Diving into the Chemistry of PLA Modifications

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PLA Chemistry Background and Objectives

Polylactic acid (PLA) has emerged as a prominent biodegradable polymer in recent years, gaining significant attention due to its renewable sourcing and eco-friendly characteristics. The development of PLA chemistry has its roots in the early 20th century, with pioneering work by Wallace Carothers at DuPont. However, it wasn't until the late 1980s and early 1990s that PLA began to gain traction as a viable alternative to petroleum-based plastics.

The evolution of PLA chemistry has been driven by the increasing demand for sustainable materials across various industries, including packaging, textiles, and biomedical applications. As environmental concerns have grown, so too has the interest in developing biodegradable polymers that can reduce our reliance on fossil fuel-derived plastics. This has led to a surge in research and development efforts focused on improving PLA's properties and expanding its potential applications.

One of the key objectives in PLA chemistry research is to enhance the polymer's mechanical properties. While PLA offers excellent biocompatibility and biodegradability, its brittleness and low heat resistance have limited its use in certain applications. Researchers are exploring various modification techniques to overcome these limitations, including copolymerization, blending with other polymers, and the incorporation of nanofillers.

Another important goal in PLA chemistry is to improve the polymer's processability. This involves developing new catalysts and polymerization methods to achieve better control over molecular weight distribution and stereochemistry. By fine-tuning these parameters, researchers aim to create PLA grades with tailored properties for specific end-use applications.

The modification of PLA's surface properties is also a critical area of focus. Researchers are investigating methods to enhance the polymer's hydrophilicity, adhesion, and barrier properties. These modifications are particularly important for applications in packaging and biomedical fields, where controlled interactions with the surrounding environment are crucial.

As we look to the future, the objectives of PLA chemistry research are expanding to include the development of more efficient and sustainable production methods. This includes exploring new feedstocks for lactic acid production, such as lignocellulosic biomass and food waste, as well as investigating novel polymerization techniques that reduce energy consumption and minimize the use of harmful solvents.

In conclusion, the field of PLA chemistry is at an exciting juncture, with ongoing research aimed at addressing current limitations and unlocking new possibilities for this versatile biopolymer. The ultimate goal is to position PLA as a viable, sustainable alternative to conventional plastics across a wide range of applications, contributing to a more circular and environmentally friendly economy.

The evolution of PLA chemistry has been driven by the increasing demand for sustainable materials across various industries, including packaging, textiles, and biomedical applications. As environmental concerns have grown, so too has the interest in developing biodegradable polymers that can reduce our reliance on fossil fuel-derived plastics. This has led to a surge in research and development efforts focused on improving PLA's properties and expanding its potential applications.

One of the key objectives in PLA chemistry research is to enhance the polymer's mechanical properties. While PLA offers excellent biocompatibility and biodegradability, its brittleness and low heat resistance have limited its use in certain applications. Researchers are exploring various modification techniques to overcome these limitations, including copolymerization, blending with other polymers, and the incorporation of nanofillers.

Another important goal in PLA chemistry is to improve the polymer's processability. This involves developing new catalysts and polymerization methods to achieve better control over molecular weight distribution and stereochemistry. By fine-tuning these parameters, researchers aim to create PLA grades with tailored properties for specific end-use applications.

The modification of PLA's surface properties is also a critical area of focus. Researchers are investigating methods to enhance the polymer's hydrophilicity, adhesion, and barrier properties. These modifications are particularly important for applications in packaging and biomedical fields, where controlled interactions with the surrounding environment are crucial.

As we look to the future, the objectives of PLA chemistry research are expanding to include the development of more efficient and sustainable production methods. This includes exploring new feedstocks for lactic acid production, such as lignocellulosic biomass and food waste, as well as investigating novel polymerization techniques that reduce energy consumption and minimize the use of harmful solvents.

In conclusion, the field of PLA chemistry is at an exciting juncture, with ongoing research aimed at addressing current limitations and unlocking new possibilities for this versatile biopolymer. The ultimate goal is to position PLA as a viable, sustainable alternative to conventional plastics across a wide range of applications, contributing to a more circular and environmentally friendly economy.

Market Analysis for Modified PLA

The market for modified PLA (Polylactic Acid) has been experiencing significant growth in recent years, driven by increasing environmental concerns and the push for sustainable alternatives to traditional plastics. The global modified PLA market is expected to expand at a compound annual growth rate (CAGR) of over 10% from 2021 to 2026. This growth is primarily fueled by the rising demand for biodegradable plastics in various industries, including packaging, automotive, and consumer goods.

One of the key factors driving the market is the growing awareness of environmental issues and the need for eco-friendly materials. Governments worldwide are implementing stringent regulations to reduce plastic waste, which has led to increased adoption of biodegradable plastics like modified PLA. The packaging industry, in particular, has emerged as a major consumer of modified PLA, with applications ranging from food packaging to disposable cutlery and containers.

The automotive sector is another significant market for modified PLA, as manufacturers seek to reduce vehicle weight and improve fuel efficiency. Modified PLA composites are being used in interior components, reducing the overall weight of vehicles while maintaining performance standards. This trend is expected to continue as automakers strive to meet increasingly stringent emissions regulations.

In the consumer goods sector, modified PLA is finding applications in various products, from electronics casings to textile fibers. The material's versatility and improved properties through modification have opened up new possibilities for product designers and manufacturers looking to create more sustainable offerings.

Geographically, North America and Europe are currently the largest markets for modified PLA, owing to stringent environmental regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing disposable incomes, and growing environmental consciousness in countries like China and India.

Despite the positive outlook, the modified PLA market faces challenges. The higher cost of production compared to conventional plastics remains a significant barrier to widespread adoption. Additionally, the limited availability of industrial composting facilities in many regions hinders the proper disposal and recycling of PLA products, potentially impacting its environmental benefits.

To address these challenges, ongoing research and development efforts are focused on improving the cost-effectiveness of PLA production and enhancing its properties through various modification techniques. These advancements are expected to further expand the application scope of modified PLA and drive market growth in the coming years.

One of the key factors driving the market is the growing awareness of environmental issues and the need for eco-friendly materials. Governments worldwide are implementing stringent regulations to reduce plastic waste, which has led to increased adoption of biodegradable plastics like modified PLA. The packaging industry, in particular, has emerged as a major consumer of modified PLA, with applications ranging from food packaging to disposable cutlery and containers.

The automotive sector is another significant market for modified PLA, as manufacturers seek to reduce vehicle weight and improve fuel efficiency. Modified PLA composites are being used in interior components, reducing the overall weight of vehicles while maintaining performance standards. This trend is expected to continue as automakers strive to meet increasingly stringent emissions regulations.

In the consumer goods sector, modified PLA is finding applications in various products, from electronics casings to textile fibers. The material's versatility and improved properties through modification have opened up new possibilities for product designers and manufacturers looking to create more sustainable offerings.

Geographically, North America and Europe are currently the largest markets for modified PLA, owing to stringent environmental regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing disposable incomes, and growing environmental consciousness in countries like China and India.

Despite the positive outlook, the modified PLA market faces challenges. The higher cost of production compared to conventional plastics remains a significant barrier to widespread adoption. Additionally, the limited availability of industrial composting facilities in many regions hinders the proper disposal and recycling of PLA products, potentially impacting its environmental benefits.

To address these challenges, ongoing research and development efforts are focused on improving the cost-effectiveness of PLA production and enhancing its properties through various modification techniques. These advancements are expected to further expand the application scope of modified PLA and drive market growth in the coming years.

Current PLA Modification Techniques and Challenges

Polylactic acid (PLA) modification techniques have evolved significantly in recent years, addressing various challenges and limitations of unmodified PLA. Current modification approaches primarily focus on enhancing PLA's mechanical properties, thermal stability, and biodegradation rates to expand its applications in diverse industries.

One of the most widely employed modification techniques is blending PLA with other polymers or additives. This method allows for the tailoring of PLA's properties without altering its fundamental chemical structure. Common blending agents include other biodegradable polymers like polyhydroxyalkanoates (PHAs) or non-biodegradable polymers such as polypropylene. These blends often result in improved mechanical strength, flexibility, and impact resistance.

Surface modification techniques have gained prominence in addressing PLA's hydrophobicity and limited cell adhesion properties. Plasma treatment, UV irradiation, and chemical etching are frequently used to modify PLA's surface characteristics. These methods can enhance the material's wettability, printability, and biocompatibility, making it more suitable for medical and packaging applications.

Copolymerization represents another significant approach to PLA modification. By introducing different monomers during the polymerization process, researchers can create PLA-based copolymers with enhanced properties. For instance, copolymerization with caprolactone can improve PLA's flexibility and impact strength, while copolymerization with glycolic acid can alter its degradation rate.

Nanocomposite formation has emerged as a promising technique for enhancing PLA's properties. Incorporating nanofillers such as clay, carbon nanotubes, or cellulose nanocrystals can significantly improve the material's mechanical strength, barrier properties, and thermal stability. These nanocomposites often exhibit superior performance compared to conventional PLA blends.

Despite these advancements, several challenges persist in PLA modification. Maintaining biodegradability while improving mechanical and thermal properties remains a significant hurdle. Many modification techniques that enhance PLA's performance often compromise its biodegradability, limiting its eco-friendly appeal. Additionally, achieving consistent and reproducible results across different modification methods poses a challenge, particularly in large-scale production settings.

The cost-effectiveness of modification techniques is another critical challenge. Some advanced modification methods, especially those involving nanocomposites or complex copolymerization, can significantly increase production costs, potentially limiting their commercial viability. Balancing enhanced properties with economic feasibility remains a key consideration for industry adoption.

Furthermore, the long-term stability and performance of modified PLA products under various environmental conditions require extensive testing and validation. This is particularly crucial for applications in sectors like medical implants or long-term packaging, where material reliability is paramount.

One of the most widely employed modification techniques is blending PLA with other polymers or additives. This method allows for the tailoring of PLA's properties without altering its fundamental chemical structure. Common blending agents include other biodegradable polymers like polyhydroxyalkanoates (PHAs) or non-biodegradable polymers such as polypropylene. These blends often result in improved mechanical strength, flexibility, and impact resistance.

Surface modification techniques have gained prominence in addressing PLA's hydrophobicity and limited cell adhesion properties. Plasma treatment, UV irradiation, and chemical etching are frequently used to modify PLA's surface characteristics. These methods can enhance the material's wettability, printability, and biocompatibility, making it more suitable for medical and packaging applications.

Copolymerization represents another significant approach to PLA modification. By introducing different monomers during the polymerization process, researchers can create PLA-based copolymers with enhanced properties. For instance, copolymerization with caprolactone can improve PLA's flexibility and impact strength, while copolymerization with glycolic acid can alter its degradation rate.

Nanocomposite formation has emerged as a promising technique for enhancing PLA's properties. Incorporating nanofillers such as clay, carbon nanotubes, or cellulose nanocrystals can significantly improve the material's mechanical strength, barrier properties, and thermal stability. These nanocomposites often exhibit superior performance compared to conventional PLA blends.

Despite these advancements, several challenges persist in PLA modification. Maintaining biodegradability while improving mechanical and thermal properties remains a significant hurdle. Many modification techniques that enhance PLA's performance often compromise its biodegradability, limiting its eco-friendly appeal. Additionally, achieving consistent and reproducible results across different modification methods poses a challenge, particularly in large-scale production settings.

The cost-effectiveness of modification techniques is another critical challenge. Some advanced modification methods, especially those involving nanocomposites or complex copolymerization, can significantly increase production costs, potentially limiting their commercial viability. Balancing enhanced properties with economic feasibility remains a key consideration for industry adoption.

Furthermore, the long-term stability and performance of modified PLA products under various environmental conditions require extensive testing and validation. This is particularly crucial for applications in sectors like medical implants or long-term packaging, where material reliability is paramount.

Existing PLA Modification Solutions

01 Biodegradability and compostability

PLA is known for its biodegradable and compostable properties, making it an environmentally friendly alternative to traditional plastics. It can break down into natural components under specific conditions, reducing environmental impact.- Biodegradability and compostability: PLA is known for its biodegradable and compostable properties. It can break down into natural components under specific environmental conditions, making it an eco-friendly alternative to traditional plastics. This characteristic is particularly valuable in applications where environmental impact is a concern.

- Thermal properties and processing: PLA exhibits unique thermal properties that affect its processing and application. It has a relatively low melting point and glass transition temperature compared to some conventional plastics. These properties influence its behavior during manufacturing processes such as injection molding, extrusion, and 3D printing.

- Mechanical properties and strength: The mechanical properties of PLA, including tensile strength, flexural modulus, and impact resistance, are comparable to some traditional plastics. However, these properties can vary depending on the molecular weight, crystallinity, and processing conditions. PLA's mechanical characteristics make it suitable for various applications, from packaging to medical devices.

- Chemical resistance and stability: PLA demonstrates good resistance to certain chemicals, oils, and greases. However, it is susceptible to hydrolysis in the presence of moisture and high temperatures. Understanding its chemical stability is crucial for determining appropriate applications and storage conditions for PLA-based products.

- Optical and surface properties: PLA possesses high transparency and gloss, making it suitable for applications requiring clear or aesthetically pleasing materials. Its surface properties can be modified through various treatments to enhance characteristics such as printability, adhesion, or barrier properties, expanding its potential uses in packaging and consumer goods.

02 Thermal properties and processing

PLA exhibits unique thermal properties, including a relatively low melting point and glass transition temperature. These characteristics influence its processing methods, such as injection molding, extrusion, and 3D printing, making it suitable for various manufacturing applications.Expand Specific Solutions03 Mechanical properties and modifications

PLA possesses moderate mechanical strength and stiffness, but can be brittle. Various modifications and blending techniques can be employed to enhance its mechanical properties, such as impact resistance and flexibility, to suit different applications.Expand Specific Solutions04 Chemical resistance and barrier properties

PLA demonstrates good resistance to certain chemicals and solvents, but may be susceptible to hydrolysis in high moisture environments. It also exhibits moderate barrier properties against gases and moisture, which can be improved through various treatments or coatings.Expand Specific Solutions05 Optical and surface properties

PLA is known for its high transparency and glossy surface finish, making it suitable for packaging and consumer goods applications. Its surface properties can be modified through various treatments to enhance printability, adhesion, or other desired characteristics.Expand Specific Solutions

Key Players in PLA Modification Industry

The competitive landscape for PLA modifications is evolving rapidly, with the market currently in a growth phase. The global PLA market size is expanding, driven by increasing demand for sustainable materials. Technologically, PLA modifications are advancing, with companies like NatureWorks LLC, Total Petrochemicals & Refining USA, Inc., and DuPont de Nemours, Inc. leading innovation. Research institutions such as Changchun Institute of Applied Chemistry and universities like Tongji University are contributing to technological maturity. The industry sees a mix of established chemical companies and specialized bioplastics firms, with emerging players from diverse geographical regions, indicating a dynamic and competitive environment.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed a range of PLA modifications, including their Biomax® Strong additive. This technology enhances PLA's heat resistance and impact strength through reactive extrusion. The process involves adding a multifunctional epoxy-based chain extender during melt processing, which reacts with PLA end groups to increase molecular weight and introduce branching. This modification significantly improves PLA's thermal stability, allowing it to withstand higher temperatures without deformation, and enhances its mechanical properties, particularly impact resistance.

Strengths: Improved heat resistance and impact strength, enhancing PLA's applicability in durable goods. Weaknesses: May increase production costs and complexity of processing.

NatureWorks LLC

Technical Solution: NatureWorks, a leading producer of PLA, has developed Ingeo™ biopolymers with various modifications. Their technology focuses on controlling the stereochemistry of PLA during polymerization to create different grades with tailored properties. By adjusting the ratio of L-lactide to D-lactide monomers, they can produce PLA with varying crystallinity, melt temperatures, and mechanical properties. Additionally, they have developed nucleating agents and impact modifiers specifically for PLA, allowing for faster crystallization rates and improved toughness in end products.

Strengths: Wide range of PLA grades for different applications, from packaging to durable goods. Weaknesses: Some modifications may compromise PLA's biodegradability.

Innovative PLA Modification Approaches

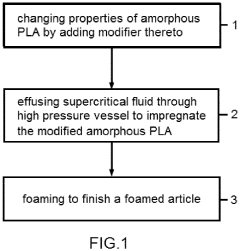

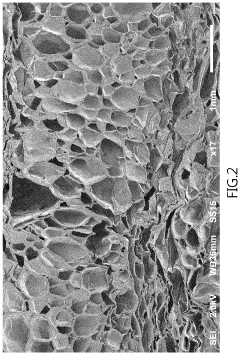

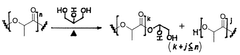

Foam molding process by modifying amorphous PLA

PatentActiveUS20210069947A1

Innovation

- A microcellular foam molding process is developed by using a chain extender or nucleating agent to modify the properties of amorphous PLA, followed by impregnation with a supercritical fluid in a high-pressure vessel, forming foamed pellets, and then processing them in a mold with controlled heating and cooling to produce foamed articles with improved density and physical properties.

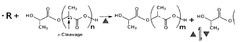

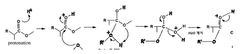

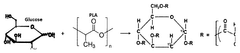

PLA modifying method using saccharide or carboxylic group substituent of saccharide, and PLA modified thereby

PatentWO2023027394A1

Innovation

- Adding saccharides or carboxyl group substituents to high molecular weight PLA, followed by heating and melting to induce hydrolysis and branching reactions, resulting in a low-molecular-weight multi-polymer with increased melt strength, enhancing the polymer's ultra-fine and ultra-thin properties.

Environmental Impact of PLA Modifications

The environmental impact of PLA modifications is a crucial aspect to consider in the development and application of this biodegradable polymer. PLA, or polylactic acid, is already known for its eco-friendly properties, but modifications can further enhance or potentially compromise its environmental profile.

One of the primary environmental benefits of PLA modifications is the potential for improved biodegradability. Certain chemical modifications can accelerate the rate at which PLA breaks down in natural environments, reducing its long-term impact on ecosystems. For instance, the incorporation of hydrophilic groups into the PLA structure can increase its susceptibility to hydrolysis, facilitating faster decomposition in various environmental conditions.

However, it is essential to note that some modifications may introduce new environmental concerns. The addition of certain chemical additives or cross-linking agents could potentially introduce toxicity or persistence issues that are not present in unmodified PLA. This underscores the importance of thorough lifecycle assessments for modified PLA materials to ensure that environmental benefits are not offset by unintended consequences.

The production processes for PLA modifications also warrant environmental scrutiny. While some modifications may be achieved through relatively benign methods, others might require energy-intensive processes or the use of hazardous chemicals. The environmental footprint of these production methods must be weighed against the potential benefits of the resulting modified PLA materials.

Another significant environmental consideration is the impact of PLA modifications on recycling and waste management systems. Some modifications may enhance the recyclability of PLA, allowing for more efficient recovery and reuse of the material. Conversely, certain modifications could complicate existing recycling processes, potentially leading to increased waste if not properly managed.

The use of renewable resources in PLA modifications presents an opportunity for further environmental improvement. Modifications that incorporate bio-based additives or utilize green chemistry principles can enhance the overall sustainability profile of PLA products. This aligns with the growing demand for materials with reduced reliance on fossil fuel-derived components.

Lastly, the potential for PLA modifications to extend product lifespans or improve material performance can have indirect environmental benefits. By enhancing durability or specific properties, modified PLA may reduce the need for frequent replacements or the use of less environmentally friendly alternatives in certain applications.

One of the primary environmental benefits of PLA modifications is the potential for improved biodegradability. Certain chemical modifications can accelerate the rate at which PLA breaks down in natural environments, reducing its long-term impact on ecosystems. For instance, the incorporation of hydrophilic groups into the PLA structure can increase its susceptibility to hydrolysis, facilitating faster decomposition in various environmental conditions.

However, it is essential to note that some modifications may introduce new environmental concerns. The addition of certain chemical additives or cross-linking agents could potentially introduce toxicity or persistence issues that are not present in unmodified PLA. This underscores the importance of thorough lifecycle assessments for modified PLA materials to ensure that environmental benefits are not offset by unintended consequences.

The production processes for PLA modifications also warrant environmental scrutiny. While some modifications may be achieved through relatively benign methods, others might require energy-intensive processes or the use of hazardous chemicals. The environmental footprint of these production methods must be weighed against the potential benefits of the resulting modified PLA materials.

Another significant environmental consideration is the impact of PLA modifications on recycling and waste management systems. Some modifications may enhance the recyclability of PLA, allowing for more efficient recovery and reuse of the material. Conversely, certain modifications could complicate existing recycling processes, potentially leading to increased waste if not properly managed.

The use of renewable resources in PLA modifications presents an opportunity for further environmental improvement. Modifications that incorporate bio-based additives or utilize green chemistry principles can enhance the overall sustainability profile of PLA products. This aligns with the growing demand for materials with reduced reliance on fossil fuel-derived components.

Lastly, the potential for PLA modifications to extend product lifespans or improve material performance can have indirect environmental benefits. By enhancing durability or specific properties, modified PLA may reduce the need for frequent replacements or the use of less environmentally friendly alternatives in certain applications.

Regulatory Framework for Modified PLA

The regulatory framework for modified PLA is a critical aspect of its development and commercialization. As the interest in biodegradable and sustainable materials grows, governments and regulatory bodies worldwide have been adapting their policies to accommodate these innovative materials. The European Union, through its European Chemicals Agency (ECHA), has been at the forefront of regulating bioplastics, including modified PLA. The EU's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation applies to PLA and its modifications, requiring manufacturers to register and provide safety data for new substances.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating modified PLA, especially for food contact applications. The FDA's Food Contact Notification (FCN) program provides a streamlined process for manufacturers to obtain clearance for new food contact substances, including modified PLA. Additionally, the Environmental Protection Agency (EPA) oversees the environmental impact of these materials under the Toxic Substances Control Act (TSCA).

Japan, a leader in bioplastics research and development, has established the BiomassPla certification system, which sets standards for biodegradable plastics, including modified PLA. This system ensures that materials meet specific criteria for biodegradability and biomass content. Similarly, China has implemented the GB/T 20197 standard for biodegradable plastics, which includes requirements for PLA and its modifications.

International standards organizations, such as ASTM International and the International Organization for Standardization (ISO), have developed specific standards for biodegradable plastics. These include ASTM D6400 and ISO 17088, which set criteria for compostability and biodegradation of plastics. Modified PLA must often meet these standards to be marketed as biodegradable or compostable.

As the field of PLA modifications continues to evolve, regulatory frameworks are expected to adapt. There is a growing emphasis on life cycle assessments and circular economy principles in regulatory approaches. Future regulations may focus more on the end-of-life management of modified PLA products, encouraging designs that facilitate recycling or composting. Additionally, as new modification techniques emerge, regulators may need to develop more specific guidelines to address potential environmental and health impacts of these novel materials.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating modified PLA, especially for food contact applications. The FDA's Food Contact Notification (FCN) program provides a streamlined process for manufacturers to obtain clearance for new food contact substances, including modified PLA. Additionally, the Environmental Protection Agency (EPA) oversees the environmental impact of these materials under the Toxic Substances Control Act (TSCA).

Japan, a leader in bioplastics research and development, has established the BiomassPla certification system, which sets standards for biodegradable plastics, including modified PLA. This system ensures that materials meet specific criteria for biodegradability and biomass content. Similarly, China has implemented the GB/T 20197 standard for biodegradable plastics, which includes requirements for PLA and its modifications.

International standards organizations, such as ASTM International and the International Organization for Standardization (ISO), have developed specific standards for biodegradable plastics. These include ASTM D6400 and ISO 17088, which set criteria for compostability and biodegradation of plastics. Modified PLA must often meet these standards to be marketed as biodegradable or compostable.

As the field of PLA modifications continues to evolve, regulatory frameworks are expected to adapt. There is a growing emphasis on life cycle assessments and circular economy principles in regulatory approaches. Future regulations may focus more on the end-of-life management of modified PLA products, encouraging designs that facilitate recycling or composting. Additionally, as new modification techniques emerge, regulators may need to develop more specific guidelines to address potential environmental and health impacts of these novel materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!