. The balance between improved durability and maintained biodegradability is crucial to ensure that PLA retains its environmental advantages.

Another important aspect to consider is the impact on recycling systems. Enhanced PLA with improved mechanical properties may require specialized recycling processes, potentially complicating existing waste management infrastructures. On the other hand, more durable PLA products could lead to increased recycling rates due to their longer lifespan and potentially higher value in recycling streams.

The use of bio-based additives or reinforcements to enhance PLA's properties could maintain or even improve its overall environmental profile. For instance, incorporating natural fibers or other biodegradable materials may enhance durability while preserving the polymer's compostability. This approach aligns with circular economy principles and could lead to more sustainable product lifecycles.

It's also worth noting that improved durability in PLA could expand its applications, potentially replacing less environmentally friendly materials in various industries. This substitution effect could lead to broader positive environmental impacts, such as reduced reliance on petroleum-based plastics and decreased plastic pollution in ecosystems.

In conclusion, while enhancing PLA's mechanical properties for better durability presents some environmental challenges, it also offers significant opportunities for sustainable material development. The key lies in balancing improved performance with maintained or enhanced eco-friendly characteristics, ensuring that the environmental benefits of PLA are preserved or amplified throughout its lifecycle.

Regulatory Compliance

Regulatory compliance plays a crucial role in the development and application of enhanced PLA materials for improved durability. As the demand for more sustainable and biodegradable plastics grows, manufacturers must navigate a complex landscape of regulations to ensure their products meet safety and environmental standards.

In the United States, the Food and Drug Administration (FDA) oversees the use of PLA in food contact applications. Manufacturers seeking to enhance PLA's mechanical properties must adhere to FDA regulations, particularly 21 CFR 177.1630, which outlines the requirements for polymers used in food packaging. Any modifications to PLA's composition or processing methods must be evaluated for potential migration of substances into food and overall safety.

The European Union's regulatory framework is equally stringent. The European Food Safety Authority (EFSA) assesses the safety of materials intended for food contact, including enhanced PLA. Manufacturers must comply with Regulation (EC) No 1935/2004 on materials and articles intended to come into contact with food, as well as Regulation (EU) No 10/2011 on plastic materials and articles intended to come into contact with food.

Environmental regulations also impact the development of enhanced PLA. In many jurisdictions, claims of biodegradability and compostability are subject to strict verification. For instance, the European Standard EN 13432 sets requirements for packaging recoverable through composting and biodegradation. Enhanced PLA products aiming to maintain these environmental benefits must demonstrate compliance with such standards.

As PLA finds applications in medical devices, regulatory considerations become even more critical. In the United States, the FDA's Center for Devices and Radiological Health (CDRH) regulates medical devices, including those made from enhanced PLA. Manufacturers must navigate the premarket approval (PMA) or 510(k) clearance processes, depending on the device classification.

Globally, the International Organization for Standardization (ISO) provides standards relevant to PLA enhancement, such as ISO 10993 for biocompatibility testing of medical devices. Adherence to these standards is often necessary for regulatory approval in various markets.

As research into enhancing PLA's mechanical properties progresses, manufacturers must remain vigilant of evolving regulations. This includes monitoring changes in chemical registration requirements, such as those under the European Union's REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) regulation, which may impact additives or processing aids used in PLA enhancement.

In the United States, the Food and Drug Administration (FDA) oversees the use of PLA in food contact applications. Manufacturers seeking to enhance PLA's mechanical properties must adhere to FDA regulations, particularly 21 CFR 177.1630, which outlines the requirements for polymers used in food packaging. Any modifications to PLA's composition or processing methods must be evaluated for potential migration of substances into food and overall safety.

The European Union's regulatory framework is equally stringent. The European Food Safety Authority (EFSA) assesses the safety of materials intended for food contact, including enhanced PLA. Manufacturers must comply with Regulation (EC) No 1935/2004 on materials and articles intended to come into contact with food, as well as Regulation (EU) No 10/2011 on plastic materials and articles intended to come into contact with food.

Environmental regulations also impact the development of enhanced PLA. In many jurisdictions, claims of biodegradability and compostability are subject to strict verification. For instance, the European Standard EN 13432 sets requirements for packaging recoverable through composting and biodegradation. Enhanced PLA products aiming to maintain these environmental benefits must demonstrate compliance with such standards.

As PLA finds applications in medical devices, regulatory considerations become even more critical. In the United States, the FDA's Center for Devices and Radiological Health (CDRH) regulates medical devices, including those made from enhanced PLA. Manufacturers must navigate the premarket approval (PMA) or 510(k) clearance processes, depending on the device classification.

Globally, the International Organization for Standardization (ISO) provides standards relevant to PLA enhancement, such as ISO 10993 for biocompatibility testing of medical devices. Adherence to these standards is often necessary for regulatory approval in various markets.

As research into enhancing PLA's mechanical properties progresses, manufacturers must remain vigilant of evolving regulations. This includes monitoring changes in chemical registration requirements, such as those under the European Union's REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) regulation, which may impact additives or processing aids used in PLA enhancement.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!