How to Improve PLA Thermal Stability for High-Temperature Applications?

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PLA Thermal Stability Background and Objectives

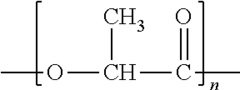

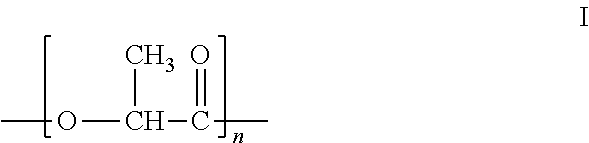

Polylactic acid (PLA) has emerged as a promising biodegradable polymer with applications spanning various industries. However, its thermal stability limitations have hindered its widespread adoption in high-temperature applications. The evolution of PLA thermal stability research can be traced back to the early 2000s when the polymer gained attention as a sustainable alternative to petroleum-based plastics.

Initially, PLA's low heat deflection temperature and poor thermal resistance restricted its use to low-temperature applications. As the demand for environmentally friendly materials grew, researchers began exploring methods to enhance PLA's thermal properties. The primary objective of improving PLA thermal stability is to expand its applicability in sectors such as automotive, electronics, and aerospace, where high-temperature resistance is crucial.

Over the past two decades, significant progress has been made in understanding the thermal degradation mechanisms of PLA. Researchers have identified that the main factors contributing to PLA's thermal instability include its low glass transition temperature, low crystallization rate, and susceptibility to hydrolysis at elevated temperatures. These insights have guided the development of various strategies to enhance PLA's thermal performance.

The technological evolution in this field has seen a shift from simple blending approaches to more sophisticated techniques. Early attempts focused on incorporating inorganic fillers and plasticizers to improve heat resistance. As research progressed, more advanced methods such as stereocomplexation, chain extension, and nanocomposite formation gained prominence. Recent years have witnessed the emergence of novel approaches like reactive extrusion and surface modification techniques to further enhance PLA's thermal stability.

The current technological goals in PLA thermal stability improvement are multifaceted. Researchers aim to develop PLA-based materials that can withstand temperatures above 100°C without significant property degradation. Additionally, there is a focus on enhancing the material's processability at high temperatures while maintaining its biodegradability. The ultimate objective is to create a thermally stable PLA that can compete with conventional petroleum-based polymers in high-temperature applications.

Looking ahead, the field of PLA thermal stability is poised for further advancements. Emerging trends include the development of bio-based additives for thermal enhancement, the exploration of synergistic effects between different stabilization techniques, and the integration of artificial intelligence in material design. These developments are expected to pave the way for next-generation PLA materials with superior thermal properties, opening up new possibilities in sustainable high-temperature applications.

Initially, PLA's low heat deflection temperature and poor thermal resistance restricted its use to low-temperature applications. As the demand for environmentally friendly materials grew, researchers began exploring methods to enhance PLA's thermal properties. The primary objective of improving PLA thermal stability is to expand its applicability in sectors such as automotive, electronics, and aerospace, where high-temperature resistance is crucial.

Over the past two decades, significant progress has been made in understanding the thermal degradation mechanisms of PLA. Researchers have identified that the main factors contributing to PLA's thermal instability include its low glass transition temperature, low crystallization rate, and susceptibility to hydrolysis at elevated temperatures. These insights have guided the development of various strategies to enhance PLA's thermal performance.

The technological evolution in this field has seen a shift from simple blending approaches to more sophisticated techniques. Early attempts focused on incorporating inorganic fillers and plasticizers to improve heat resistance. As research progressed, more advanced methods such as stereocomplexation, chain extension, and nanocomposite formation gained prominence. Recent years have witnessed the emergence of novel approaches like reactive extrusion and surface modification techniques to further enhance PLA's thermal stability.

The current technological goals in PLA thermal stability improvement are multifaceted. Researchers aim to develop PLA-based materials that can withstand temperatures above 100°C without significant property degradation. Additionally, there is a focus on enhancing the material's processability at high temperatures while maintaining its biodegradability. The ultimate objective is to create a thermally stable PLA that can compete with conventional petroleum-based polymers in high-temperature applications.

Looking ahead, the field of PLA thermal stability is poised for further advancements. Emerging trends include the development of bio-based additives for thermal enhancement, the exploration of synergistic effects between different stabilization techniques, and the integration of artificial intelligence in material design. These developments are expected to pave the way for next-generation PLA materials with superior thermal properties, opening up new possibilities in sustainable high-temperature applications.

Market Analysis for High-Temperature PLA Applications

The market for high-temperature PLA applications is experiencing significant growth, driven by the increasing demand for sustainable and biodegradable materials in various industries. PLA, or polylactic acid, is a bio-based polymer derived from renewable resources such as corn starch or sugarcane. Its potential for use in high-temperature applications has garnered substantial interest from manufacturers and end-users alike.

The automotive industry represents a key market for high-temperature PLA applications. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, they are actively seeking alternatives to traditional petroleum-based plastics. High-temperature PLA composites offer a promising solution for interior components, under-hood applications, and structural parts that require thermal stability.

In the electronics sector, the demand for high-temperature PLA is rising due to the need for heat-resistant housings and components in consumer electronics, appliances, and industrial equipment. The material's ability to withstand elevated temperatures while maintaining its mechanical properties makes it an attractive option for manufacturers looking to enhance product durability and reduce environmental impact.

The aerospace industry is another significant market for high-temperature PLA applications. The lightweight nature of PLA, combined with improved thermal stability, makes it suitable for non-critical aircraft components, interior panels, and cabin furnishings. As the industry focuses on reducing fuel consumption and emissions, the adoption of bio-based materials like high-temperature PLA is expected to increase.

The packaging industry is also exploring high-temperature PLA for applications such as hot-fill containers, microwave-safe packaging, and disposable tableware. The growing consumer preference for eco-friendly packaging solutions is driving the demand for thermally stable PLA products that can withstand higher temperatures during food processing and storage.

In the construction sector, high-temperature PLA composites are gaining traction for use in insulation materials, piping systems, and structural components. The material's fire-resistant properties, when properly formulated, make it an attractive alternative to traditional building materials in certain applications.

The global market for high-temperature PLA applications is projected to grow steadily over the next decade. Factors contributing to this growth include increasing environmental regulations, consumer demand for sustainable products, and ongoing research and development efforts to enhance PLA's thermal properties. However, challenges such as higher production costs compared to conventional plastics and limited awareness of PLA's capabilities in high-temperature applications may impact market penetration in some sectors.

The automotive industry represents a key market for high-temperature PLA applications. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, they are actively seeking alternatives to traditional petroleum-based plastics. High-temperature PLA composites offer a promising solution for interior components, under-hood applications, and structural parts that require thermal stability.

In the electronics sector, the demand for high-temperature PLA is rising due to the need for heat-resistant housings and components in consumer electronics, appliances, and industrial equipment. The material's ability to withstand elevated temperatures while maintaining its mechanical properties makes it an attractive option for manufacturers looking to enhance product durability and reduce environmental impact.

The aerospace industry is another significant market for high-temperature PLA applications. The lightweight nature of PLA, combined with improved thermal stability, makes it suitable for non-critical aircraft components, interior panels, and cabin furnishings. As the industry focuses on reducing fuel consumption and emissions, the adoption of bio-based materials like high-temperature PLA is expected to increase.

The packaging industry is also exploring high-temperature PLA for applications such as hot-fill containers, microwave-safe packaging, and disposable tableware. The growing consumer preference for eco-friendly packaging solutions is driving the demand for thermally stable PLA products that can withstand higher temperatures during food processing and storage.

In the construction sector, high-temperature PLA composites are gaining traction for use in insulation materials, piping systems, and structural components. The material's fire-resistant properties, when properly formulated, make it an attractive alternative to traditional building materials in certain applications.

The global market for high-temperature PLA applications is projected to grow steadily over the next decade. Factors contributing to this growth include increasing environmental regulations, consumer demand for sustainable products, and ongoing research and development efforts to enhance PLA's thermal properties. However, challenges such as higher production costs compared to conventional plastics and limited awareness of PLA's capabilities in high-temperature applications may impact market penetration in some sectors.

Current Limitations in PLA Thermal Stability

Polylactic acid (PLA) has gained significant attention as a biodegradable and renewable alternative to traditional petroleum-based plastics. However, its widespread adoption in high-temperature applications is hindered by several limitations in thermal stability. The primary challenge lies in PLA's relatively low glass transition temperature (Tg) and heat deflection temperature (HDT), which typically range from 55-65°C and 55-60°C, respectively. These properties severely restrict PLA's use in applications requiring heat resistance above these temperatures.

Another critical limitation is PLA's tendency to undergo rapid thermal degradation at elevated temperatures. When exposed to temperatures above 180-200°C, PLA begins to depolymerize, leading to a significant reduction in molecular weight and mechanical properties. This thermal instability not only affects the material's performance during use but also poses challenges during processing, as PLA requires careful temperature control to prevent degradation during extrusion or injection molding.

The crystallization behavior of PLA further complicates its thermal stability. PLA exhibits slow crystallization kinetics, which can result in incomplete crystallization during processing. This leads to a lower degree of crystallinity in the final product, reducing its overall thermal resistance. The amorphous regions in PLA are particularly susceptible to thermal degradation, exacerbating the material's instability at elevated temperatures.

Moreover, PLA's poor melt strength at high temperatures presents difficulties in various processing techniques, such as film blowing and foam extrusion. As the temperature increases, PLA's melt viscosity decreases rapidly, making it challenging to maintain dimensional stability during processing and limiting its applicability in certain manufacturing processes.

The thermal decomposition of PLA also results in the release of volatile organic compounds (VOCs), primarily lactide monomers and oligomers. This not only contributes to material loss but can also lead to environmental and health concerns in high-temperature applications. Additionally, the release of these compounds can cause surface defects and compromise the aesthetic and functional properties of PLA-based products.

Lastly, PLA's susceptibility to hydrolysis at elevated temperatures and in humid environments further limits its thermal stability. The presence of moisture accelerates the degradation process, leading to a more rapid decline in mechanical properties and molecular weight. This hygroscopic nature of PLA necessitates careful consideration of environmental conditions during both processing and end-use applications, particularly in high-temperature scenarios where moisture absorption is more pronounced.

Another critical limitation is PLA's tendency to undergo rapid thermal degradation at elevated temperatures. When exposed to temperatures above 180-200°C, PLA begins to depolymerize, leading to a significant reduction in molecular weight and mechanical properties. This thermal instability not only affects the material's performance during use but also poses challenges during processing, as PLA requires careful temperature control to prevent degradation during extrusion or injection molding.

The crystallization behavior of PLA further complicates its thermal stability. PLA exhibits slow crystallization kinetics, which can result in incomplete crystallization during processing. This leads to a lower degree of crystallinity in the final product, reducing its overall thermal resistance. The amorphous regions in PLA are particularly susceptible to thermal degradation, exacerbating the material's instability at elevated temperatures.

Moreover, PLA's poor melt strength at high temperatures presents difficulties in various processing techniques, such as film blowing and foam extrusion. As the temperature increases, PLA's melt viscosity decreases rapidly, making it challenging to maintain dimensional stability during processing and limiting its applicability in certain manufacturing processes.

The thermal decomposition of PLA also results in the release of volatile organic compounds (VOCs), primarily lactide monomers and oligomers. This not only contributes to material loss but can also lead to environmental and health concerns in high-temperature applications. Additionally, the release of these compounds can cause surface defects and compromise the aesthetic and functional properties of PLA-based products.

Lastly, PLA's susceptibility to hydrolysis at elevated temperatures and in humid environments further limits its thermal stability. The presence of moisture accelerates the degradation process, leading to a more rapid decline in mechanical properties and molecular weight. This hygroscopic nature of PLA necessitates careful consideration of environmental conditions during both processing and end-use applications, particularly in high-temperature scenarios where moisture absorption is more pronounced.

Existing PLA Thermal Stability Solutions

01 Additives for improving thermal stability

Various additives can be incorporated into PLA to enhance its thermal stability. These may include antioxidants, stabilizers, and other compounds that help prevent degradation at high temperatures. The addition of these substances can significantly improve the heat resistance of PLA, making it suitable for a wider range of applications.- Additives for improving thermal stability: Various additives can be incorporated into PLA to enhance its thermal stability. These may include antioxidants, stabilizers, and other compounds that help prevent degradation at high temperatures. By carefully selecting and combining these additives, the overall thermal performance of PLA can be significantly improved.

- Blending with other polymers: Blending PLA with other thermally stable polymers can enhance its overall thermal stability. This approach combines the desirable properties of PLA with the heat resistance of other materials, resulting in a composite with improved thermal characteristics. The selection of compatible polymers and optimal blending ratios is crucial for achieving the desired thermal stability.

- Crystallization control: Controlling the crystallization behavior of PLA can significantly impact its thermal stability. By optimizing processing conditions and using nucleating agents, the degree of crystallinity can be increased, leading to improved heat resistance. Techniques such as annealing and controlled cooling can be employed to achieve the desired crystalline structure.

- Surface modifications: Modifying the surface of PLA can enhance its thermal stability. This can be achieved through various methods such as coating, grafting, or chemical treatments. These modifications can create a protective layer or alter the surface properties of PLA, resulting in improved resistance to thermal degradation.

- Nanocomposite formation: Incorporating nanoparticles or nanofillers into PLA can significantly improve its thermal stability. These nanocomposites often exhibit enhanced heat resistance due to the unique properties of the nanomaterials and their interactions with the polymer matrix. The type, size, and dispersion of nanofillers play crucial roles in determining the thermal performance of the resulting nanocomposite.

02 Blending with other polymers

Blending PLA with other thermally stable polymers can improve its overall thermal stability. This approach combines the biodegradability of PLA with the heat resistance of other materials, resulting in a composite with enhanced thermal properties. The selection of compatible polymers and optimal blending ratios is crucial for achieving the desired thermal stability.Expand Specific Solutions03 Crystallization and annealing techniques

Improving the crystallinity of PLA through various processing techniques can enhance its thermal stability. Methods such as annealing, controlled cooling, and the use of nucleating agents can increase the degree of crystallinity in PLA. Higher crystallinity typically results in better heat resistance and improved mechanical properties at elevated temperatures.Expand Specific Solutions04 Chemical modification of PLA

Chemical modification of the PLA polymer chain can lead to improved thermal stability. This may involve techniques such as copolymerization, grafting, or cross-linking. These modifications can alter the molecular structure of PLA, resulting in a material with enhanced heat resistance and reduced susceptibility to thermal degradation.Expand Specific Solutions05 Nanocomposite formulations

Incorporating nanoparticles or nanofillers into PLA can significantly improve its thermal stability. Materials such as nanoclays, carbon nanotubes, or metal oxide nanoparticles can be dispersed within the PLA matrix. These nanocomposites often exhibit enhanced heat resistance, barrier properties, and mechanical strength compared to neat PLA.Expand Specific Solutions

Key Players in High-Temperature PLA Development

The competition landscape for improving PLA thermal stability for high-temperature applications is evolving rapidly. The industry is in a growth phase, with increasing market size driven by demand for sustainable, high-performance materials. The technology is advancing, but still maturing, as evidenced by ongoing research and development efforts. Companies like NatureWorks LLC, DuPont de Nemours, Inc., and Far Eastern New Century Corp. are at the forefront, leveraging their expertise in polymer science. Academic institutions such as Jiangnan University and Sichuan University are contributing to fundamental research. The market is characterized by a mix of established players and innovative startups, with collaborations between industry and academia driving progress towards more thermally stable PLA formulations for diverse high-temperature applications.

Far Eastern New Century Corp.

Technical Solution: Far Eastern New Century has developed a multi-component blending technology called "ThermoStable PLA" to enhance the thermal stability of PLA. This approach involves carefully selecting and blending compatible biopolymers and additives with PLA to create a synergistic effect. The company uses a proprietary compatibilization technique to ensure good miscibility between the components. Additionally, they have implemented a controlled cooling process during manufacturing that optimizes the crystalline structure of the blend. This technology results in a PLA-based material with significantly improved heat resistance and dimensional stability at elevated temperatures.

Strengths: Offers a versatile approach that can be tailored for different applications. Maintains a high bio-based content. Weaknesses: May require fine-tuning of the blend composition for specific end-use requirements.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed a proprietary technology called "Thermal Stabilization System" for PLA. This system involves incorporating specially designed additives and modifiers into the PLA matrix. The additives work synergistically to enhance the polymer's crystallization rate and thermal resistance. By promoting rapid and uniform crystallization, the system creates a more stable molecular structure that can withstand higher temperatures. Additionally, DuPont has implemented a unique processing technique that optimizes the distribution of these stabilizers throughout the polymer, ensuring consistent performance across the material.

Strengths: Significantly improves PLA's heat deflection temperature, allowing for use in high-temperature applications. Maintains PLA's biodegradability. Weaknesses: May slightly increase production costs due to specialized additives.

Innovative Approaches to PLA Heat Resistance

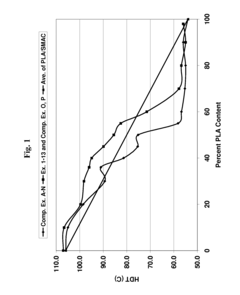

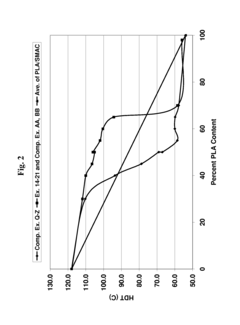

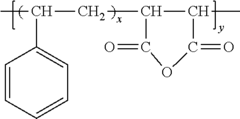

Heat resistant polylactic acid compositions

PatentInactiveUS20120208947A1

Innovation

- Reacting PLA with an oligomeric chain extender and a styrene-maleic anhydride copolymer (SMAC) to form a new polymer composition that increases the heat deflection temperature beyond the limitations of pure PLA, achieving a heat deflection temperature of at least 65°C at 66 psi, thereby enhancing its thermal stability.

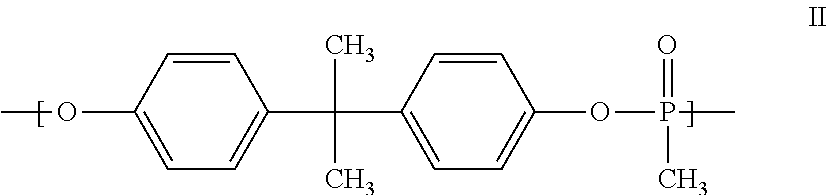

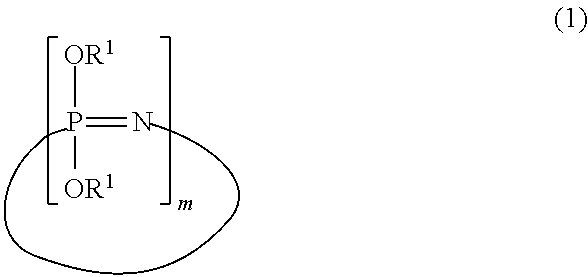

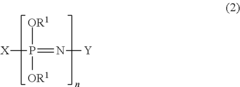

Flame retardant polylactic acid compounds

PatentInactiveUS20150274966A1

Innovation

- Compounding PLA with specific non-halogenated flame retardants, such as polyphosphonate-co-carbonate, polyphosphazene, and phosphate esters, along with a drip suppressant and optionally an impact modifier, to enhance its heat deflection temperature and achieve V-0 UL94 flame retardance ratings.

Environmental Impact of Enhanced PLA

The environmental impact of enhanced PLA (Polylactic Acid) with improved thermal stability for high-temperature applications is a critical consideration in the development and adoption of this advanced material. As PLA gains traction in various industries due to its biodegradability and renewable sourcing, the modifications required to enhance its thermal properties may introduce new environmental challenges.

One of the primary environmental benefits of standard PLA is its biodegradability. However, the additives and modifications used to improve thermal stability could potentially alter this characteristic. Some thermal stabilizers or reinforcing agents may slow down or inhibit the biodegradation process, extending the material's persistence in the environment. This could lead to increased accumulation of plastic waste if not properly managed.

The production of thermally enhanced PLA may require additional energy-intensive processes or the incorporation of non-renewable additives. This could increase the overall carbon footprint of the material, partially offsetting the environmental benefits associated with its bio-based origin. The extraction and processing of these additives may also have localized environmental impacts, such as resource depletion or ecosystem disturbance.

On the positive side, improving PLA's thermal stability expands its potential applications, particularly in high-temperature scenarios. This could lead to the replacement of less environmentally friendly materials in various industries, including automotive, electronics, and industrial components. The extended durability and heat resistance of enhanced PLA may also contribute to longer product lifespans, reducing the frequency of replacement and associated waste generation.

The end-of-life management of thermally enhanced PLA presents both challenges and opportunities. While the material may be more difficult to biodegrade, it could potentially be more suitable for recycling due to its improved thermal properties. This could lead to the development of new recycling streams and technologies specifically designed for these advanced bioplastics, promoting a more circular economy approach.

The environmental impact assessment of enhanced PLA must also consider the potential for reduced energy consumption in product manufacturing and use phases. High-temperature resistant PLA could enable more efficient production processes and improved product performance, potentially leading to energy savings throughout the product lifecycle. This indirect environmental benefit could partially mitigate the increased environmental burden of the material's production.

In conclusion, while the enhancement of PLA's thermal stability offers significant potential for expanding its applications and replacing less sustainable materials, it also introduces new environmental considerations. Balancing the trade-offs between improved performance and environmental impact will be crucial in determining the overall sustainability of thermally enhanced PLA in high-temperature applications.

One of the primary environmental benefits of standard PLA is its biodegradability. However, the additives and modifications used to improve thermal stability could potentially alter this characteristic. Some thermal stabilizers or reinforcing agents may slow down or inhibit the biodegradation process, extending the material's persistence in the environment. This could lead to increased accumulation of plastic waste if not properly managed.

The production of thermally enhanced PLA may require additional energy-intensive processes or the incorporation of non-renewable additives. This could increase the overall carbon footprint of the material, partially offsetting the environmental benefits associated with its bio-based origin. The extraction and processing of these additives may also have localized environmental impacts, such as resource depletion or ecosystem disturbance.

On the positive side, improving PLA's thermal stability expands its potential applications, particularly in high-temperature scenarios. This could lead to the replacement of less environmentally friendly materials in various industries, including automotive, electronics, and industrial components. The extended durability and heat resistance of enhanced PLA may also contribute to longer product lifespans, reducing the frequency of replacement and associated waste generation.

The end-of-life management of thermally enhanced PLA presents both challenges and opportunities. While the material may be more difficult to biodegrade, it could potentially be more suitable for recycling due to its improved thermal properties. This could lead to the development of new recycling streams and technologies specifically designed for these advanced bioplastics, promoting a more circular economy approach.

The environmental impact assessment of enhanced PLA must also consider the potential for reduced energy consumption in product manufacturing and use phases. High-temperature resistant PLA could enable more efficient production processes and improved product performance, potentially leading to energy savings throughout the product lifecycle. This indirect environmental benefit could partially mitigate the increased environmental burden of the material's production.

In conclusion, while the enhancement of PLA's thermal stability offers significant potential for expanding its applications and replacing less sustainable materials, it also introduces new environmental considerations. Balancing the trade-offs between improved performance and environmental impact will be crucial in determining the overall sustainability of thermally enhanced PLA in high-temperature applications.

Regulatory Considerations for High-Temperature PLA

When considering the use of high-temperature PLA in various applications, it is crucial to address the regulatory considerations that govern its production, use, and disposal. These regulations are designed to ensure the safety, quality, and environmental impact of materials used in high-temperature applications. One of the primary regulatory bodies overseeing the use of polymers in high-temperature applications is the Food and Drug Administration (FDA) in the United States, particularly for food contact and medical applications.

The FDA has established specific guidelines for the use of polymers in food contact applications, including those exposed to high temperatures. These guidelines outline the acceptable levels of monomers, additives, and other substances that may migrate from the polymer into food. For high-temperature PLA, manufacturers must demonstrate compliance with these regulations through extensive testing and documentation.

In the European Union, the European Food Safety Authority (EFSA) provides similar regulatory oversight for food contact materials. The EFSA has established specific migration limits for substances used in food contact materials, including those used at elevated temperatures. Manufacturers of high-temperature PLA must ensure their products meet these stringent requirements to be approved for use in the EU market.

Beyond food contact applications, regulatory considerations for high-temperature PLA extend to other sectors such as automotive, aerospace, and electronics. In these industries, materials must comply with various safety and performance standards set by organizations like the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM).

Environmental regulations also play a significant role in the development and use of high-temperature PLA. As sustainability becomes an increasingly important factor in material selection, manufacturers must consider regulations related to biodegradability, recyclability, and end-of-life disposal. The European Union's Waste Electrical and Electronic Equipment (WEEE) Directive, for example, sets guidelines for the recycling and disposal of electronic products, which may impact the use of high-temperature PLA in electronic applications.

Occupational safety regulations must also be considered when working with high-temperature PLA. Organizations such as the Occupational Safety and Health Administration (OSHA) in the United States provide guidelines for handling and processing polymers at elevated temperatures to ensure worker safety.

As the development of high-temperature PLA progresses, it is essential for manufacturers and researchers to stay informed about evolving regulations and standards. This includes monitoring changes in existing regulations and anticipating new requirements that may emerge as the technology advances. Compliance with these regulatory considerations is not only crucial for market access but also for ensuring the long-term viability and acceptance of high-temperature PLA in various applications.

The FDA has established specific guidelines for the use of polymers in food contact applications, including those exposed to high temperatures. These guidelines outline the acceptable levels of monomers, additives, and other substances that may migrate from the polymer into food. For high-temperature PLA, manufacturers must demonstrate compliance with these regulations through extensive testing and documentation.

In the European Union, the European Food Safety Authority (EFSA) provides similar regulatory oversight for food contact materials. The EFSA has established specific migration limits for substances used in food contact materials, including those used at elevated temperatures. Manufacturers of high-temperature PLA must ensure their products meet these stringent requirements to be approved for use in the EU market.

Beyond food contact applications, regulatory considerations for high-temperature PLA extend to other sectors such as automotive, aerospace, and electronics. In these industries, materials must comply with various safety and performance standards set by organizations like the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM).

Environmental regulations also play a significant role in the development and use of high-temperature PLA. As sustainability becomes an increasingly important factor in material selection, manufacturers must consider regulations related to biodegradability, recyclability, and end-of-life disposal. The European Union's Waste Electrical and Electronic Equipment (WEEE) Directive, for example, sets guidelines for the recycling and disposal of electronic products, which may impact the use of high-temperature PLA in electronic applications.

Occupational safety regulations must also be considered when working with high-temperature PLA. Organizations such as the Occupational Safety and Health Administration (OSHA) in the United States provide guidelines for handling and processing polymers at elevated temperatures to ensure worker safety.

As the development of high-temperature PLA progresses, it is essential for manufacturers and researchers to stay informed about evolving regulations and standards. This includes monitoring changes in existing regulations and anticipating new requirements that may emerge as the technology advances. Compliance with these regulatory considerations is not only crucial for market access but also for ensuring the long-term viability and acceptance of high-temperature PLA in various applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!