The Convergence of Technology and Sustainability in PLA

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PLA Tech Evolution

The evolution of PLA (Polylactic Acid) technology has been marked by significant advancements in both material science and sustainable manufacturing practices. Initially developed in the 1920s, PLA remained largely unexplored until the late 20th century when environmental concerns and the need for biodegradable alternatives to petroleum-based plastics gained prominence.

The 1990s saw a resurgence of interest in PLA, driven by breakthroughs in fermentation technology and polymer processing. This period marked the beginning of PLA's commercial viability, with researchers focusing on improving its mechanical properties and thermal stability. The early 2000s witnessed a rapid expansion in PLA production capacity, as major chemical companies invested in large-scale manufacturing facilities.

A critical milestone in PLA's evolution was the development of high-molecular-weight PLA in the mid-2000s. This innovation significantly enhanced the material's strength and durability, broadening its potential applications beyond packaging to include textiles, automotive parts, and even medical implants. Concurrently, advancements in catalyst technology and polymerization processes led to more efficient and cost-effective production methods.

The 2010s brought a focus on enhancing PLA's biodegradability and compostability. Researchers developed new blends and additives to accelerate the material's decomposition in various environments, addressing concerns about its persistence in natural ecosystems. This period also saw the emergence of PLA-based composites, combining the biodegradable polymer with natural fibers to create materials with improved mechanical and thermal properties.

Recent years have witnessed a convergence of PLA technology with other cutting-edge fields. The integration of nanotechnology has led to PLA nanocomposites with enhanced barrier properties and antimicrobial characteristics. Additionally, the advent of 3D printing has opened new avenues for PLA applications, with the material becoming a popular choice for sustainable, customizable manufacturing.

Looking ahead, the PLA tech evolution is poised to continue its trajectory towards greater sustainability and versatility. Current research focuses on developing fully bio-based PLA, eliminating the need for petroleum-derived additives. Efforts are also underway to create PLA variants with improved heat resistance and flexibility, potentially expanding its use in durable goods and high-performance applications.

The convergence of PLA technology with artificial intelligence and machine learning presents exciting possibilities for optimizing production processes and tailoring material properties for specific end-uses. As global demand for sustainable materials grows, PLA's evolution is likely to accelerate, driven by interdisciplinary collaborations and innovative approaches to polymer science and green chemistry.

The 1990s saw a resurgence of interest in PLA, driven by breakthroughs in fermentation technology and polymer processing. This period marked the beginning of PLA's commercial viability, with researchers focusing on improving its mechanical properties and thermal stability. The early 2000s witnessed a rapid expansion in PLA production capacity, as major chemical companies invested in large-scale manufacturing facilities.

A critical milestone in PLA's evolution was the development of high-molecular-weight PLA in the mid-2000s. This innovation significantly enhanced the material's strength and durability, broadening its potential applications beyond packaging to include textiles, automotive parts, and even medical implants. Concurrently, advancements in catalyst technology and polymerization processes led to more efficient and cost-effective production methods.

The 2010s brought a focus on enhancing PLA's biodegradability and compostability. Researchers developed new blends and additives to accelerate the material's decomposition in various environments, addressing concerns about its persistence in natural ecosystems. This period also saw the emergence of PLA-based composites, combining the biodegradable polymer with natural fibers to create materials with improved mechanical and thermal properties.

Recent years have witnessed a convergence of PLA technology with other cutting-edge fields. The integration of nanotechnology has led to PLA nanocomposites with enhanced barrier properties and antimicrobial characteristics. Additionally, the advent of 3D printing has opened new avenues for PLA applications, with the material becoming a popular choice for sustainable, customizable manufacturing.

Looking ahead, the PLA tech evolution is poised to continue its trajectory towards greater sustainability and versatility. Current research focuses on developing fully bio-based PLA, eliminating the need for petroleum-derived additives. Efforts are also underway to create PLA variants with improved heat resistance and flexibility, potentially expanding its use in durable goods and high-performance applications.

The convergence of PLA technology with artificial intelligence and machine learning presents exciting possibilities for optimizing production processes and tailoring material properties for specific end-uses. As global demand for sustainable materials grows, PLA's evolution is likely to accelerate, driven by interdisciplinary collaborations and innovative approaches to polymer science and green chemistry.

Green Market Demand

The convergence of technology and sustainability in PLA (Polylactic Acid) has sparked significant interest in the green market, driven by increasing environmental awareness and regulatory pressures. Consumer demand for eco-friendly products has surged, with PLA emerging as a promising alternative to traditional petroleum-based plastics. This biodegradable and compostable material, derived from renewable resources such as corn starch or sugarcane, aligns well with the growing sustainability ethos in various industries.

Market research indicates a robust growth trajectory for PLA, with the global market expected to expand substantially in the coming years. This growth is fueled by the material's versatility and its potential to replace conventional plastics in numerous applications, including packaging, textiles, and consumer goods. The food and beverage industry, in particular, has shown keen interest in PLA-based packaging solutions, responding to consumer preferences for environmentally responsible products.

The automotive and electronics sectors are also exploring PLA applications, seeking to reduce their carbon footprint and meet increasingly stringent environmental regulations. This diversification of end-use industries contributes to the overall market expansion and underscores the material's broad appeal in the green economy.

Geographically, North America and Europe lead in PLA adoption, driven by stringent environmental policies and high consumer awareness. However, Asia-Pacific is emerging as a rapidly growing market, propelled by increasing industrialization and a shift towards sustainable practices in developing economies.

Despite its promising outlook, the PLA market faces challenges. The higher production costs compared to traditional plastics and limitations in certain performance characteristics have somewhat constrained widespread adoption. However, ongoing technological advancements and economies of scale are gradually addressing these issues, improving PLA's competitiveness.

The COVID-19 pandemic has had a mixed impact on the PLA market. While it initially disrupted supply chains and manufacturing processes, the crisis has also heightened awareness of environmental issues and health concerns, potentially accelerating the shift towards sustainable materials like PLA in the long term.

Looking ahead, the green market demand for PLA is expected to continue its upward trajectory. Factors such as increasing environmental regulations, corporate sustainability initiatives, and growing consumer preference for eco-friendly products are likely to drive further adoption across various industries. As technology continues to improve PLA's properties and reduce production costs, its market penetration is anticipated to deepen, solidifying its position as a key player in the sustainable materials landscape.

Market research indicates a robust growth trajectory for PLA, with the global market expected to expand substantially in the coming years. This growth is fueled by the material's versatility and its potential to replace conventional plastics in numerous applications, including packaging, textiles, and consumer goods. The food and beverage industry, in particular, has shown keen interest in PLA-based packaging solutions, responding to consumer preferences for environmentally responsible products.

The automotive and electronics sectors are also exploring PLA applications, seeking to reduce their carbon footprint and meet increasingly stringent environmental regulations. This diversification of end-use industries contributes to the overall market expansion and underscores the material's broad appeal in the green economy.

Geographically, North America and Europe lead in PLA adoption, driven by stringent environmental policies and high consumer awareness. However, Asia-Pacific is emerging as a rapidly growing market, propelled by increasing industrialization and a shift towards sustainable practices in developing economies.

Despite its promising outlook, the PLA market faces challenges. The higher production costs compared to traditional plastics and limitations in certain performance characteristics have somewhat constrained widespread adoption. However, ongoing technological advancements and economies of scale are gradually addressing these issues, improving PLA's competitiveness.

The COVID-19 pandemic has had a mixed impact on the PLA market. While it initially disrupted supply chains and manufacturing processes, the crisis has also heightened awareness of environmental issues and health concerns, potentially accelerating the shift towards sustainable materials like PLA in the long term.

Looking ahead, the green market demand for PLA is expected to continue its upward trajectory. Factors such as increasing environmental regulations, corporate sustainability initiatives, and growing consumer preference for eco-friendly products are likely to drive further adoption across various industries. As technology continues to improve PLA's properties and reduce production costs, its market penetration is anticipated to deepen, solidifying its position as a key player in the sustainable materials landscape.

PLA Challenges

Despite the growing popularity of PLA as a sustainable alternative to traditional plastics, the material faces several significant challenges that hinder its widespread adoption and effectiveness in various applications. One of the primary concerns is PLA's inherent brittleness, which limits its use in products requiring high impact resistance or flexibility. This characteristic makes PLA less suitable for certain packaging applications and durable goods, where toughness is a critical factor.

Another major challenge is PLA's relatively low heat resistance compared to conventional plastics. The material begins to soften at temperatures around 60°C (140°F), which restricts its use in hot-fill applications, microwave-safe containers, and automotive parts exposed to high temperatures. This thermal sensitivity also complicates processing and manufacturing techniques, as PLA requires careful temperature control during production to maintain its structural integrity.

PLA's moisture sensitivity presents additional hurdles in both processing and end-use applications. The material tends to absorb moisture from the environment, which can lead to hydrolysis and degradation of its mechanical properties over time. This characteristic necessitates careful storage and handling procedures, as well as the implementation of moisture removal techniques during processing, adding complexity and cost to manufacturing processes.

The biodegradability of PLA, while generally considered an advantage, also poses challenges in certain contexts. The material's degradation rate can be inconsistent and highly dependent on environmental conditions, making it difficult to predict and control its lifespan in various applications. Furthermore, the lack of widespread industrial composting facilities capable of properly processing PLA waste limits the realization of its full environmental benefits.

Cost remains a significant barrier to PLA's broader adoption. Despite improvements in production efficiency, PLA is still generally more expensive than conventional petroleum-based plastics. This price differential can be a deterrent for manufacturers and consumers, particularly in price-sensitive markets or applications where large volumes of material are required.

Lastly, the limited availability of feedstock for PLA production raises concerns about scalability and long-term sustainability. While PLA is derived from renewable resources, primarily corn starch, the expansion of its production could potentially compete with food crops for agricultural land, leading to ethical and environmental dilemmas. This challenge underscores the need for diversifying feedstock sources and developing more efficient production methods to ensure PLA's viability as a truly sustainable alternative to conventional plastics.

Another major challenge is PLA's relatively low heat resistance compared to conventional plastics. The material begins to soften at temperatures around 60°C (140°F), which restricts its use in hot-fill applications, microwave-safe containers, and automotive parts exposed to high temperatures. This thermal sensitivity also complicates processing and manufacturing techniques, as PLA requires careful temperature control during production to maintain its structural integrity.

PLA's moisture sensitivity presents additional hurdles in both processing and end-use applications. The material tends to absorb moisture from the environment, which can lead to hydrolysis and degradation of its mechanical properties over time. This characteristic necessitates careful storage and handling procedures, as well as the implementation of moisture removal techniques during processing, adding complexity and cost to manufacturing processes.

The biodegradability of PLA, while generally considered an advantage, also poses challenges in certain contexts. The material's degradation rate can be inconsistent and highly dependent on environmental conditions, making it difficult to predict and control its lifespan in various applications. Furthermore, the lack of widespread industrial composting facilities capable of properly processing PLA waste limits the realization of its full environmental benefits.

Cost remains a significant barrier to PLA's broader adoption. Despite improvements in production efficiency, PLA is still generally more expensive than conventional petroleum-based plastics. This price differential can be a deterrent for manufacturers and consumers, particularly in price-sensitive markets or applications where large volumes of material are required.

Lastly, the limited availability of feedstock for PLA production raises concerns about scalability and long-term sustainability. While PLA is derived from renewable resources, primarily corn starch, the expansion of its production could potentially compete with food crops for agricultural land, leading to ethical and environmental dilemmas. This challenge underscores the need for diversifying feedstock sources and developing more efficient production methods to ensure PLA's viability as a truly sustainable alternative to conventional plastics.

Current PLA Solutions

01 PLA-based composite materials

Development of composite materials using PLA as a base polymer, incorporating various additives or fillers to enhance properties such as strength, durability, or biodegradability. These composites can be used in a wide range of applications, from packaging to medical devices.- PLA-based composite materials: Development of composite materials using PLA as a base polymer, incorporating various additives or fillers to enhance properties such as strength, durability, or biodegradability. These composites can be used in a wide range of applications, from packaging to medical devices.

- PLA processing techniques: Innovative methods for processing PLA, including extrusion, injection molding, and 3D printing. These techniques aim to improve the material's performance, reduce production costs, and expand its potential applications in various industries.

- PLA modification for improved properties: Chemical or physical modification of PLA to enhance its properties such as thermal stability, mechanical strength, or barrier properties. This includes techniques like blending with other polymers, crosslinking, or surface treatments to overcome limitations of pure PLA.

- Biodegradable PLA applications: Development of biodegradable products using PLA for various applications, including packaging, disposable items, and agricultural films. These innovations focus on reducing environmental impact while maintaining product functionality.

- PLA in medical and pharmaceutical applications: Utilization of PLA in medical and pharmaceutical fields, including drug delivery systems, tissue engineering scaffolds, and bioabsorbable implants. These applications leverage PLA's biocompatibility and controlled degradation properties.

02 PLA processing techniques

Innovative methods for processing PLA, including extrusion, injection molding, and 3D printing. These techniques aim to improve the material's performance, reduce production costs, and expand its potential applications in various industries.Expand Specific Solutions03 PLA modification for enhanced properties

Chemical or physical modification of PLA to improve its properties such as thermal stability, mechanical strength, or barrier properties. This includes techniques like blending with other polymers, crosslinking, or surface treatments to expand PLA's use in demanding applications.Expand Specific Solutions04 Biodegradable PLA formulations

Development of specialized PLA formulations designed to enhance biodegradability while maintaining desired material properties. These formulations often include additives or processing techniques that accelerate decomposition in specific environments without compromising performance during use.Expand Specific Solutions05 PLA in medical and pharmaceutical applications

Utilization of PLA in medical devices, drug delivery systems, and tissue engineering scaffolds. This includes the development of biocompatible and bioresorbable PLA-based materials tailored for specific medical applications, such as implants or controlled release formulations.Expand Specific Solutions

Key PLA Players

The convergence of technology and sustainability in PLA is at a critical juncture, with the market experiencing rapid growth and increasing technological maturity. The industry is transitioning from early adoption to mainstream acceptance, driven by environmental concerns and regulatory pressures. Key players like NatureWorks LLC, Total Research Corp, and LG Chem Ltd. are leading innovation, focusing on improving PLA's properties and production efficiency. Companies such as Industrial Technology Research Institute and Avantium Knowledge Centre BV are contributing to technological advancements, while universities like Sichuan University and Tongji University are conducting cutting-edge research. The market is characterized by intense competition and collaboration, with both established corporations and innovative startups vying for market share in this expanding sector.

LG Chem Ltd.

Technical Solution: LG Chem has developed a proprietary technology for producing bio-based PLA. Their process involves the fermentation of corn or other biomass to produce lactic acid, which is then polymerized into high-molecular-weight PLA. They have focused on improving the mechanical properties and heat resistance of PLA through the development of stereocomplex PLA, which combines L-lactic acid and D-lactic acid polymers. LG Chem has also invested in the development of PLA composites and blends to enhance its performance for various applications.

Strengths: Advanced polymer technology, improved material properties. Weaknesses: Reliance on agricultural feedstocks, potential competition with food sources.

Kingfa Sci. & Tech. Co., Ltd.

Technical Solution: Kingfa has developed a range of PLA-based compounds and composites. Their technology focuses on enhancing the properties of PLA through blending with other biopolymers and adding various reinforcing agents. They have created PLA formulations with improved heat resistance, impact strength, and processability. Kingfa's research also extends to the development of PLA-based foams and flame-retardant PLA compounds, expanding the potential applications of PLA in industries such as automotive and construction.

Strengths: Wide range of PLA formulations, improved material properties. Weaknesses: Complexity in formulation may increase costs, potential challenges in recycling mixed materials.

PLA Core Patents

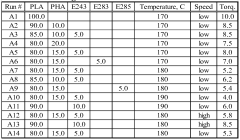

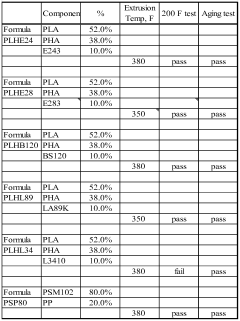

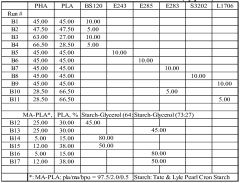

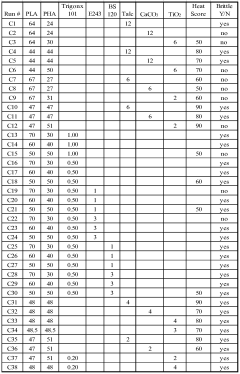

Thermoformed articles made from reactive extrusion products of biobased materials

PatentWO2011071666A1

Innovation

- Development of thermoformable composite materials through blending PHAs and PLA with additives, processed via extrusion, to enhance thermal and mechanical performance while maintaining sustainability, with specific formulations achieving higher heat distortion indices and Vicat softening points.

Bioabsorbable polymer blends

PatentActiveUS20150291791A1

Innovation

- A bioabsorbable blend of polylactic acid and thermoplastic polyurethane, tailored with specific components like diisocyanates, diol chain extenders, and polyols to achieve a controlled degradation rate and physical properties, allowing for adjustable ratios to meet specific medical application requirements.

PLA Regulations

The regulatory landscape surrounding Polylactic Acid (PLA) is evolving rapidly as governments and industries recognize the importance of sustainable materials in addressing environmental challenges. PLA, a biodegradable polymer derived from renewable resources, has gained significant attention in recent years due to its potential to replace conventional plastics in various applications.

In the United States, the Food and Drug Administration (FDA) has approved PLA for use in food contact applications, including packaging and disposable utensils. The FDA's regulation 21 CFR 177.1630 specifically addresses the use of PLA in food contact materials, ensuring its safety for consumers. Additionally, the Environmental Protection Agency (EPA) has classified PLA as a biodegradable material under certain conditions, which has implications for waste management and disposal regulations.

The European Union has also implemented regulations pertaining to PLA. The European Food Safety Authority (EFSA) has evaluated PLA and deemed it safe for food contact applications. The EU's Packaging and Packaging Waste Directive (94/62/EC) promotes the use of biodegradable materials like PLA, encouraging member states to implement policies that favor sustainable packaging solutions.

In Asia, countries like Japan and China have introduced regulations to promote the use of biodegradable plastics, including PLA. Japan's Biomass Plastics Mark certification system, established by the Japan BioPlastics Association, provides a framework for identifying and promoting bio-based plastics, including PLA. China has implemented the GB/T 20197-2006 standard, which specifies requirements for biodegradable plastics and includes provisions for PLA-based materials.

As the adoption of PLA increases, regulatory bodies are working to develop more comprehensive standards and guidelines. The International Organization for Standardization (ISO) has published several standards related to biodegradable plastics, including ISO 17088:2021, which specifies requirements for compostable plastics. These standards provide a framework for assessing the environmental impact and performance of PLA-based products.

Regulatory efforts are also focusing on end-of-life management for PLA products. Many jurisdictions are implementing extended producer responsibility (EPR) programs, which require manufacturers to take responsibility for the entire lifecycle of their products, including disposal. These regulations are driving innovation in PLA recycling and composting technologies, as well as encouraging the development of more efficient collection and processing systems for biodegradable materials.

In the United States, the Food and Drug Administration (FDA) has approved PLA for use in food contact applications, including packaging and disposable utensils. The FDA's regulation 21 CFR 177.1630 specifically addresses the use of PLA in food contact materials, ensuring its safety for consumers. Additionally, the Environmental Protection Agency (EPA) has classified PLA as a biodegradable material under certain conditions, which has implications for waste management and disposal regulations.

The European Union has also implemented regulations pertaining to PLA. The European Food Safety Authority (EFSA) has evaluated PLA and deemed it safe for food contact applications. The EU's Packaging and Packaging Waste Directive (94/62/EC) promotes the use of biodegradable materials like PLA, encouraging member states to implement policies that favor sustainable packaging solutions.

In Asia, countries like Japan and China have introduced regulations to promote the use of biodegradable plastics, including PLA. Japan's Biomass Plastics Mark certification system, established by the Japan BioPlastics Association, provides a framework for identifying and promoting bio-based plastics, including PLA. China has implemented the GB/T 20197-2006 standard, which specifies requirements for biodegradable plastics and includes provisions for PLA-based materials.

As the adoption of PLA increases, regulatory bodies are working to develop more comprehensive standards and guidelines. The International Organization for Standardization (ISO) has published several standards related to biodegradable plastics, including ISO 17088:2021, which specifies requirements for compostable plastics. These standards provide a framework for assessing the environmental impact and performance of PLA-based products.

Regulatory efforts are also focusing on end-of-life management for PLA products. Many jurisdictions are implementing extended producer responsibility (EPR) programs, which require manufacturers to take responsibility for the entire lifecycle of their products, including disposal. These regulations are driving innovation in PLA recycling and composting technologies, as well as encouraging the development of more efficient collection and processing systems for biodegradable materials.

PLA Life Cycle Analysis

Life Cycle Analysis (LCA) plays a crucial role in understanding the environmental impact of Polylactic Acid (PLA) throughout its entire lifecycle. This comprehensive approach examines PLA from raw material extraction to final disposal, providing valuable insights into its sustainability profile.

The LCA of PLA typically begins with the production of lactic acid, which is derived from renewable resources such as corn, sugarcane, or cassava. This initial stage involves agricultural practices, including land use, water consumption, and energy inputs for crop cultivation and harvesting. The fermentation process to convert these feedstocks into lactic acid is then evaluated for its energy requirements and potential emissions.

The next phase in the PLA lifecycle is polymerization, where lactic acid monomers are converted into long-chain polymers. This stage is energy-intensive and may involve the use of catalysts and other chemical additives. The LCA assesses the environmental impacts associated with these processes, including energy consumption, greenhouse gas emissions, and potential chemical releases.

Manufacturing of PLA products is the subsequent step, which may involve various processes such as extrusion, injection molding, or 3D printing. The LCA examines the energy efficiency of these manufacturing methods, material waste generation, and any additional resources required for product formation.

The use phase of PLA products is generally considered to have minimal direct environmental impact. However, the LCA may consider factors such as product durability, potential for reuse, and any maintenance requirements that could affect its overall environmental footprint.

End-of-life management is a critical aspect of PLA's lifecycle analysis. PLA's biodegradability and compostability are often touted as environmental advantages. The LCA evaluates different disposal scenarios, including industrial composting, home composting, recycling, and landfilling. It assesses the actual decomposition rates, methane emissions from anaerobic degradation, and the potential for nutrient recovery in composting systems.

Transportation and distribution are considered throughout the lifecycle, from raw material sourcing to product delivery and waste management. The LCA quantifies the environmental impacts associated with these logistics, including fuel consumption and emissions from various modes of transport.

By conducting a thorough LCA, researchers and industry professionals can identify hotspots in PLA's lifecycle where environmental impacts are most significant. This information is invaluable for guiding technological innovations and sustainability initiatives in PLA production and use, ultimately contributing to the convergence of advanced materials technology with environmental stewardship.

The LCA of PLA typically begins with the production of lactic acid, which is derived from renewable resources such as corn, sugarcane, or cassava. This initial stage involves agricultural practices, including land use, water consumption, and energy inputs for crop cultivation and harvesting. The fermentation process to convert these feedstocks into lactic acid is then evaluated for its energy requirements and potential emissions.

The next phase in the PLA lifecycle is polymerization, where lactic acid monomers are converted into long-chain polymers. This stage is energy-intensive and may involve the use of catalysts and other chemical additives. The LCA assesses the environmental impacts associated with these processes, including energy consumption, greenhouse gas emissions, and potential chemical releases.

Manufacturing of PLA products is the subsequent step, which may involve various processes such as extrusion, injection molding, or 3D printing. The LCA examines the energy efficiency of these manufacturing methods, material waste generation, and any additional resources required for product formation.

The use phase of PLA products is generally considered to have minimal direct environmental impact. However, the LCA may consider factors such as product durability, potential for reuse, and any maintenance requirements that could affect its overall environmental footprint.

End-of-life management is a critical aspect of PLA's lifecycle analysis. PLA's biodegradability and compostability are often touted as environmental advantages. The LCA evaluates different disposal scenarios, including industrial composting, home composting, recycling, and landfilling. It assesses the actual decomposition rates, methane emissions from anaerobic degradation, and the potential for nutrient recovery in composting systems.

Transportation and distribution are considered throughout the lifecycle, from raw material sourcing to product delivery and waste management. The LCA quantifies the environmental impacts associated with these logistics, including fuel consumption and emissions from various modes of transport.

By conducting a thorough LCA, researchers and industry professionals can identify hotspots in PLA's lifecycle where environmental impacts are most significant. This information is invaluable for guiding technological innovations and sustainability initiatives in PLA production and use, ultimately contributing to the convergence of advanced materials technology with environmental stewardship.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!