Exploring PLA's Potential in Food Packaging Solutions

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PLA in Food Packaging: Background and Objectives

Polylactic acid (PLA) has emerged as a promising sustainable alternative in the food packaging industry, driven by growing environmental concerns and the need for eco-friendly solutions. The evolution of PLA technology can be traced back to the 1930s when it was first synthesized, but its commercial viability for food packaging applications has only gained significant traction in recent decades.

The development of PLA as a food packaging material has been propelled by advancements in polymer science and biotechnology. Initially, PLA was limited by high production costs and inferior mechanical properties compared to conventional plastics. However, continuous research and innovation have led to improved PLA formulations and processing techniques, enhancing its suitability for various food packaging applications.

The primary objective of exploring PLA's potential in food packaging solutions is to address the pressing need for sustainable packaging alternatives that can reduce environmental impact while maintaining food safety and quality. This aligns with global efforts to mitigate plastic pollution and transition towards a circular economy.

Key technological goals in PLA food packaging development include enhancing barrier properties to extend shelf life, improving mechanical strength for durability, and optimizing biodegradability rates to balance environmental benefits with practical use. Additionally, researchers aim to develop PLA blends and composites that can match or exceed the performance of traditional petroleum-based plastics in specific applications.

The food packaging industry has witnessed a gradual shift towards bio-based materials, with PLA at the forefront of this transition. This trend is driven by consumer demand for environmentally friendly products, stringent regulations on single-use plastics, and corporate sustainability initiatives. As a result, the market for PLA in food packaging has experienced substantial growth, with projections indicating continued expansion in the coming years.

Technological advancements in PLA production have focused on improving its scalability and cost-effectiveness. Innovations in fermentation processes and the use of alternative feedstocks have contributed to reducing production costs, making PLA more competitive with conventional plastics. Concurrently, efforts to enhance PLA's functional properties have led to the development of specialized grades tailored for specific food packaging applications, such as films, trays, and bottles.

The exploration of PLA's potential in food packaging solutions represents a convergence of technological innovation, market demand, and environmental responsibility. As research continues to address current limitations and unlock new possibilities, PLA is poised to play an increasingly significant role in shaping the future of sustainable food packaging.

The development of PLA as a food packaging material has been propelled by advancements in polymer science and biotechnology. Initially, PLA was limited by high production costs and inferior mechanical properties compared to conventional plastics. However, continuous research and innovation have led to improved PLA formulations and processing techniques, enhancing its suitability for various food packaging applications.

The primary objective of exploring PLA's potential in food packaging solutions is to address the pressing need for sustainable packaging alternatives that can reduce environmental impact while maintaining food safety and quality. This aligns with global efforts to mitigate plastic pollution and transition towards a circular economy.

Key technological goals in PLA food packaging development include enhancing barrier properties to extend shelf life, improving mechanical strength for durability, and optimizing biodegradability rates to balance environmental benefits with practical use. Additionally, researchers aim to develop PLA blends and composites that can match or exceed the performance of traditional petroleum-based plastics in specific applications.

The food packaging industry has witnessed a gradual shift towards bio-based materials, with PLA at the forefront of this transition. This trend is driven by consumer demand for environmentally friendly products, stringent regulations on single-use plastics, and corporate sustainability initiatives. As a result, the market for PLA in food packaging has experienced substantial growth, with projections indicating continued expansion in the coming years.

Technological advancements in PLA production have focused on improving its scalability and cost-effectiveness. Innovations in fermentation processes and the use of alternative feedstocks have contributed to reducing production costs, making PLA more competitive with conventional plastics. Concurrently, efforts to enhance PLA's functional properties have led to the development of specialized grades tailored for specific food packaging applications, such as films, trays, and bottles.

The exploration of PLA's potential in food packaging solutions represents a convergence of technological innovation, market demand, and environmental responsibility. As research continues to address current limitations and unlock new possibilities, PLA is poised to play an increasingly significant role in shaping the future of sustainable food packaging.

Market Analysis for Sustainable Food Packaging

The sustainable food packaging market has witnessed significant growth in recent years, driven by increasing environmental concerns and consumer demand for eco-friendly alternatives. As a key player in this market, Polylactic Acid (PLA) has emerged as a promising biodegradable material for food packaging solutions. The global market for sustainable food packaging is projected to reach substantial value in the coming years, with PLA-based packaging playing a crucial role in this expansion.

Consumer awareness regarding the environmental impact of traditional plastic packaging has led to a shift in preferences towards sustainable alternatives. This trend is particularly evident in developed regions such as North America and Europe, where stringent regulations on single-use plastics have accelerated the adoption of biodegradable packaging materials. In these markets, PLA-based food packaging has gained traction across various food and beverage segments, including fresh produce, dairy products, and ready-to-eat meals.

The Asia-Pacific region presents a rapidly growing market for sustainable food packaging, driven by urbanization, rising disposable incomes, and increasing environmental consciousness. Countries like China and India are witnessing a surge in demand for eco-friendly packaging solutions, creating significant opportunities for PLA-based products. However, challenges such as cost competitiveness and limited infrastructure for proper disposal and recycling of biodegradable materials persist in these emerging markets.

The food service industry has emerged as a key adopter of PLA-based packaging, particularly in the quick-service restaurant sector. Major fast-food chains and coffee shops have begun incorporating PLA products into their packaging portfolios, responding to consumer demands for more sustainable options. This trend is expected to continue, with the potential for widespread adoption across various food service segments.

E-commerce and food delivery services have experienced exponential growth, further driving the demand for sustainable packaging solutions. PLA-based materials offer advantages in terms of lightweight properties and customizable designs, making them suitable for online food retail and delivery applications. As these sectors continue to expand, the market for PLA food packaging is likely to see substantial growth opportunities.

Despite the positive market outlook, challenges remain in the widespread adoption of PLA-based food packaging. These include concerns about the material's performance in certain applications, such as hot food packaging, and the need for improved end-of-life management systems. Addressing these challenges through continued research and development efforts and investment in recycling infrastructure will be crucial for realizing the full market potential of PLA in food packaging solutions.

Consumer awareness regarding the environmental impact of traditional plastic packaging has led to a shift in preferences towards sustainable alternatives. This trend is particularly evident in developed regions such as North America and Europe, where stringent regulations on single-use plastics have accelerated the adoption of biodegradable packaging materials. In these markets, PLA-based food packaging has gained traction across various food and beverage segments, including fresh produce, dairy products, and ready-to-eat meals.

The Asia-Pacific region presents a rapidly growing market for sustainable food packaging, driven by urbanization, rising disposable incomes, and increasing environmental consciousness. Countries like China and India are witnessing a surge in demand for eco-friendly packaging solutions, creating significant opportunities for PLA-based products. However, challenges such as cost competitiveness and limited infrastructure for proper disposal and recycling of biodegradable materials persist in these emerging markets.

The food service industry has emerged as a key adopter of PLA-based packaging, particularly in the quick-service restaurant sector. Major fast-food chains and coffee shops have begun incorporating PLA products into their packaging portfolios, responding to consumer demands for more sustainable options. This trend is expected to continue, with the potential for widespread adoption across various food service segments.

E-commerce and food delivery services have experienced exponential growth, further driving the demand for sustainable packaging solutions. PLA-based materials offer advantages in terms of lightweight properties and customizable designs, making them suitable for online food retail and delivery applications. As these sectors continue to expand, the market for PLA food packaging is likely to see substantial growth opportunities.

Despite the positive market outlook, challenges remain in the widespread adoption of PLA-based food packaging. These include concerns about the material's performance in certain applications, such as hot food packaging, and the need for improved end-of-life management systems. Addressing these challenges through continued research and development efforts and investment in recycling infrastructure will be crucial for realizing the full market potential of PLA in food packaging solutions.

Current PLA Technology and Challenges

Polylactic acid (PLA) has emerged as a promising biodegradable polymer for food packaging applications, offering a sustainable alternative to conventional petroleum-based plastics. However, the current state of PLA technology presents both opportunities and challenges in its widespread adoption for food packaging solutions.

PLA's biodegradability and compostability under specific conditions make it an attractive option for environmentally conscious consumers and businesses. It can be processed using conventional plastic processing equipment, allowing for relatively easy integration into existing manufacturing processes. PLA also exhibits good transparency, glossiness, and stiffness, making it suitable for various food packaging applications.

Despite these advantages, PLA faces several technical challenges that limit its broader adoption in food packaging. One significant issue is its relatively low barrier properties, particularly against water vapor and oxygen. This limitation can affect the shelf life of packaged foods, especially those sensitive to moisture or oxidation. Researchers are actively working on improving PLA's barrier properties through various methods, including the development of multilayer structures and the incorporation of nanoparticles.

Another challenge is PLA's thermal stability. The material has a relatively low glass transition temperature and heat deflection temperature compared to conventional plastics, which can limit its use in hot-fill applications or microwaveable packaging. Efforts are underway to enhance PLA's heat resistance through techniques such as annealing, blending with other polymers, or adding nucleating agents.

PLA's mechanical properties, while suitable for many applications, can be a limitation in others. It tends to be brittle and has lower impact strength compared to some conventional plastics. This characteristic can lead to packaging failure during transportation or handling. Researchers are exploring various strategies to improve PLA's toughness, including the development of PLA blends and composites.

The cost of PLA production remains higher than that of conventional plastics, primarily due to the expenses associated with feedstock and processing. While economies of scale have led to some cost reductions, further technological advancements and increased production capacity are needed to make PLA more cost-competitive with traditional packaging materials.

Lastly, the end-of-life management of PLA presents both opportunities and challenges. While PLA is compostable under industrial composting conditions, it requires specific temperature and humidity levels that are not typically achieved in home composting systems or landfills. This discrepancy can lead to confusion among consumers and potential contamination of recycling streams. Efforts are being made to develop more efficient composting infrastructure and to educate consumers about proper disposal methods for PLA products.

PLA's biodegradability and compostability under specific conditions make it an attractive option for environmentally conscious consumers and businesses. It can be processed using conventional plastic processing equipment, allowing for relatively easy integration into existing manufacturing processes. PLA also exhibits good transparency, glossiness, and stiffness, making it suitable for various food packaging applications.

Despite these advantages, PLA faces several technical challenges that limit its broader adoption in food packaging. One significant issue is its relatively low barrier properties, particularly against water vapor and oxygen. This limitation can affect the shelf life of packaged foods, especially those sensitive to moisture or oxidation. Researchers are actively working on improving PLA's barrier properties through various methods, including the development of multilayer structures and the incorporation of nanoparticles.

Another challenge is PLA's thermal stability. The material has a relatively low glass transition temperature and heat deflection temperature compared to conventional plastics, which can limit its use in hot-fill applications or microwaveable packaging. Efforts are underway to enhance PLA's heat resistance through techniques such as annealing, blending with other polymers, or adding nucleating agents.

PLA's mechanical properties, while suitable for many applications, can be a limitation in others. It tends to be brittle and has lower impact strength compared to some conventional plastics. This characteristic can lead to packaging failure during transportation or handling. Researchers are exploring various strategies to improve PLA's toughness, including the development of PLA blends and composites.

The cost of PLA production remains higher than that of conventional plastics, primarily due to the expenses associated with feedstock and processing. While economies of scale have led to some cost reductions, further technological advancements and increased production capacity are needed to make PLA more cost-competitive with traditional packaging materials.

Lastly, the end-of-life management of PLA presents both opportunities and challenges. While PLA is compostable under industrial composting conditions, it requires specific temperature and humidity levels that are not typically achieved in home composting systems or landfills. This discrepancy can lead to confusion among consumers and potential contamination of recycling streams. Efforts are being made to develop more efficient composting infrastructure and to educate consumers about proper disposal methods for PLA products.

Existing PLA Food Packaging Solutions

01 PLA-based composite materials

Development of composite materials using PLA as a base polymer, incorporating various additives or reinforcing agents to enhance properties such as strength, durability, and biodegradability. These composites can be used in a wide range of applications, from packaging to biomedical devices.- PLA-based composite materials: Development of composite materials using PLA as a base polymer, incorporating various additives or fillers to enhance properties such as strength, durability, or biodegradability. These composites can be used in a wide range of applications, from packaging to medical devices.

- PLA processing techniques: Innovative methods for processing PLA, including extrusion, injection molding, and 3D printing. These techniques aim to improve the material's performance, reduce production costs, and expand its potential applications in various industries.

- PLA modification for improved properties: Chemical or physical modification of PLA to enhance its properties such as thermal stability, mechanical strength, or barrier properties. This includes techniques like blending with other polymers, crosslinking, or surface treatments to overcome limitations of pure PLA.

- Biodegradable PLA applications: Development of biodegradable products using PLA for various applications, including packaging, disposable items, and agricultural films. These innovations focus on reducing environmental impact while maintaining product functionality.

- PLA in medical and pharmaceutical applications: Utilization of PLA in medical devices, drug delivery systems, and tissue engineering scaffolds. These applications leverage PLA's biocompatibility and biodegradability to create innovative solutions in healthcare and regenerative medicine.

02 PLA processing techniques

Innovative methods for processing PLA, including extrusion, injection molding, and 3D printing. These techniques aim to improve the material's performance, reduce production costs, and expand its potential applications in various industries.Expand Specific Solutions03 PLA blends and copolymers

Creation of PLA blends and copolymers with other biodegradable or synthetic polymers to overcome limitations of pure PLA, such as brittleness or low heat resistance. These modified materials offer improved properties for specific applications while maintaining biodegradability.Expand Specific Solutions04 PLA surface modifications

Development of surface modification techniques for PLA to enhance its properties such as hydrophilicity, adhesion, or biocompatibility. These modifications can improve the material's performance in specific applications, particularly in the biomedical field.Expand Specific Solutions05 PLA degradation and recycling

Research on PLA degradation mechanisms and development of efficient recycling processes. This includes studies on enzymatic degradation, composting conditions, and chemical recycling methods to address end-of-life issues and promote circular economy principles for PLA-based products.Expand Specific Solutions

Key Players in PLA Food Packaging Industry

The market for PLA in food packaging solutions is in a growth phase, driven by increasing environmental concerns and regulatory pressures. The global market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, PLA is maturing but still faces challenges in performance and cost-effectiveness. Companies like Stora Enso Oyj, International Paper Co., and DuPont de Nemours, Inc. are at the forefront of PLA development, focusing on improving barrier properties and processability. Emerging players such as Lygos, Inc. and Avantium Knowledge Centre BV are exploring novel production methods to enhance PLA's competitiveness. Academic institutions like Tongji University and the University of Coimbra are contributing to fundamental research, potentially leading to breakthrough innovations in PLA technology for food packaging applications.

Stora Enso Oyj

Technical Solution: Stora Enso has developed a range of PLA-based food packaging solutions under their NaturaTM product line. Their approach involves blending PLA with other bio-based materials to create customized packaging solutions for different food applications. The company has implemented a proprietary extrusion process that allows for the production of multi-layer structures, combining the benefits of PLA with other materials to enhance barrier properties and mechanical strength. Additionally, Stora Enso has developed a specialized coating technology that improves the material's resistance to oxygen and moisture, extending the shelf life of packaged foods.

Strengths: Customizable solutions for different food applications, enhanced barrier properties, improved mechanical strength, and extended shelf life for packaged foods. Weaknesses: Potential higher costs compared to conventional packaging and possible limitations in high-temperature applications.

Toray Plastics (America), Inc.

Technical Solution: Toray Plastics has developed a high-performance PLA film for food packaging called Ecodear. This film is produced using a proprietary stretching technology that enhances the material's barrier properties and heat resistance. The company has also implemented a unique nucleation process that improves the film's crystallinity, resulting in better mechanical properties and increased stability at higher temperatures. Furthermore, Toray has developed a specialized surface treatment technique that enhances the film's printability and sealability, making it suitable for various food packaging formats.

Strengths: Enhanced barrier properties, improved heat resistance, better mechanical properties, and increased printability and sealability. Weaknesses: May have higher production costs and potential limitations in certain high-moisture applications.

Innovations in PLA Material Science

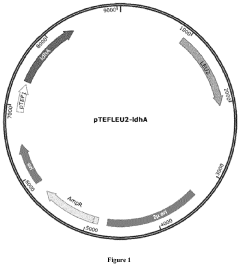

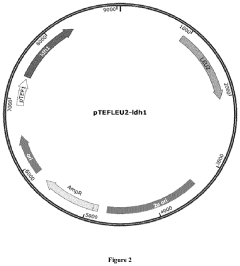

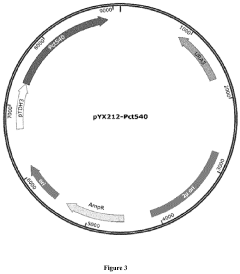

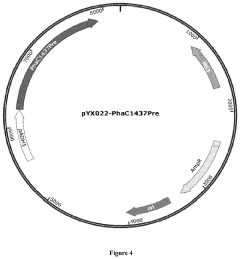

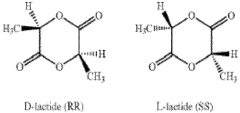

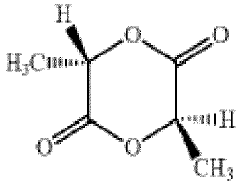

Process for cellular biosynthesis of poly d-lactic acid and poly l-lactic acid

PatentActiveUS20210324429A1

Innovation

- Engineering eukaryotic cells, such as yeast strains, to redirect metabolic pathways for the direct biological synthesis of PLLA and PDLA from carbon sources like glucose, using enzymes like D-lactate dehydrogenase, propionyl-CoA transferase, and polyhydroxyalkanoate synthase to convert pyruvate into lactyl-CoA and subsequently polymerize it into the desired polymers.

Multilayered products for food packaging

PatentInactiveEP3922458A1

Innovation

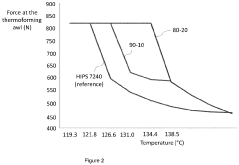

- A multilayered product comprising layers of polylactic acid (PLA) and polystyrene (PS), with a weight ratio of 5-25% PLA to 95-80% PS, which allows for thermoforming and minimizes sagging, enabling the use of renewable resources while maintaining production line efficiency and compliance with food contact regulations.

Environmental Impact Assessment

The environmental impact of PLA (Polylactic Acid) in food packaging solutions is a critical aspect to consider when exploring its potential as a sustainable alternative to traditional plastics. PLA, derived from renewable resources such as corn starch or sugarcane, offers several environmental benefits throughout its lifecycle.

During production, PLA requires less energy and generates fewer greenhouse gas emissions compared to petroleum-based plastics. The manufacturing process of PLA can reduce carbon dioxide emissions by up to 80% when compared to conventional plastics. Additionally, the use of renewable resources in PLA production helps conserve fossil fuel reserves and reduces dependence on non-renewable resources.

In terms of biodegradability, PLA presents a significant advantage over traditional plastics. Under proper composting conditions, PLA can break down into carbon dioxide, water, and biomass within 3-6 months. This characteristic greatly reduces the environmental burden associated with plastic waste accumulation in landfills and oceans. However, it is important to note that PLA requires specific industrial composting facilities to biodegrade effectively, which may not be widely available in all regions.

The end-of-life options for PLA packaging also contribute to its environmental profile. PLA can be recycled through existing recycling streams, although it requires separation from other plastics to maintain the quality of recycled materials. When incinerated, PLA produces fewer toxic emissions compared to petroleum-based plastics, further reducing its environmental impact.

Water consumption is another factor to consider in the environmental assessment of PLA. While the production of PLA does require water, particularly for growing the crops used as raw materials, advancements in agricultural practices and water management techniques have helped to mitigate this concern. Some studies suggest that the overall water footprint of PLA can be lower than that of conventional plastics when considering the entire lifecycle.

Despite these benefits, there are some environmental challenges associated with PLA. The use of agricultural land for PLA production raises concerns about competition with food crops and potential impacts on biodiversity. Additionally, the energy-intensive nature of some PLA manufacturing processes may offset some of its environmental advantages, depending on the energy sources used.

In conclusion, while PLA offers significant environmental benefits in food packaging applications, a comprehensive lifecycle assessment is necessary to fully understand its impact. Factors such as raw material sourcing, production methods, transportation, and end-of-life management all play crucial roles in determining the overall environmental footprint of PLA-based packaging solutions.

During production, PLA requires less energy and generates fewer greenhouse gas emissions compared to petroleum-based plastics. The manufacturing process of PLA can reduce carbon dioxide emissions by up to 80% when compared to conventional plastics. Additionally, the use of renewable resources in PLA production helps conserve fossil fuel reserves and reduces dependence on non-renewable resources.

In terms of biodegradability, PLA presents a significant advantage over traditional plastics. Under proper composting conditions, PLA can break down into carbon dioxide, water, and biomass within 3-6 months. This characteristic greatly reduces the environmental burden associated with plastic waste accumulation in landfills and oceans. However, it is important to note that PLA requires specific industrial composting facilities to biodegrade effectively, which may not be widely available in all regions.

The end-of-life options for PLA packaging also contribute to its environmental profile. PLA can be recycled through existing recycling streams, although it requires separation from other plastics to maintain the quality of recycled materials. When incinerated, PLA produces fewer toxic emissions compared to petroleum-based plastics, further reducing its environmental impact.

Water consumption is another factor to consider in the environmental assessment of PLA. While the production of PLA does require water, particularly for growing the crops used as raw materials, advancements in agricultural practices and water management techniques have helped to mitigate this concern. Some studies suggest that the overall water footprint of PLA can be lower than that of conventional plastics when considering the entire lifecycle.

Despite these benefits, there are some environmental challenges associated with PLA. The use of agricultural land for PLA production raises concerns about competition with food crops and potential impacts on biodiversity. Additionally, the energy-intensive nature of some PLA manufacturing processes may offset some of its environmental advantages, depending on the energy sources used.

In conclusion, while PLA offers significant environmental benefits in food packaging applications, a comprehensive lifecycle assessment is necessary to fully understand its impact. Factors such as raw material sourcing, production methods, transportation, and end-of-life management all play crucial roles in determining the overall environmental footprint of PLA-based packaging solutions.

Regulatory Framework for Bioplastics in Food Contact

The regulatory framework for bioplastics in food contact applications is a critical aspect of the adoption and implementation of PLA (Polylactic Acid) in food packaging solutions. As the use of bioplastics in food packaging continues to grow, governments and regulatory bodies worldwide have been developing and refining guidelines to ensure consumer safety and environmental protection.

In the European Union, the European Food Safety Authority (EFSA) plays a crucial role in evaluating the safety of materials intended for food contact. The EU Regulation No. 10/2011 on plastic materials and articles intended to come into contact with food provides specific requirements for PLA and other bioplastics. This regulation sets migration limits for substances that may transfer from the packaging to the food, ensuring that any potential migration does not pose a risk to human health.

The United States Food and Drug Administration (FDA) regulates food contact materials through the Food Contact Notification (FCN) program. PLA has been approved for use in food packaging under several FCNs, with specific conditions and limitations. The FDA evaluates the safety of the material, its intended use, and potential migration of substances into food.

In Japan, the Ministry of Health, Labour and Welfare (MHLW) oversees the regulation of food contact materials. The Positive List System for food contact materials includes PLA and other bioplastics, specifying the conditions under which they can be used in food packaging applications.

Many other countries have developed their own regulatory frameworks or adopted international standards. For instance, China's GB 4806 series of national food safety standards includes provisions for food contact materials, including bioplastics like PLA.

One of the challenges in the regulatory landscape is the harmonization of standards across different regions. Efforts are being made to align regulations and testing methods to facilitate international trade and ensure consistent safety standards globally. The Global Bioplastics Alliance and other industry organizations are working with regulatory bodies to promote standardization and clarity in regulations.

As environmental concerns drive the adoption of bioplastics, regulators are also considering the end-of-life aspects of these materials. Compostability and biodegradability claims are coming under increased scrutiny, with standards such as EN 13432 in Europe and ASTM D6400 in the United States providing guidelines for certification of compostable plastics.

The evolving nature of bioplastic technology necessitates ongoing updates to regulatory frameworks. As new formulations and applications of PLA and other bioplastics emerge, regulatory bodies must continually assess their safety and environmental impact. This dynamic regulatory environment requires food packaging manufacturers to stay informed and adaptable to ensure compliance across different markets.

In the European Union, the European Food Safety Authority (EFSA) plays a crucial role in evaluating the safety of materials intended for food contact. The EU Regulation No. 10/2011 on plastic materials and articles intended to come into contact with food provides specific requirements for PLA and other bioplastics. This regulation sets migration limits for substances that may transfer from the packaging to the food, ensuring that any potential migration does not pose a risk to human health.

The United States Food and Drug Administration (FDA) regulates food contact materials through the Food Contact Notification (FCN) program. PLA has been approved for use in food packaging under several FCNs, with specific conditions and limitations. The FDA evaluates the safety of the material, its intended use, and potential migration of substances into food.

In Japan, the Ministry of Health, Labour and Welfare (MHLW) oversees the regulation of food contact materials. The Positive List System for food contact materials includes PLA and other bioplastics, specifying the conditions under which they can be used in food packaging applications.

Many other countries have developed their own regulatory frameworks or adopted international standards. For instance, China's GB 4806 series of national food safety standards includes provisions for food contact materials, including bioplastics like PLA.

One of the challenges in the regulatory landscape is the harmonization of standards across different regions. Efforts are being made to align regulations and testing methods to facilitate international trade and ensure consistent safety standards globally. The Global Bioplastics Alliance and other industry organizations are working with regulatory bodies to promote standardization and clarity in regulations.

As environmental concerns drive the adoption of bioplastics, regulators are also considering the end-of-life aspects of these materials. Compostability and biodegradability claims are coming under increased scrutiny, with standards such as EN 13432 in Europe and ASTM D6400 in the United States providing guidelines for certification of compostable plastics.

The evolving nature of bioplastic technology necessitates ongoing updates to regulatory frameworks. As new formulations and applications of PLA and other bioplastics emerge, regulatory bodies must continually assess their safety and environmental impact. This dynamic regulatory environment requires food packaging manufacturers to stay informed and adaptable to ensure compliance across different markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!