Expanding PLA Use Cases in Everyday Life Settings

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PLA Technology Evolution and Objectives

Polylactic acid (PLA) has emerged as a promising biodegradable polymer with a wide range of potential applications in everyday life settings. The evolution of PLA technology can be traced back to the 1930s when it was first synthesized, but significant advancements in its production and applications have occurred in recent decades.

The primary objective of expanding PLA use cases in everyday life settings is to replace conventional petroleum-based plastics with a more environmentally friendly alternative. This aligns with global efforts to reduce plastic pollution and transition towards a circular economy. PLA offers the advantage of being derived from renewable resources, primarily corn starch or sugarcane, making it a sustainable choice for various consumer products.

In the early stages of PLA development, the focus was on improving its production efficiency and reducing costs. As the technology matured, researchers and industry players shifted their attention to enhancing PLA's material properties to broaden its applicability. Key objectives in this evolution include improving PLA's heat resistance, mechanical strength, and barrier properties to make it suitable for a wider range of everyday products.

One of the significant milestones in PLA technology was the development of industrial-scale production methods in the 1990s. This breakthrough made PLA commercially viable and paved the way for its adoption in various industries. Since then, the objectives have expanded to include the development of PLA composites and blends to tailor its properties for specific applications.

Recent technological advancements have focused on improving PLA's end-of-life options, particularly in composting and recycling. The goal is to create a closed-loop system where PLA products can be efficiently collected, processed, and reintroduced into the production cycle. This aligns with the broader objective of creating a sustainable material ecosystem that minimizes waste and environmental impact.

Looking ahead, the objectives for PLA technology evolution include developing new grades of PLA with enhanced properties, such as increased flexibility or improved UV resistance. There is also a growing emphasis on creating PLA-based materials that can directly compete with conventional plastics in demanding applications, such as automotive parts or durable consumer goods.

In conclusion, the evolution of PLA technology and its objectives are driven by the need for sustainable alternatives to traditional plastics in everyday life settings. As research and development continue, PLA is poised to play an increasingly important role in addressing environmental challenges while meeting the diverse needs of consumers and industries.

The primary objective of expanding PLA use cases in everyday life settings is to replace conventional petroleum-based plastics with a more environmentally friendly alternative. This aligns with global efforts to reduce plastic pollution and transition towards a circular economy. PLA offers the advantage of being derived from renewable resources, primarily corn starch or sugarcane, making it a sustainable choice for various consumer products.

In the early stages of PLA development, the focus was on improving its production efficiency and reducing costs. As the technology matured, researchers and industry players shifted their attention to enhancing PLA's material properties to broaden its applicability. Key objectives in this evolution include improving PLA's heat resistance, mechanical strength, and barrier properties to make it suitable for a wider range of everyday products.

One of the significant milestones in PLA technology was the development of industrial-scale production methods in the 1990s. This breakthrough made PLA commercially viable and paved the way for its adoption in various industries. Since then, the objectives have expanded to include the development of PLA composites and blends to tailor its properties for specific applications.

Recent technological advancements have focused on improving PLA's end-of-life options, particularly in composting and recycling. The goal is to create a closed-loop system where PLA products can be efficiently collected, processed, and reintroduced into the production cycle. This aligns with the broader objective of creating a sustainable material ecosystem that minimizes waste and environmental impact.

Looking ahead, the objectives for PLA technology evolution include developing new grades of PLA with enhanced properties, such as increased flexibility or improved UV resistance. There is also a growing emphasis on creating PLA-based materials that can directly compete with conventional plastics in demanding applications, such as automotive parts or durable consumer goods.

In conclusion, the evolution of PLA technology and its objectives are driven by the need for sustainable alternatives to traditional plastics in everyday life settings. As research and development continue, PLA is poised to play an increasingly important role in addressing environmental challenges while meeting the diverse needs of consumers and industries.

Market Demand for PLA Products

The market demand for PLA (Polylactic Acid) products has been steadily increasing in recent years, driven by growing environmental consciousness and the push for sustainable alternatives to traditional plastics. As consumers become more aware of the environmental impact of their purchasing decisions, there is a rising preference for biodegradable and compostable materials in everyday products.

In the packaging industry, PLA has gained significant traction as a viable alternative to petroleum-based plastics. Food packaging, particularly for fresh produce and ready-to-eat meals, has seen a surge in PLA adoption. The material's ability to maintain food freshness while being environmentally friendly has resonated well with both consumers and food retailers. Additionally, the beverage industry has shown interest in PLA for bottled water and other cold drinks, as it offers similar performance to PET bottles but with a reduced carbon footprint.

The disposable cutlery and tableware sector has also witnessed a notable shift towards PLA products. Restaurants, catering services, and event organizers are increasingly opting for PLA-based disposables to align with sustainability goals and meet consumer expectations. This trend has been further accelerated by regulations in various countries limiting or banning single-use plastics, creating a favorable market environment for PLA alternatives.

In the textile industry, PLA fibers are gaining popularity for their potential to replace synthetic fibers in clothing and home textiles. The material's breathability, moisture-wicking properties, and biodegradability make it an attractive option for eco-conscious fashion brands and consumers. As the demand for sustainable fashion grows, the market for PLA-based textiles is expected to expand significantly in the coming years.

The agriculture sector presents another promising market for PLA products. Biodegradable mulch films made from PLA offer farmers an environmentally friendly alternative to traditional plastic films, reducing soil pollution and simplifying post-harvest cleanup. Additionally, PLA-based plant pots and seed trays are gaining traction in horticulture and gardening, appealing to both commercial growers and home gardeners.

The medical and healthcare industry has also shown increasing interest in PLA for various applications. Biodegradable sutures, implants, and drug delivery systems made from PLA are being developed and adopted, leveraging the material's biocompatibility and controlled degradation properties. This sector represents a high-value market segment with significant growth potential for PLA products.

As research and development efforts continue to improve PLA's performance characteristics and reduce production costs, the material is expected to find new applications in various industries. The growing market demand for PLA products is not only driven by consumer preferences but also by corporate sustainability initiatives and regulatory pressures, creating a favorable environment for the expansion of PLA use cases in everyday life settings.

In the packaging industry, PLA has gained significant traction as a viable alternative to petroleum-based plastics. Food packaging, particularly for fresh produce and ready-to-eat meals, has seen a surge in PLA adoption. The material's ability to maintain food freshness while being environmentally friendly has resonated well with both consumers and food retailers. Additionally, the beverage industry has shown interest in PLA for bottled water and other cold drinks, as it offers similar performance to PET bottles but with a reduced carbon footprint.

The disposable cutlery and tableware sector has also witnessed a notable shift towards PLA products. Restaurants, catering services, and event organizers are increasingly opting for PLA-based disposables to align with sustainability goals and meet consumer expectations. This trend has been further accelerated by regulations in various countries limiting or banning single-use plastics, creating a favorable market environment for PLA alternatives.

In the textile industry, PLA fibers are gaining popularity for their potential to replace synthetic fibers in clothing and home textiles. The material's breathability, moisture-wicking properties, and biodegradability make it an attractive option for eco-conscious fashion brands and consumers. As the demand for sustainable fashion grows, the market for PLA-based textiles is expected to expand significantly in the coming years.

The agriculture sector presents another promising market for PLA products. Biodegradable mulch films made from PLA offer farmers an environmentally friendly alternative to traditional plastic films, reducing soil pollution and simplifying post-harvest cleanup. Additionally, PLA-based plant pots and seed trays are gaining traction in horticulture and gardening, appealing to both commercial growers and home gardeners.

The medical and healthcare industry has also shown increasing interest in PLA for various applications. Biodegradable sutures, implants, and drug delivery systems made from PLA are being developed and adopted, leveraging the material's biocompatibility and controlled degradation properties. This sector represents a high-value market segment with significant growth potential for PLA products.

As research and development efforts continue to improve PLA's performance characteristics and reduce production costs, the material is expected to find new applications in various industries. The growing market demand for PLA products is not only driven by consumer preferences but also by corporate sustainability initiatives and regulatory pressures, creating a favorable environment for the expansion of PLA use cases in everyday life settings.

Current PLA Limitations and Challenges

Despite the growing interest in PLA (Polylactic Acid) as a biodegradable alternative to traditional plastics, several limitations and challenges hinder its widespread adoption in everyday life settings. One of the primary obstacles is the higher production cost compared to conventional plastics, which makes PLA products less economically competitive in many markets. This cost differential is particularly significant for mass-produced consumer goods where price sensitivity is high.

Another challenge lies in PLA's mechanical properties. While suitable for many applications, PLA exhibits lower impact resistance and flexibility compared to some petroleum-based plastics. This limitation restricts its use in products that require high durability or elasticity, such as certain packaging materials or flexible components in consumer electronics.

The thermal stability of PLA presents another hurdle. Its relatively low heat deflection temperature limits its application in scenarios involving hot liquids or high-temperature environments. This characteristic makes PLA less suitable for certain food packaging applications, especially those requiring microwave heating or hot-fill processes.

Moisture sensitivity is an additional concern for PLA products. In high-humidity environments, PLA can absorb moisture, leading to degradation of its mechanical properties and dimensional stability. This issue complicates the use of PLA in outdoor applications or in products exposed to varying environmental conditions.

The biodegradability of PLA, while generally considered an advantage, also presents challenges in certain contexts. PLA requires specific industrial composting conditions to degrade efficiently, which are not widely available in many regions. This limitation can lead to misconceptions about its environmental benefits and potential mismanagement of PLA waste in conventional waste streams.

Furthermore, the current recycling infrastructure is not well-equipped to handle PLA separately from other plastics. This lack of dedicated recycling streams can result in PLA contaminating other plastic recycling processes, potentially reducing the overall efficiency of plastic recycling efforts.

Lastly, there are challenges related to the scalability of PLA production. While the raw materials for PLA (such as corn or sugarcane) are renewable, there are concerns about the sustainability of large-scale production, particularly regarding land use and competition with food crops. Addressing these production challenges is crucial for expanding PLA's role in everyday life applications.

Another challenge lies in PLA's mechanical properties. While suitable for many applications, PLA exhibits lower impact resistance and flexibility compared to some petroleum-based plastics. This limitation restricts its use in products that require high durability or elasticity, such as certain packaging materials or flexible components in consumer electronics.

The thermal stability of PLA presents another hurdle. Its relatively low heat deflection temperature limits its application in scenarios involving hot liquids or high-temperature environments. This characteristic makes PLA less suitable for certain food packaging applications, especially those requiring microwave heating or hot-fill processes.

Moisture sensitivity is an additional concern for PLA products. In high-humidity environments, PLA can absorb moisture, leading to degradation of its mechanical properties and dimensional stability. This issue complicates the use of PLA in outdoor applications or in products exposed to varying environmental conditions.

The biodegradability of PLA, while generally considered an advantage, also presents challenges in certain contexts. PLA requires specific industrial composting conditions to degrade efficiently, which are not widely available in many regions. This limitation can lead to misconceptions about its environmental benefits and potential mismanagement of PLA waste in conventional waste streams.

Furthermore, the current recycling infrastructure is not well-equipped to handle PLA separately from other plastics. This lack of dedicated recycling streams can result in PLA contaminating other plastic recycling processes, potentially reducing the overall efficiency of plastic recycling efforts.

Lastly, there are challenges related to the scalability of PLA production. While the raw materials for PLA (such as corn or sugarcane) are renewable, there are concerns about the sustainability of large-scale production, particularly regarding land use and competition with food crops. Addressing these production challenges is crucial for expanding PLA's role in everyday life applications.

Existing PLA Applications

01 PLA-based composite materials

Development of composite materials using PLA as a matrix, incorporating various fillers or reinforcements to enhance properties such as strength, durability, and functionality. These composites can be used in applications ranging from packaging to biomedical devices.- PLA-based composite materials: Development of composite materials using PLA as a base polymer, incorporating various additives or reinforcing agents to enhance properties such as strength, durability, or biodegradability. These composites can be used in a wide range of applications, from packaging to medical devices.

- PLA processing techniques: Innovative methods for processing PLA, including extrusion, injection molding, and 3D printing. These techniques aim to improve the material's performance, reduce production costs, and expand its potential applications in various industries.

- PLA blends and copolymers: Creation of PLA blends and copolymers with other biodegradable or synthetic polymers to achieve specific properties or overcome limitations of pure PLA. These blends can offer improved mechanical properties, thermal stability, or processability for targeted applications.

- Surface modification of PLA: Techniques for modifying the surface properties of PLA materials to enhance their functionality, such as improving adhesion, hydrophobicity, or biocompatibility. These modifications can be achieved through chemical treatments, plasma processing, or coating applications.

- PLA-based packaging solutions: Development of sustainable packaging solutions using PLA-based materials, focusing on biodegradability, compostability, and reduced environmental impact. These innovations address the growing demand for eco-friendly alternatives to traditional plastic packaging in various industries.

02 PLA processing techniques

Advancements in processing techniques for PLA, including extrusion, injection molding, and 3D printing. These methods aim to improve the manufacturability and expand the application range of PLA-based products while maintaining or enhancing their biodegradable properties.Expand Specific Solutions03 PLA modification for improved properties

Chemical and physical modifications of PLA to enhance its properties such as thermal stability, mechanical strength, and barrier properties. This includes blending with other polymers, plasticization, and surface treatments to overcome limitations of pure PLA.Expand Specific Solutions04 Biodegradable PLA applications

Development of biodegradable products using PLA for various applications including packaging, agriculture, and consumer goods. Focus on creating sustainable alternatives to traditional plastics while ensuring comparable performance and cost-effectiveness.Expand Specific Solutions05 PLA in biomedical applications

Utilization of PLA in biomedical fields, including drug delivery systems, tissue engineering scaffolds, and implantable medical devices. Research focuses on biocompatibility, controlled degradation, and functionalization of PLA for specific medical applications.Expand Specific Solutions

Key PLA Industry Players

The market for expanding PLA use cases in everyday life settings is in a growth phase, driven by increasing environmental awareness and demand for sustainable materials. The global PLA market size is projected to reach several billion dollars by 2025, with a compound annual growth rate of over 15%. Technological maturity varies across applications, with companies like NatureWorks LLC and Total Research Corp leading in PLA production and research. Emerging players such as Sulapac Oy and Galatea Biotech SRL are focusing on innovative PLA-based products for consumer goods. Academic institutions like Tongji University and the University of Milano-Bicocca are contributing to advancements in PLA technology, while established corporations like LG Chem Ltd. and Stora Enso Oyj are integrating PLA into their product lines, indicating a growing industry-wide adoption.

NatureWorks LLC

Technical Solution: NatureWorks has developed Ingeo, a biopolymer made from renewable resources like corn starch or sugarcane. This PLA-based material is used in various everyday applications such as food packaging, disposable tableware, and textiles. Their technology involves fermenting plant sugars to produce lactic acid, which is then polymerized into PLA. NatureWorks has also focused on improving the material's heat resistance and durability to expand its use in durable goods and electronics.

Strengths: Renewable sourcing, biodegradability, and versatility in applications. Weaknesses: Higher production costs compared to traditional plastics and limited high-temperature performance.

Sulapac Oy

Technical Solution: Sulapac has developed a unique biodegradable material that combines wood and natural binders. While not strictly PLA, their technology represents an innovative approach to expanding bioplastic use in everyday settings. Their material mimics plastic but is fully biodegradable and microplastic-free. Sulapac's products are primarily used in cosmetics packaging, straws, and other consumer goods, demonstrating the potential for bio-based materials in premium applications.

Strengths: Fully biodegradable, premium look and feel, suitable for luxury markets. Weaknesses: Limited to specific applications, potentially higher cost than traditional PLA.

Innovative PLA Formulations

Refreshing and relaxing fabric with painkilling properties

PatentWO2023282863A1

Innovation

- Development of a refreshing and relaxing fabric using biocompatible PLA polymer and nano-sized tourmaline additives through bicomponent fiber spinning, achieving painkilling and negative ion emission properties, suitable for medical and home textile applications, with a focus on renewable resources and biodegradability.

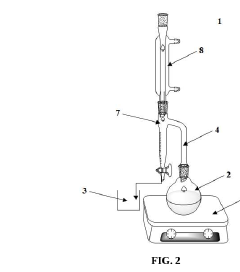

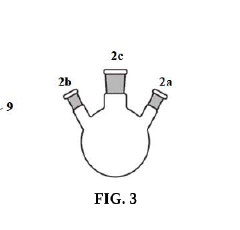

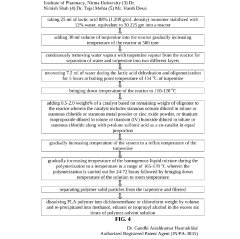

Synthesis of biopolymer polylactic acid using azeotropic polycondensation method

PatentPendingIN202421030473A

Innovation

- Azeotropic dehydrative polycondensation using turpentine, a FDA-approved green bio-solvent, is employed to synthesize PLA, allowing for solvent recovery and recycling, reducing environmental impact and operational costs.

Environmental Impact of PLA

The environmental impact of PLA (Polylactic Acid) is a crucial consideration as its use cases expand in everyday life settings. PLA, derived from renewable resources such as corn starch or sugarcane, offers a promising alternative to traditional petroleum-based plastics. Its biodegradability and compostability under specific conditions contribute to its appeal as an eco-friendly material.

One of the primary environmental benefits of PLA is its potential to reduce carbon footprint. The production of PLA generally requires less energy and generates fewer greenhouse gas emissions compared to conventional plastics. This advantage becomes more significant as PLA production scales up and manufacturing processes become more efficient.

However, the environmental impact of PLA is not without complexities. While it is biodegradable, PLA requires specific industrial composting conditions to break down effectively. In landfills or natural environments, it may persist for extended periods, potentially contributing to plastic pollution if not properly managed. This highlights the importance of developing appropriate waste management infrastructure to handle PLA products at the end of their lifecycle.

The sourcing of raw materials for PLA production also warrants consideration. As demand for PLA increases, there are concerns about the potential competition with food crops for agricultural land. This could lead to land-use changes and associated environmental impacts. Efforts to develop PLA from non-food crop sources or agricultural waste are underway to address these concerns.

Water usage in PLA production is another environmental factor to consider. While generally lower than that of petroleum-based plastics, the cultivation of crops for PLA feedstock can be water-intensive. Sustainable water management practices in agriculture are crucial to mitigate this impact.

The durability and performance of PLA in various applications can indirectly affect its environmental impact. In some cases, PLA may have a shorter lifespan or require more material to achieve the same performance as traditional plastics. This could potentially offset some of its environmental benefits if it leads to increased production and consumption.

As PLA use expands, its impact on recycling systems must be carefully managed. PLA can contaminate existing plastic recycling streams if not properly sorted. Developing separate collection and recycling infrastructure for PLA products is essential to maximize its environmental benefits and prevent unintended consequences in waste management systems.

One of the primary environmental benefits of PLA is its potential to reduce carbon footprint. The production of PLA generally requires less energy and generates fewer greenhouse gas emissions compared to conventional plastics. This advantage becomes more significant as PLA production scales up and manufacturing processes become more efficient.

However, the environmental impact of PLA is not without complexities. While it is biodegradable, PLA requires specific industrial composting conditions to break down effectively. In landfills or natural environments, it may persist for extended periods, potentially contributing to plastic pollution if not properly managed. This highlights the importance of developing appropriate waste management infrastructure to handle PLA products at the end of their lifecycle.

The sourcing of raw materials for PLA production also warrants consideration. As demand for PLA increases, there are concerns about the potential competition with food crops for agricultural land. This could lead to land-use changes and associated environmental impacts. Efforts to develop PLA from non-food crop sources or agricultural waste are underway to address these concerns.

Water usage in PLA production is another environmental factor to consider. While generally lower than that of petroleum-based plastics, the cultivation of crops for PLA feedstock can be water-intensive. Sustainable water management practices in agriculture are crucial to mitigate this impact.

The durability and performance of PLA in various applications can indirectly affect its environmental impact. In some cases, PLA may have a shorter lifespan or require more material to achieve the same performance as traditional plastics. This could potentially offset some of its environmental benefits if it leads to increased production and consumption.

As PLA use expands, its impact on recycling systems must be carefully managed. PLA can contaminate existing plastic recycling streams if not properly sorted. Developing separate collection and recycling infrastructure for PLA products is essential to maximize its environmental benefits and prevent unintended consequences in waste management systems.

PLA Regulatory Framework

The regulatory framework for PLA (Polylactic Acid) plays a crucial role in expanding its use cases in everyday life settings. As a biodegradable and renewable material, PLA has gained significant attention from regulatory bodies worldwide. The United States Food and Drug Administration (FDA) has approved PLA for food contact applications, including packaging and disposable utensils. This approval has paved the way for widespread adoption in the food industry, promoting sustainable alternatives to traditional plastics.

In the European Union, PLA falls under the broader category of bioplastics and is regulated by the European Food Safety Authority (EFSA). The EFSA has established guidelines for the use of PLA in food contact materials, ensuring its safety for consumers. These regulations have facilitated the integration of PLA into various everyday products, from food packaging to disposable tableware.

Japan, known for its advanced recycling systems, has incorporated PLA into its regulatory framework for biodegradable plastics. The Japanese government has implemented policies to promote the use of bioplastics, including PLA, in various consumer goods. This regulatory support has led to increased adoption of PLA in everyday items such as shopping bags, beverage bottles, and electronics casings.

China, recognizing the potential of PLA in addressing plastic pollution, has introduced standards for biodegradable plastics. The Chinese government has set targets for increasing the use of biodegradable materials, including PLA, in packaging and disposable products. These regulatory measures have stimulated research and development in PLA applications, leading to innovative products in the Chinese market.

Globally, the regulatory landscape for PLA is evolving to address environmental concerns and promote sustainable materials. Many countries are implementing regulations that favor biodegradable plastics, creating a conducive environment for PLA adoption. These regulations often include incentives for manufacturers to switch to eco-friendly materials and penalties for the use of non-biodegradable plastics.

As PLA gains traction in everyday life settings, regulatory bodies are also focusing on end-of-life management. Composting regulations are being updated to include PLA and other bioplastics, ensuring proper disposal and biodegradation. This regulatory support for composting infrastructure is crucial for realizing the full environmental benefits of PLA in various applications.

In the European Union, PLA falls under the broader category of bioplastics and is regulated by the European Food Safety Authority (EFSA). The EFSA has established guidelines for the use of PLA in food contact materials, ensuring its safety for consumers. These regulations have facilitated the integration of PLA into various everyday products, from food packaging to disposable tableware.

Japan, known for its advanced recycling systems, has incorporated PLA into its regulatory framework for biodegradable plastics. The Japanese government has implemented policies to promote the use of bioplastics, including PLA, in various consumer goods. This regulatory support has led to increased adoption of PLA in everyday items such as shopping bags, beverage bottles, and electronics casings.

China, recognizing the potential of PLA in addressing plastic pollution, has introduced standards for biodegradable plastics. The Chinese government has set targets for increasing the use of biodegradable materials, including PLA, in packaging and disposable products. These regulatory measures have stimulated research and development in PLA applications, leading to innovative products in the Chinese market.

Globally, the regulatory landscape for PLA is evolving to address environmental concerns and promote sustainable materials. Many countries are implementing regulations that favor biodegradable plastics, creating a conducive environment for PLA adoption. These regulations often include incentives for manufacturers to switch to eco-friendly materials and penalties for the use of non-biodegradable plastics.

As PLA gains traction in everyday life settings, regulatory bodies are also focusing on end-of-life management. Composting regulations are being updated to include PLA and other bioplastics, ensuring proper disposal and biodegradation. This regulatory support for composting infrastructure is crucial for realizing the full environmental benefits of PLA in various applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!