How to Color and Finish PLA Objects for Better Aesthetic?

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PLA Finishing Background

Polylactic acid (PLA) has emerged as a popular material in the 3D printing industry due to its biodegradability, ease of use, and wide availability. However, the aesthetic appeal of raw PLA prints often falls short of consumer expectations, necessitating post-processing techniques to enhance their visual quality. The quest for improved aesthetics in PLA objects has led to the development of various coloring and finishing methods over the years.

The journey of PLA finishing began shortly after the material's introduction to the 3D printing market in the early 2000s. Initially, simple painting techniques were employed, but these often resulted in uneven coverage and poor adhesion to the plastic surface. As the demand for higher-quality finishes grew, researchers and hobbyists alike began experimenting with different approaches to overcome these limitations.

One significant milestone in PLA finishing was the adaptation of automotive painting techniques to 3D printed objects. This involved the use of primers, fillers, and specialized paints designed to adhere to plastic surfaces. The automotive industry's experience with durable, attractive finishes provided valuable insights that were gradually incorporated into PLA finishing processes.

Concurrent with painting advancements, chemical treatments for PLA surfaces were explored. Acetone smoothing, a technique commonly used with ABS plastic, was found to be ineffective on PLA due to its different chemical structure. This led to the investigation of alternative solvents and methods to achieve smooth surfaces without compromising the object's structural integrity.

The development of specialized PLA filaments with enhanced aesthetic properties marked another important step in the evolution of PLA finishing. Manufacturers began producing filaments infused with metallic particles, wood fibers, and other materials that could yield more visually appealing prints straight from the printer, reducing the need for extensive post-processing.

As environmental concerns gained prominence, the focus shifted towards developing eco-friendly finishing methods that would maintain PLA's biodegradable properties. This trend has driven research into water-based paints, natural dyes, and biodegradable sealants that can enhance the appearance of PLA objects without significantly impacting their end-of-life disposal.

The current landscape of PLA finishing encompasses a wide range of techniques, from traditional painting and polishing to more advanced methods like hydro dipping and UV curing. Each approach offers unique advantages and challenges, catering to different aesthetic goals and production scales. The ongoing evolution of these techniques continues to push the boundaries of what is possible in terms of color, texture, and overall visual appeal for PLA-printed objects.

The journey of PLA finishing began shortly after the material's introduction to the 3D printing market in the early 2000s. Initially, simple painting techniques were employed, but these often resulted in uneven coverage and poor adhesion to the plastic surface. As the demand for higher-quality finishes grew, researchers and hobbyists alike began experimenting with different approaches to overcome these limitations.

One significant milestone in PLA finishing was the adaptation of automotive painting techniques to 3D printed objects. This involved the use of primers, fillers, and specialized paints designed to adhere to plastic surfaces. The automotive industry's experience with durable, attractive finishes provided valuable insights that were gradually incorporated into PLA finishing processes.

Concurrent with painting advancements, chemical treatments for PLA surfaces were explored. Acetone smoothing, a technique commonly used with ABS plastic, was found to be ineffective on PLA due to its different chemical structure. This led to the investigation of alternative solvents and methods to achieve smooth surfaces without compromising the object's structural integrity.

The development of specialized PLA filaments with enhanced aesthetic properties marked another important step in the evolution of PLA finishing. Manufacturers began producing filaments infused with metallic particles, wood fibers, and other materials that could yield more visually appealing prints straight from the printer, reducing the need for extensive post-processing.

As environmental concerns gained prominence, the focus shifted towards developing eco-friendly finishing methods that would maintain PLA's biodegradable properties. This trend has driven research into water-based paints, natural dyes, and biodegradable sealants that can enhance the appearance of PLA objects without significantly impacting their end-of-life disposal.

The current landscape of PLA finishing encompasses a wide range of techniques, from traditional painting and polishing to more advanced methods like hydro dipping and UV curing. Each approach offers unique advantages and challenges, catering to different aesthetic goals and production scales. The ongoing evolution of these techniques continues to push the boundaries of what is possible in terms of color, texture, and overall visual appeal for PLA-printed objects.

Market Demand Analysis

The market demand for coloring and finishing PLA objects has seen significant growth in recent years, driven by the increasing popularity of 3D printing and the desire for more aesthetically pleasing end products. As 3D printing technology becomes more accessible to consumers and businesses alike, there is a growing need for methods to enhance the appearance of printed objects beyond their basic monochromatic finish.

The 3D printing industry has experienced rapid expansion, with the global market size projected to reach $40 billion by 2024. Within this market, PLA (Polylactic Acid) filament remains one of the most widely used materials due to its biodegradability, ease of use, and low cost. However, the inherent limitations of PLA in terms of color options and surface finish have created a substantial demand for post-processing techniques.

Consumer preferences are shifting towards customized and visually appealing products, driving the need for advanced coloring and finishing solutions. This trend is particularly evident in industries such as product prototyping, architectural modeling, and personalized consumer goods. The ability to produce high-quality, aesthetically pleasing PLA objects is becoming a key differentiator for businesses in these sectors.

The DIY and maker communities have also contributed significantly to the market demand for PLA coloring and finishing techniques. These enthusiasts are constantly seeking new ways to improve the appearance of their 3D printed creations, leading to a thriving market for paints, dyes, and finishing tools specifically designed for PLA.

In the professional sector, industries such as automotive, aerospace, and consumer electronics are increasingly utilizing 3D printing for prototyping and small-scale production. These industries require high-quality finishes that can accurately represent the final product, creating a demand for advanced coloring and finishing techniques that can achieve professional-grade results.

The environmental aspect of PLA coloring and finishing is also driving market demand. As sustainability becomes a key concern for consumers and businesses, there is a growing interest in eco-friendly coloring and finishing methods that maintain PLA's biodegradable properties while enhancing its aesthetic appeal.

Market research indicates that the global 3D printing materials market, which includes PLA and associated finishing products, is expected to grow at a CAGR of 24% from 2021 to 2028. This growth is partly attributed to the increasing demand for customized and aesthetically enhanced 3D printed objects across various industries.

In conclusion, the market demand for coloring and finishing PLA objects is robust and growing, driven by the expansion of the 3D printing industry, changing consumer preferences, and the need for high-quality finishes in professional applications. This demand presents significant opportunities for innovation in coloring and finishing techniques, as well as the development of new products and services in this space.

The 3D printing industry has experienced rapid expansion, with the global market size projected to reach $40 billion by 2024. Within this market, PLA (Polylactic Acid) filament remains one of the most widely used materials due to its biodegradability, ease of use, and low cost. However, the inherent limitations of PLA in terms of color options and surface finish have created a substantial demand for post-processing techniques.

Consumer preferences are shifting towards customized and visually appealing products, driving the need for advanced coloring and finishing solutions. This trend is particularly evident in industries such as product prototyping, architectural modeling, and personalized consumer goods. The ability to produce high-quality, aesthetically pleasing PLA objects is becoming a key differentiator for businesses in these sectors.

The DIY and maker communities have also contributed significantly to the market demand for PLA coloring and finishing techniques. These enthusiasts are constantly seeking new ways to improve the appearance of their 3D printed creations, leading to a thriving market for paints, dyes, and finishing tools specifically designed for PLA.

In the professional sector, industries such as automotive, aerospace, and consumer electronics are increasingly utilizing 3D printing for prototyping and small-scale production. These industries require high-quality finishes that can accurately represent the final product, creating a demand for advanced coloring and finishing techniques that can achieve professional-grade results.

The environmental aspect of PLA coloring and finishing is also driving market demand. As sustainability becomes a key concern for consumers and businesses, there is a growing interest in eco-friendly coloring and finishing methods that maintain PLA's biodegradable properties while enhancing its aesthetic appeal.

Market research indicates that the global 3D printing materials market, which includes PLA and associated finishing products, is expected to grow at a CAGR of 24% from 2021 to 2028. This growth is partly attributed to the increasing demand for customized and aesthetically enhanced 3D printed objects across various industries.

In conclusion, the market demand for coloring and finishing PLA objects is robust and growing, driven by the expansion of the 3D printing industry, changing consumer preferences, and the need for high-quality finishes in professional applications. This demand presents significant opportunities for innovation in coloring and finishing techniques, as well as the development of new products and services in this space.

Current Challenges

Despite the growing popularity of 3D printing with PLA (Polylactic Acid), achieving high-quality aesthetic finishes remains a significant challenge. One of the primary issues is the inherent surface texture of 3D printed objects, which often exhibits visible layer lines and imperfections. These artifacts can detract from the overall appearance and perceived quality of the final product.

Color consistency is another major hurdle in PLA finishing. The natural color of PLA filaments can vary between manufacturers and even batches, making it difficult to achieve uniform coloration across large or multiple objects. Additionally, PLA's low heat resistance can complicate traditional painting and finishing techniques, as excessive heat can cause deformation or warping of the printed parts.

Adhesion of paints and coatings to PLA surfaces presents another challenge. The smooth, non-porous nature of PLA can make it difficult for paints to bond effectively, often resulting in poor coverage, peeling, or chipping over time. This issue is particularly pronounced when attempting to achieve a glossy or high-shine finish on PLA objects.

The limited color options available in PLA filaments also pose a constraint for designers and makers. While the range of colors has expanded in recent years, it still falls short of the virtually unlimited palette available through painting or other finishing techniques. This limitation can force compromises in design or require more complex post-processing to achieve desired color effects.

Environmental considerations add another layer of complexity to PLA finishing. As a biodegradable material, PLA is often chosen for its eco-friendly properties. However, many traditional paints and finishes contain chemicals that may negate these environmental benefits, creating a dilemma for those seeking both aesthetic appeal and sustainability.

Durability of finishes on PLA objects is an ongoing concern. The material's tendency to absorb moisture and its relatively low impact resistance can lead to degradation of applied finishes over time, especially for objects exposed to outdoor conditions or frequent handling. This necessitates the development of specialized coatings that can withstand these challenges while maintaining the desired aesthetic qualities.

Lastly, the time and skill required for high-quality finishing of PLA objects present a significant barrier for many users. Achieving professional-grade results often demands multiple steps, including sanding, priming, painting, and sealing, each requiring patience and expertise. This complexity can be daunting for hobbyists and can increase production costs for commercial applications, limiting the widespread adoption of advanced finishing techniques for PLA-printed objects.

Color consistency is another major hurdle in PLA finishing. The natural color of PLA filaments can vary between manufacturers and even batches, making it difficult to achieve uniform coloration across large or multiple objects. Additionally, PLA's low heat resistance can complicate traditional painting and finishing techniques, as excessive heat can cause deformation or warping of the printed parts.

Adhesion of paints and coatings to PLA surfaces presents another challenge. The smooth, non-porous nature of PLA can make it difficult for paints to bond effectively, often resulting in poor coverage, peeling, or chipping over time. This issue is particularly pronounced when attempting to achieve a glossy or high-shine finish on PLA objects.

The limited color options available in PLA filaments also pose a constraint for designers and makers. While the range of colors has expanded in recent years, it still falls short of the virtually unlimited palette available through painting or other finishing techniques. This limitation can force compromises in design or require more complex post-processing to achieve desired color effects.

Environmental considerations add another layer of complexity to PLA finishing. As a biodegradable material, PLA is often chosen for its eco-friendly properties. However, many traditional paints and finishes contain chemicals that may negate these environmental benefits, creating a dilemma for those seeking both aesthetic appeal and sustainability.

Durability of finishes on PLA objects is an ongoing concern. The material's tendency to absorb moisture and its relatively low impact resistance can lead to degradation of applied finishes over time, especially for objects exposed to outdoor conditions or frequent handling. This necessitates the development of specialized coatings that can withstand these challenges while maintaining the desired aesthetic qualities.

Lastly, the time and skill required for high-quality finishing of PLA objects present a significant barrier for many users. Achieving professional-grade results often demands multiple steps, including sanding, priming, painting, and sealing, each requiring patience and expertise. This complexity can be daunting for hobbyists and can increase production costs for commercial applications, limiting the widespread adoption of advanced finishing techniques for PLA-printed objects.

Existing Coloring Methods

01 Surface treatment techniques for PLA objects

Various surface treatment techniques can be applied to PLA objects to enhance their aesthetic appeal. These methods may include polishing, coating, or texturing processes that improve the visual and tactile qualities of the PLA surface. Such treatments can result in smoother finishes, unique textures, or improved color retention, contributing to the overall aesthetic value of the PLA object.- Surface treatment techniques for PLA objects: Various surface treatment techniques can be applied to PLA objects to enhance their aesthetic appeal. These methods may include polishing, coating, or texturing processes that improve the visual and tactile qualities of the PLA surface. Such treatments can result in smoother finishes, unique textures, or improved color consistency, contributing to the overall aesthetic value of the PLA objects.

- Color enhancement and customization for PLA objects: Methods for enhancing and customizing the color of PLA objects are crucial for improving their aesthetic appeal. This may involve techniques such as pigment incorporation during the manufacturing process, post-production dyeing, or the application of color-changing materials. These approaches allow for a wide range of color options and effects, enabling the creation of visually striking PLA objects.

- Design optimization for PLA object aesthetics: Optimizing the design of PLA objects is essential for enhancing their aesthetic appeal. This may involve using advanced modeling software, incorporating organic shapes, or implementing biomimetic design principles. By focusing on design optimization, manufacturers can create PLA objects with improved visual appeal, ergonomics, and overall attractiveness.

- Texture and pattern application for PLA objects: Applying textures and patterns to PLA objects can significantly enhance their aesthetic value. This may include techniques such as embossing, engraving, or the use of molds with intricate designs. These methods allow for the creation of unique surface features that can improve both the visual and tactile appeal of PLA objects.

- Post-processing techniques for PLA object aesthetics: Various post-processing techniques can be employed to enhance the aesthetics of PLA objects after their initial production. These may include heat treatment, chemical smoothing, or the application of protective coatings. Such post-processing methods can improve surface finish, increase durability, and enhance the overall visual appeal of PLA objects.

02 Color enhancement and customization of PLA objects

Techniques for enhancing and customizing the color of PLA objects are crucial for improving their aesthetic appeal. This may involve the use of pigments, dyes, or other coloring agents that can be incorporated into the PLA material during processing or applied as a surface treatment. Advanced color customization methods allow for the creation of unique patterns, gradients, or multi-color designs on PLA objects.Expand Specific Solutions03 Design optimization for PLA 3D printing

Optimizing the design of PLA objects for 3D printing can significantly enhance their aesthetic qualities. This involves considerations such as layer height, infill patterns, and support structures to minimize visible layer lines and achieve smoother surfaces. Advanced design techniques may also incorporate complex geometries or organic shapes that showcase the unique capabilities of PLA 3D printing.Expand Specific Solutions04 Post-processing techniques for PLA objects

Post-processing techniques play a crucial role in enhancing the aesthetic appeal of PLA objects. These may include methods such as sanding, vapor smoothing, or chemical treatments that can improve surface finish and overall appearance. Additionally, post-processing can involve the application of decorative elements or finishes that further enhance the visual appeal of the PLA object.Expand Specific Solutions05 Integration of functional and aesthetic elements in PLA objects

Combining functional and aesthetic elements in PLA object design can create visually appealing products with practical applications. This approach may involve incorporating textures or patterns that serve both decorative and functional purposes, such as improving grip or reducing glare. It can also include the integration of other materials or components that enhance both the aesthetic and functional aspects of the PLA object.Expand Specific Solutions

Key Industry Players

The market for coloring and finishing PLA objects is in a growth phase, driven by increasing demand for customized and aesthetically pleasing 3D printed products. The global market size for 3D printing materials, including PLA, is expanding rapidly. Technologically, the field is advancing, with companies like DyeMansion GmbH and Rize, Inc. developing specialized solutions for post-processing PLA objects. Established players such as 3M Innovative Properties Co. and Covestro Deutschland AG are also contributing to the technological maturity of PLA finishing techniques. The involvement of academic institutions like the University of Leeds and the Technical University of Denmark indicates ongoing research and development in this area, suggesting potential for further innovation and market growth.

DyeMansion GmbH

Technical Solution: DyeMansion specializes in post-processing solutions for 3D-printed parts, including coloring and finishing PLA objects. Their PolyShot Surfacing (PSS) technology uses compressed air and abrasive media to smooth and prepare surfaces for dyeing. The DM60 dyeing system then uses a water-based process to deeply penetrate and color PLA parts, offering a wide range of vibrant, consistent colors. Finally, their DeepDye Coloring (DDC) process ensures color fastness and UV stability.

Strengths: Comprehensive post-processing solution, consistent and vibrant colors, environmentally friendly water-based process. Weaknesses: Requires multiple steps and specialized equipment, potentially higher cost for small-scale production.

Covestro Deutschland AG

Technical Solution: Covestro has developed a range of color masterbatches specifically designed for PLA. Their technology involves incorporating specially formulated pigments and additives into PLA pellets, which can then be used in injection molding or 3D printing processes. This method allows for consistent coloration throughout the entire PLA object, rather than just surface treatment. Additionally, they have developed UV-stable formulations to prevent color fading and degradation when exposed to sunlight.

Strengths: Consistent coloration throughout the object, UV-stable formulations, suitable for various manufacturing processes. Weaknesses: Limited to pre-determined colors, may require specialized equipment for small-scale or custom production.

Innovative Techniques

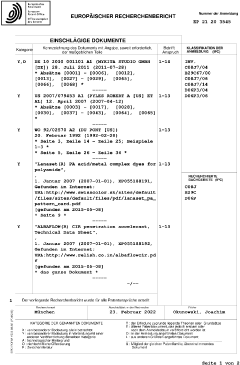

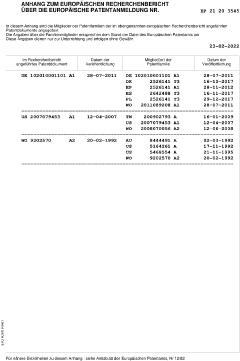

Deep color dyeing and finishing technique of poly lactic acid (PLA) fiber and gossamer fiber blending fabrics

PatentActiveCN102864663A

Innovation

- Medium-temperature disperse dyes and environmentally friendly medium-temperature direct dyes are used for dyeing. The temperature and pH value are controlled. Carriers and fixing agents are used for multi-step processing, including pre-forming, pre-treatment, dyeing, fixation and post-finishing to ensure uniform dyeing. Adhesion and fiber protection.

Method for treating surfaces of plastic items

PatentPendingEP3978555A1

Innovation

- A method involving a dyeing mixture of metal complex, acid, reactive, azo, or disperse dyes dissolved in a solvent, heated to a temperature below the plastic's melting or glass transition point, combined with a pretreatment step for surface smoothing and an amphoteric wetting agent, followed by a post-treatment impregnation and sealing to ensure color penetration and durability.

Environmental Impact

The environmental impact of coloring and finishing PLA objects is a crucial consideration in the pursuit of enhanced aesthetics. PLA (Polylactic Acid) is widely recognized as a biodegradable and eco-friendly material, but the processes and materials used for coloring and finishing can significantly alter its environmental profile.

Traditional coloring methods often involve the use of chemical-based dyes and paints, which may introduce harmful substances into the environment. These additives can potentially leach into soil and water systems, negatively impacting ecosystems. Moreover, some finishing techniques may require solvents or other volatile organic compounds (VOCs) that contribute to air pollution and pose health risks to both workers and end-users.

However, recent advancements in eco-friendly coloring and finishing techniques are mitigating these concerns. Water-based paints and natural dyes derived from plant sources offer more sustainable alternatives. These options not only reduce the environmental footprint but also maintain the biodegradability of PLA objects. Additionally, innovative surface treatment methods, such as UV curing and plasma coating, provide durable finishes with minimal environmental impact.

The lifecycle assessment of colored and finished PLA objects reveals that the choice of coloring and finishing methods can significantly influence the overall sustainability of the product. Techniques that preserve or enhance the recyclability of PLA are particularly valuable from an environmental perspective. For instance, some pigments and coatings can be designed to separate easily from PLA during the recycling process, ensuring that the base material remains recyclable.

Energy consumption during the coloring and finishing processes is another critical environmental factor. Traditional heat-based methods can be energy-intensive, contributing to increased carbon emissions. In contrast, emerging low-temperature techniques and energy-efficient equipment are helping to reduce the carbon footprint associated with these processes.

The durability of the colored and finished PLA objects also plays a role in their environmental impact. Finishes that extend the lifespan of products can offset the initial environmental costs by reducing the need for frequent replacements. This aspect underscores the importance of balancing immediate aesthetic improvements with long-term sustainability considerations.

As the demand for environmentally responsible manufacturing grows, the development of green chemistry solutions for coloring and finishing PLA objects is gaining momentum. These innovations aim to create aesthetically pleasing products while minimizing ecological harm, aligning with circular economy principles and sustainable design practices.

Traditional coloring methods often involve the use of chemical-based dyes and paints, which may introduce harmful substances into the environment. These additives can potentially leach into soil and water systems, negatively impacting ecosystems. Moreover, some finishing techniques may require solvents or other volatile organic compounds (VOCs) that contribute to air pollution and pose health risks to both workers and end-users.

However, recent advancements in eco-friendly coloring and finishing techniques are mitigating these concerns. Water-based paints and natural dyes derived from plant sources offer more sustainable alternatives. These options not only reduce the environmental footprint but also maintain the biodegradability of PLA objects. Additionally, innovative surface treatment methods, such as UV curing and plasma coating, provide durable finishes with minimal environmental impact.

The lifecycle assessment of colored and finished PLA objects reveals that the choice of coloring and finishing methods can significantly influence the overall sustainability of the product. Techniques that preserve or enhance the recyclability of PLA are particularly valuable from an environmental perspective. For instance, some pigments and coatings can be designed to separate easily from PLA during the recycling process, ensuring that the base material remains recyclable.

Energy consumption during the coloring and finishing processes is another critical environmental factor. Traditional heat-based methods can be energy-intensive, contributing to increased carbon emissions. In contrast, emerging low-temperature techniques and energy-efficient equipment are helping to reduce the carbon footprint associated with these processes.

The durability of the colored and finished PLA objects also plays a role in their environmental impact. Finishes that extend the lifespan of products can offset the initial environmental costs by reducing the need for frequent replacements. This aspect underscores the importance of balancing immediate aesthetic improvements with long-term sustainability considerations.

As the demand for environmentally responsible manufacturing grows, the development of green chemistry solutions for coloring and finishing PLA objects is gaining momentum. These innovations aim to create aesthetically pleasing products while minimizing ecological harm, aligning with circular economy principles and sustainable design practices.

Consumer Preferences

Consumer preferences for colored and finished PLA objects have evolved significantly in recent years, driven by the growing popularity of 3D printing and the increasing demand for customized products. Users are no longer satisfied with plain, monochromatic PLA prints; they now seek aesthetically pleasing, professional-looking objects that can rival traditionally manufactured items.

Color preferences vary widely depending on the intended use of the PLA object. For decorative items and artistic pieces, vibrant and bold colors are often favored, with metallic finishes gaining popularity for their luxurious appearance. In contrast, for functional objects or prototypes, more subdued colors and matte finishes are preferred, as they convey a sense of professionalism and durability.

Texture plays a crucial role in consumer satisfaction. While the layer lines characteristic of 3D printing were once accepted as unavoidable, consumers now expect smoother surfaces. This has led to a growing interest in post-processing techniques that can achieve a more polished look. Soft-touch finishes are particularly popular for handheld objects, as they enhance the tactile experience.

Durability is another key factor influencing consumer preferences. Users expect colored and finished PLA objects to maintain their appearance over time, resisting fading, chipping, or peeling. This has driven demand for high-quality coloring and finishing methods that not only enhance aesthetics but also improve the object's longevity.

Customization options are highly valued by consumers. The ability to match specific color schemes or create unique patterns has become a significant selling point for colored PLA objects. This trend is particularly evident in the maker community and among businesses offering personalized products.

Environmental considerations are increasingly influencing consumer choices. There is a growing preference for eco-friendly coloring and finishing methods that maintain PLA's biodegradability. Water-based paints and natural dyes are gaining traction among environmentally conscious consumers.

The perceived value of colored and finished PLA objects is closely tied to their visual quality. Consumers are willing to pay a premium for items that exhibit a high level of craftsmanship in their coloring and finishing. This has led to a market segmentation where higher-priced, professionally finished PLA objects coexist with more affordable, DIY-finished alternatives.

Color preferences vary widely depending on the intended use of the PLA object. For decorative items and artistic pieces, vibrant and bold colors are often favored, with metallic finishes gaining popularity for their luxurious appearance. In contrast, for functional objects or prototypes, more subdued colors and matte finishes are preferred, as they convey a sense of professionalism and durability.

Texture plays a crucial role in consumer satisfaction. While the layer lines characteristic of 3D printing were once accepted as unavoidable, consumers now expect smoother surfaces. This has led to a growing interest in post-processing techniques that can achieve a more polished look. Soft-touch finishes are particularly popular for handheld objects, as they enhance the tactile experience.

Durability is another key factor influencing consumer preferences. Users expect colored and finished PLA objects to maintain their appearance over time, resisting fading, chipping, or peeling. This has driven demand for high-quality coloring and finishing methods that not only enhance aesthetics but also improve the object's longevity.

Customization options are highly valued by consumers. The ability to match specific color schemes or create unique patterns has become a significant selling point for colored PLA objects. This trend is particularly evident in the maker community and among businesses offering personalized products.

Environmental considerations are increasingly influencing consumer choices. There is a growing preference for eco-friendly coloring and finishing methods that maintain PLA's biodegradability. Water-based paints and natural dyes are gaining traction among environmentally conscious consumers.

The perceived value of colored and finished PLA objects is closely tied to their visual quality. Consumers are willing to pay a premium for items that exhibit a high level of craftsmanship in their coloring and finishing. This has led to a market segmentation where higher-priced, professionally finished PLA objects coexist with more affordable, DIY-finished alternatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!