PLA's Role in Circular Economy: Strategies and Solutions

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PLA Circular Economy Background and Objectives

Polylactic acid (PLA) has emerged as a promising biodegradable polymer in the context of circular economy initiatives. The evolution of PLA technology can be traced back to the 1930s, with significant advancements in production methods and applications occurring in the late 20th and early 21st centuries. As global concerns about plastic pollution and resource depletion have intensified, PLA has gained prominence as a potential solution for sustainable packaging and other applications.

The circular economy concept, which aims to eliminate waste and maximize resource efficiency, has become increasingly relevant in recent years. PLA's biodegradability and renewable sourcing align well with circular economy principles, making it a focal point for research and development in sustainable materials. The technology's progression has been driven by a combination of environmental pressures, regulatory initiatives, and consumer demand for eco-friendly alternatives to conventional plastics.

Current technological objectives for PLA in the circular economy context are multifaceted. Researchers and industry players are working to enhance PLA's mechanical properties, improve its thermal stability, and extend its shelf life to broaden its applicability across various sectors. Additionally, efforts are being made to optimize PLA production processes, reducing energy consumption and overall environmental impact.

A key goal is to develop more efficient recycling and composting systems specifically tailored for PLA products. This includes improving the collection and sorting of PLA waste, as well as refining industrial composting facilities to handle increased volumes of biodegradable plastics. Furthermore, there is a push to create closed-loop systems where PLA products can be effectively recovered and reprocessed into new materials, truly embodying the circular economy model.

Another critical objective is to address the end-of-life management of PLA products. This involves developing standardized protocols for composting and biodegradation, ensuring that PLA materials break down as intended in various environmental conditions. Researchers are also exploring ways to enhance the biodegradation rate of PLA while maintaining its useful properties during its intended lifespan.

As the technology continues to evolve, there is a growing focus on integrating PLA into broader circular economy strategies. This includes exploring synergies with other sustainable materials and processes, as well as developing innovative applications that can maximize the environmental benefits of PLA. The ultimate aim is to position PLA as a key component in the transition towards a more sustainable and circular global economy.

The circular economy concept, which aims to eliminate waste and maximize resource efficiency, has become increasingly relevant in recent years. PLA's biodegradability and renewable sourcing align well with circular economy principles, making it a focal point for research and development in sustainable materials. The technology's progression has been driven by a combination of environmental pressures, regulatory initiatives, and consumer demand for eco-friendly alternatives to conventional plastics.

Current technological objectives for PLA in the circular economy context are multifaceted. Researchers and industry players are working to enhance PLA's mechanical properties, improve its thermal stability, and extend its shelf life to broaden its applicability across various sectors. Additionally, efforts are being made to optimize PLA production processes, reducing energy consumption and overall environmental impact.

A key goal is to develop more efficient recycling and composting systems specifically tailored for PLA products. This includes improving the collection and sorting of PLA waste, as well as refining industrial composting facilities to handle increased volumes of biodegradable plastics. Furthermore, there is a push to create closed-loop systems where PLA products can be effectively recovered and reprocessed into new materials, truly embodying the circular economy model.

Another critical objective is to address the end-of-life management of PLA products. This involves developing standardized protocols for composting and biodegradation, ensuring that PLA materials break down as intended in various environmental conditions. Researchers are also exploring ways to enhance the biodegradation rate of PLA while maintaining its useful properties during its intended lifespan.

As the technology continues to evolve, there is a growing focus on integrating PLA into broader circular economy strategies. This includes exploring synergies with other sustainable materials and processes, as well as developing innovative applications that can maximize the environmental benefits of PLA. The ultimate aim is to position PLA as a key component in the transition towards a more sustainable and circular global economy.

Market Demand for Sustainable Bioplastics

The market demand for sustainable bioplastics, particularly Polylactic Acid (PLA), has been experiencing significant growth in recent years. This surge is driven by increasing environmental awareness, stringent regulations on single-use plastics, and a growing consumer preference for eco-friendly products. PLA, derived from renewable resources such as corn starch or sugarcane, has emerged as a promising alternative to conventional petroleum-based plastics.

The global bioplastics market, including PLA, is projected to expand rapidly. Key industries driving this demand include packaging, consumer goods, automotive, and medical sectors. In the packaging industry, which accounts for the largest share of PLA usage, there is a strong push towards sustainable solutions for food packaging, beverage bottles, and disposable cutlery. Major food and beverage companies are increasingly adopting PLA-based packaging to meet their sustainability goals and consumer expectations.

Consumer goods manufacturers are also incorporating PLA into various products, from disposable razors to electronics casings, responding to the growing eco-conscious consumer base. The automotive industry is exploring PLA for interior components, aiming to reduce vehicle weight and improve fuel efficiency while meeting sustainability targets. In the medical field, PLA's biocompatibility and biodegradability make it an attractive material for implants, drug delivery systems, and disposable medical devices.

Geographically, Europe leads in PLA adoption, driven by stringent environmental regulations and high consumer awareness. North America follows closely, with significant growth potential in the packaging and consumer goods sectors. The Asia-Pacific region, particularly China and Japan, is emerging as a key market for PLA, fueled by rapid industrialization and increasing environmental concerns.

Despite the growing demand, challenges remain in scaling up PLA production and improving its performance characteristics. The relatively higher cost of PLA compared to conventional plastics remains a barrier to widespread adoption in price-sensitive markets. However, ongoing research and development efforts are focused on enhancing PLA's properties, such as heat resistance and durability, to expand its application range and competitiveness.

The circular economy concept is driving further interest in PLA, as it aligns well with principles of recyclability and biodegradability. Companies are investing in developing efficient recycling and composting infrastructure for PLA products, which is expected to boost its market appeal and long-term sustainability credentials.

The global bioplastics market, including PLA, is projected to expand rapidly. Key industries driving this demand include packaging, consumer goods, automotive, and medical sectors. In the packaging industry, which accounts for the largest share of PLA usage, there is a strong push towards sustainable solutions for food packaging, beverage bottles, and disposable cutlery. Major food and beverage companies are increasingly adopting PLA-based packaging to meet their sustainability goals and consumer expectations.

Consumer goods manufacturers are also incorporating PLA into various products, from disposable razors to electronics casings, responding to the growing eco-conscious consumer base. The automotive industry is exploring PLA for interior components, aiming to reduce vehicle weight and improve fuel efficiency while meeting sustainability targets. In the medical field, PLA's biocompatibility and biodegradability make it an attractive material for implants, drug delivery systems, and disposable medical devices.

Geographically, Europe leads in PLA adoption, driven by stringent environmental regulations and high consumer awareness. North America follows closely, with significant growth potential in the packaging and consumer goods sectors. The Asia-Pacific region, particularly China and Japan, is emerging as a key market for PLA, fueled by rapid industrialization and increasing environmental concerns.

Despite the growing demand, challenges remain in scaling up PLA production and improving its performance characteristics. The relatively higher cost of PLA compared to conventional plastics remains a barrier to widespread adoption in price-sensitive markets. However, ongoing research and development efforts are focused on enhancing PLA's properties, such as heat resistance and durability, to expand its application range and competitiveness.

The circular economy concept is driving further interest in PLA, as it aligns well with principles of recyclability and biodegradability. Companies are investing in developing efficient recycling and composting infrastructure for PLA products, which is expected to boost its market appeal and long-term sustainability credentials.

PLA Recycling Challenges and Limitations

Despite the growing popularity of PLA as a biodegradable alternative to traditional plastics, its recycling process faces several significant challenges and limitations. One of the primary obstacles is the lack of established infrastructure for PLA collection and sorting. Unlike conventional plastics, PLA requires specialized recycling facilities, which are currently scarce in many regions. This scarcity leads to a significant portion of PLA waste being diverted to landfills or incineration, undermining its potential for circular economy integration.

Another critical challenge is the contamination of PLA waste streams. PLA products are often mixed with other types of plastics or materials during disposal, making it difficult to isolate pure PLA for recycling. Even small amounts of contaminants can significantly degrade the quality of recycled PLA, limiting its potential applications. This issue is further compounded by the fact that PLA can contaminate other plastic recycling streams, potentially disrupting established recycling processes for conventional plastics.

The thermal sensitivity of PLA presents additional recycling limitations. PLA has a lower melting point compared to many other plastics, which can cause issues during the recycling process. If not carefully controlled, the heat applied during recycling can lead to degradation of the polymer chains, resulting in a loss of material properties and reduced quality of the recycled product. This sensitivity necessitates precise temperature control and specialized equipment, adding complexity and cost to the recycling process.

Furthermore, the economic viability of PLA recycling remains a significant hurdle. The current scale of PLA production and consumption is relatively small compared to traditional plastics, leading to low volumes of recyclable material. This lack of economies of scale makes it challenging to justify the investment in specialized recycling infrastructure. Additionally, the cost of recycling PLA can be higher than producing virgin PLA, particularly when considering the energy and resources required for collection, sorting, and processing.

The biodegradability of PLA, while generally considered an environmental advantage, can paradoxically pose challenges for recycling. PLA's susceptibility to degradation under certain conditions can lead to a reduction in material quality over time, potentially limiting the number of recycling cycles it can undergo. This degradation can occur during use, storage, or even during the recycling process itself, affecting the consistency and reliability of recycled PLA materials.

Lastly, there is a lack of standardization in PLA formulations and additives across different manufacturers. This variability can lead to inconsistencies in the recycled material, making it difficult to achieve consistent quality and properties in recycled PLA products. The presence of various additives, while beneficial for specific applications, can complicate the recycling process and potentially introduce undesirable properties in the recycled material.

Another critical challenge is the contamination of PLA waste streams. PLA products are often mixed with other types of plastics or materials during disposal, making it difficult to isolate pure PLA for recycling. Even small amounts of contaminants can significantly degrade the quality of recycled PLA, limiting its potential applications. This issue is further compounded by the fact that PLA can contaminate other plastic recycling streams, potentially disrupting established recycling processes for conventional plastics.

The thermal sensitivity of PLA presents additional recycling limitations. PLA has a lower melting point compared to many other plastics, which can cause issues during the recycling process. If not carefully controlled, the heat applied during recycling can lead to degradation of the polymer chains, resulting in a loss of material properties and reduced quality of the recycled product. This sensitivity necessitates precise temperature control and specialized equipment, adding complexity and cost to the recycling process.

Furthermore, the economic viability of PLA recycling remains a significant hurdle. The current scale of PLA production and consumption is relatively small compared to traditional plastics, leading to low volumes of recyclable material. This lack of economies of scale makes it challenging to justify the investment in specialized recycling infrastructure. Additionally, the cost of recycling PLA can be higher than producing virgin PLA, particularly when considering the energy and resources required for collection, sorting, and processing.

The biodegradability of PLA, while generally considered an environmental advantage, can paradoxically pose challenges for recycling. PLA's susceptibility to degradation under certain conditions can lead to a reduction in material quality over time, potentially limiting the number of recycling cycles it can undergo. This degradation can occur during use, storage, or even during the recycling process itself, affecting the consistency and reliability of recycled PLA materials.

Lastly, there is a lack of standardization in PLA formulations and additives across different manufacturers. This variability can lead to inconsistencies in the recycled material, making it difficult to achieve consistent quality and properties in recycled PLA products. The presence of various additives, while beneficial for specific applications, can complicate the recycling process and potentially introduce undesirable properties in the recycled material.

Current PLA Circular Economy Solutions

01 PLA composites and blends

PLA can be combined with other materials to form composites or blends, enhancing its properties for various applications. These combinations can improve mechanical strength, thermal stability, or biodegradability. Common materials used in PLA composites include natural fibers, other biodegradable polymers, or inorganic fillers.- PLA-based composite materials: Development of composite materials using PLA as a base polymer, incorporating various additives or fillers to enhance properties such as strength, durability, or biodegradability. These composites can be used in a wide range of applications, from packaging to medical devices.

- PLA processing techniques: Innovative methods for processing PLA, including extrusion, injection molding, and 3D printing. These techniques aim to improve the material's performance, reduce production costs, and expand its potential applications in various industries.

- PLA modification for improved properties: Chemical or physical modification of PLA to enhance its properties, such as thermal stability, mechanical strength, or barrier properties. This includes techniques like blending with other polymers, crosslinking, or surface treatments to overcome limitations of pure PLA.

- Biodegradable PLA applications: Development of biodegradable products using PLA, focusing on environmentally friendly alternatives to traditional plastics. Applications include packaging materials, disposable items, and agricultural films that can decompose naturally in the environment.

- PLA in medical and pharmaceutical applications: Utilization of PLA in medical and pharmaceutical fields, including drug delivery systems, tissue engineering scaffolds, and bioabsorbable implants. The biocompatibility and controlled degradation properties of PLA make it suitable for various medical applications.

02 PLA processing techniques

Various processing techniques are employed to manufacture PLA-based products. These may include extrusion, injection molding, 3D printing, or electrospinning. Each technique offers unique advantages for specific applications, allowing for the creation of diverse PLA products with tailored properties.Expand Specific Solutions03 PLA modifications for improved properties

Chemical or physical modifications can be applied to PLA to enhance its properties. These modifications may include plasticization, copolymerization, or surface treatments. Such modifications can improve flexibility, impact resistance, or barrier properties of PLA-based materials.Expand Specific Solutions04 PLA in packaging applications

PLA is widely used in packaging applications due to its biodegradability and renewability. It can be used to create films, containers, or coatings for food packaging, as well as other consumer goods packaging. Research focuses on improving PLA's barrier properties and shelf life for these applications.Expand Specific Solutions05 PLA in biomedical applications

PLA finds extensive use in biomedical applications due to its biocompatibility and biodegradability. It can be used in tissue engineering scaffolds, drug delivery systems, or surgical implants. Research in this area focuses on tailoring PLA properties for specific medical needs and improving its performance in the body.Expand Specific Solutions

Key Players in PLA Production and Recycling

The circular economy strategies for PLA are evolving rapidly, with the market in a growth phase. The global PLA market is expanding, driven by increasing demand for sustainable materials. Technologically, PLA solutions are advancing, with companies like NatureWorks LLC and Total Research Corp leading innovation. 3M Innovative Properties Co. and Galactic SA/NV are also contributing significantly to PLA's circular economy applications. Research institutions such as The Iowa State University Research Foundation and Centre National de la Recherche Scientifique are pushing boundaries in PLA recycling and biodegradability. The industry is seeing a blend of established players and emerging startups, indicating a dynamic and competitive landscape with room for further technological advancements and market expansion.

NatureWorks LLC

Technical Solution: NatureWorks has developed a proprietary process for producing polylactic acid (PLA) from renewable resources, primarily corn starch. Their Ingeo biopolymer is used in various applications, including packaging, fibers, and 3D printing. In the context of circular economy, NatureWorks has implemented a closed-loop system for PLA production and recycling. They have developed chemical recycling technologies to break down PLA back into lactic acid, which can then be used to produce new PLA products. This approach allows for multiple cycles of use and recycling, reducing waste and dependence on fossil-based resources.

Strengths: Renewable feedstock, biodegradability, established recycling infrastructure. Weaknesses: Energy-intensive production process, limited end-of-life options in some regions.

Arctic Biomaterials Oy

Technical Solution: Arctic Biomaterials specializes in developing and producing bio-based and biodegradable plastics, with a focus on PLA compounds. Their technology involves reinforcing PLA with natural fibers and minerals to enhance its mechanical properties and heat resistance. In the context of circular economy, they have developed a range of compostable PLA compounds that can be used in various applications, including packaging and consumer goods. Their materials are designed to biodegrade in industrial composting facilities, providing an environmentally friendly end-of-life option.

Strengths: Enhanced material properties, compostability, versatile applications. Weaknesses: Requires specific composting conditions, limited recycling options.

Innovations in PLA Recycling Technologies

Depolymerization of polylactic acid

PatentInactiveUS20130096342A1

Innovation

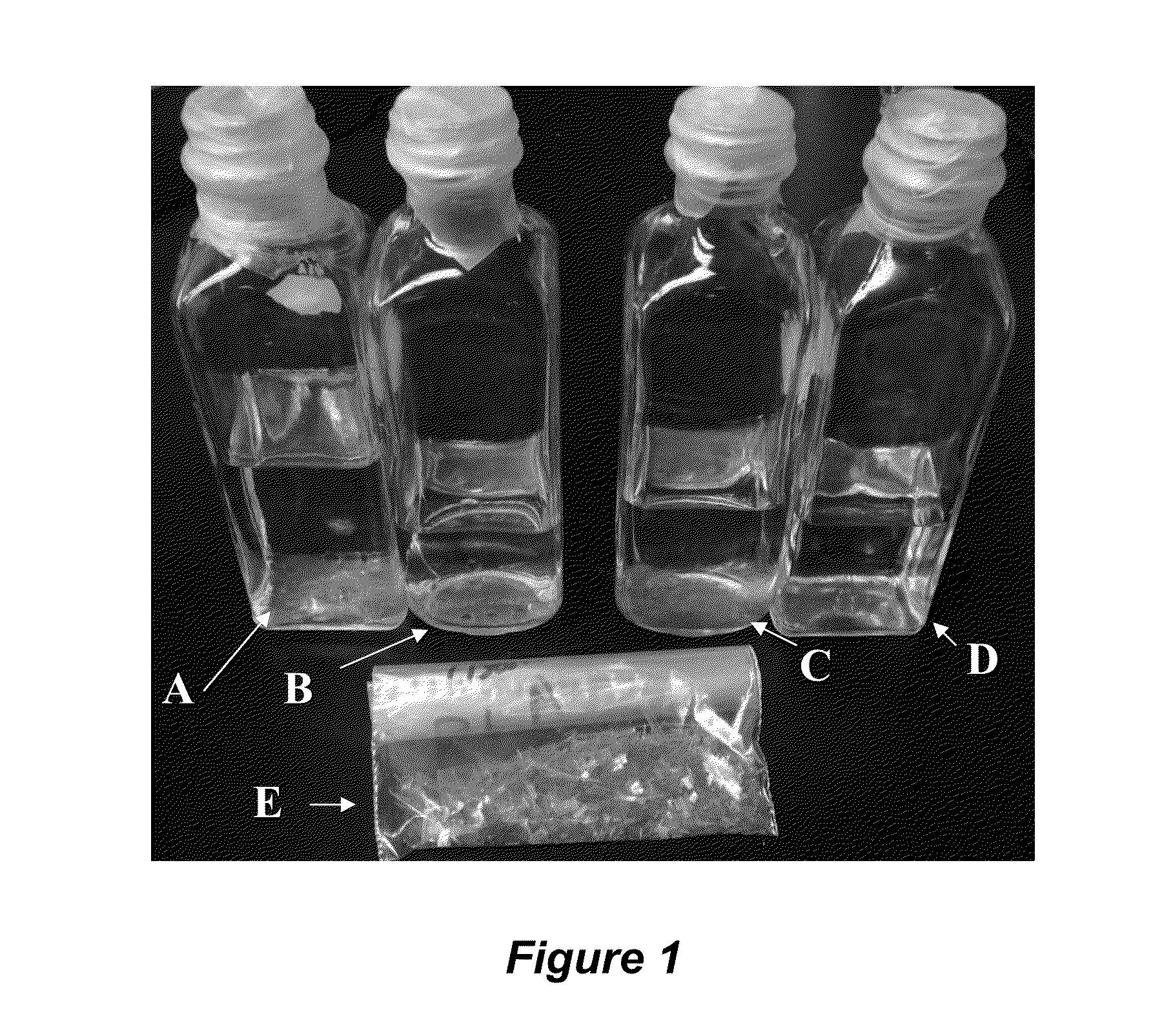

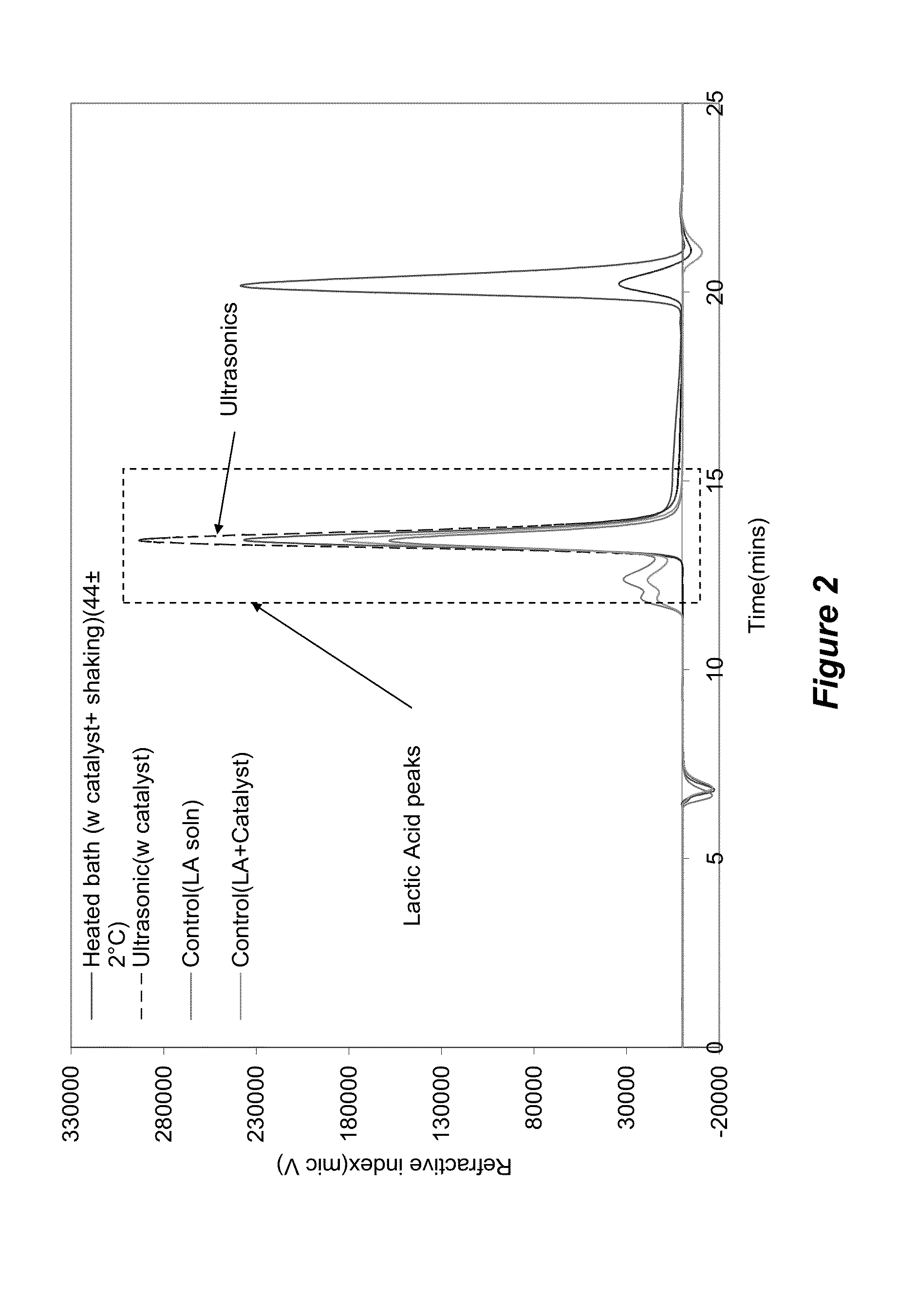

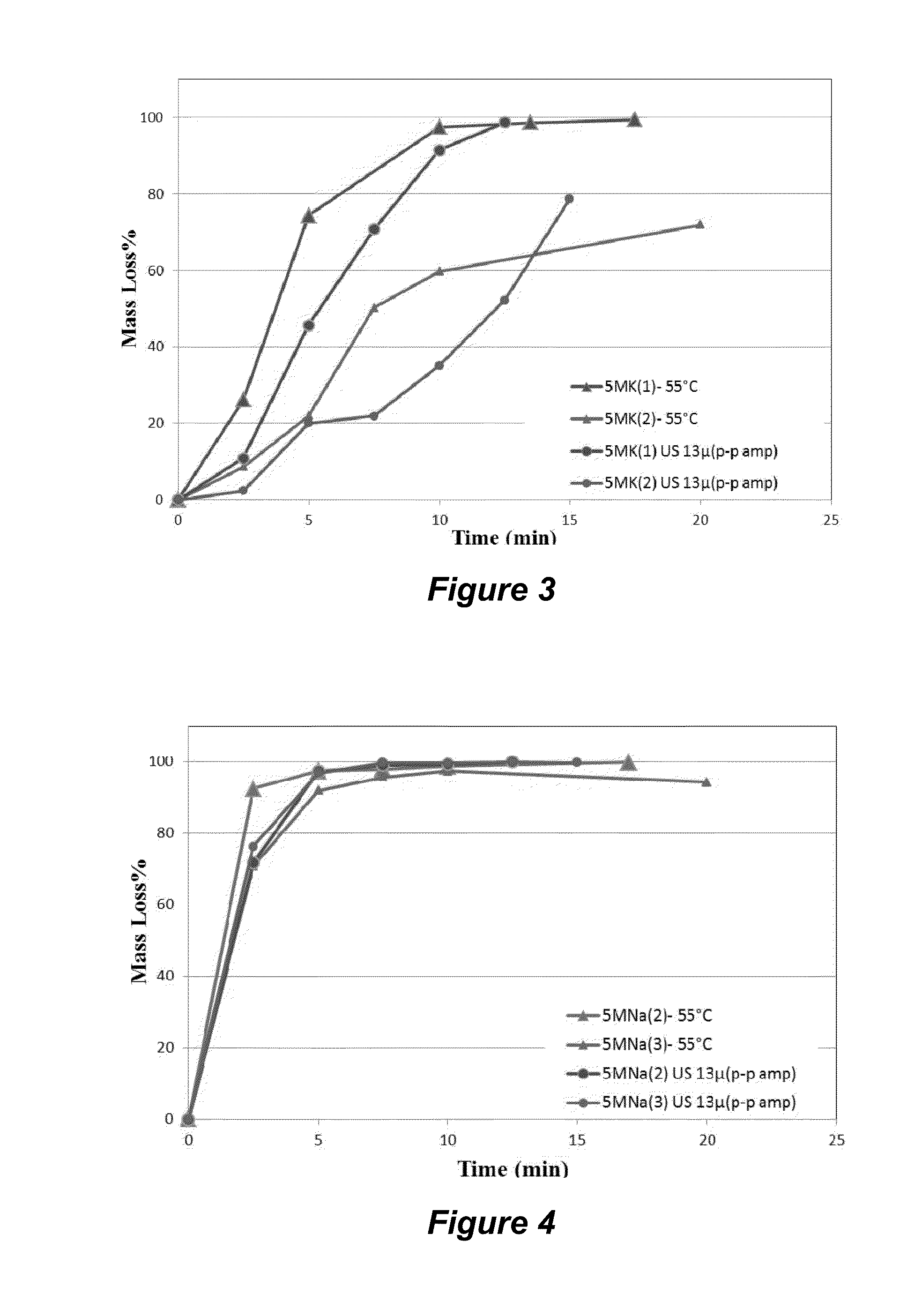

- A method involving the use of an alcoholic solution with alkali metal hydroxides or carbonates, such as lithium, sodium, or potassium hydroxide/carbonate, in combination with ultrasonics, to depolymerize PLA at moderate temperatures (30° C to 90° C) to achieve high rates of lactic acid recovery, reducing the process time and energy consumption.

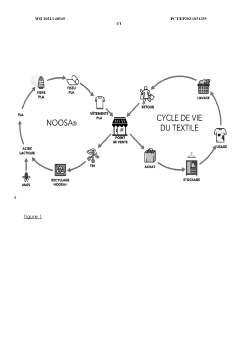

Method for recycling textiles containing polylactic acid

PatentWO2021148549A1

Innovation

- A process for recycling textiles containing polylactic acid (PLA) that involves decontamination, mechanical treatment, hydrolysis to recover lactic acid, and subsequent repolymerization to form new PLA fibers, reducing environmental impact and promoting a circular economy.

Environmental Impact Assessment of PLA

The environmental impact assessment of PLA (Polylactic Acid) is crucial in understanding its role within the circular economy. PLA, a biodegradable polymer derived from renewable resources, has gained significant attention as a potential alternative to conventional plastics. However, its environmental footprint must be thoroughly evaluated to ensure its sustainability and alignment with circular economy principles.

Life cycle assessment (LCA) studies have shown that PLA production generally has a lower carbon footprint compared to traditional petroleum-based plastics. The renewable nature of its feedstock, typically corn or sugarcane, contributes to reduced greenhouse gas emissions. However, the environmental benefits can vary depending on agricultural practices, land use changes, and energy sources used in production.

Water consumption is another critical factor in PLA's environmental impact. While the polymer itself requires less water during manufacturing compared to some conventional plastics, the cultivation of feedstock crops can be water-intensive. This aspect necessitates careful consideration of water management practices in regions where PLA feedstock is grown.

Biodegradability is often cited as a key environmental advantage of PLA. Under industrial composting conditions, PLA can break down into water, carbon dioxide, and biomass. However, it's important to note that PLA does not readily biodegrade in natural environments or landfills, which can lead to misconceptions about its end-of-life impact.

The end-of-life management of PLA products plays a crucial role in its overall environmental impact. While theoretically compostable, the lack of widespread industrial composting facilities in many regions can limit the realization of this benefit. Improper disposal of PLA in conventional recycling streams can also contaminate other plastic recycling processes.

Energy consumption during PLA production is generally lower than that of petroleum-based plastics. However, the energy mix used in production significantly influences its carbon footprint. Utilizing renewable energy sources in PLA manufacturing can further enhance its environmental credentials.

Land use and biodiversity impacts associated with feedstock cultivation must also be considered. Expanding crop production for PLA feedstock could potentially lead to land-use changes, affecting local ecosystems and biodiversity. Sustainable agricultural practices and responsible land management are essential to mitigate these risks.

In conclusion, while PLA offers several environmental advantages over conventional plastics, its overall impact depends on various factors throughout its lifecycle. Continuous improvement in production processes, feedstock sourcing, and end-of-life management is crucial to maximize PLA's positive contribution to the circular economy and minimize its environmental footprint.

Life cycle assessment (LCA) studies have shown that PLA production generally has a lower carbon footprint compared to traditional petroleum-based plastics. The renewable nature of its feedstock, typically corn or sugarcane, contributes to reduced greenhouse gas emissions. However, the environmental benefits can vary depending on agricultural practices, land use changes, and energy sources used in production.

Water consumption is another critical factor in PLA's environmental impact. While the polymer itself requires less water during manufacturing compared to some conventional plastics, the cultivation of feedstock crops can be water-intensive. This aspect necessitates careful consideration of water management practices in regions where PLA feedstock is grown.

Biodegradability is often cited as a key environmental advantage of PLA. Under industrial composting conditions, PLA can break down into water, carbon dioxide, and biomass. However, it's important to note that PLA does not readily biodegrade in natural environments or landfills, which can lead to misconceptions about its end-of-life impact.

The end-of-life management of PLA products plays a crucial role in its overall environmental impact. While theoretically compostable, the lack of widespread industrial composting facilities in many regions can limit the realization of this benefit. Improper disposal of PLA in conventional recycling streams can also contaminate other plastic recycling processes.

Energy consumption during PLA production is generally lower than that of petroleum-based plastics. However, the energy mix used in production significantly influences its carbon footprint. Utilizing renewable energy sources in PLA manufacturing can further enhance its environmental credentials.

Land use and biodiversity impacts associated with feedstock cultivation must also be considered. Expanding crop production for PLA feedstock could potentially lead to land-use changes, affecting local ecosystems and biodiversity. Sustainable agricultural practices and responsible land management are essential to mitigate these risks.

In conclusion, while PLA offers several environmental advantages over conventional plastics, its overall impact depends on various factors throughout its lifecycle. Continuous improvement in production processes, feedstock sourcing, and end-of-life management is crucial to maximize PLA's positive contribution to the circular economy and minimize its environmental footprint.

Policy Frameworks for Bioplastics Circularity

Policy frameworks play a crucial role in promoting the circularity of bioplastics, including Polylactic Acid (PLA). These frameworks are essential for creating an enabling environment that supports the development, production, and end-of-life management of bioplastics within a circular economy context.

At the international level, organizations such as the United Nations Environment Programme (UNEP) and the European Union (EU) have developed guidelines and directives that address bioplastics and circular economy principles. The EU's Circular Economy Action Plan, for instance, includes specific measures to promote bio-based plastics and ensure their biodegradability.

National governments have also implemented policies to support bioplastics circularity. For example, Japan's Biomass Nippon Strategy promotes the use of biomass-derived materials, including bioplastics, and encourages their recycling and composting. Similarly, Italy has introduced legislation mandating the use of compostable plastic bags, which has significantly boosted the market for PLA and other biodegradable plastics.

Policy frameworks often include economic instruments to incentivize the adoption of bioplastics and circular practices. These may include tax incentives for companies using bio-based materials, subsidies for research and development in bioplastics technology, and extended producer responsibility schemes that encourage manufacturers to design products for easier recycling or composting.

Standardization and labeling policies are also critical components of bioplastics circularity frameworks. These ensure that bioplastics meet specific environmental and performance criteria and help consumers make informed choices. The European Committee for Standardization (CEN) has developed standards for bio-based products, including EN 16785 for bio-based content and EN 13432 for compostability.

Waste management policies are particularly important for closing the loop on bioplastics. Many countries are implementing organic waste collection systems and industrial composting facilities that can process compostable PLA products. However, these systems require clear guidelines and infrastructure to prevent contamination and ensure effective processing.

Research and innovation policies are also integral to advancing bioplastics circularity. Governments and regional bodies often provide funding for projects that aim to improve the production, properties, and end-of-life options for bioplastics. The EU's Horizon Europe program, for instance, includes specific calls for research on bio-based materials and their circular applications.

As the bioplastics industry continues to evolve, policy frameworks must remain flexible and adaptable. Regular reviews and updates are necessary to ensure that regulations keep pace with technological advancements and changing market dynamics in the field of PLA and other bioplastics.

At the international level, organizations such as the United Nations Environment Programme (UNEP) and the European Union (EU) have developed guidelines and directives that address bioplastics and circular economy principles. The EU's Circular Economy Action Plan, for instance, includes specific measures to promote bio-based plastics and ensure their biodegradability.

National governments have also implemented policies to support bioplastics circularity. For example, Japan's Biomass Nippon Strategy promotes the use of biomass-derived materials, including bioplastics, and encourages their recycling and composting. Similarly, Italy has introduced legislation mandating the use of compostable plastic bags, which has significantly boosted the market for PLA and other biodegradable plastics.

Policy frameworks often include economic instruments to incentivize the adoption of bioplastics and circular practices. These may include tax incentives for companies using bio-based materials, subsidies for research and development in bioplastics technology, and extended producer responsibility schemes that encourage manufacturers to design products for easier recycling or composting.

Standardization and labeling policies are also critical components of bioplastics circularity frameworks. These ensure that bioplastics meet specific environmental and performance criteria and help consumers make informed choices. The European Committee for Standardization (CEN) has developed standards for bio-based products, including EN 16785 for bio-based content and EN 13432 for compostability.

Waste management policies are particularly important for closing the loop on bioplastics. Many countries are implementing organic waste collection systems and industrial composting facilities that can process compostable PLA products. However, these systems require clear guidelines and infrastructure to prevent contamination and ensure effective processing.

Research and innovation policies are also integral to advancing bioplastics circularity. Governments and regional bodies often provide funding for projects that aim to improve the production, properties, and end-of-life options for bioplastics. The EU's Horizon Europe program, for instance, includes specific calls for research on bio-based materials and their circular applications.

As the bioplastics industry continues to evolve, policy frameworks must remain flexible and adaptable. Regular reviews and updates are necessary to ensure that regulations keep pace with technological advancements and changing market dynamics in the field of PLA and other bioplastics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!