How to Implement PLA Solutions in Waste Management?

JUN 25, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PLA in Waste Management: Background and Objectives

Polylactic acid (PLA) has emerged as a promising solution in waste management, offering a biodegradable alternative to traditional plastics. The evolution of PLA technology in waste management can be traced back to the early 1990s when researchers began exploring its potential as an environmentally friendly material. Since then, PLA has gained significant attention due to its ability to decompose under specific conditions, addressing the growing concern of plastic pollution.

The primary objective of implementing PLA solutions in waste management is to reduce the environmental impact of non-biodegradable plastics. By utilizing PLA in various applications, from packaging to disposable items, the aim is to create a more sustainable waste stream that can be effectively managed through composting or other biodegradation processes. This approach aligns with the global push towards circular economy principles and the reduction of plastic waste in landfills and oceans.

As the technology has progressed, the focus has shifted from merely developing PLA materials to optimizing their properties for specific waste management applications. This includes enhancing the material's durability during use while ensuring its biodegradability under controlled conditions. The goal is to strike a balance between functionality and environmental responsibility, making PLA a viable alternative in various industries.

The trend in PLA development for waste management has been towards improving its mechanical properties, thermal stability, and biodegradation rates. Researchers and industry players have been working on tailoring PLA formulations to meet the diverse requirements of different waste management scenarios. This includes developing PLA blends and composites that can withstand various environmental conditions while maintaining their biodegradable characteristics.

Another critical aspect of PLA implementation in waste management is the development of appropriate end-of-life solutions. This involves creating efficient composting systems and educating consumers and waste management professionals about proper disposal methods for PLA products. The objective is to ensure that PLA materials are correctly sorted and processed, maximizing their environmental benefits.

Looking ahead, the future of PLA in waste management is likely to focus on scaling up production, reducing costs, and expanding applications. There is also a growing emphasis on developing advanced recycling technologies specifically designed for PLA, which could further enhance its circular economy potential. As regulations around single-use plastics tighten globally, PLA is positioned to play a crucial role in providing sustainable alternatives across various sectors.

The primary objective of implementing PLA solutions in waste management is to reduce the environmental impact of non-biodegradable plastics. By utilizing PLA in various applications, from packaging to disposable items, the aim is to create a more sustainable waste stream that can be effectively managed through composting or other biodegradation processes. This approach aligns with the global push towards circular economy principles and the reduction of plastic waste in landfills and oceans.

As the technology has progressed, the focus has shifted from merely developing PLA materials to optimizing their properties for specific waste management applications. This includes enhancing the material's durability during use while ensuring its biodegradability under controlled conditions. The goal is to strike a balance between functionality and environmental responsibility, making PLA a viable alternative in various industries.

The trend in PLA development for waste management has been towards improving its mechanical properties, thermal stability, and biodegradation rates. Researchers and industry players have been working on tailoring PLA formulations to meet the diverse requirements of different waste management scenarios. This includes developing PLA blends and composites that can withstand various environmental conditions while maintaining their biodegradable characteristics.

Another critical aspect of PLA implementation in waste management is the development of appropriate end-of-life solutions. This involves creating efficient composting systems and educating consumers and waste management professionals about proper disposal methods for PLA products. The objective is to ensure that PLA materials are correctly sorted and processed, maximizing their environmental benefits.

Looking ahead, the future of PLA in waste management is likely to focus on scaling up production, reducing costs, and expanding applications. There is also a growing emphasis on developing advanced recycling technologies specifically designed for PLA, which could further enhance its circular economy potential. As regulations around single-use plastics tighten globally, PLA is positioned to play a crucial role in providing sustainable alternatives across various sectors.

Market Analysis for PLA-based Waste Solutions

The market for PLA-based waste management solutions is experiencing significant growth, driven by increasing environmental concerns and stringent regulations on plastic waste. The global biodegradable plastics market, of which PLA is a key component, is projected to reach $6.12 billion by 2025, growing at a CAGR of 21.3% from 2020 to 2025. This growth is particularly pronounced in the packaging and food service industries, where PLA-based products are increasingly replacing traditional petroleum-based plastics.

In the waste management sector, PLA solutions are gaining traction due to their biodegradability and compostability. Municipal waste management facilities and industrial composting operations are showing increased interest in PLA-based products as they seek to reduce landfill waste and meet sustainability targets. The market for PLA in waste management is expected to grow as more cities and countries implement organic waste collection programs and invest in industrial composting infrastructure.

Consumer demand for eco-friendly packaging and products is a significant driver of the PLA market. A survey conducted in 2022 revealed that 73% of consumers are willing to pay more for products with sustainable packaging. This shift in consumer preferences is pushing brands to adopt PLA-based packaging solutions, further stimulating market growth.

Geographically, Europe leads the market for PLA-based waste solutions, followed by North America and Asia-Pacific. Europe's dominance is attributed to its advanced waste management infrastructure and stringent regulations on single-use plastics. The Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing environmental awareness, and government initiatives to reduce plastic waste.

Challenges in the market include the higher cost of PLA compared to conventional plastics and the need for specialized composting facilities. However, ongoing research and development efforts are focused on reducing production costs and improving the properties of PLA, which is expected to address these challenges and further expand market opportunities.

The waste management industry is increasingly recognizing the potential of PLA in achieving circular economy goals. As landfill space becomes scarce and waste-to-energy solutions gain popularity, PLA's ability to be composted or converted into biogas through anaerobic digestion presents a compelling value proposition for waste management companies and municipalities alike.

In the waste management sector, PLA solutions are gaining traction due to their biodegradability and compostability. Municipal waste management facilities and industrial composting operations are showing increased interest in PLA-based products as they seek to reduce landfill waste and meet sustainability targets. The market for PLA in waste management is expected to grow as more cities and countries implement organic waste collection programs and invest in industrial composting infrastructure.

Consumer demand for eco-friendly packaging and products is a significant driver of the PLA market. A survey conducted in 2022 revealed that 73% of consumers are willing to pay more for products with sustainable packaging. This shift in consumer preferences is pushing brands to adopt PLA-based packaging solutions, further stimulating market growth.

Geographically, Europe leads the market for PLA-based waste solutions, followed by North America and Asia-Pacific. Europe's dominance is attributed to its advanced waste management infrastructure and stringent regulations on single-use plastics. The Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing environmental awareness, and government initiatives to reduce plastic waste.

Challenges in the market include the higher cost of PLA compared to conventional plastics and the need for specialized composting facilities. However, ongoing research and development efforts are focused on reducing production costs and improving the properties of PLA, which is expected to address these challenges and further expand market opportunities.

The waste management industry is increasingly recognizing the potential of PLA in achieving circular economy goals. As landfill space becomes scarce and waste-to-energy solutions gain popularity, PLA's ability to be composted or converted into biogas through anaerobic digestion presents a compelling value proposition for waste management companies and municipalities alike.

Current Challenges in PLA Waste Management

The implementation of PLA (Polylactic Acid) solutions in waste management faces several significant challenges. One of the primary issues is the lack of widespread infrastructure for proper collection and sorting of PLA waste. Many existing waste management systems are not equipped to handle biodegradable plastics separately, leading to contamination of recycling streams or improper disposal in landfills.

Another challenge is the limited awareness among consumers about the proper disposal methods for PLA products. This often results in PLA items being mixed with conventional plastics, complicating the recycling process and reducing the efficiency of waste management systems.

The biodegradation process of PLA requires specific conditions, including high temperatures and humidity levels, which are not typically found in natural environments or standard landfills. This means that PLA products may not degrade as quickly or efficiently as expected when disposed of improperly, potentially contributing to environmental pollution.

The economic viability of PLA recycling and composting facilities presents another hurdle. The current scale of PLA usage does not always justify the investment in specialized processing equipment, making it challenging for waste management companies to adopt PLA-specific solutions.

Furthermore, there is a lack of standardization in PLA production and labeling. Different manufacturers may use varying additives or blends, which can affect the biodegradability and recyclability of the final product. This inconsistency makes it difficult for waste management facilities to develop uniform processing methods.

The potential for cross-contamination between PLA and traditional plastics in recycling streams is also a significant concern. Even small amounts of PLA can compromise the quality of recycled conventional plastics, leading to resistance from recyclers to accept PLA materials.

Additionally, the energy and resource requirements for producing PLA, while generally lower than those for traditional plastics, still present environmental challenges. The cultivation of crops for PLA production raises questions about land use and potential competition with food production.

Lastly, the regulatory landscape surrounding biodegradable plastics, including PLA, is still evolving. The lack of clear, consistent policies and guidelines across different regions complicates the implementation of effective PLA waste management solutions on a global scale.

Another challenge is the limited awareness among consumers about the proper disposal methods for PLA products. This often results in PLA items being mixed with conventional plastics, complicating the recycling process and reducing the efficiency of waste management systems.

The biodegradation process of PLA requires specific conditions, including high temperatures and humidity levels, which are not typically found in natural environments or standard landfills. This means that PLA products may not degrade as quickly or efficiently as expected when disposed of improperly, potentially contributing to environmental pollution.

The economic viability of PLA recycling and composting facilities presents another hurdle. The current scale of PLA usage does not always justify the investment in specialized processing equipment, making it challenging for waste management companies to adopt PLA-specific solutions.

Furthermore, there is a lack of standardization in PLA production and labeling. Different manufacturers may use varying additives or blends, which can affect the biodegradability and recyclability of the final product. This inconsistency makes it difficult for waste management facilities to develop uniform processing methods.

The potential for cross-contamination between PLA and traditional plastics in recycling streams is also a significant concern. Even small amounts of PLA can compromise the quality of recycled conventional plastics, leading to resistance from recyclers to accept PLA materials.

Additionally, the energy and resource requirements for producing PLA, while generally lower than those for traditional plastics, still present environmental challenges. The cultivation of crops for PLA production raises questions about land use and potential competition with food production.

Lastly, the regulatory landscape surrounding biodegradable plastics, including PLA, is still evolving. The lack of clear, consistent policies and guidelines across different regions complicates the implementation of effective PLA waste management solutions on a global scale.

Existing PLA Waste Management Solutions

01 PLA-based composite materials

Development of composite materials using PLA as a base polymer, incorporating various additives or fillers to enhance properties such as strength, durability, or biodegradability. These composites can be used in a wide range of applications, from packaging to medical devices.- PLA-based composite materials: Development of composite materials using PLA as a base polymer, incorporating various additives or fillers to enhance properties such as strength, durability, and biodegradability. These composites can be used in a wide range of applications, from packaging to biomedical devices.

- PLA processing techniques: Innovative methods for processing PLA, including extrusion, injection molding, and 3D printing. These techniques aim to improve the material's performance, reduce production costs, and expand its potential applications in various industries.

- PLA blends and copolymers: Creation of PLA blends and copolymers with other biodegradable or non-biodegradable polymers to achieve specific properties. These blends can offer improved mechanical strength, flexibility, or thermal stability compared to pure PLA.

- Surface modification of PLA: Techniques for modifying the surface properties of PLA to enhance its compatibility with other materials, improve adhesion, or add functionality. This can include plasma treatment, chemical grafting, or coating processes.

- PLA-based biodegradable packaging: Development of biodegradable packaging solutions using PLA, focusing on improving barrier properties, extending shelf life, and ensuring complete biodegradability. This includes films, containers, and other packaging formats for food and non-food applications.

02 PLA processing techniques

Innovative methods for processing PLA, including extrusion, injection molding, and 3D printing. These techniques aim to improve the material's performance, reduce production costs, and expand its applicability in various industries.Expand Specific Solutions03 PLA modification for specific applications

Chemical or physical modification of PLA to tailor its properties for specific applications, such as improving its heat resistance, flexibility, or barrier properties. This includes blending with other polymers or adding functional groups to the PLA chain.Expand Specific Solutions04 Biodegradable PLA formulations

Development of PLA formulations with enhanced biodegradability for environmentally friendly applications. This includes research into additives that accelerate decomposition and studies on the material's behavior in various disposal conditions.Expand Specific Solutions05 PLA in medical and pharmaceutical applications

Utilization of PLA in medical devices, drug delivery systems, and tissue engineering. This includes the development of biocompatible PLA formulations, controlled release mechanisms, and scaffolds for regenerative medicine.Expand Specific Solutions

Key Players in PLA Waste Management Industry

The implementation of PLA solutions in waste management is gaining traction as the industry evolves towards more sustainable practices. The market is in a growth phase, with increasing demand for biodegradable alternatives driving innovation. The global PLA market size is projected to expand significantly, fueled by environmental concerns and regulatory pressures. Technologically, PLA solutions are advancing rapidly, with companies like Total Research Corp, Galactic SA/NV, and Futerro SA leading research efforts. Universities such as Qingdao University of Science & Technology and Huazhong University of Science & Technology are contributing to technological advancements. While PLA technology is relatively mature, ongoing research by entities like Centre National de la Recherche Scientifique and Fraunhofer-Gesellschaft eV aims to enhance its properties and applications in waste management.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive PLA-based waste management solution. Their approach involves the production of biodegradable PLA materials for packaging and disposable products. These materials are designed to decompose naturally in industrial composting facilities, reducing the burden on landfills. Sinopec has also invested in the development of specialized PLA recycling technologies, including chemical recycling processes that break down PLA into its monomer components for reuse in new PLA products.

Strengths: Large-scale production capabilities, extensive research and development resources, and integrated supply chain. Weaknesses: High initial investment costs and potential competition from traditional petroleum-based plastics.

Arctic Biomaterials Oy

Technical Solution: Arctic Biomaterials Oy has pioneered an innovative PLA-based solution for waste management. Their technology focuses on enhancing the biodegradability of PLA materials through the incorporation of proprietary additives. These additives accelerate the breakdown of PLA in various environmental conditions, including industrial composting facilities and marine environments. The company has also developed a range of PLA compounds that maintain excellent mechanical properties while offering improved end-of-life options, such as easier recycling or faster decomposition in natural settings.

Strengths: Specialized expertise in PLA modification, focus on environmental sustainability. Weaknesses: Limited production scale compared to larger corporations, potential regulatory challenges in different markets.

Innovative PLA Waste Processing Techniques

Method for degradation of a plastic-containing waste

PatentPendingUS20230278083A1

Innovation

- A method involving mixing plastic-containing waste with bacteria in a digesting apparatus with a high surface-to-volume ratio, using Geobacillus bacteria and other microorganisms, to achieve rapid biodegradation of PLA and other biodegradable plastics on-site, reducing the need for industrial processing.

Methods and Systems for Lactic Acid Production and Polylactic Acid Recycling

PatentPendingAU2024201801A1

Innovation

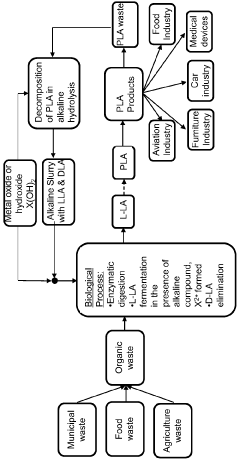

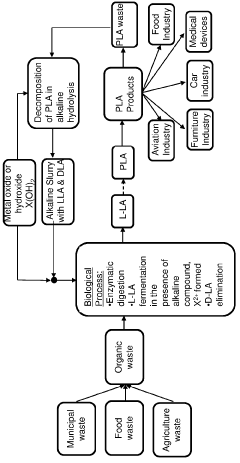

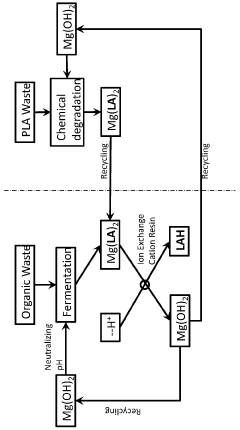

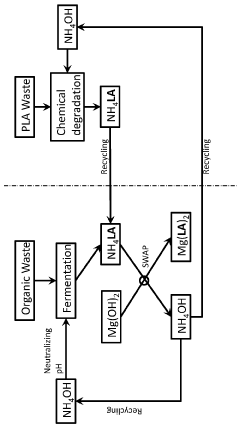

- A method that integrates the recycling of PLA waste through hydrolysis with lactic acid fermentation using alkaline compounds and metal oxides or hydroxides to produce enantiomerically pure L-lactate salts, combining the processes for downstream purification and increasing yield.

Environmental Impact Assessment of PLA Solutions

The environmental impact assessment of PLA (Polylactic Acid) solutions in waste management reveals both positive and negative effects on ecosystems and resource conservation. PLA, derived from renewable resources such as corn starch or sugarcane, offers a biodegradable alternative to traditional plastics. This characteristic significantly reduces the long-term environmental burden associated with plastic waste accumulation in landfills and oceans.

When properly managed, PLA products can decompose in industrial composting facilities within 3-6 months, returning to the natural carbon cycle. This process results in lower greenhouse gas emissions compared to the production and disposal of conventional plastics. Additionally, the use of PLA reduces dependence on fossil fuels, as its production relies on renewable biomass sources.

However, the environmental benefits of PLA are contingent upon proper waste management practices. Inadequate sorting and disposal can lead to contamination of recycling streams, potentially compromising the recycling process for other materials. Furthermore, PLA requires specific conditions for optimal biodegradation, which are not always met in natural environments or standard landfills.

The production of PLA also raises concerns about land use and food security. As PLA is primarily derived from food crops, its increased adoption could potentially compete with food production, leading to land-use changes and potential impacts on biodiversity. This aspect necessitates careful consideration of sustainable sourcing practices and the development of second-generation feedstocks from non-food sources.

Water consumption and eutrophication are additional environmental factors to consider. The agricultural production of PLA feedstocks may require significant water resources and potentially contribute to water pollution through fertilizer runoff. However, advancements in agricultural practices and the development of more efficient PLA production processes are continually improving these aspects.

Life cycle assessments comparing PLA to traditional plastics generally show favorable results for PLA in terms of reduced carbon footprint and fossil fuel consumption. However, these assessments also highlight the importance of end-of-life management in realizing the full environmental benefits of PLA solutions.

In conclusion, while PLA offers promising environmental advantages in waste management, its overall impact depends heavily on the implementation of appropriate collection, sorting, and processing infrastructure. The development of more efficient PLA production methods and the expansion of industrial composting facilities are crucial steps in maximizing the environmental benefits of this biodegradable alternative in waste management systems.

When properly managed, PLA products can decompose in industrial composting facilities within 3-6 months, returning to the natural carbon cycle. This process results in lower greenhouse gas emissions compared to the production and disposal of conventional plastics. Additionally, the use of PLA reduces dependence on fossil fuels, as its production relies on renewable biomass sources.

However, the environmental benefits of PLA are contingent upon proper waste management practices. Inadequate sorting and disposal can lead to contamination of recycling streams, potentially compromising the recycling process for other materials. Furthermore, PLA requires specific conditions for optimal biodegradation, which are not always met in natural environments or standard landfills.

The production of PLA also raises concerns about land use and food security. As PLA is primarily derived from food crops, its increased adoption could potentially compete with food production, leading to land-use changes and potential impacts on biodiversity. This aspect necessitates careful consideration of sustainable sourcing practices and the development of second-generation feedstocks from non-food sources.

Water consumption and eutrophication are additional environmental factors to consider. The agricultural production of PLA feedstocks may require significant water resources and potentially contribute to water pollution through fertilizer runoff. However, advancements in agricultural practices and the development of more efficient PLA production processes are continually improving these aspects.

Life cycle assessments comparing PLA to traditional plastics generally show favorable results for PLA in terms of reduced carbon footprint and fossil fuel consumption. However, these assessments also highlight the importance of end-of-life management in realizing the full environmental benefits of PLA solutions.

In conclusion, while PLA offers promising environmental advantages in waste management, its overall impact depends heavily on the implementation of appropriate collection, sorting, and processing infrastructure. The development of more efficient PLA production methods and the expansion of industrial composting facilities are crucial steps in maximizing the environmental benefits of this biodegradable alternative in waste management systems.

Policy Framework for Biodegradable Plastics

The policy framework for biodegradable plastics plays a crucial role in implementing PLA solutions in waste management. Governments worldwide are recognizing the need to address plastic pollution and are developing comprehensive policies to promote the use of biodegradable alternatives like PLA.

At the national level, many countries are introducing legislation to phase out single-use plastics and incentivize the adoption of biodegradable materials. These policies often include bans on certain plastic products, taxes on non-biodegradable plastics, and financial incentives for companies that switch to biodegradable alternatives. For instance, the European Union's Single-Use Plastics Directive aims to reduce plastic waste by promoting the use of sustainable materials, including PLA.

Local governments are also implementing their own policies to support the transition to biodegradable plastics. These may include mandatory composting programs, requirements for businesses to use biodegradable packaging, and public education campaigns about proper disposal of biodegradable materials. Such initiatives create a supportive environment for PLA adoption in waste management systems.

Standardization and certification processes are essential components of the policy framework. Governments are working with industry stakeholders to develop clear standards for biodegradability and compostability. These standards ensure that PLA and other biodegradable plastics meet specific environmental criteria and can be effectively processed in existing waste management facilities.

Extended Producer Responsibility (EPR) schemes are being incorporated into policy frameworks to encourage manufacturers to take responsibility for the entire lifecycle of their products. These policies require producers to consider the end-of-life management of PLA products, promoting circular economy principles and improving overall waste management practices.

Research and development support is another critical aspect of the policy framework. Governments are allocating funds and resources to advance PLA technology and improve its properties for various applications. This support helps overcome technical challenges and enhances the viability of PLA as a sustainable alternative to conventional plastics.

International cooperation and harmonization of policies are also emerging as important elements in the biodegradable plastics framework. Countries are collaborating to align their approaches, share best practices, and create consistent regulations across borders. This global coordination facilitates the widespread adoption of PLA solutions in waste management systems worldwide.

At the national level, many countries are introducing legislation to phase out single-use plastics and incentivize the adoption of biodegradable materials. These policies often include bans on certain plastic products, taxes on non-biodegradable plastics, and financial incentives for companies that switch to biodegradable alternatives. For instance, the European Union's Single-Use Plastics Directive aims to reduce plastic waste by promoting the use of sustainable materials, including PLA.

Local governments are also implementing their own policies to support the transition to biodegradable plastics. These may include mandatory composting programs, requirements for businesses to use biodegradable packaging, and public education campaigns about proper disposal of biodegradable materials. Such initiatives create a supportive environment for PLA adoption in waste management systems.

Standardization and certification processes are essential components of the policy framework. Governments are working with industry stakeholders to develop clear standards for biodegradability and compostability. These standards ensure that PLA and other biodegradable plastics meet specific environmental criteria and can be effectively processed in existing waste management facilities.

Extended Producer Responsibility (EPR) schemes are being incorporated into policy frameworks to encourage manufacturers to take responsibility for the entire lifecycle of their products. These policies require producers to consider the end-of-life management of PLA products, promoting circular economy principles and improving overall waste management practices.

Research and development support is another critical aspect of the policy framework. Governments are allocating funds and resources to advance PLA technology and improve its properties for various applications. This support helps overcome technical challenges and enhances the viability of PLA as a sustainable alternative to conventional plastics.

International cooperation and harmonization of policies are also emerging as important elements in the biodegradable plastics framework. Countries are collaborating to align their approaches, share best practices, and create consistent regulations across borders. This global coordination facilitates the widespread adoption of PLA solutions in waste management systems worldwide.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!