PLA Filament for Eco-Friendly 3D Printing: Benefits and Drawbacks

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PLA Filament Evolution

PLA filament has undergone significant evolution since its introduction to the 3D printing industry. Initially developed as a biodegradable alternative to traditional petroleum-based plastics, PLA filament has become a staple material in additive manufacturing due to its eco-friendly properties and ease of use.

The journey of PLA filament began in the early 2000s when researchers started exploring its potential for 3D printing applications. Early versions of PLA filament were limited in color options and had inconsistent quality, often resulting in print failures or subpar finished products. However, as demand for sustainable 3D printing materials grew, manufacturers invested in improving PLA formulations and production processes.

By the mid-2010s, PLA filament had evolved to offer a wider range of colors and improved mechanical properties. Manufacturers introduced blends that incorporated additives to enhance strength, flexibility, and heat resistance. This evolution expanded the applications of PLA beyond simple prototyping to functional parts and end-use products.

A significant milestone in PLA filament evolution was the development of specialty grades. These included wood-filled PLA, which mimics the appearance and texture of wood, and metal-filled PLA, which can produce prints with metallic finishes. These innovations broadened the creative possibilities for designers and hobbyists alike.

Recent advancements have focused on addressing PLA's limitations, such as its low heat resistance and brittleness. Researchers have developed heat-resistant PLA formulations that can withstand higher temperatures, making them suitable for automotive and aerospace applications. Additionally, the introduction of impact-modified PLA has improved toughness and durability, expanding its use in consumer products.

The latest evolution in PLA filament technology involves the integration of recycled materials. Manufacturers are now producing PLA filaments made from post-consumer plastic waste, further enhancing the material's eco-friendly credentials. This development aligns with the growing emphasis on circular economy principles in the 3D printing industry.

Looking ahead, the evolution of PLA filament is expected to continue with a focus on enhancing biodegradability and compostability. Researchers are exploring ways to accelerate the decomposition process of PLA without compromising its performance during use. This ongoing evolution aims to position PLA as the go-to material for sustainable 3D printing in various industries, from packaging to medical devices.

The journey of PLA filament began in the early 2000s when researchers started exploring its potential for 3D printing applications. Early versions of PLA filament were limited in color options and had inconsistent quality, often resulting in print failures or subpar finished products. However, as demand for sustainable 3D printing materials grew, manufacturers invested in improving PLA formulations and production processes.

By the mid-2010s, PLA filament had evolved to offer a wider range of colors and improved mechanical properties. Manufacturers introduced blends that incorporated additives to enhance strength, flexibility, and heat resistance. This evolution expanded the applications of PLA beyond simple prototyping to functional parts and end-use products.

A significant milestone in PLA filament evolution was the development of specialty grades. These included wood-filled PLA, which mimics the appearance and texture of wood, and metal-filled PLA, which can produce prints with metallic finishes. These innovations broadened the creative possibilities for designers and hobbyists alike.

Recent advancements have focused on addressing PLA's limitations, such as its low heat resistance and brittleness. Researchers have developed heat-resistant PLA formulations that can withstand higher temperatures, making them suitable for automotive and aerospace applications. Additionally, the introduction of impact-modified PLA has improved toughness and durability, expanding its use in consumer products.

The latest evolution in PLA filament technology involves the integration of recycled materials. Manufacturers are now producing PLA filaments made from post-consumer plastic waste, further enhancing the material's eco-friendly credentials. This development aligns with the growing emphasis on circular economy principles in the 3D printing industry.

Looking ahead, the evolution of PLA filament is expected to continue with a focus on enhancing biodegradability and compostability. Researchers are exploring ways to accelerate the decomposition process of PLA without compromising its performance during use. This ongoing evolution aims to position PLA as the go-to material for sustainable 3D printing in various industries, from packaging to medical devices.

Eco-Friendly 3D Printing Market

The eco-friendly 3D printing market has experienced significant growth in recent years, driven by increasing environmental awareness and the demand for sustainable manufacturing solutions. This market segment focuses on the use of biodegradable and recyclable materials, such as PLA (Polylactic Acid) filaments, which offer a more environmentally friendly alternative to traditional petroleum-based plastics.

The global eco-friendly 3D printing market is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to remain in the double digits over the next five years. This growth is fueled by several factors, including stricter environmental regulations, consumer preferences for sustainable products, and the expanding applications of 3D printing technology across various industries.

One of the key drivers of market demand is the industrial sector, where eco-friendly 3D printing is being adopted for prototyping, tooling, and small-scale production. The automotive and aerospace industries, in particular, are increasingly utilizing PLA and other biodegradable materials to reduce their environmental footprint while maintaining the benefits of additive manufacturing.

The consumer segment also plays a crucial role in market expansion, with hobbyists and small businesses embracing eco-friendly 3D printing for personal projects, custom products, and educational purposes. The accessibility of desktop 3D printers and the availability of sustainable filaments have contributed to this trend.

In the medical and healthcare sectors, there is a growing interest in using biodegradable materials for applications such as customized implants, prosthetics, and anatomical models. PLA's biocompatibility makes it an attractive option for these purposes, driving demand in this specialized market segment.

The packaging industry is another area where eco-friendly 3D printing is gaining traction. Companies are exploring the use of biodegradable materials for creating sustainable packaging solutions, prototypes, and molds, aligning with the broader trend towards reducing plastic waste.

Geographically, North America and Europe currently lead the eco-friendly 3D printing market, owing to their advanced technological infrastructure and stringent environmental policies. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing adoption of 3D printing technologies, and growing environmental consciousness in countries like China and Japan.

Despite the positive outlook, challenges remain in the eco-friendly 3D printing market. These include the higher cost of sustainable materials compared to traditional plastics, limitations in material properties for certain applications, and the need for further research and development to improve the performance and versatility of biodegradable filaments.

The global eco-friendly 3D printing market is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to remain in the double digits over the next five years. This growth is fueled by several factors, including stricter environmental regulations, consumer preferences for sustainable products, and the expanding applications of 3D printing technology across various industries.

One of the key drivers of market demand is the industrial sector, where eco-friendly 3D printing is being adopted for prototyping, tooling, and small-scale production. The automotive and aerospace industries, in particular, are increasingly utilizing PLA and other biodegradable materials to reduce their environmental footprint while maintaining the benefits of additive manufacturing.

The consumer segment also plays a crucial role in market expansion, with hobbyists and small businesses embracing eco-friendly 3D printing for personal projects, custom products, and educational purposes. The accessibility of desktop 3D printers and the availability of sustainable filaments have contributed to this trend.

In the medical and healthcare sectors, there is a growing interest in using biodegradable materials for applications such as customized implants, prosthetics, and anatomical models. PLA's biocompatibility makes it an attractive option for these purposes, driving demand in this specialized market segment.

The packaging industry is another area where eco-friendly 3D printing is gaining traction. Companies are exploring the use of biodegradable materials for creating sustainable packaging solutions, prototypes, and molds, aligning with the broader trend towards reducing plastic waste.

Geographically, North America and Europe currently lead the eco-friendly 3D printing market, owing to their advanced technological infrastructure and stringent environmental policies. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing adoption of 3D printing technologies, and growing environmental consciousness in countries like China and Japan.

Despite the positive outlook, challenges remain in the eco-friendly 3D printing market. These include the higher cost of sustainable materials compared to traditional plastics, limitations in material properties for certain applications, and the need for further research and development to improve the performance and versatility of biodegradable filaments.

PLA Filament Challenges

Despite the numerous advantages of PLA filament in 3D printing, several challenges persist that hinder its widespread adoption and optimal performance. One of the primary issues is the material's susceptibility to moisture absorption. PLA is hygroscopic, meaning it readily absorbs moisture from the air, which can lead to degradation of the filament's quality and printing performance. This moisture absorption can cause bubbling, stringing, and inconsistent extrusion during the printing process, resulting in poor print quality and reduced mechanical properties of the final product.

Another significant challenge is the limited temperature resistance of PLA. The material has a relatively low glass transition temperature, typically around 60-65°C, which restricts its use in applications requiring higher temperature resistance. This characteristic makes PLA unsuitable for certain end-use products that may be exposed to elevated temperatures, such as automotive parts or household items that come into contact with hot liquids.

The brittleness of PLA presents another hurdle, particularly in applications requiring high impact resistance or flexibility. While PLA offers good tensile strength, its low impact strength and elongation at break make it prone to shattering or cracking under sudden stress or impact. This limitation narrows the range of potential applications for PLA-printed parts, especially in industries where durability and toughness are crucial.

Biodegradability, often touted as a key advantage of PLA, also poses challenges in certain scenarios. The material's tendency to break down under specific environmental conditions can be problematic for long-term outdoor applications or products that require extended shelf life. Controlling the degradation process and ensuring the material maintains its integrity for the desired product lifespan can be complex and may require additional treatments or modifications to the base PLA material.

Furthermore, the printing process itself presents challenges when working with PLA filament. The material requires careful temperature control during printing, as it has a narrow optimal printing temperature range. Slight variations in temperature can lead to issues such as under-extrusion, over-extrusion, or poor layer adhesion. Additionally, PLA's tendency to warp or shrink during cooling necessitates careful consideration of print bed adhesion and cooling strategies to ensure dimensional accuracy and prevent print failures.

Lastly, while PLA is derived from renewable resources, the production process still has environmental implications. The energy consumption and potential use of chemical additives in PLA production raise questions about its overall environmental impact compared to traditional plastics. Balancing the material's eco-friendly attributes with these production-related concerns remains an ongoing challenge for manufacturers and researchers in the field of sustainable 3D printing materials.

Another significant challenge is the limited temperature resistance of PLA. The material has a relatively low glass transition temperature, typically around 60-65°C, which restricts its use in applications requiring higher temperature resistance. This characteristic makes PLA unsuitable for certain end-use products that may be exposed to elevated temperatures, such as automotive parts or household items that come into contact with hot liquids.

The brittleness of PLA presents another hurdle, particularly in applications requiring high impact resistance or flexibility. While PLA offers good tensile strength, its low impact strength and elongation at break make it prone to shattering or cracking under sudden stress or impact. This limitation narrows the range of potential applications for PLA-printed parts, especially in industries where durability and toughness are crucial.

Biodegradability, often touted as a key advantage of PLA, also poses challenges in certain scenarios. The material's tendency to break down under specific environmental conditions can be problematic for long-term outdoor applications or products that require extended shelf life. Controlling the degradation process and ensuring the material maintains its integrity for the desired product lifespan can be complex and may require additional treatments or modifications to the base PLA material.

Furthermore, the printing process itself presents challenges when working with PLA filament. The material requires careful temperature control during printing, as it has a narrow optimal printing temperature range. Slight variations in temperature can lead to issues such as under-extrusion, over-extrusion, or poor layer adhesion. Additionally, PLA's tendency to warp or shrink during cooling necessitates careful consideration of print bed adhesion and cooling strategies to ensure dimensional accuracy and prevent print failures.

Lastly, while PLA is derived from renewable resources, the production process still has environmental implications. The energy consumption and potential use of chemical additives in PLA production raise questions about its overall environmental impact compared to traditional plastics. Balancing the material's eco-friendly attributes with these production-related concerns remains an ongoing challenge for manufacturers and researchers in the field of sustainable 3D printing materials.

Current PLA Filament Solutions

01 Biodegradable PLA filament composition

Development of PLA filament compositions that are biodegradable and eco-friendly. These formulations may include additives or modifications to enhance the biodegradability of the PLA material, making it more environmentally sustainable for 3D printing applications.- Biodegradable PLA filament composition: Development of PLA filament compositions that are biodegradable, enhancing their eco-friendliness. These compositions may include additives or modifications to improve biodegradability while maintaining desired mechanical properties for 3D printing applications.

- Recycling and reuse of PLA filaments: Methods and systems for recycling used PLA filaments or failed 3D prints, allowing for the reprocessing of PLA material into new filaments. This approach reduces waste and improves the overall eco-friendliness of PLA-based 3D printing.

- Sustainable production of PLA filaments: Techniques for producing PLA filaments using renewable resources and energy-efficient processes. This may include the use of bio-based feedstocks, optimized manufacturing methods, and reduced environmental impact during production.

- PLA filament blends with other eco-friendly materials: Development of PLA filament blends incorporating other environmentally friendly materials to enhance overall eco-friendliness. These blends may improve biodegradability, reduce environmental impact, or introduce additional beneficial properties to the filament.

- End-of-life management for PLA filament products: Strategies and technologies for managing PLA filament products at the end of their lifecycle. This may include composting solutions, chemical recycling methods, or other environmentally responsible disposal techniques to minimize the ecological footprint of PLA-based 3D printed items.

02 Recycling and reuse of PLA filaments

Methods and systems for recycling and reusing PLA filaments, reducing waste and improving the overall eco-friendliness of 3D printing processes. This may include techniques for processing used PLA filaments or failed prints to create new filament material.Expand Specific Solutions03 Eco-friendly additives for PLA filaments

Incorporation of environmentally friendly additives into PLA filaments to enhance their properties while maintaining or improving their eco-friendliness. These additives may improve strength, flexibility, or other characteristics without compromising the material's biodegradability.Expand Specific Solutions04 Energy-efficient PLA filament production

Development of energy-efficient processes for manufacturing PLA filaments, reducing the overall environmental impact of production. This may include optimized extrusion techniques, use of renewable energy sources, or improved process control systems.Expand Specific Solutions05 Bio-based sources for PLA filament production

Utilization of sustainable, bio-based sources for producing PLA filaments, further enhancing their eco-friendliness. This may involve using agricultural waste, algae, or other renewable resources as raw materials for PLA production, reducing reliance on fossil-based plastics.Expand Specific Solutions

Key PLA Filament Manufacturers

The PLA filament market for eco-friendly 3D printing is in a growth phase, driven by increasing environmental awareness and demand for sustainable materials. The market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, PLA filament is relatively mature, with ongoing improvements in performance and sustainability. Companies like Kingfa Sci. & Tech. Co., Ltd., TerraVerdae Bioworks, Inc., and Avantium Knowledge Centre BV are at the forefront of PLA filament development, focusing on enhancing material properties and production efficiency. Academic institutions such as Southern University of Science & Technology and Nanjing Forestry University are contributing to research and innovation in this field, while established players like Goodyear Tire & Rubber Co. and SK Chemicals Co. Ltd. are exploring PLA applications in various industries.

TerraVerdae Bioworks, Inc.

Technical Solution: TerraVerdae Bioworks has developed a unique PHA-based (polyhydroxyalkanoate) biopolymer technology that can be blended with PLA for 3D printing applications. Their approach combines the biodegradability of PLA with the improved mechanical properties of PHA. The company uses a proprietary fermentation process to produce PHA, which is then compounded with PLA to create filaments with enhanced flexibility, impact resistance, and biodegradability in various environments, including marine ecosystems.

Strengths: Improved mechanical properties, broader range of biodegradation environments, and potential for customized formulations. Weaknesses: Higher production costs due to the use of PHA, and potential challenges in achieving consistent material properties.

SK Chemicals Co. Ltd.

Technical Solution: SK Chemicals has developed a proprietary PLA copolymer technology for 3D printing applications. Their approach involves synthesizing PLA with other bio-based monomers to create copolymers with improved thermal and mechanical properties. The company's technology focuses on enhancing the heat resistance and impact strength of PLA while maintaining its biodegradability. SK Chemicals also incorporates additives to improve the filament's processing characteristics and reduce printing defects such as warping and shrinkage.

Strengths: Enhanced thermal and mechanical properties, improved printability, and maintained biodegradability. Weaknesses: Potentially higher material costs due to the use of specialized copolymers and additives, and possible limitations in the range of available colors and finishes.

PLA Filament Innovations

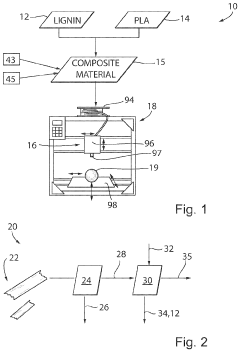

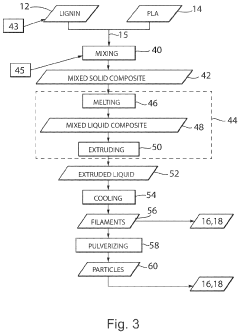

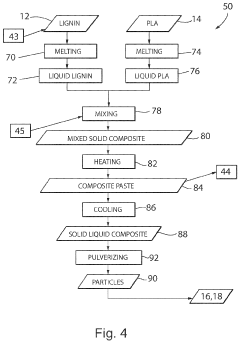

Polyactic Acid and Lignin Composite Thermoplastic for 3D Printing

PatentInactiveUS20210171764A1

Innovation

- A composite thermoplastic material is developed by blending purified polylactic acid (PLA) with high amounts of purified lignin, using a silane coupling agent to improve compatibility, and optionally incorporating carbon fibers, which enhances mechanical properties and thermal stability, while being environmentally friendly and cost-effective.

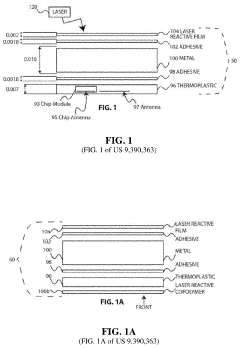

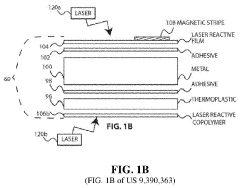

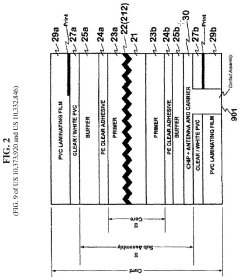

RFID-enabled metal transaction cards with foil, special texture, color and carbon fiber

PatentInactiveUS20210174159A1

Innovation

- The development of RFID-enabled metal transaction cards with a composite layer of carbon fiber and a micro-slit metal layer, where a hologram or diffraction grating is assembled on the metal layer with a micro-slit, and a conductive foil is applied to act as an antenna and coupling frame, ensuring radio frequency reception and transmission while camouflaging the slit.

Environmental Impact Analysis

The environmental impact of PLA (Polylactic Acid) filament in 3D printing is a critical consideration for eco-friendly manufacturing practices. PLA, derived from renewable resources such as corn starch or sugarcane, offers several environmental benefits compared to traditional petroleum-based plastics.

One of the primary advantages of PLA is its biodegradability. Under proper composting conditions, PLA can break down into natural components within a few months to a year, significantly reducing long-term environmental pollution. This characteristic makes PLA an attractive option for reducing plastic waste in landfills and oceans.

Furthermore, the production of PLA consumes less energy compared to conventional plastics, resulting in a lower carbon footprint. Studies have shown that PLA manufacturing can reduce greenhouse gas emissions by up to 80% compared to traditional petroleum-based plastics. This reduction in energy consumption and emissions contributes to mitigating climate change impacts.

PLA also boasts a lower toxicity profile during production and use. Unlike some other plastics, PLA does not release harmful fumes or chemicals during the 3D printing process, making it safer for both users and the environment. This aspect is particularly important in enclosed spaces or when considering the potential health impacts of 3D printing emissions.

However, the environmental benefits of PLA are not without challenges. The biodegradability of PLA requires specific industrial composting conditions, which are not widely available in many regions. In standard landfill conditions, PLA may not degrade significantly faster than conventional plastics, potentially contributing to long-term waste accumulation.

Additionally, the agricultural production of PLA's raw materials raises concerns about land use and food security. The cultivation of crops for PLA production could potentially compete with food crops, leading to debates about the ethical implications of using agricultural resources for plastic production.

The recycling of PLA presents another environmental challenge. While theoretically recyclable, PLA requires specialized facilities that are not as common as those for traditional plastics. This limitation can result in PLA products being disposed of in regular waste streams, negating some of its environmental benefits.

In conclusion, while PLA filament offers significant environmental advantages in 3D printing, including biodegradability, lower energy consumption, and reduced toxicity, its overall environmental impact is complex. The realization of PLA's full eco-friendly potential depends on the development of appropriate waste management infrastructure and the careful consideration of its entire lifecycle, from production to disposal.

One of the primary advantages of PLA is its biodegradability. Under proper composting conditions, PLA can break down into natural components within a few months to a year, significantly reducing long-term environmental pollution. This characteristic makes PLA an attractive option for reducing plastic waste in landfills and oceans.

Furthermore, the production of PLA consumes less energy compared to conventional plastics, resulting in a lower carbon footprint. Studies have shown that PLA manufacturing can reduce greenhouse gas emissions by up to 80% compared to traditional petroleum-based plastics. This reduction in energy consumption and emissions contributes to mitigating climate change impacts.

PLA also boasts a lower toxicity profile during production and use. Unlike some other plastics, PLA does not release harmful fumes or chemicals during the 3D printing process, making it safer for both users and the environment. This aspect is particularly important in enclosed spaces or when considering the potential health impacts of 3D printing emissions.

However, the environmental benefits of PLA are not without challenges. The biodegradability of PLA requires specific industrial composting conditions, which are not widely available in many regions. In standard landfill conditions, PLA may not degrade significantly faster than conventional plastics, potentially contributing to long-term waste accumulation.

Additionally, the agricultural production of PLA's raw materials raises concerns about land use and food security. The cultivation of crops for PLA production could potentially compete with food crops, leading to debates about the ethical implications of using agricultural resources for plastic production.

The recycling of PLA presents another environmental challenge. While theoretically recyclable, PLA requires specialized facilities that are not as common as those for traditional plastics. This limitation can result in PLA products being disposed of in regular waste streams, negating some of its environmental benefits.

In conclusion, while PLA filament offers significant environmental advantages in 3D printing, including biodegradability, lower energy consumption, and reduced toxicity, its overall environmental impact is complex. The realization of PLA's full eco-friendly potential depends on the development of appropriate waste management infrastructure and the careful consideration of its entire lifecycle, from production to disposal.

Biodegradability Standards

Biodegradability standards play a crucial role in assessing the environmental impact of PLA (Polylactic Acid) filaments used in 3D printing. These standards provide a framework for evaluating the rate and extent of decomposition of PLA materials under specific conditions, ensuring that claims of biodegradability are substantiated and consistent across different products and manufacturers.

The most widely recognized standard for biodegradability is ASTM D6400, which sets the criteria for compostable plastics designed to be composted in municipal and industrial aerobic composting facilities. This standard requires that the material must disintegrate into fine particles within 12 weeks and completely biodegrade within 180 days in a composting environment. Additionally, the resulting compost should not contain any toxic residues that could harm plant growth.

For PLA filaments specifically, the European Standard EN 13432 is often referenced. This standard is similar to ASTM D6400 but is tailored for the European market. It requires that at least 90% of the organic material is converted into CO2 within six months, and that the residues do not contain any harmful substances.

The ISO 17088 standard is another international benchmark for compostable plastics. It defines the specifications for compostable plastics, including the test methods and criteria for the final acceptance of products. This standard is particularly relevant for PLA filaments as it covers materials that are intended to be composted in well-managed composting facilities.

It's important to note that these standards typically apply to industrial composting conditions, which involve higher temperatures and controlled environments. Home composting standards, such as the Australian AS 5810-2010 and the European OK Compost Home certification, are more stringent as they reflect the lower temperatures and less controlled conditions of home composting systems.

For PLA filaments used in 3D printing, meeting these biodegradability standards is essential for manufacturers to substantiate eco-friendly claims. However, it's crucial to understand that biodegradability in controlled testing environments may not translate directly to real-world conditions. Factors such as temperature, moisture, and the presence of specific microorganisms can significantly affect the biodegradation process.

Manufacturers of PLA filaments for 3D printing must conduct thorough testing to ensure compliance with these standards. This typically involves submitting samples to accredited laboratories for testing under the specified conditions. The results of these tests provide valuable information on the environmental performance of the filaments and can guide improvements in material formulation to enhance biodegradability.

The most widely recognized standard for biodegradability is ASTM D6400, which sets the criteria for compostable plastics designed to be composted in municipal and industrial aerobic composting facilities. This standard requires that the material must disintegrate into fine particles within 12 weeks and completely biodegrade within 180 days in a composting environment. Additionally, the resulting compost should not contain any toxic residues that could harm plant growth.

For PLA filaments specifically, the European Standard EN 13432 is often referenced. This standard is similar to ASTM D6400 but is tailored for the European market. It requires that at least 90% of the organic material is converted into CO2 within six months, and that the residues do not contain any harmful substances.

The ISO 17088 standard is another international benchmark for compostable plastics. It defines the specifications for compostable plastics, including the test methods and criteria for the final acceptance of products. This standard is particularly relevant for PLA filaments as it covers materials that are intended to be composted in well-managed composting facilities.

It's important to note that these standards typically apply to industrial composting conditions, which involve higher temperatures and controlled environments. Home composting standards, such as the Australian AS 5810-2010 and the European OK Compost Home certification, are more stringent as they reflect the lower temperatures and less controlled conditions of home composting systems.

For PLA filaments used in 3D printing, meeting these biodegradability standards is essential for manufacturers to substantiate eco-friendly claims. However, it's crucial to understand that biodegradability in controlled testing environments may not translate directly to real-world conditions. Factors such as temperature, moisture, and the presence of specific microorganisms can significantly affect the biodegradation process.

Manufacturers of PLA filaments for 3D printing must conduct thorough testing to ensure compliance with these standards. This typically involves submitting samples to accredited laboratories for testing under the specified conditions. The results of these tests provide valuable information on the environmental performance of the filaments and can guide improvements in material formulation to enhance biodegradability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!