How to Optimize PLA Biodegradability in Industrial Applications?

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PLA Biodegradability Background and Objectives

Polylactic acid (PLA) has emerged as a promising biodegradable polymer in recent years, gaining significant attention in various industrial applications due to its eco-friendly nature. The development of PLA can be traced back to the 1920s, but it wasn't until the late 20th century that its potential for widespread use was fully recognized. As environmental concerns have grown, the demand for sustainable materials has increased, propelling PLA to the forefront of biodegradable polymer research and development.

The evolution of PLA technology has been marked by continuous improvements in production processes, material properties, and biodegradability. Initially, the high cost of production and limited understanding of its degradation mechanisms hindered widespread adoption. However, advancements in fermentation techniques and polymer science have significantly reduced production costs and enhanced material performance, making PLA a viable alternative to conventional plastics in many applications.

The primary objective in optimizing PLA biodegradability for industrial applications is to strike a balance between functionality during use and rapid decomposition after disposal. This involves tailoring the polymer's molecular structure, crystallinity, and additives to achieve desired mechanical properties while ensuring complete biodegradation within a reasonable timeframe under various environmental conditions.

Key technological goals include enhancing the rate of hydrolysis, which is the primary mechanism of PLA degradation, without compromising the material's stability during its intended use. Additionally, researchers aim to develop PLA formulations that can biodegrade effectively in diverse environments, from industrial composting facilities to marine ecosystems, broadening its applicability across different sectors.

Another critical objective is to improve the compatibility of PLA with existing manufacturing processes and equipment, facilitating its integration into current industrial production lines. This includes enhancing thermal stability, melt strength, and processability to enable the production of a wide range of products, from packaging materials to durable goods.

The optimization of PLA biodegradability also encompasses the development of standardized testing methods and certification processes to accurately assess and communicate the material's environmental impact. This is crucial for building consumer trust and ensuring regulatory compliance across different regions and industries.

As the field progresses, there is a growing focus on creating circular economy models for PLA, where the polymer can be efficiently recycled or composted at the end of its life cycle. This holistic approach aims to minimize waste and maximize resource utilization, aligning with global sustainability goals and driving innovation in biodegradable polymer technology.

The evolution of PLA technology has been marked by continuous improvements in production processes, material properties, and biodegradability. Initially, the high cost of production and limited understanding of its degradation mechanisms hindered widespread adoption. However, advancements in fermentation techniques and polymer science have significantly reduced production costs and enhanced material performance, making PLA a viable alternative to conventional plastics in many applications.

The primary objective in optimizing PLA biodegradability for industrial applications is to strike a balance between functionality during use and rapid decomposition after disposal. This involves tailoring the polymer's molecular structure, crystallinity, and additives to achieve desired mechanical properties while ensuring complete biodegradation within a reasonable timeframe under various environmental conditions.

Key technological goals include enhancing the rate of hydrolysis, which is the primary mechanism of PLA degradation, without compromising the material's stability during its intended use. Additionally, researchers aim to develop PLA formulations that can biodegrade effectively in diverse environments, from industrial composting facilities to marine ecosystems, broadening its applicability across different sectors.

Another critical objective is to improve the compatibility of PLA with existing manufacturing processes and equipment, facilitating its integration into current industrial production lines. This includes enhancing thermal stability, melt strength, and processability to enable the production of a wide range of products, from packaging materials to durable goods.

The optimization of PLA biodegradability also encompasses the development of standardized testing methods and certification processes to accurately assess and communicate the material's environmental impact. This is crucial for building consumer trust and ensuring regulatory compliance across different regions and industries.

As the field progresses, there is a growing focus on creating circular economy models for PLA, where the polymer can be efficiently recycled or composted at the end of its life cycle. This holistic approach aims to minimize waste and maximize resource utilization, aligning with global sustainability goals and driving innovation in biodegradable polymer technology.

Market Analysis for Biodegradable PLA Products

The market for biodegradable PLA (Polylactic Acid) products has been experiencing significant growth in recent years, driven by increasing environmental concerns and regulatory pressures to reduce plastic waste. PLA, derived from renewable resources such as corn starch or sugarcane, offers a promising alternative to traditional petroleum-based plastics in various industrial applications.

The global biodegradable plastics market, of which PLA is a key component, was valued at approximately $4.1 billion in 2020 and is projected to reach $7.8 billion by 2025, growing at a CAGR of 13.7% during the forecast period. PLA accounts for a substantial portion of this market, with its share expected to increase due to its versatility and improving biodegradability characteristics.

Key industries driving the demand for biodegradable PLA products include packaging, agriculture, textiles, and consumer goods. The packaging sector, in particular, represents the largest market segment, with food packaging being a primary application area. The shift towards sustainable packaging solutions in response to consumer preferences and regulatory mandates has significantly boosted PLA adoption in this sector.

In the agricultural sector, PLA-based mulch films and plant pots are gaining traction due to their ability to biodegrade in soil, reducing plastic accumulation in farmlands. The textile industry is also exploring PLA fibers as an eco-friendly alternative to synthetic fibers, particularly in disposable garments and non-woven applications.

Geographically, Europe and North America currently lead the market for biodegradable PLA products, owing to stringent environmental regulations and higher consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing environmental concerns, and supportive government policies in countries like China and India.

Despite the positive market outlook, challenges remain in optimizing PLA biodegradability for industrial applications. The rate of biodegradation can vary significantly depending on environmental conditions, which has led to concerns about its effectiveness in real-world scenarios. Additionally, the higher cost of PLA compared to conventional plastics remains a barrier to widespread adoption in price-sensitive markets.

To address these challenges and capitalize on market opportunities, industry players are focusing on research and development to enhance PLA's biodegradability while maintaining its mechanical properties. Collaborations between material scientists, manufacturers, and end-users are becoming increasingly common to develop tailored PLA formulations for specific industrial applications.

The global biodegradable plastics market, of which PLA is a key component, was valued at approximately $4.1 billion in 2020 and is projected to reach $7.8 billion by 2025, growing at a CAGR of 13.7% during the forecast period. PLA accounts for a substantial portion of this market, with its share expected to increase due to its versatility and improving biodegradability characteristics.

Key industries driving the demand for biodegradable PLA products include packaging, agriculture, textiles, and consumer goods. The packaging sector, in particular, represents the largest market segment, with food packaging being a primary application area. The shift towards sustainable packaging solutions in response to consumer preferences and regulatory mandates has significantly boosted PLA adoption in this sector.

In the agricultural sector, PLA-based mulch films and plant pots are gaining traction due to their ability to biodegrade in soil, reducing plastic accumulation in farmlands. The textile industry is also exploring PLA fibers as an eco-friendly alternative to synthetic fibers, particularly in disposable garments and non-woven applications.

Geographically, Europe and North America currently lead the market for biodegradable PLA products, owing to stringent environmental regulations and higher consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing environmental concerns, and supportive government policies in countries like China and India.

Despite the positive market outlook, challenges remain in optimizing PLA biodegradability for industrial applications. The rate of biodegradation can vary significantly depending on environmental conditions, which has led to concerns about its effectiveness in real-world scenarios. Additionally, the higher cost of PLA compared to conventional plastics remains a barrier to widespread adoption in price-sensitive markets.

To address these challenges and capitalize on market opportunities, industry players are focusing on research and development to enhance PLA's biodegradability while maintaining its mechanical properties. Collaborations between material scientists, manufacturers, and end-users are becoming increasingly common to develop tailored PLA formulations for specific industrial applications.

Current PLA Biodegradability Challenges

Despite the growing popularity of Polylactic Acid (PLA) as a biodegradable alternative to traditional plastics, several challenges persist in optimizing its biodegradability for industrial applications. One of the primary issues is the slow degradation rate of PLA under ambient conditions. While PLA can decompose in industrial composting facilities, it requires specific temperature and humidity conditions that are not typically found in natural environments.

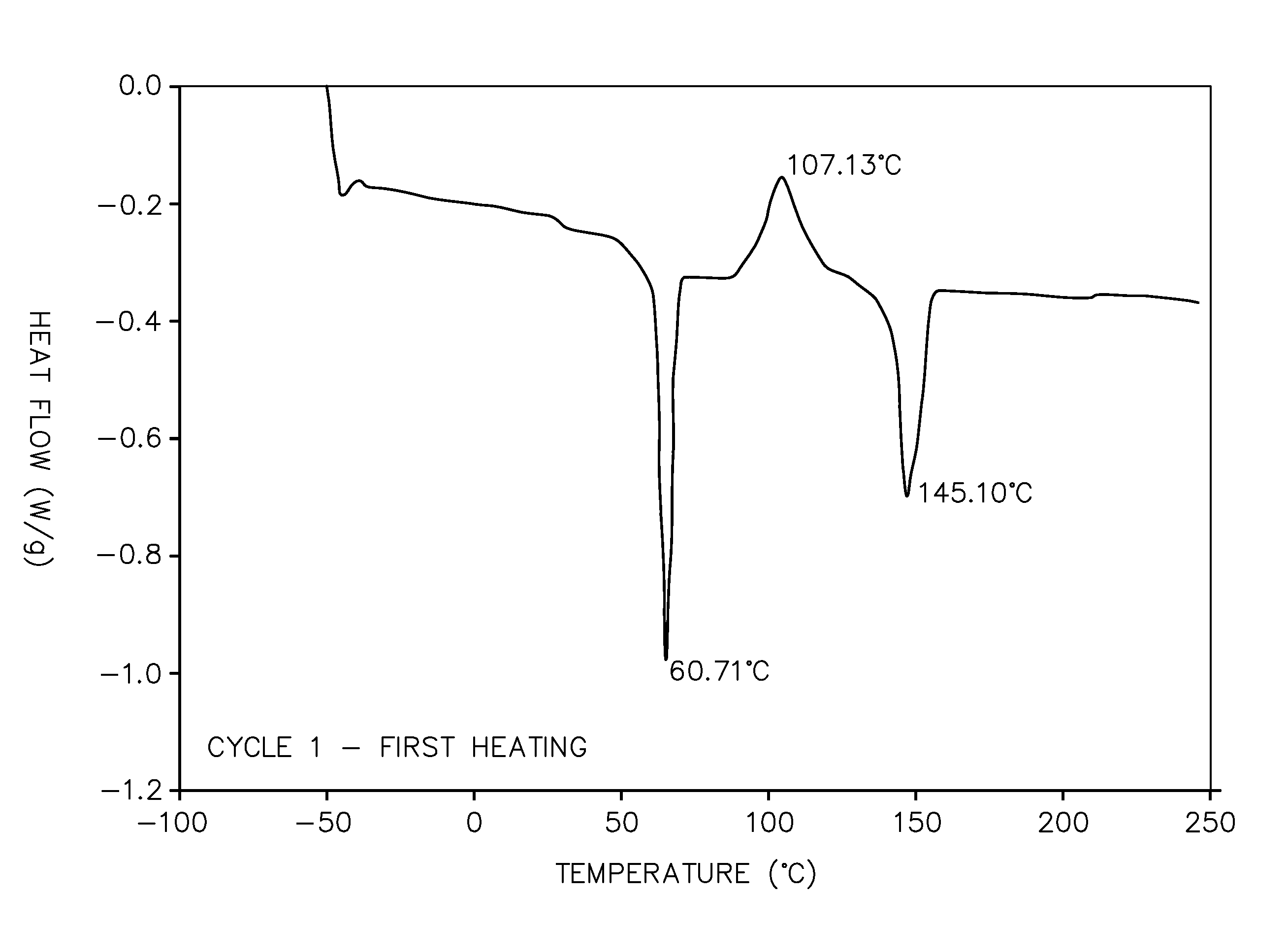

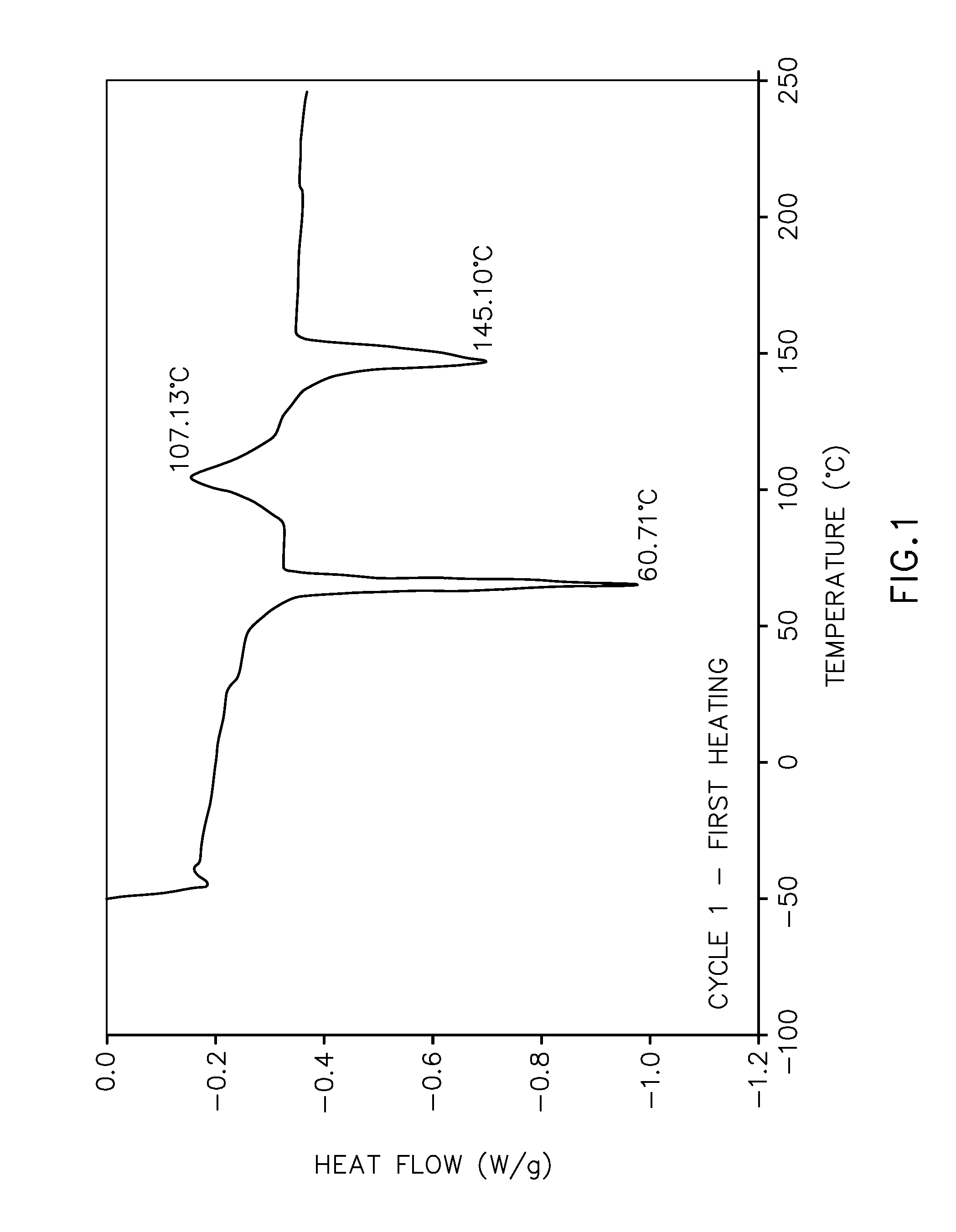

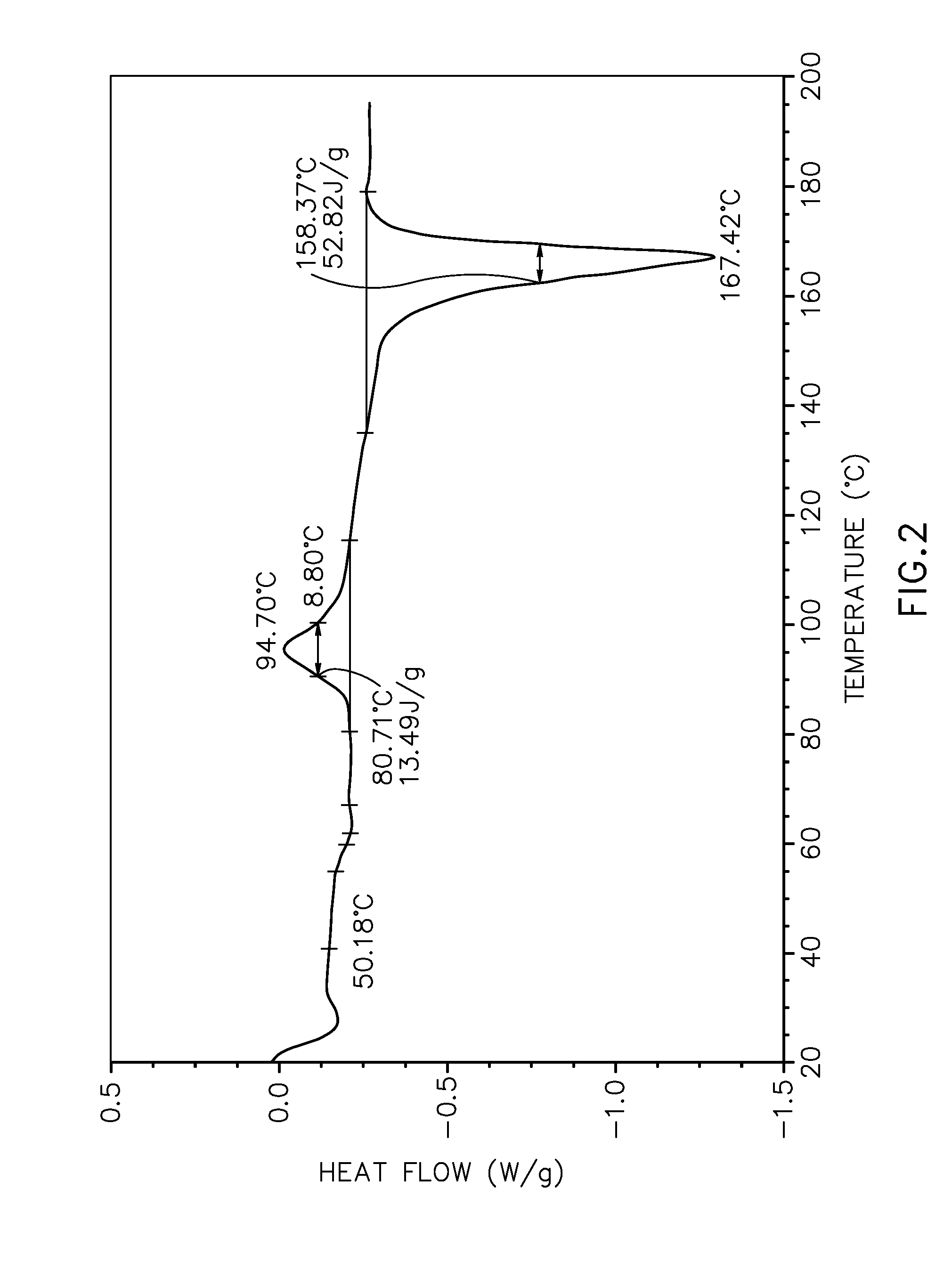

The inconsistency in biodegradation rates across different PLA products poses another significant challenge. Factors such as molecular weight, crystallinity, and the presence of additives can greatly influence the biodegradation process, making it difficult to predict and control the degradation timeline in various industrial settings. This variability complicates waste management strategies and hinders the widespread adoption of PLA in certain industries.

Another hurdle is the limited availability of industrial composting facilities capable of processing PLA effectively. Many regions lack the infrastructure necessary to handle PLA waste, leading to improper disposal and negating the material's biodegradable benefits. This infrastructure gap presents a significant obstacle to the large-scale implementation of PLA in industrial applications.

The incomplete biodegradation of PLA is also a concern. In some cases, PLA may break down into microplastics rather than fully decomposing, potentially contributing to environmental pollution. This issue raises questions about the long-term ecological impact of PLA and challenges its positioning as a truly sustainable material.

Furthermore, the cost-effectiveness of PLA production and processing remains a challenge for many industries. The higher production costs compared to conventional plastics, coupled with the need for specialized composting facilities, can make PLA less economically viable for certain applications. This economic barrier often leads industries to opt for cheaper, non-biodegradable alternatives.

The sensitivity of PLA to moisture and temperature during processing and storage also presents challenges in industrial settings. This sensitivity can lead to premature degradation or loss of mechanical properties, limiting its use in certain applications that require long shelf life or exposure to harsh environmental conditions.

Lastly, the lack of standardized testing methods for assessing PLA biodegradability across different industrial contexts hampers the development of optimized formulations. Without consistent and reliable evaluation protocols, it becomes challenging to compare different PLA products and improve their biodegradation performance for specific industrial needs.

The inconsistency in biodegradation rates across different PLA products poses another significant challenge. Factors such as molecular weight, crystallinity, and the presence of additives can greatly influence the biodegradation process, making it difficult to predict and control the degradation timeline in various industrial settings. This variability complicates waste management strategies and hinders the widespread adoption of PLA in certain industries.

Another hurdle is the limited availability of industrial composting facilities capable of processing PLA effectively. Many regions lack the infrastructure necessary to handle PLA waste, leading to improper disposal and negating the material's biodegradable benefits. This infrastructure gap presents a significant obstacle to the large-scale implementation of PLA in industrial applications.

The incomplete biodegradation of PLA is also a concern. In some cases, PLA may break down into microplastics rather than fully decomposing, potentially contributing to environmental pollution. This issue raises questions about the long-term ecological impact of PLA and challenges its positioning as a truly sustainable material.

Furthermore, the cost-effectiveness of PLA production and processing remains a challenge for many industries. The higher production costs compared to conventional plastics, coupled with the need for specialized composting facilities, can make PLA less economically viable for certain applications. This economic barrier often leads industries to opt for cheaper, non-biodegradable alternatives.

The sensitivity of PLA to moisture and temperature during processing and storage also presents challenges in industrial settings. This sensitivity can lead to premature degradation or loss of mechanical properties, limiting its use in certain applications that require long shelf life or exposure to harsh environmental conditions.

Lastly, the lack of standardized testing methods for assessing PLA biodegradability across different industrial contexts hampers the development of optimized formulations. Without consistent and reliable evaluation protocols, it becomes challenging to compare different PLA products and improve their biodegradation performance for specific industrial needs.

Existing PLA Biodegradability Enhancement Methods

01 Biodegradation mechanisms of PLA

PLA biodegradation occurs through hydrolysis and microbial action. The process begins with water absorption, leading to hydrolytic chain scission. Microorganisms then metabolize the resulting oligomers and monomers. Factors such as temperature, humidity, and microbial activity influence the rate of biodegradation.- Biodegradation mechanisms of PLA: PLA biodegradation occurs through hydrolysis and microbial action. The process begins with water absorption, leading to chain scission of the polymer. Microorganisms then metabolize the resulting oligomers and monomers. Factors such as temperature, humidity, and microbial activity influence the rate of biodegradation.

- Enhancing PLA biodegradability: Various methods are employed to improve PLA biodegradability, including blending with other biodegradable polymers, incorporating additives, and modifying the polymer structure. These techniques aim to increase the material's susceptibility to environmental degradation while maintaining its desirable properties during use.

- Environmental factors affecting PLA biodegradation: The biodegradation of PLA is influenced by environmental conditions such as temperature, humidity, pH, and the presence of specific microorganisms. Understanding these factors is crucial for predicting and controlling the biodegradation process in various applications and disposal scenarios.

- PLA composites and their biodegradability: PLA-based composites, incorporating natural fibers or inorganic fillers, can exhibit modified biodegradation profiles. These composites often aim to balance improved mechanical properties with maintained or enhanced biodegradability, expanding the range of applications for PLA-based materials.

- Industrial applications considering PLA biodegradability: The biodegradability of PLA is a key consideration in various industrial applications, including packaging, agriculture, and biomedical fields. Tailoring PLA formulations to achieve desired biodegradation rates while meeting performance requirements is crucial for successful implementation in these sectors.

02 Enhancing PLA biodegradability

Various methods can improve PLA biodegradability, including blending with other biodegradable polymers, incorporating additives, and modifying the polymer structure. These techniques aim to increase the material's susceptibility to environmental degradation while maintaining its desirable properties during use.Expand Specific Solutions03 Environmental impact of PLA biodegradation

The biodegradation of PLA offers potential environmental benefits compared to conventional plastics. It can reduce plastic waste accumulation and microplastic pollution. However, proper disposal conditions are crucial for optimal biodegradation, and the environmental impact may vary depending on disposal methods and local ecosystems.Expand Specific Solutions04 Industrial applications of biodegradable PLA

Biodegradable PLA finds applications in various industries, including packaging, agriculture, and biomedical fields. Its biodegradability makes it suitable for single-use items, compostable products, and controlled-release systems in agriculture and medicine. Ongoing research focuses on expanding its use in more demanding applications.Expand Specific Solutions05 Measuring and standardizing PLA biodegradability

Standardized testing methods and certifications are essential for assessing PLA biodegradability. These include composting tests, soil burial tests, and aquatic biodegradation tests. Efforts are ongoing to develop and refine international standards for biodegradability claims, ensuring consistency and reliability in product labeling and environmental impact assessments.Expand Specific Solutions

Key Players in PLA Biodegradable Materials

The optimization of PLA biodegradability in industrial applications is currently in a growth phase, with increasing market size driven by sustainability demands. The global biodegradable plastics market is expanding rapidly, expected to reach $7.59 billion by 2025. Technologically, PLA biodegradability optimization is progressing but still evolving. Companies like Sulapac Oy, Avantium Knowledge Centre BV, and Arctic Biomaterials Oy are at the forefront, developing innovative solutions. Academic institutions such as Sichuan University, University of Coimbra, and Cornell University are contributing significant research. Collaborations between industry players like TotalEnergies OneTech SAS and research centers like Centre National de la Recherche Scientifique are accelerating technological advancements, indicating a competitive yet collaborative landscape in this field.

Sulapac Oy

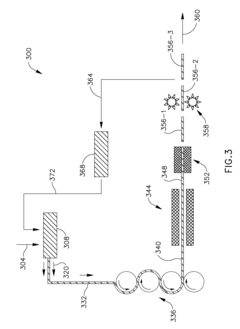

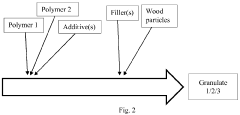

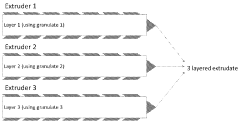

Technical Solution: Sulapac Oy has developed a biodegradable material made from wood and natural binders. Their technology focuses on creating a fully biodegradable alternative to plastic that maintains the functional properties required for industrial applications. The material is designed to biodegrade in industrial composting conditions within 12 weeks, leaving no microplastics behind. Sulapac's innovation lies in their proprietary recipe that combines wood chips from industrial side streams with biodegradable and bio-based binders. This composition allows for the material to be molded and processed using existing plastic product manufacturing machinery, making it a versatile solution for various industries.

Strengths: Fully biodegradable, leaves no microplastics, compatible with existing manufacturing processes. Weaknesses: May have limited resistance to certain chemicals or extreme temperatures compared to traditional plastics.

Arctic Biomaterials Oy

Technical Solution: Arctic Biomaterials Oy specializes in developing and producing biodegradable PLA compounds and composites. Their technology focuses on enhancing the properties of PLA through the addition of natural fibers and minerals. They have developed a proprietary additive technology that significantly improves the biodegradation rate of PLA in industrial composting conditions. Their approach involves creating a PLA-based material that can maintain its structural integrity during use but break down rapidly when exposed to specific environmental conditions. The company's innovation also extends to improving the heat resistance and mechanical properties of PLA, making it suitable for a wider range of industrial applications.

Strengths: Enhanced biodegradation rate, improved mechanical properties, and heat resistance of PLA. Weaknesses: May have higher production costs compared to standard PLA materials.

Core Innovations in PLA Biodegradation

Thermoformed articles made from reactive extrusion products of biobased materials

PatentActiveUS8231954B2

Innovation

- Development of thermoformable composite materials comprising blends of PLA and polyhydroxyalkanoates (PHAs) with specific additives, processed via extrusion, to enhance thermal and mechanical performance, achieving a Vicat softening point up to 180°C and heat distortion index up to 160°C, thereby improving resistance to deformation at higher temperatures.

Flexible multi-layer composite material

PatentWO2024013432A1

Innovation

- A multi-layer composite material is developed using biopolymer layers with distinct properties, including a grease barrier, oxygen barrier, and moisture-resistant layers, incorporating hydrophilic natural fibers to enhance degradation and mechanical properties, suitable for extrusion and food/cosmetic contact.

Environmental Impact Assessment

The environmental impact assessment of optimizing PLA biodegradability in industrial applications is a critical aspect of sustainable development. PLA, or polylactic acid, is a biodegradable polymer derived from renewable resources, making it an attractive alternative to traditional petroleum-based plastics. However, its biodegradability in industrial settings requires careful evaluation to ensure positive environmental outcomes.

One of the primary considerations is the reduction of plastic waste accumulation in landfills and natural environments. By enhancing PLA's biodegradability, the time required for complete decomposition can be significantly reduced, minimizing long-term environmental pollution. This is particularly important in addressing the global plastic waste crisis and its associated ecological impacts.

The optimization of PLA biodegradability also has implications for greenhouse gas emissions. As PLA breaks down, it releases carbon dioxide, a greenhouse gas. However, when compared to the emissions from the production and disposal of conventional plastics, optimized PLA biodegradation can lead to a net reduction in overall carbon footprint. This aspect is crucial in the context of climate change mitigation efforts.

Water pollution is another environmental factor to consider. Improved PLA biodegradability can reduce the risk of microplastic formation in aquatic ecosystems. This is particularly relevant for industrial applications where PLA products may come into contact with water bodies, either through direct use or as waste.

The impact on soil health is also significant. As PLA degrades in soil, it can potentially enhance soil quality by providing organic matter. However, the rate and nature of this degradation must be carefully managed to prevent any negative effects on soil ecosystems, such as changes in pH or nutrient balance.

Energy consumption in waste management processes is another environmental consideration. Optimized PLA biodegradability can lead to more efficient composting and waste treatment processes, potentially reducing the energy required for waste management. This can contribute to overall energy conservation efforts in industrial settings.

The assessment must also consider the lifecycle impact of PLA production. While optimizing biodegradability is beneficial at the end-of-life stage, it's crucial to ensure that the production processes and additives used to enhance biodegradability do not negate these benefits through increased environmental impacts during manufacturing.

Lastly, the potential for PLA to replace more environmentally harmful materials in various industrial applications should be evaluated. The improved biodegradability of PLA could make it a viable substitute for non-biodegradable plastics in many industries, leading to broader positive environmental impacts across multiple sectors.

One of the primary considerations is the reduction of plastic waste accumulation in landfills and natural environments. By enhancing PLA's biodegradability, the time required for complete decomposition can be significantly reduced, minimizing long-term environmental pollution. This is particularly important in addressing the global plastic waste crisis and its associated ecological impacts.

The optimization of PLA biodegradability also has implications for greenhouse gas emissions. As PLA breaks down, it releases carbon dioxide, a greenhouse gas. However, when compared to the emissions from the production and disposal of conventional plastics, optimized PLA biodegradation can lead to a net reduction in overall carbon footprint. This aspect is crucial in the context of climate change mitigation efforts.

Water pollution is another environmental factor to consider. Improved PLA biodegradability can reduce the risk of microplastic formation in aquatic ecosystems. This is particularly relevant for industrial applications where PLA products may come into contact with water bodies, either through direct use or as waste.

The impact on soil health is also significant. As PLA degrades in soil, it can potentially enhance soil quality by providing organic matter. However, the rate and nature of this degradation must be carefully managed to prevent any negative effects on soil ecosystems, such as changes in pH or nutrient balance.

Energy consumption in waste management processes is another environmental consideration. Optimized PLA biodegradability can lead to more efficient composting and waste treatment processes, potentially reducing the energy required for waste management. This can contribute to overall energy conservation efforts in industrial settings.

The assessment must also consider the lifecycle impact of PLA production. While optimizing biodegradability is beneficial at the end-of-life stage, it's crucial to ensure that the production processes and additives used to enhance biodegradability do not negate these benefits through increased environmental impacts during manufacturing.

Lastly, the potential for PLA to replace more environmentally harmful materials in various industrial applications should be evaluated. The improved biodegradability of PLA could make it a viable substitute for non-biodegradable plastics in many industries, leading to broader positive environmental impacts across multiple sectors.

Regulatory Framework for Biodegradable Plastics

The regulatory framework for biodegradable plastics plays a crucial role in optimizing PLA biodegradability in industrial applications. As governments and international organizations increasingly recognize the environmental impact of plastic waste, they have implemented various policies and standards to promote the use of biodegradable materials.

At the international level, organizations such as the International Organization for Standardization (ISO) have developed standards for biodegradable plastics. ISO 17088 and ISO 14855 provide guidelines for determining the biodegradability and compostability of plastic materials. These standards serve as benchmarks for manufacturers and help ensure consistency in product claims across different regions.

In the European Union, the EN 13432 standard is widely recognized for certifying compostable and biodegradable packaging materials. This standard requires that at least 90% of the plastic material be converted into CO2 within six months under industrial composting conditions. The EU has also introduced the Single-Use Plastics Directive, which encourages the use of biodegradable alternatives for certain single-use plastic products.

The United States has a more fragmented approach to regulating biodegradable plastics. The Federal Trade Commission (FTC) provides guidelines for environmental marketing claims, including those related to biodegradability. Several states, such as California, have implemented their own regulations on biodegradable plastic labeling to prevent misleading claims and ensure proper disposal.

In Asia, countries like Japan and South Korea have established certification systems for biodegradable plastics. Japan's GreenPla certification and South Korea's EL724 standard provide frameworks for evaluating and certifying biodegradable materials, encouraging their adoption in various industries.

These regulatory frameworks not only set standards for biodegradability but also influence research and development efforts in optimizing PLA biodegradability. They drive innovation in areas such as polymer blending, additive incorporation, and processing techniques to enhance PLA's biodegradation rates and meet regulatory requirements.

However, the diversity of standards and regulations across different regions can pose challenges for manufacturers operating in global markets. Harmonization efforts are underway to create more unified international standards, which would facilitate trade and accelerate the adoption of biodegradable plastics in industrial applications.

As the regulatory landscape continues to evolve, it is crucial for stakeholders in the PLA industry to stay informed about current and upcoming regulations. This knowledge can guide research priorities, product development strategies, and market entry decisions, ultimately contributing to the optimization of PLA biodegradability in industrial applications.

At the international level, organizations such as the International Organization for Standardization (ISO) have developed standards for biodegradable plastics. ISO 17088 and ISO 14855 provide guidelines for determining the biodegradability and compostability of plastic materials. These standards serve as benchmarks for manufacturers and help ensure consistency in product claims across different regions.

In the European Union, the EN 13432 standard is widely recognized for certifying compostable and biodegradable packaging materials. This standard requires that at least 90% of the plastic material be converted into CO2 within six months under industrial composting conditions. The EU has also introduced the Single-Use Plastics Directive, which encourages the use of biodegradable alternatives for certain single-use plastic products.

The United States has a more fragmented approach to regulating biodegradable plastics. The Federal Trade Commission (FTC) provides guidelines for environmental marketing claims, including those related to biodegradability. Several states, such as California, have implemented their own regulations on biodegradable plastic labeling to prevent misleading claims and ensure proper disposal.

In Asia, countries like Japan and South Korea have established certification systems for biodegradable plastics. Japan's GreenPla certification and South Korea's EL724 standard provide frameworks for evaluating and certifying biodegradable materials, encouraging their adoption in various industries.

These regulatory frameworks not only set standards for biodegradability but also influence research and development efforts in optimizing PLA biodegradability. They drive innovation in areas such as polymer blending, additive incorporation, and processing techniques to enhance PLA's biodegradation rates and meet regulatory requirements.

However, the diversity of standards and regulations across different regions can pose challenges for manufacturers operating in global markets. Harmonization efforts are underway to create more unified international standards, which would facilitate trade and accelerate the adoption of biodegradable plastics in industrial applications.

As the regulatory landscape continues to evolve, it is crucial for stakeholders in the PLA industry to stay informed about current and upcoming regulations. This knowledge can guide research priorities, product development strategies, and market entry decisions, ultimately contributing to the optimization of PLA biodegradability in industrial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!