Building a Resilient PLA Ecosystem for Future Demands

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PLA Ecosystem Evolution and Objectives

The evolution of the PLA (Polylactic Acid) ecosystem has been marked by significant advancements in bioplastic technology and a growing emphasis on sustainable materials. Initially developed as a biodegradable alternative to traditional plastics, PLA has undergone substantial improvements in its production processes, material properties, and applications over the past few decades.

The primary objective in building a resilient PLA ecosystem is to create a sustainable, circular economy for bioplastics that can meet future demands while minimizing environmental impact. This involves enhancing PLA's performance characteristics, expanding its range of applications, and developing more efficient production methods.

One of the key evolutionary milestones in the PLA ecosystem has been the optimization of fermentation processes for lactic acid production. This has led to increased yields and reduced costs, making PLA more competitive with conventional plastics. Additionally, advancements in polymer science have resulted in PLA variants with improved thermal stability, mechanical strength, and barrier properties, broadening its potential uses across various industries.

The development of more efficient and environmentally friendly catalysts for PLA polymerization represents another crucial step in the ecosystem's evolution. These innovations have not only improved the quality of PLA but also reduced energy consumption and waste generation during production.

A significant objective for the future of the PLA ecosystem is the establishment of a robust recycling infrastructure. This includes developing technologies for efficient PLA sorting, depolymerization, and repolymerization, enabling a true circular economy for bioplastics. Research into chemical recycling methods, such as hydrolysis and thermal depolymerization, shows promise in achieving this goal.

Another important aim is to diversify PLA feedstocks beyond corn and sugarcane. Exploring alternative sources, such as agricultural waste and non-food crops, could enhance the sustainability of PLA production and reduce competition with food resources. This aligns with the broader objective of creating a more resilient and adaptable PLA supply chain.

Improving PLA's end-of-life options is also a critical focus. While PLA is biodegradable under specific conditions, enhancing its compostability in various environments and developing more efficient industrial composting facilities are key objectives. This would ensure that PLA products can be effectively managed at the end of their lifecycle, regardless of the disposal method available.

As the PLA ecosystem continues to evolve, collaboration between academia, industry, and policymakers will be crucial in driving innovation and overcoming challenges. The ultimate goal is to create a PLA ecosystem that is not only environmentally sustainable but also economically viable and technologically advanced, capable of meeting the growing demand for eco-friendly materials in a rapidly changing world.

The primary objective in building a resilient PLA ecosystem is to create a sustainable, circular economy for bioplastics that can meet future demands while minimizing environmental impact. This involves enhancing PLA's performance characteristics, expanding its range of applications, and developing more efficient production methods.

One of the key evolutionary milestones in the PLA ecosystem has been the optimization of fermentation processes for lactic acid production. This has led to increased yields and reduced costs, making PLA more competitive with conventional plastics. Additionally, advancements in polymer science have resulted in PLA variants with improved thermal stability, mechanical strength, and barrier properties, broadening its potential uses across various industries.

The development of more efficient and environmentally friendly catalysts for PLA polymerization represents another crucial step in the ecosystem's evolution. These innovations have not only improved the quality of PLA but also reduced energy consumption and waste generation during production.

A significant objective for the future of the PLA ecosystem is the establishment of a robust recycling infrastructure. This includes developing technologies for efficient PLA sorting, depolymerization, and repolymerization, enabling a true circular economy for bioplastics. Research into chemical recycling methods, such as hydrolysis and thermal depolymerization, shows promise in achieving this goal.

Another important aim is to diversify PLA feedstocks beyond corn and sugarcane. Exploring alternative sources, such as agricultural waste and non-food crops, could enhance the sustainability of PLA production and reduce competition with food resources. This aligns with the broader objective of creating a more resilient and adaptable PLA supply chain.

Improving PLA's end-of-life options is also a critical focus. While PLA is biodegradable under specific conditions, enhancing its compostability in various environments and developing more efficient industrial composting facilities are key objectives. This would ensure that PLA products can be effectively managed at the end of their lifecycle, regardless of the disposal method available.

As the PLA ecosystem continues to evolve, collaboration between academia, industry, and policymakers will be crucial in driving innovation and overcoming challenges. The ultimate goal is to create a PLA ecosystem that is not only environmentally sustainable but also economically viable and technologically advanced, capable of meeting the growing demand for eco-friendly materials in a rapidly changing world.

Market Analysis for PLA Applications

The PLA (Polylactic Acid) market has experienced significant growth in recent years, driven by increasing environmental concerns and the shift towards sustainable materials. The global PLA market size was valued at approximately $698 million in 2020 and is projected to reach $2.9 billion by 2028, growing at a CAGR of 19.5% during the forecast period. This robust growth is primarily attributed to the rising demand for biodegradable plastics across various industries.

The packaging sector remains the largest application area for PLA, accounting for over 60% of the market share. This dominance is expected to continue due to the material's excellent barrier properties, transparency, and biodegradability, making it an ideal choice for food packaging, disposable cutlery, and beverage bottles. The automotive industry is also emerging as a significant consumer of PLA, particularly in interior components and upholstery, as manufacturers seek to reduce vehicle weight and improve fuel efficiency.

In the medical field, PLA's biocompatibility and biodegradability have led to its increased adoption in implants, drug delivery systems, and tissue engineering scaffolds. The market for PLA in medical applications is expected to grow at a CAGR of 22% from 2021 to 2028, outpacing the overall market growth rate.

Geographically, Europe leads the PLA market, followed closely by North America. However, the Asia-Pacific region is anticipated to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing environmental regulations, and growing consumer awareness about sustainable products. China, in particular, is expected to become a major player in both PLA production and consumption.

Despite the positive outlook, several challenges persist in the PLA market. The higher cost of PLA compared to conventional plastics remains a significant barrier to widespread adoption, especially in price-sensitive markets. Additionally, limitations in PLA's heat resistance and impact strength restrict its use in certain high-performance applications.

To address these challenges and capitalize on market opportunities, industry players are focusing on technological innovations to improve PLA's properties and reduce production costs. Collaborations between raw material suppliers, manufacturers, and end-users are becoming increasingly common to develop tailored PLA solutions for specific applications. Furthermore, government initiatives promoting bio-based materials and circular economy principles are expected to provide additional impetus to the PLA market growth in the coming years.

The packaging sector remains the largest application area for PLA, accounting for over 60% of the market share. This dominance is expected to continue due to the material's excellent barrier properties, transparency, and biodegradability, making it an ideal choice for food packaging, disposable cutlery, and beverage bottles. The automotive industry is also emerging as a significant consumer of PLA, particularly in interior components and upholstery, as manufacturers seek to reduce vehicle weight and improve fuel efficiency.

In the medical field, PLA's biocompatibility and biodegradability have led to its increased adoption in implants, drug delivery systems, and tissue engineering scaffolds. The market for PLA in medical applications is expected to grow at a CAGR of 22% from 2021 to 2028, outpacing the overall market growth rate.

Geographically, Europe leads the PLA market, followed closely by North America. However, the Asia-Pacific region is anticipated to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing environmental regulations, and growing consumer awareness about sustainable products. China, in particular, is expected to become a major player in both PLA production and consumption.

Despite the positive outlook, several challenges persist in the PLA market. The higher cost of PLA compared to conventional plastics remains a significant barrier to widespread adoption, especially in price-sensitive markets. Additionally, limitations in PLA's heat resistance and impact strength restrict its use in certain high-performance applications.

To address these challenges and capitalize on market opportunities, industry players are focusing on technological innovations to improve PLA's properties and reduce production costs. Collaborations between raw material suppliers, manufacturers, and end-users are becoming increasingly common to develop tailored PLA solutions for specific applications. Furthermore, government initiatives promoting bio-based materials and circular economy principles are expected to provide additional impetus to the PLA market growth in the coming years.

PLA Technology Challenges

The development of a resilient PLA (Polylactic Acid) ecosystem faces several significant technological challenges. One of the primary issues is the inherent brittleness of PLA, which limits its applications in sectors requiring high impact resistance or flexibility. This characteristic necessitates the development of advanced blending techniques or the creation of novel PLA-based composites to enhance its mechanical properties without compromising its biodegradability.

Another critical challenge lies in the optimization of PLA production processes to reduce costs and improve scalability. Current manufacturing methods often involve energy-intensive steps, leading to higher production expenses compared to conventional plastics. Innovations in fermentation technologies and more efficient catalysts are needed to streamline production and make PLA more economically competitive.

The thermal stability of PLA presents a further hurdle, particularly in high-temperature applications. PLA's relatively low glass transition temperature and heat deflection temperature limit its use in certain industrial and consumer products. Addressing this issue requires advancements in polymer chemistry to enhance PLA's thermal properties without sacrificing its biodegradability or food-contact safety.

Recycling and end-of-life management of PLA products pose additional challenges. While PLA is compostable under specific industrial conditions, many regions lack the infrastructure to properly process these materials. Developing more robust recycling technologies and establishing widespread composting facilities are crucial steps in creating a truly circular PLA economy.

The variability in feedstock quality and availability presents another obstacle. PLA production relies heavily on agricultural inputs, primarily corn or sugarcane. Fluctuations in crop yields due to climate change or shifts in agricultural practices can impact the consistency and cost of PLA production. Research into alternative feedstocks and more resilient crop varieties is essential to ensure a stable supply chain.

Lastly, the challenge of enhancing PLA's barrier properties, particularly its resistance to moisture and gas permeation, remains significant. This limitation affects PLA's suitability for certain packaging applications, especially in the food and beverage industry. Developing effective coating technologies or modifying PLA's molecular structure to improve its barrier properties without compromising its biodegradability is a key area of ongoing research and development.

Another critical challenge lies in the optimization of PLA production processes to reduce costs and improve scalability. Current manufacturing methods often involve energy-intensive steps, leading to higher production expenses compared to conventional plastics. Innovations in fermentation technologies and more efficient catalysts are needed to streamline production and make PLA more economically competitive.

The thermal stability of PLA presents a further hurdle, particularly in high-temperature applications. PLA's relatively low glass transition temperature and heat deflection temperature limit its use in certain industrial and consumer products. Addressing this issue requires advancements in polymer chemistry to enhance PLA's thermal properties without sacrificing its biodegradability or food-contact safety.

Recycling and end-of-life management of PLA products pose additional challenges. While PLA is compostable under specific industrial conditions, many regions lack the infrastructure to properly process these materials. Developing more robust recycling technologies and establishing widespread composting facilities are crucial steps in creating a truly circular PLA economy.

The variability in feedstock quality and availability presents another obstacle. PLA production relies heavily on agricultural inputs, primarily corn or sugarcane. Fluctuations in crop yields due to climate change or shifts in agricultural practices can impact the consistency and cost of PLA production. Research into alternative feedstocks and more resilient crop varieties is essential to ensure a stable supply chain.

Lastly, the challenge of enhancing PLA's barrier properties, particularly its resistance to moisture and gas permeation, remains significant. This limitation affects PLA's suitability for certain packaging applications, especially in the food and beverage industry. Developing effective coating technologies or modifying PLA's molecular structure to improve its barrier properties without compromising its biodegradability is a key area of ongoing research and development.

Current PLA Production Methods

01 Biodegradable PLA composites for ecosystem resilience

Development of biodegradable PLA composites that enhance ecosystem resilience by reducing environmental impact. These composites are designed to break down naturally, contributing to soil health and minimizing pollution in various ecosystems.- Biodegradable PLA materials for ecosystem sustainability: Development of biodegradable PLA (Polylactic Acid) materials that contribute to ecosystem resilience by reducing environmental impact. These materials are designed to break down naturally, minimizing long-term pollution and supporting the regeneration of ecosystems.

- PLA-based composites for enhanced environmental adaptability: Creation of PLA-based composite materials that improve the adaptability of products to various environmental conditions. These composites combine PLA with other materials to enhance durability, flexibility, and resistance to degradation, contributing to the overall resilience of ecosystems where they are used.

- Ecosystem monitoring systems using PLA sensors: Implementation of ecosystem monitoring systems utilizing PLA-based sensors. These systems help in tracking environmental changes, biodiversity, and ecosystem health, providing valuable data for maintaining and improving ecosystem resilience.

- PLA in sustainable agriculture practices: Application of PLA materials in agricultural practices to promote ecosystem resilience. This includes the use of PLA-based products for soil management, crop protection, and sustainable farming techniques that minimize environmental impact and support long-term ecosystem health.

- PLA-based solutions for ecosystem restoration: Development of PLA-based solutions specifically designed for ecosystem restoration projects. These include biodegradable structures, seed carriers, and other materials that aid in the recovery and resilience of damaged ecosystems, promoting natural regeneration and biodiversity.

02 PLA-based materials for sustainable agriculture

Creation of PLA-based materials specifically tailored for agricultural applications, promoting ecosystem resilience through sustainable farming practices. These materials include biodegradable mulch films, seed coatings, and controlled-release fertilizer capsules.Expand Specific Solutions03 PLA ecosystem monitoring and analysis systems

Development of advanced monitoring and analysis systems using PLA-based sensors and devices to assess ecosystem health and resilience. These systems provide real-time data on environmental parameters, enabling proactive management of ecosystems.Expand Specific Solutions04 PLA-based solutions for marine ecosystem protection

Innovation of PLA-based materials and technologies specifically designed to protect and restore marine ecosystems. This includes biodegradable fishing gear, artificial reefs, and marine pollution remediation solutions that enhance ocean ecosystem resilience.Expand Specific Solutions05 PLA applications in ecosystem restoration and conservation

Utilization of PLA-based products and techniques in ecosystem restoration and conservation efforts. This includes biodegradable plant containers, erosion control materials, and wildlife habitat structures that support the recovery and resilience of damaged ecosystems.Expand Specific Solutions

Key Players in PLA Industry

The development of a resilient PLA ecosystem for future demands is currently in a growth phase, with increasing market size and technological advancements. The global PLA market is expanding rapidly, driven by growing environmental concerns and demand for sustainable materials. Technologically, PLA is maturing, with companies like Total Research Corp, LG Chem Ltd., and Avantium Knowledge Centre BV leading innovation. Academic institutions such as MIT, Cornell University, and Sichuan University are contributing significantly to research and development. The ecosystem is diverse, involving players from various sectors, including material science, packaging, and biotechnology, indicating a robust and competitive landscape with potential for further growth and innovation.

LG Chem Ltd.

Technical Solution: LG Chem has developed an innovative PLA production process that addresses future demands for sustainability and performance. Their approach involves a proprietary catalytic system that enables the production of high-molecular-weight PLA with enhanced thermal stability and mechanical properties. The process also incorporates renewable feedstocks and green chemistry principles to minimize environmental impact. LG Chem's PLA ecosystem includes the development of specialized additives and compatibilizers that allow for tailored material properties, making their PLA suitable for a wide range of applications from packaging to automotive parts.

Strengths: Improved material properties and versatility in applications. Weaknesses: Dependence on proprietary technology may limit widespread adoption.

Floreon Technology Ltd.

Technical Solution: Floreon has developed a proprietary PLA compound that significantly enhances the material's performance while maintaining its biodegradability. Their technology involves blending PLA with carefully selected bio-based additives and modifiers, resulting in a material with improved impact resistance, heat stability, and processing characteristics. Floreon's PLA ecosystem extends beyond material development to include partnerships with manufacturers and end-users, ensuring that their enhanced PLA can be effectively integrated into existing production processes and applications. They also provide guidance on optimal end-of-life scenarios for their materials, including industrial composting and chemical recycling options.

Strengths: Enhanced material properties without sacrificing biodegradability, established industry partnerships. Weaknesses: Limited to specific formulations, potentially higher cost compared to standard PLA.

Innovations in PLA Technology

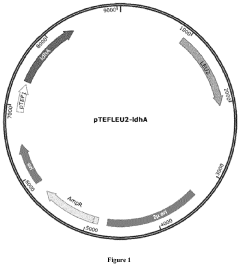

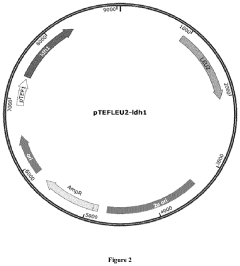

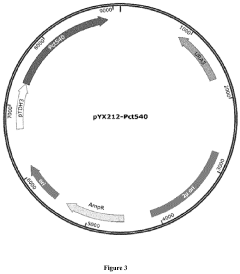

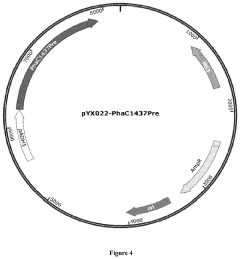

Process for cellular biosynthesis of poly d-lactic acid and poly l-lactic acid

PatentActiveUS20210324429A1

Innovation

- Engineering eukaryotic cells, such as yeast strains, to redirect metabolic pathways for the direct biological synthesis of PLLA and PDLA from carbon sources like glucose, using enzymes like D-lactate dehydrogenase, propionyl-CoA transferase, and polyhydroxyalkanoate synthase to convert pyruvate into lactyl-CoA and subsequently polymerize it into the desired polymers.

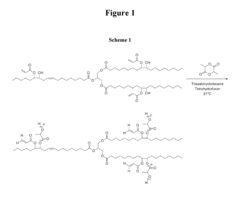

Biorenewable blends of polylactide and acrylated epoxidized soybean oil compatibilized by a polylactide star polymer

PatentActiveUS20190010326A1

Innovation

- A biorenewable thermoplastic additive blend comprising up to 99% of a modified natural oil, such as acrylated epoxidized soybean oil (AESO), an unmodified natural oil, and a compatibilizer like a PLA star polymer, which enhances interfacial adhesion and reduces blend interfacial tension, resulting in improved tensile properties and toughness.

Environmental Impact of PLA

The environmental impact of PLA (Polylactic Acid) is a crucial consideration in building a resilient PLA ecosystem for future demands. PLA, derived from renewable resources such as corn starch or sugarcane, offers a promising alternative to traditional petroleum-based plastics. However, its environmental footprint extends beyond its biodegradability and requires a comprehensive analysis.

One of the primary environmental benefits of PLA is its potential for carbon neutrality. The plants used to produce PLA absorb carbon dioxide during growth, potentially offsetting the emissions generated during production. This characteristic positions PLA as a more sustainable option compared to conventional plastics. However, the actual carbon footprint depends on various factors, including agricultural practices, processing methods, and end-of-life management.

The production of PLA generally requires less energy compared to petroleum-based plastics, contributing to reduced greenhouse gas emissions. Additionally, PLA production does not rely on finite fossil fuel resources, aligning with long-term sustainability goals. However, the environmental impact of large-scale agricultural production for PLA feedstock must be carefully managed to prevent issues such as deforestation, soil degradation, and water pollution.

While PLA is biodegradable under specific conditions, its end-of-life management presents both opportunities and challenges. In industrial composting facilities, PLA can break down into water, carbon dioxide, and biomass within a few months. However, these facilities are not universally available, and improper disposal can lead to PLA persisting in the environment. Moreover, the mixing of PLA with traditional plastics in recycling streams can complicate recycling processes.

The water usage in PLA production, primarily for crop irrigation and processing, is another environmental consideration. While some studies suggest that PLA production may require less water than certain conventional plastics, the impact can vary significantly based on geographical location and agricultural practices. Implementing efficient irrigation systems and selecting drought-resistant crop varieties can help mitigate water-related concerns.

As the demand for PLA grows, addressing these environmental aspects becomes increasingly important. Innovations in feedstock production, such as utilizing agricultural waste or non-food crops, could further enhance PLA's environmental profile. Additionally, developing more efficient composting infrastructure and improving PLA's compatibility with existing recycling systems are crucial steps in maximizing its environmental benefits.

One of the primary environmental benefits of PLA is its potential for carbon neutrality. The plants used to produce PLA absorb carbon dioxide during growth, potentially offsetting the emissions generated during production. This characteristic positions PLA as a more sustainable option compared to conventional plastics. However, the actual carbon footprint depends on various factors, including agricultural practices, processing methods, and end-of-life management.

The production of PLA generally requires less energy compared to petroleum-based plastics, contributing to reduced greenhouse gas emissions. Additionally, PLA production does not rely on finite fossil fuel resources, aligning with long-term sustainability goals. However, the environmental impact of large-scale agricultural production for PLA feedstock must be carefully managed to prevent issues such as deforestation, soil degradation, and water pollution.

While PLA is biodegradable under specific conditions, its end-of-life management presents both opportunities and challenges. In industrial composting facilities, PLA can break down into water, carbon dioxide, and biomass within a few months. However, these facilities are not universally available, and improper disposal can lead to PLA persisting in the environment. Moreover, the mixing of PLA with traditional plastics in recycling streams can complicate recycling processes.

The water usage in PLA production, primarily for crop irrigation and processing, is another environmental consideration. While some studies suggest that PLA production may require less water than certain conventional plastics, the impact can vary significantly based on geographical location and agricultural practices. Implementing efficient irrigation systems and selecting drought-resistant crop varieties can help mitigate water-related concerns.

As the demand for PLA grows, addressing these environmental aspects becomes increasingly important. Innovations in feedstock production, such as utilizing agricultural waste or non-food crops, could further enhance PLA's environmental profile. Additionally, developing more efficient composting infrastructure and improving PLA's compatibility with existing recycling systems are crucial steps in maximizing its environmental benefits.

PLA Supply Chain Resilience

Building a resilient PLA (Polylactic Acid) ecosystem for future demands requires a comprehensive approach to supply chain management. The PLA industry faces unique challenges due to its reliance on agricultural feedstocks and the need for specialized processing facilities. To enhance supply chain resilience, stakeholders must focus on diversifying raw material sources, optimizing production processes, and developing robust distribution networks.

One key aspect of improving PLA supply chain resilience is the diversification of feedstock sources. Currently, the industry heavily relies on corn and sugarcane as primary raw materials. By expanding the range of feedstocks to include alternative sources such as agricultural waste, cellulosic biomass, and even algae, manufacturers can reduce their vulnerability to supply disruptions and price fluctuations in any single commodity market.

Vertical integration within the PLA supply chain can also contribute significantly to resilience. By controlling multiple stages of production, from feedstock cultivation to polymer synthesis and product manufacturing, companies can better manage risks and respond more quickly to market changes. This approach allows for greater flexibility in adjusting production volumes and product specifications to meet evolving customer demands.

Implementing advanced inventory management systems and predictive analytics can help PLA manufacturers anticipate and mitigate potential supply chain disruptions. By leveraging real-time data on raw material availability, production capacity, and market demand, companies can optimize their inventory levels and production schedules, reducing the risk of stockouts or excess inventory.

Developing strategic partnerships and collaborations across the PLA value chain is crucial for building a resilient ecosystem. This includes fostering relationships with feedstock suppliers, logistics providers, and end-users to ensure a stable and efficient flow of materials and products. Such partnerships can also facilitate knowledge sharing and joint innovation efforts, leading to improved processes and products that enhance overall supply chain performance.

Investing in research and development to improve PLA production technologies is essential for long-term supply chain resilience. Advancements in fermentation processes, polymer synthesis, and product formulation can lead to more efficient use of raw materials, reduced energy consumption, and enhanced product properties. These improvements can help PLA manufacturers maintain competitiveness and adapt to changing market conditions.

Lastly, establishing a circular economy approach within the PLA ecosystem can significantly contribute to supply chain resilience. By developing effective collection, sorting, and recycling systems for PLA products, manufacturers can reduce their dependence on virgin raw materials and create a more sustainable and resilient supply chain. This approach not only addresses environmental concerns but also provides a buffer against potential disruptions in the primary feedstock supply.

One key aspect of improving PLA supply chain resilience is the diversification of feedstock sources. Currently, the industry heavily relies on corn and sugarcane as primary raw materials. By expanding the range of feedstocks to include alternative sources such as agricultural waste, cellulosic biomass, and even algae, manufacturers can reduce their vulnerability to supply disruptions and price fluctuations in any single commodity market.

Vertical integration within the PLA supply chain can also contribute significantly to resilience. By controlling multiple stages of production, from feedstock cultivation to polymer synthesis and product manufacturing, companies can better manage risks and respond more quickly to market changes. This approach allows for greater flexibility in adjusting production volumes and product specifications to meet evolving customer demands.

Implementing advanced inventory management systems and predictive analytics can help PLA manufacturers anticipate and mitigate potential supply chain disruptions. By leveraging real-time data on raw material availability, production capacity, and market demand, companies can optimize their inventory levels and production schedules, reducing the risk of stockouts or excess inventory.

Developing strategic partnerships and collaborations across the PLA value chain is crucial for building a resilient ecosystem. This includes fostering relationships with feedstock suppliers, logistics providers, and end-users to ensure a stable and efficient flow of materials and products. Such partnerships can also facilitate knowledge sharing and joint innovation efforts, leading to improved processes and products that enhance overall supply chain performance.

Investing in research and development to improve PLA production technologies is essential for long-term supply chain resilience. Advancements in fermentation processes, polymer synthesis, and product formulation can lead to more efficient use of raw materials, reduced energy consumption, and enhanced product properties. These improvements can help PLA manufacturers maintain competitiveness and adapt to changing market conditions.

Lastly, establishing a circular economy approach within the PLA ecosystem can significantly contribute to supply chain resilience. By developing effective collection, sorting, and recycling systems for PLA products, manufacturers can reduce their dependence on virgin raw materials and create a more sustainable and resilient supply chain. This approach not only addresses environmental concerns but also provides a buffer against potential disruptions in the primary feedstock supply.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!