How to Design with PLA for Structural Integrity?

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PLA Design Background and Objectives

Polylactic acid (PLA) has emerged as a prominent biodegradable polymer in recent years, gaining significant attention in various industries due to its eco-friendly properties and versatile applications. The evolution of PLA technology has been driven by the growing demand for sustainable materials and the need to reduce environmental impact across multiple sectors.

The development of PLA can be traced back to the 1930s when Wallace Carothers first synthesized the polymer. However, it wasn't until the late 20th century that PLA gained traction as a viable alternative to traditional petroleum-based plastics. The technological advancements in fermentation processes and polymer science have significantly improved PLA production efficiency and material properties over the past few decades.

In recent years, the focus has shifted towards enhancing PLA's structural integrity to expand its applications beyond packaging and disposable items. This technological trend aims to address the limitations of PLA, such as its relatively low heat resistance and mechanical strength compared to conventional plastics.

The primary objective in designing with PLA for structural integrity is to develop innovative solutions that can overcome these inherent limitations while maintaining the material's biodegradability and eco-friendly characteristics. This involves exploring various strategies, including polymer blending, composite formulations, and novel processing techniques to enhance PLA's mechanical properties and thermal stability.

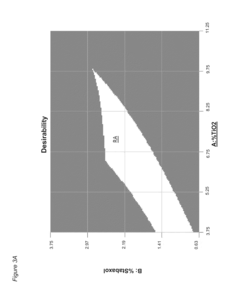

One of the key goals is to improve PLA's crystallinity, which directly impacts its structural performance. Researchers and engineers are investigating methods to control and optimize the crystallization process, aiming to achieve a balance between strength, toughness, and biodegradability. This includes the development of nucleating agents and the fine-tuning of processing parameters to manipulate the material's microstructure.

Another critical objective is to enhance PLA's durability and long-term performance under various environmental conditions. This involves addressing issues such as hydrolytic degradation and thermal aging, which can compromise the structural integrity of PLA-based products over time. Researchers are exploring surface modification techniques and the incorporation of stabilizers to improve PLA's resistance to environmental factors without sacrificing its biodegradability.

The pursuit of these technological goals is driven by the increasing demand for sustainable materials in industries such as automotive, construction, and consumer goods. As environmental regulations become more stringent and consumer awareness of ecological issues grows, the pressure to develop high-performance, bio-based materials like PLA continues to mount.

The development of PLA can be traced back to the 1930s when Wallace Carothers first synthesized the polymer. However, it wasn't until the late 20th century that PLA gained traction as a viable alternative to traditional petroleum-based plastics. The technological advancements in fermentation processes and polymer science have significantly improved PLA production efficiency and material properties over the past few decades.

In recent years, the focus has shifted towards enhancing PLA's structural integrity to expand its applications beyond packaging and disposable items. This technological trend aims to address the limitations of PLA, such as its relatively low heat resistance and mechanical strength compared to conventional plastics.

The primary objective in designing with PLA for structural integrity is to develop innovative solutions that can overcome these inherent limitations while maintaining the material's biodegradability and eco-friendly characteristics. This involves exploring various strategies, including polymer blending, composite formulations, and novel processing techniques to enhance PLA's mechanical properties and thermal stability.

One of the key goals is to improve PLA's crystallinity, which directly impacts its structural performance. Researchers and engineers are investigating methods to control and optimize the crystallization process, aiming to achieve a balance between strength, toughness, and biodegradability. This includes the development of nucleating agents and the fine-tuning of processing parameters to manipulate the material's microstructure.

Another critical objective is to enhance PLA's durability and long-term performance under various environmental conditions. This involves addressing issues such as hydrolytic degradation and thermal aging, which can compromise the structural integrity of PLA-based products over time. Researchers are exploring surface modification techniques and the incorporation of stabilizers to improve PLA's resistance to environmental factors without sacrificing its biodegradability.

The pursuit of these technological goals is driven by the increasing demand for sustainable materials in industries such as automotive, construction, and consumer goods. As environmental regulations become more stringent and consumer awareness of ecological issues grows, the pressure to develop high-performance, bio-based materials like PLA continues to mount.

Market Analysis for PLA Structural Applications

The market for PLA (Polylactic Acid) in structural applications has been experiencing significant growth in recent years, driven by increasing environmental concerns and the push for sustainable materials. PLA, a biodegradable and renewable thermoplastic derived from plant-based sources, has emerged as a promising alternative to traditional petroleum-based plastics in various structural applications.

The global PLA market is projected to expand at a compound annual growth rate (CAGR) of over 15% from 2021 to 2026. This growth is primarily attributed to the rising demand for eco-friendly materials in industries such as automotive, construction, and consumer goods. The automotive sector, in particular, has shown a keen interest in PLA-based composites for interior components and non-structural parts, aiming to reduce vehicle weight and improve fuel efficiency while meeting sustainability goals.

In the construction industry, PLA-based materials are gaining traction for applications such as insulation, paneling, and temporary structures. The material's biodegradability and low environmental impact make it an attractive option for green building initiatives. Additionally, the consumer goods sector has seen an uptick in the use of PLA for durable products, packaging, and disposable items, driven by consumer preferences for environmentally responsible products.

The market demand for PLA in structural applications is further bolstered by supportive government regulations and policies promoting the use of biodegradable materials. Many countries have implemented stringent environmental regulations, incentivizing manufacturers to adopt sustainable materials like PLA. This regulatory landscape is expected to continue driving market growth in the coming years.

However, challenges remain in the widespread adoption of PLA for structural applications. The material's relatively higher cost compared to conventional plastics and limitations in mechanical properties, such as impact resistance and heat deflection temperature, have hindered its use in certain high-performance applications. Ongoing research and development efforts are focused on addressing these challenges through improved formulations, blending with other materials, and advanced processing techniques.

The competitive landscape of the PLA market for structural applications is characterized by a mix of established chemical companies and innovative startups. Key players are investing in research and development to enhance PLA's properties and expand its application range. Collaborations between material suppliers, manufacturers, and end-users are becoming increasingly common to develop tailored PLA-based solutions for specific structural requirements.

Looking ahead, the market for PLA in structural applications is poised for continued growth. Advancements in PLA production technologies, coupled with increasing environmental awareness and regulatory support, are expected to drive further adoption across various industries. As the material's performance characteristics improve and costs decrease, PLA is likely to penetrate more demanding structural applications, potentially challenging traditional materials in sectors previously dominated by petroleum-based plastics.

The global PLA market is projected to expand at a compound annual growth rate (CAGR) of over 15% from 2021 to 2026. This growth is primarily attributed to the rising demand for eco-friendly materials in industries such as automotive, construction, and consumer goods. The automotive sector, in particular, has shown a keen interest in PLA-based composites for interior components and non-structural parts, aiming to reduce vehicle weight and improve fuel efficiency while meeting sustainability goals.

In the construction industry, PLA-based materials are gaining traction for applications such as insulation, paneling, and temporary structures. The material's biodegradability and low environmental impact make it an attractive option for green building initiatives. Additionally, the consumer goods sector has seen an uptick in the use of PLA for durable products, packaging, and disposable items, driven by consumer preferences for environmentally responsible products.

The market demand for PLA in structural applications is further bolstered by supportive government regulations and policies promoting the use of biodegradable materials. Many countries have implemented stringent environmental regulations, incentivizing manufacturers to adopt sustainable materials like PLA. This regulatory landscape is expected to continue driving market growth in the coming years.

However, challenges remain in the widespread adoption of PLA for structural applications. The material's relatively higher cost compared to conventional plastics and limitations in mechanical properties, such as impact resistance and heat deflection temperature, have hindered its use in certain high-performance applications. Ongoing research and development efforts are focused on addressing these challenges through improved formulations, blending with other materials, and advanced processing techniques.

The competitive landscape of the PLA market for structural applications is characterized by a mix of established chemical companies and innovative startups. Key players are investing in research and development to enhance PLA's properties and expand its application range. Collaborations between material suppliers, manufacturers, and end-users are becoming increasingly common to develop tailored PLA-based solutions for specific structural requirements.

Looking ahead, the market for PLA in structural applications is poised for continued growth. Advancements in PLA production technologies, coupled with increasing environmental awareness and regulatory support, are expected to drive further adoption across various industries. As the material's performance characteristics improve and costs decrease, PLA is likely to penetrate more demanding structural applications, potentially challenging traditional materials in sectors previously dominated by petroleum-based plastics.

PLA Structural Challenges and Limitations

Polylactic acid (PLA) has gained significant attention in structural applications due to its biodegradability and renewable sourcing. However, designing with PLA for structural integrity presents several challenges and limitations that must be addressed to ensure reliable performance.

One of the primary challenges is PLA's inherent brittleness and low impact resistance. This characteristic makes PLA susceptible to sudden failure under high-stress conditions or impact loads, limiting its use in applications requiring high toughness. The material's low glass transition temperature, typically around 60°C, further restricts its use in high-temperature environments, as it can lead to softening and deformation under moderate heat exposure.

PLA also exhibits relatively low mechanical strength compared to traditional engineering plastics, particularly in terms of tensile and flexural properties. This limitation necessitates careful consideration of load-bearing requirements and often results in the need for thicker wall sections or additional reinforcement in structural designs. The material's tendency to creep under sustained loads further complicates long-term structural applications, potentially leading to dimensional instability and reduced load-bearing capacity over time.

Moisture sensitivity is another significant challenge when designing with PLA for structural integrity. The material can absorb moisture from the environment, leading to hydrolysis and degradation of mechanical properties. This sensitivity not only affects the long-term durability of PLA structures but also complicates processing and storage requirements.

The biodegradability of PLA, while advantageous from an environmental perspective, poses challenges for long-term structural applications. The material's susceptibility to degradation in various environments can lead to a gradual loss of mechanical properties over time, potentially compromising structural integrity. This characteristic necessitates careful consideration of the intended service life and environmental conditions in which the PLA structure will be used.

PLA's limited thermal stability during processing presents additional challenges in manufacturing structural components. The narrow processing window can lead to thermal degradation, affecting the material's mechanical properties and potentially introducing defects in the final product. This limitation requires precise control of processing parameters and often restricts the use of certain manufacturing techniques commonly employed with other thermoplastics.

Furthermore, the anisotropic behavior of PLA in 3D printed structures adds complexity to design considerations. The layer-by-layer deposition process can result in directional variations in mechanical properties, potentially leading to unexpected failure modes if not properly accounted for in the design phase.

Addressing these challenges and limitations requires innovative approaches in material formulation, processing techniques, and design strategies. Ongoing research focuses on developing PLA blends and composites to enhance mechanical properties, improve thermal stability, and reduce moisture sensitivity. Additionally, advanced design methodologies, such as topology optimization and generative design, are being explored to maximize the structural performance of PLA components within its inherent material constraints.

One of the primary challenges is PLA's inherent brittleness and low impact resistance. This characteristic makes PLA susceptible to sudden failure under high-stress conditions or impact loads, limiting its use in applications requiring high toughness. The material's low glass transition temperature, typically around 60°C, further restricts its use in high-temperature environments, as it can lead to softening and deformation under moderate heat exposure.

PLA also exhibits relatively low mechanical strength compared to traditional engineering plastics, particularly in terms of tensile and flexural properties. This limitation necessitates careful consideration of load-bearing requirements and often results in the need for thicker wall sections or additional reinforcement in structural designs. The material's tendency to creep under sustained loads further complicates long-term structural applications, potentially leading to dimensional instability and reduced load-bearing capacity over time.

Moisture sensitivity is another significant challenge when designing with PLA for structural integrity. The material can absorb moisture from the environment, leading to hydrolysis and degradation of mechanical properties. This sensitivity not only affects the long-term durability of PLA structures but also complicates processing and storage requirements.

The biodegradability of PLA, while advantageous from an environmental perspective, poses challenges for long-term structural applications. The material's susceptibility to degradation in various environments can lead to a gradual loss of mechanical properties over time, potentially compromising structural integrity. This characteristic necessitates careful consideration of the intended service life and environmental conditions in which the PLA structure will be used.

PLA's limited thermal stability during processing presents additional challenges in manufacturing structural components. The narrow processing window can lead to thermal degradation, affecting the material's mechanical properties and potentially introducing defects in the final product. This limitation requires precise control of processing parameters and often restricts the use of certain manufacturing techniques commonly employed with other thermoplastics.

Furthermore, the anisotropic behavior of PLA in 3D printed structures adds complexity to design considerations. The layer-by-layer deposition process can result in directional variations in mechanical properties, potentially leading to unexpected failure modes if not properly accounted for in the design phase.

Addressing these challenges and limitations requires innovative approaches in material formulation, processing techniques, and design strategies. Ongoing research focuses on developing PLA blends and composites to enhance mechanical properties, improve thermal stability, and reduce moisture sensitivity. Additionally, advanced design methodologies, such as topology optimization and generative design, are being explored to maximize the structural performance of PLA components within its inherent material constraints.

Current PLA Structural Design Methodologies

01 Enhancing PLA structural integrity through blending

Blending PLA with other materials can improve its structural integrity. This approach involves combining PLA with compatible polymers or additives to enhance its mechanical properties, such as strength and durability. The resulting composite materials often exhibit better performance characteristics than pure PLA.- Enhancing PLA structural integrity through blending: Blending PLA with other polymers or additives can significantly improve its structural integrity. This approach can enhance mechanical properties, thermal stability, and overall durability of PLA-based materials. Various blending techniques and compatible materials are explored to achieve optimal structural performance while maintaining biodegradability.

- Reinforcement of PLA with nanofillers: Incorporating nanofillers into PLA matrices can greatly enhance structural integrity. Nanoparticles, nanofibers, or nanoplatelets can be dispersed within the PLA to improve mechanical strength, barrier properties, and thermal stability. This approach allows for the creation of high-performance PLA nanocomposites with enhanced structural characteristics.

- Modification of PLA molecular structure: Altering the molecular structure of PLA through various chemical or physical methods can lead to improved structural integrity. Techniques such as crosslinking, chain extension, or stereocomplexation can be employed to enhance the mechanical properties and thermal resistance of PLA-based materials, resulting in more robust and durable structures.

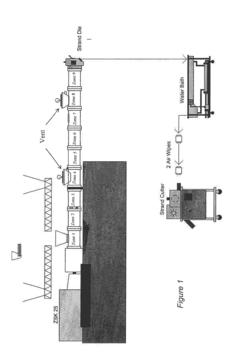

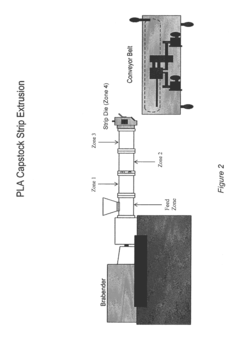

- Processing techniques for enhanced PLA structural integrity: Advanced processing techniques can be utilized to improve the structural integrity of PLA products. Methods such as orientation, annealing, or specific molding processes can be optimized to enhance crystallinity, reduce internal stresses, and improve overall mechanical performance of PLA-based materials.

- Surface treatments for improved PLA durability: Various surface treatments can be applied to PLA materials to enhance their structural integrity and durability. Techniques such as plasma treatment, coating applications, or surface functionalization can improve surface properties, adhesion, and resistance to environmental factors, thereby extending the lifespan and performance of PLA-based products.

02 Modification of PLA molecular structure

Altering the molecular structure of PLA can lead to improved structural integrity. This can be achieved through various methods such as copolymerization, crosslinking, or chain extension. These modifications can result in enhanced mechanical properties, thermal stability, and overall durability of PLA-based materials.Expand Specific Solutions03 Processing techniques for improved PLA performance

Specific processing techniques can be employed to enhance the structural integrity of PLA. These may include optimized extrusion parameters, annealing processes, or specialized molding techniques. Such methods can lead to improved crystallinity, better molecular orientation, and enhanced mechanical properties of PLA products.Expand Specific Solutions04 Reinforcement of PLA with nanofillers

Incorporating nanofillers into PLA can significantly improve its structural integrity. Nanofillers such as nanocellulose, carbon nanotubes, or nanoclays can be dispersed within the PLA matrix, leading to enhanced mechanical strength, barrier properties, and thermal stability of the resulting nanocomposites.Expand Specific Solutions05 Surface treatments for PLA structural enhancement

Various surface treatments can be applied to PLA to improve its structural integrity. These treatments may include plasma treatment, chemical modifications, or coating applications. Such processes can enhance the surface properties of PLA, leading to improved adhesion, wear resistance, and overall structural performance.Expand Specific Solutions

Key Players in PLA Structural Design Industry

The design of PLA for structural integrity is a growing field in the advanced materials sector, currently in its early growth stage. The market size is expanding rapidly, driven by increasing demand for sustainable and biodegradable materials in various industries. The technology's maturity is progressing, with companies like Arkema France SA, BASF Corp., and 3M Innovative Properties Co. leading research and development efforts. Academic institutions such as Sichuan University and École Polytechnique Fédérale de Lausanne are also contributing significantly to advancements in PLA structural design. The competitive landscape is diverse, with both established chemical companies and innovative startups like Floreon Technology Ltd. vying for market share, indicating a dynamic and evolving market with substantial growth potential.

Floreon Technology Ltd.

Technical Solution: Floreon has developed a proprietary PLA compound specifically designed for enhanced structural integrity. Their technology involves blending PLA with carefully selected additives and modifiers to improve impact resistance, heat stability, and overall mechanical performance. Floreon's approach includes optimizing the crystallization behavior of PLA to achieve a balance between strength and toughness. They have also developed processing guidelines for various manufacturing methods, including injection molding and extrusion, to ensure optimal structural properties in the final parts.

Strengths: Specialized focus on PLA technology, improved thermal and mechanical properties compared to standard PLA. Weaknesses: Limited product range, potentially higher cost due to specialized formulations.

Stora Enso Oyj

Technical Solution: Stora Enso has developed a biocomposite material that combines PLA with wood fibers to enhance structural integrity. Their approach involves optimizing the fiber content, length, and orientation within the PLA matrix to achieve improved mechanical properties. They use proprietary processing techniques to ensure good fiber dispersion and adhesion. Stora Enso's design strategy includes tailoring the material composition for specific applications, such as automotive parts or consumer goods. They have also developed guidelines for part design and manufacturing processes to maximize the structural performance of their PLA-based biocomposites.

Strengths: Integration of renewable resources, enhanced sustainability profile, and potential for improved mechanical properties. Weaknesses: Complexity in processing and potential moisture sensitivity of wood fibers.

Innovative PLA Structural Enhancement Strategies

Polylactic acid containing building component

PatentWO2013123364A1

Innovation

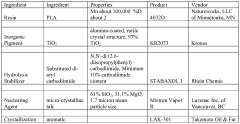

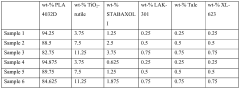

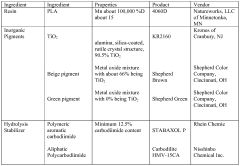

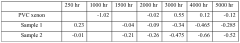

- A PLA-containing material is developed with the addition of inorganic pigments, such as Ti02, and stabilizers with carbodiimide functional groups, optimized to maintain color stability and gloss retention over extended periods under harsh weather conditions, specifically in South Florida exposure simulations.

PLA-containing material

PatentActiveUS20160039997A9

Innovation

- Incorporating inorganic pigments, such as TiO2, and stabilizers with carbodiimide functional groups into PLA-containing materials to enhance weatherability, color stability, and adhesion, allowing for the creation of building components that can withstand South Florida exposure conditions without significant color change or degradation.

Environmental Impact of PLA Structural Design

The environmental impact of PLA structural design is a critical consideration in the development and implementation of sustainable engineering solutions. PLA, or polylactic acid, is a biodegradable thermoplastic derived from renewable resources such as corn starch or sugarcane. Its use in structural applications offers significant environmental benefits compared to traditional petroleum-based plastics.

One of the primary advantages of PLA in structural design is its reduced carbon footprint. The production of PLA requires less energy and generates fewer greenhouse gas emissions compared to conventional plastics. This lower environmental impact extends throughout the entire lifecycle of PLA-based structures, from raw material extraction to end-of-life disposal.

PLA's biodegradability is another key factor in its environmental profile. Under proper conditions, PLA can decompose into natural substances, reducing the long-term environmental burden associated with plastic waste. This characteristic is particularly valuable in applications where the structure's lifespan is limited or where recovery for recycling may be challenging.

The recyclability of PLA further enhances its environmental credentials. While not as widely established as recycling systems for other plastics, PLA can be mechanically recycled or chemically processed to recover lactic acid for new PLA production. This circular approach to material use aligns with principles of sustainable design and waste reduction.

In structural applications, the lightweight nature of PLA can contribute to reduced material consumption and transportation-related emissions. Structures designed with PLA may require less material to achieve the same strength and performance as those made with traditional materials, leading to resource conservation and energy savings throughout the supply chain.

However, the environmental benefits of PLA structural design must be balanced against potential drawbacks. The agricultural production of PLA feedstocks can have land use implications and may compete with food crops. Additionally, the energy-intensive processes required for PLA production and the limited infrastructure for its proper disposal or recycling in many regions can offset some of its environmental advantages.

Designers must also consider the durability and longevity of PLA structures in relation to their intended use. While biodegradability is an asset in some contexts, it may be a liability in applications requiring long-term structural integrity. Balancing the material's environmental benefits with its performance characteristics is crucial for sustainable design practices.

One of the primary advantages of PLA in structural design is its reduced carbon footprint. The production of PLA requires less energy and generates fewer greenhouse gas emissions compared to conventional plastics. This lower environmental impact extends throughout the entire lifecycle of PLA-based structures, from raw material extraction to end-of-life disposal.

PLA's biodegradability is another key factor in its environmental profile. Under proper conditions, PLA can decompose into natural substances, reducing the long-term environmental burden associated with plastic waste. This characteristic is particularly valuable in applications where the structure's lifespan is limited or where recovery for recycling may be challenging.

The recyclability of PLA further enhances its environmental credentials. While not as widely established as recycling systems for other plastics, PLA can be mechanically recycled or chemically processed to recover lactic acid for new PLA production. This circular approach to material use aligns with principles of sustainable design and waste reduction.

In structural applications, the lightweight nature of PLA can contribute to reduced material consumption and transportation-related emissions. Structures designed with PLA may require less material to achieve the same strength and performance as those made with traditional materials, leading to resource conservation and energy savings throughout the supply chain.

However, the environmental benefits of PLA structural design must be balanced against potential drawbacks. The agricultural production of PLA feedstocks can have land use implications and may compete with food crops. Additionally, the energy-intensive processes required for PLA production and the limited infrastructure for its proper disposal or recycling in many regions can offset some of its environmental advantages.

Designers must also consider the durability and longevity of PLA structures in relation to their intended use. While biodegradability is an asset in some contexts, it may be a liability in applications requiring long-term structural integrity. Balancing the material's environmental benefits with its performance characteristics is crucial for sustainable design practices.

PLA Structural Design Standards and Regulations

The design of PLA (Polylactic Acid) structures for integrity requires adherence to specific standards and regulations. These guidelines ensure that PLA-based products meet safety, performance, and quality requirements across various applications. The American Society for Testing and Materials (ASTM) has developed several standards relevant to PLA structural design, including ASTM D6400 for compostable plastics and ASTM D5338 for determining aerobic biodegradation of plastic materials.

In the European Union, the EN 13432 standard governs the use of biodegradable plastics, including PLA, in packaging applications. This standard specifies requirements for packaging recoverable through composting and biodegradation. For medical applications, ISO 10993 series of standards are crucial, as they address the biocompatibility of medical devices, including those made from PLA.

The Food and Drug Administration (FDA) in the United States has approved PLA for food contact applications, subject to specific conditions outlined in 21 CFR 175.105. This regulation details the requirements for adhesives used in food packaging, including those containing PLA. For structural applications in construction, the International Building Code (IBC) provides guidelines that may be applicable to PLA-based materials, although specific provisions for bioplastics are still evolving.

In the automotive sector, the Federal Motor Vehicle Safety Standards (FMVSS) in the U.S. and the United Nations Economic Commission for Europe (UNECE) regulations in Europe provide frameworks that PLA-based components must adhere to when used in vehicle structures. These standards focus on crash safety, durability, and environmental performance.

For 3D printing applications using PLA, the ISO/ASTM 52900 standard provides terminology for additive manufacturing, while ISO/ASTM 52901 outlines requirements for purchased AM parts. These standards help ensure consistency and quality in PLA-based 3D printed structures.

As the use of PLA in structural applications continues to grow, regulatory bodies are working to develop more specific standards. The European Committee for Standardization (CEN) is actively developing standards for bio-based products, which will likely include provisions for PLA structural design. Similarly, the International Organization for Standardization (ISO) is expanding its portfolio of standards related to bioplastics and their applications.

In the European Union, the EN 13432 standard governs the use of biodegradable plastics, including PLA, in packaging applications. This standard specifies requirements for packaging recoverable through composting and biodegradation. For medical applications, ISO 10993 series of standards are crucial, as they address the biocompatibility of medical devices, including those made from PLA.

The Food and Drug Administration (FDA) in the United States has approved PLA for food contact applications, subject to specific conditions outlined in 21 CFR 175.105. This regulation details the requirements for adhesives used in food packaging, including those containing PLA. For structural applications in construction, the International Building Code (IBC) provides guidelines that may be applicable to PLA-based materials, although specific provisions for bioplastics are still evolving.

In the automotive sector, the Federal Motor Vehicle Safety Standards (FMVSS) in the U.S. and the United Nations Economic Commission for Europe (UNECE) regulations in Europe provide frameworks that PLA-based components must adhere to when used in vehicle structures. These standards focus on crash safety, durability, and environmental performance.

For 3D printing applications using PLA, the ISO/ASTM 52900 standard provides terminology for additive manufacturing, while ISO/ASTM 52901 outlines requirements for purchased AM parts. These standards help ensure consistency and quality in PLA-based 3D printed structures.

As the use of PLA in structural applications continues to grow, regulatory bodies are working to develop more specific standards. The European Committee for Standardization (CEN) is actively developing standards for bio-based products, which will likely include provisions for PLA structural design. Similarly, the International Organization for Standardization (ISO) is expanding its portfolio of standards related to bioplastics and their applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!