How to Maximize PLA's Use in Biodegradable Packaging?

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PLA Packaging Evolution

The evolution of PLA (Polylactic Acid) packaging has been a significant journey in the realm of sustainable materials. Initially developed in the 1920s, PLA gained prominence in the packaging industry during the late 1990s and early 2000s as environmental concerns grew. The technology behind PLA production has undergone several iterations, each aimed at improving its properties and expanding its applications in biodegradable packaging.

In the early stages, PLA was primarily derived from corn starch, limiting its production scale and increasing costs. The first generation of PLA packaging faced challenges such as low heat resistance and brittleness, restricting its use to limited applications. However, as research progressed, new production methods emerged, allowing for the use of various plant-based sources like cassava, sugarcane, and even agricultural waste.

A significant milestone in PLA packaging evolution came with the development of improved polymerization techniques. These advancements led to PLA with enhanced mechanical properties, making it more suitable for a wider range of packaging applications. The introduction of stereocomplex PLA in the mid-2000s marked another leap forward, addressing issues of heat resistance and durability.

The late 2000s and early 2010s saw a focus on blending PLA with other biodegradable materials to create composites with superior properties. This approach expanded PLA's versatility, enabling its use in flexible packaging, rigid containers, and even as a coating for paper-based packaging. Concurrently, efforts to reduce production costs intensified, making PLA more competitive with traditional petroleum-based plastics.

Recent years have witnessed a surge in research aimed at enhancing PLA's barrier properties, crucial for food packaging applications. Innovations in nanocomposite technology and surface treatments have significantly improved PLA's resistance to moisture and gas permeation. This has opened up new possibilities in the food and beverage packaging sector, traditionally dominated by non-biodegradable materials.

The latest frontier in PLA packaging evolution involves the development of fully compostable additives and inks, ensuring that every component of the packaging meets biodegradability standards. Additionally, advancements in PLA's end-of-life management have led to more efficient composting and recycling processes, further solidifying its position as a sustainable packaging solution.

As we look to the future, the evolution of PLA packaging continues to focus on improving its performance while maintaining its eco-friendly credentials. Emerging areas of research include the development of PLA with self-healing properties, smart PLA packaging with embedded sensors for food freshness monitoring, and the integration of PLA into 3D printing technologies for customized, on-demand packaging solutions.

In the early stages, PLA was primarily derived from corn starch, limiting its production scale and increasing costs. The first generation of PLA packaging faced challenges such as low heat resistance and brittleness, restricting its use to limited applications. However, as research progressed, new production methods emerged, allowing for the use of various plant-based sources like cassava, sugarcane, and even agricultural waste.

A significant milestone in PLA packaging evolution came with the development of improved polymerization techniques. These advancements led to PLA with enhanced mechanical properties, making it more suitable for a wider range of packaging applications. The introduction of stereocomplex PLA in the mid-2000s marked another leap forward, addressing issues of heat resistance and durability.

The late 2000s and early 2010s saw a focus on blending PLA with other biodegradable materials to create composites with superior properties. This approach expanded PLA's versatility, enabling its use in flexible packaging, rigid containers, and even as a coating for paper-based packaging. Concurrently, efforts to reduce production costs intensified, making PLA more competitive with traditional petroleum-based plastics.

Recent years have witnessed a surge in research aimed at enhancing PLA's barrier properties, crucial for food packaging applications. Innovations in nanocomposite technology and surface treatments have significantly improved PLA's resistance to moisture and gas permeation. This has opened up new possibilities in the food and beverage packaging sector, traditionally dominated by non-biodegradable materials.

The latest frontier in PLA packaging evolution involves the development of fully compostable additives and inks, ensuring that every component of the packaging meets biodegradability standards. Additionally, advancements in PLA's end-of-life management have led to more efficient composting and recycling processes, further solidifying its position as a sustainable packaging solution.

As we look to the future, the evolution of PLA packaging continues to focus on improving its performance while maintaining its eco-friendly credentials. Emerging areas of research include the development of PLA with self-healing properties, smart PLA packaging with embedded sensors for food freshness monitoring, and the integration of PLA into 3D printing technologies for customized, on-demand packaging solutions.

Market Demand Analysis

The market demand for biodegradable packaging solutions has been experiencing significant growth in recent years, driven by increasing environmental concerns and regulatory pressures. PLA (Polylactic Acid), as a biodegradable and compostable bioplastic, has emerged as a promising material for sustainable packaging applications. The global biodegradable packaging market is expected to expand rapidly, with PLA playing a crucial role in this growth.

Consumer awareness and preference for eco-friendly products have been key drivers in the adoption of biodegradable packaging. Retailers and brand owners are increasingly seeking sustainable packaging solutions to meet consumer demands and improve their environmental credentials. This shift in consumer behavior has created a substantial market opportunity for PLA-based packaging products across various industries, including food and beverage, personal care, and consumer goods.

The food packaging sector represents the largest market segment for PLA-based biodegradable packaging. The material's properties, such as transparency, barrier performance, and food contact safety, make it particularly suitable for fresh produce, bakery items, and ready-to-eat meals. The growing trend of on-the-go consumption and the rise of e-commerce have further boosted the demand for convenient, sustainable packaging solutions, where PLA can offer significant advantages.

In the personal care and cosmetics industry, there is a rising demand for sustainable packaging options. PLA's versatility in molding and forming processes allows for the creation of various packaging formats, from bottles and jars to tubes and closures. This adaptability positions PLA as a viable alternative to conventional plastics in this sector, addressing both functional requirements and sustainability goals.

The retail and e-commerce sectors have also shown increasing interest in PLA-based packaging materials. As online shopping continues to grow, there is a pressing need for protective packaging that is both effective and environmentally friendly. PLA-based foam cushioning and void-fill materials offer a sustainable alternative to traditional petroleum-based packaging, meeting the dual requirements of product protection and environmental responsibility.

Geographically, North America and Europe lead in the adoption of PLA-based biodegradable packaging, driven by stringent regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth, fueled by rapid industrialization, increasing disposable incomes, and growing environmental consciousness in countries like China and India.

Despite the positive market outlook, challenges remain in maximizing PLA's use in biodegradable packaging. These include cost competitiveness compared to conventional plastics, limitations in certain performance characteristics, and the need for proper waste management infrastructure to ensure effective composting or recycling. Addressing these challenges through technological advancements and supportive policies will be crucial in fully realizing the market potential of PLA in biodegradable packaging applications.

Consumer awareness and preference for eco-friendly products have been key drivers in the adoption of biodegradable packaging. Retailers and brand owners are increasingly seeking sustainable packaging solutions to meet consumer demands and improve their environmental credentials. This shift in consumer behavior has created a substantial market opportunity for PLA-based packaging products across various industries, including food and beverage, personal care, and consumer goods.

The food packaging sector represents the largest market segment for PLA-based biodegradable packaging. The material's properties, such as transparency, barrier performance, and food contact safety, make it particularly suitable for fresh produce, bakery items, and ready-to-eat meals. The growing trend of on-the-go consumption and the rise of e-commerce have further boosted the demand for convenient, sustainable packaging solutions, where PLA can offer significant advantages.

In the personal care and cosmetics industry, there is a rising demand for sustainable packaging options. PLA's versatility in molding and forming processes allows for the creation of various packaging formats, from bottles and jars to tubes and closures. This adaptability positions PLA as a viable alternative to conventional plastics in this sector, addressing both functional requirements and sustainability goals.

The retail and e-commerce sectors have also shown increasing interest in PLA-based packaging materials. As online shopping continues to grow, there is a pressing need for protective packaging that is both effective and environmentally friendly. PLA-based foam cushioning and void-fill materials offer a sustainable alternative to traditional petroleum-based packaging, meeting the dual requirements of product protection and environmental responsibility.

Geographically, North America and Europe lead in the adoption of PLA-based biodegradable packaging, driven by stringent regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth, fueled by rapid industrialization, increasing disposable incomes, and growing environmental consciousness in countries like China and India.

Despite the positive market outlook, challenges remain in maximizing PLA's use in biodegradable packaging. These include cost competitiveness compared to conventional plastics, limitations in certain performance characteristics, and the need for proper waste management infrastructure to ensure effective composting or recycling. Addressing these challenges through technological advancements and supportive policies will be crucial in fully realizing the market potential of PLA in biodegradable packaging applications.

PLA Challenges

Despite the promising potential of PLA in biodegradable packaging, several challenges hinder its widespread adoption and maximization in this field. One of the primary obstacles is the higher production cost compared to conventional plastics. The raw materials and manufacturing processes for PLA are more expensive, making it less competitive in price-sensitive markets.

Another significant challenge is PLA's limited barrier properties. It exhibits higher permeability to gases and moisture compared to traditional packaging materials, which can affect the shelf life and quality of packaged products. This limitation restricts its use in certain food packaging applications where extended shelf life is crucial.

PLA's thermal stability is also a concern. It has a relatively low glass transition temperature and melting point, which can lead to deformation or degradation when exposed to high temperatures during storage or transportation. This characteristic limits its use in hot-fill applications or products that require heat sterilization.

The mechanical properties of PLA pose another challenge. While suitable for many applications, PLA can be brittle and less flexible compared to some conventional plastics. This brittleness can lead to packaging failures during handling and transportation, particularly in thin-film applications.

Biodegradation rates and conditions present a complex challenge. While PLA is biodegradable, it requires specific industrial composting conditions to break down efficiently. In many regions, the lack of appropriate composting infrastructure hampers the realization of PLA's environmental benefits.

The variability in PLA grades and formulations also presents difficulties in standardization and quality control. Different PLA types may have varying properties, making it challenging for manufacturers to maintain consistent performance across different batches or suppliers.

Recycling PLA poses another hurdle. While theoretically recyclable, PLA requires specialized recycling facilities, which are not widely available. Moreover, PLA can contaminate conventional plastic recycling streams if not properly sorted, potentially undermining existing recycling efforts.

Lastly, market acceptance and consumer perception remain challenges. Despite growing environmental awareness, there is still a lack of understanding about bioplastics among consumers. Misconceptions about biodegradability and composting requirements can lead to improper disposal, negating the environmental benefits of PLA packaging.

Another significant challenge is PLA's limited barrier properties. It exhibits higher permeability to gases and moisture compared to traditional packaging materials, which can affect the shelf life and quality of packaged products. This limitation restricts its use in certain food packaging applications where extended shelf life is crucial.

PLA's thermal stability is also a concern. It has a relatively low glass transition temperature and melting point, which can lead to deformation or degradation when exposed to high temperatures during storage or transportation. This characteristic limits its use in hot-fill applications or products that require heat sterilization.

The mechanical properties of PLA pose another challenge. While suitable for many applications, PLA can be brittle and less flexible compared to some conventional plastics. This brittleness can lead to packaging failures during handling and transportation, particularly in thin-film applications.

Biodegradation rates and conditions present a complex challenge. While PLA is biodegradable, it requires specific industrial composting conditions to break down efficiently. In many regions, the lack of appropriate composting infrastructure hampers the realization of PLA's environmental benefits.

The variability in PLA grades and formulations also presents difficulties in standardization and quality control. Different PLA types may have varying properties, making it challenging for manufacturers to maintain consistent performance across different batches or suppliers.

Recycling PLA poses another hurdle. While theoretically recyclable, PLA requires specialized recycling facilities, which are not widely available. Moreover, PLA can contaminate conventional plastic recycling streams if not properly sorted, potentially undermining existing recycling efforts.

Lastly, market acceptance and consumer perception remain challenges. Despite growing environmental awareness, there is still a lack of understanding about bioplastics among consumers. Misconceptions about biodegradability and composting requirements can lead to improper disposal, negating the environmental benefits of PLA packaging.

Current PLA Solutions

01 Biodegradable packaging applications

PLA is widely used in biodegradable packaging applications due to its environmentally friendly properties. It can be used to create various packaging materials, including food containers, bottles, and films. This application maximizes PLA use by replacing traditional petroleum-based plastics in packaging, reducing environmental impact.- PLA blends and composites: Developing PLA blends and composites with other materials to enhance its properties and expand its applications. This includes combining PLA with other polymers, natural fibers, or additives to improve mechanical strength, thermal stability, and biodegradability.

- PLA processing techniques: Optimizing processing techniques for PLA, such as extrusion, injection molding, and 3D printing. This involves developing new methods or modifying existing processes to improve PLA's processability, reduce cycle times, and enhance the quality of final products.

- PLA surface modifications: Modifying the surface properties of PLA to improve its compatibility with other materials, enhance its barrier properties, or add functionality. This can include techniques such as plasma treatment, chemical grafting, or coating applications.

- PLA in packaging applications: Expanding the use of PLA in packaging applications by developing new formulations and designs. This includes creating PLA-based packaging materials with improved barrier properties, shelf life, and compatibility with various food and non-food products.

- PLA recycling and end-of-life management: Developing efficient recycling methods and end-of-life management strategies for PLA products. This involves creating closed-loop systems, improving the biodegradability of PLA in various environments, and exploring chemical recycling techniques to maximize material recovery.

02 3D printing and additive manufacturing

PLA is a popular material for 3D printing and additive manufacturing due to its ease of use and low melting point. It can be used to create prototypes, custom parts, and various consumer products. This application maximizes PLA use by enabling rapid prototyping and small-scale manufacturing across various industries.Expand Specific Solutions03 Biomedical applications

PLA is utilized in various biomedical applications due to its biocompatibility and biodegradability. It can be used for tissue engineering scaffolds, drug delivery systems, and implantable medical devices. This application maximizes PLA use by leveraging its unique properties in the healthcare sector.Expand Specific Solutions04 Textile and fiber applications

PLA can be used to create biodegradable fibers and textiles, offering an eco-friendly alternative to traditional synthetic fibers. It can be used in clothing, upholstery, and other textile applications. This use maximizes PLA by providing sustainable options in the textile industry.Expand Specific Solutions05 Composite materials and blends

PLA can be blended with other materials or used as a matrix in composite materials to enhance its properties and expand its applications. This includes creating bio-based composites with natural fibers or blending PLA with other polymers to improve performance. This approach maximizes PLA use by broadening its potential applications across various industries.Expand Specific Solutions

Key PLA Players

The biodegradable packaging market, focusing on PLA maximization, is in a growth phase with increasing market size due to rising environmental concerns. The technology is maturing rapidly, with companies like Stora Enso Oyj, LG Chem Ltd., and Avantium Knowledge Centre BV leading innovation. Academic institutions such as Sichuan University and University of Coimbra are contributing to research advancements. The competitive landscape is diverse, including established players like International Paper Co. and emerging specialists like Sulapac Oy. Collaboration between industry and academia, exemplified by partnerships involving TotalEnergies OneTech SAS and CNRS, is driving technological progress and market expansion in this sector.

Sulapac Oy

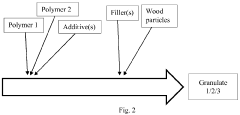

Technical Solution: Sulapac has developed a unique wood-based biodegradable material that can be used as an alternative to traditional plastic packaging. While not strictly PLA-based, their technology incorporates PLA as one of the components in their proprietary blend. The material mimics the properties of plastic while being fully biodegradable. Sulapac's innovation lies in the combination of wood chips and biodegradable polymers, creating a material that is both aesthetically pleasing and environmentally friendly.

Strengths: Unique aesthetic appeal, fully biodegradable, versatile applications. Weaknesses: Limited to certain types of packaging due to material properties, potentially higher production costs.

Stora Enso Oyj

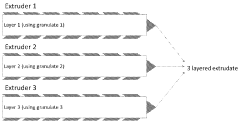

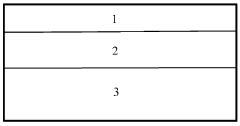

Technical Solution: Stora Enso has developed a range of bio-based packaging materials that incorporate PLA. Their technology focuses on creating multi-layer structures that combine the benefits of PLA with those of other bio-based materials like cellulose. This approach results in packaging solutions with enhanced barrier properties, strength, and biodegradability. Stora Enso's innovation lies in their ability to tailor the material properties for specific packaging applications, from food containers to flexible packaging.

Strengths: Customizable material properties, strong barrier performance, leverages company's expertise in cellulose-based materials. Weaknesses: Complex manufacturing process, may require specialized equipment for some applications.

PLA Innovations

Degradable recycling material

PatentPendingHK1214287A

Innovation

- Novel biodegradable material prepared from PHA and PLA polymers with accelerated biodegradation in microorganic environments.

- Versatile application in producing various products through thermal forming, injection moulding, or melt spinning while maintaining long shelf life in clean environments.

- Utilization of PLA's isomer control (L, D, and racemic forms) to design a broad range of fiber properties.

Flexible multi-layer composite material

PatentWO2024013432A1

Innovation

- A multi-layer composite material is developed using biopolymer layers with distinct properties, including a grease barrier, oxygen barrier, and moisture-resistant layers, incorporating hydrophilic natural fibers to enhance degradation and mechanical properties, suitable for extrusion and food/cosmetic contact.

Environmental Impact

The environmental impact of maximizing PLA's use in biodegradable packaging is a critical consideration in the pursuit of sustainable packaging solutions. PLA, or polylactic acid, offers significant advantages over traditional petroleum-based plastics in terms of its biodegradability and reduced carbon footprint. When properly disposed of in industrial composting facilities, PLA can break down into water, carbon dioxide, and biomass within a few months, leaving no toxic residues.

However, the environmental benefits of PLA are not without caveats. The production of PLA requires significant amounts of energy and water, primarily due to the cultivation and processing of its feedstock, typically corn or sugarcane. This agricultural dependency raises concerns about land use competition with food crops and potential deforestation. Additionally, the use of genetically modified crops and pesticides in feedstock production can have negative impacts on biodiversity and soil health.

The end-of-life management of PLA packaging also presents challenges. While biodegradable in industrial composting facilities, PLA does not readily decompose in natural environments or home composting systems. Improper disposal can lead to PLA contaminating recycling streams for conventional plastics, potentially compromising the recycling process. Furthermore, in landfill conditions, PLA may generate methane, a potent greenhouse gas, as it breaks down anaerobically.

To maximize the environmental benefits of PLA in packaging, a holistic approach is necessary. This includes optimizing production processes to reduce energy and water consumption, exploring alternative feedstocks such as agricultural waste or algae, and developing more efficient composting infrastructure. Implementing clear labeling and consumer education programs can also help ensure proper disposal and reduce contamination of recycling streams.

Research into improving PLA's properties, such as enhancing its barrier characteristics and heat resistance, can expand its applications in packaging and potentially reduce the overall amount of plastic used. Additionally, exploring blends of PLA with other biodegradable materials may lead to composites with improved environmental profiles and performance characteristics.

In conclusion, while PLA offers promising environmental benefits for biodegradable packaging, maximizing its use requires careful consideration of its entire lifecycle impact. Continued research, development, and infrastructure improvements are essential to fully realize PLA's potential as a sustainable packaging solution.

However, the environmental benefits of PLA are not without caveats. The production of PLA requires significant amounts of energy and water, primarily due to the cultivation and processing of its feedstock, typically corn or sugarcane. This agricultural dependency raises concerns about land use competition with food crops and potential deforestation. Additionally, the use of genetically modified crops and pesticides in feedstock production can have negative impacts on biodiversity and soil health.

The end-of-life management of PLA packaging also presents challenges. While biodegradable in industrial composting facilities, PLA does not readily decompose in natural environments or home composting systems. Improper disposal can lead to PLA contaminating recycling streams for conventional plastics, potentially compromising the recycling process. Furthermore, in landfill conditions, PLA may generate methane, a potent greenhouse gas, as it breaks down anaerobically.

To maximize the environmental benefits of PLA in packaging, a holistic approach is necessary. This includes optimizing production processes to reduce energy and water consumption, exploring alternative feedstocks such as agricultural waste or algae, and developing more efficient composting infrastructure. Implementing clear labeling and consumer education programs can also help ensure proper disposal and reduce contamination of recycling streams.

Research into improving PLA's properties, such as enhancing its barrier characteristics and heat resistance, can expand its applications in packaging and potentially reduce the overall amount of plastic used. Additionally, exploring blends of PLA with other biodegradable materials may lead to composites with improved environmental profiles and performance characteristics.

In conclusion, while PLA offers promising environmental benefits for biodegradable packaging, maximizing its use requires careful consideration of its entire lifecycle impact. Continued research, development, and infrastructure improvements are essential to fully realize PLA's potential as a sustainable packaging solution.

Regulatory Landscape

The regulatory landscape surrounding PLA's use in biodegradable packaging is complex and evolving, with different regions implementing varying policies to address environmental concerns and promote sustainable practices. In the European Union, the Single-Use Plastics Directive has been a significant driver for the adoption of biodegradable materials like PLA. This directive aims to reduce the impact of certain plastic products on the environment, encouraging the use of more sustainable alternatives.

In the United States, regulations vary by state, with some implementing stricter measures than others. California, for instance, has been at the forefront with its Rigid Plastic Packaging Container (RPPC) program, which mandates minimum recycled content and recyclability standards. These regulations indirectly benefit PLA as a viable alternative to traditional plastics.

Asian countries, particularly Japan and South Korea, have also been proactive in implementing regulations that favor biodegradable materials. Japan's Containers and Packaging Recycling Law has been instrumental in promoting the use of environmentally friendly packaging materials, including PLA.

Certification standards play a crucial role in the regulatory landscape. The ASTM D6400 and EN 13432 standards for compostability are widely recognized and often referenced in regulations. These standards ensure that PLA-based packaging meets specific biodegradability and compostability criteria, providing a framework for compliance and market acceptance.

However, the lack of harmonized global standards presents challenges for manufacturers and distributors operating across multiple regions. Different countries may have varying definitions of biodegradability and compostability, leading to potential confusion and compliance issues.

The regulatory landscape also extends to end-of-life management for PLA products. Many jurisdictions are implementing or considering extended producer responsibility (EPR) schemes, which could impact how PLA packaging is collected, processed, and recycled. These regulations aim to create closed-loop systems for packaging materials, potentially benefiting PLA due to its biodegradable nature.

As environmental concerns continue to grow, it is anticipated that regulations will become increasingly stringent, potentially favoring materials like PLA over traditional plastics. However, this also means that PLA manufacturers and users must stay vigilant and adaptable to changing regulatory requirements to maximize its use in biodegradable packaging.

In the United States, regulations vary by state, with some implementing stricter measures than others. California, for instance, has been at the forefront with its Rigid Plastic Packaging Container (RPPC) program, which mandates minimum recycled content and recyclability standards. These regulations indirectly benefit PLA as a viable alternative to traditional plastics.

Asian countries, particularly Japan and South Korea, have also been proactive in implementing regulations that favor biodegradable materials. Japan's Containers and Packaging Recycling Law has been instrumental in promoting the use of environmentally friendly packaging materials, including PLA.

Certification standards play a crucial role in the regulatory landscape. The ASTM D6400 and EN 13432 standards for compostability are widely recognized and often referenced in regulations. These standards ensure that PLA-based packaging meets specific biodegradability and compostability criteria, providing a framework for compliance and market acceptance.

However, the lack of harmonized global standards presents challenges for manufacturers and distributors operating across multiple regions. Different countries may have varying definitions of biodegradability and compostability, leading to potential confusion and compliance issues.

The regulatory landscape also extends to end-of-life management for PLA products. Many jurisdictions are implementing or considering extended producer responsibility (EPR) schemes, which could impact how PLA packaging is collected, processed, and recycled. These regulations aim to create closed-loop systems for packaging materials, potentially benefiting PLA due to its biodegradable nature.

As environmental concerns continue to grow, it is anticipated that regulations will become increasingly stringent, potentially favoring materials like PLA over traditional plastics. However, this also means that PLA manufacturers and users must stay vigilant and adaptable to changing regulatory requirements to maximize its use in biodegradable packaging.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!