Cutting‑edge Research on PLA Polymer Enhancements

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PLA Polymer Evolution and Research Objectives

Polylactic acid (PLA) polymers have emerged as a promising sustainable alternative to traditional petroleum-based plastics. The evolution of PLA technology has been marked by significant advancements in material properties and production processes over the past few decades. Initially developed in the 1960s, PLA gained traction in the 1990s as environmental concerns and the need for biodegradable materials grew.

The primary objective of cutting-edge research on PLA polymer enhancements is to address the material's inherent limitations while capitalizing on its eco-friendly attributes. Researchers aim to improve PLA's mechanical properties, thermal stability, and barrier characteristics to expand its applicability across various industries. This involves exploring novel synthesis methods, developing innovative copolymerization techniques, and investigating the potential of nanocomposites.

One key focus area is enhancing PLA's toughness and flexibility without compromising its biodegradability. This is crucial for broadening its use in packaging applications, where it competes with more flexible petroleum-based plastics. Another critical research objective is to increase PLA's heat resistance, enabling its use in high-temperature applications such as automotive parts and electronics.

Improving PLA's barrier properties against oxygen and water vapor is also a priority, particularly for food packaging applications. Researchers are exploring various approaches, including the incorporation of nanoparticles and the development of multi-layer structures, to enhance these properties while maintaining the material's biodegradability.

The evolution of PLA technology is closely tied to advancements in biotechnology and green chemistry. Efforts are underway to optimize the fermentation processes used to produce lactic acid, the precursor to PLA, from renewable resources such as corn starch or sugarcane. This includes developing more efficient bacterial strains and refining separation techniques to reduce production costs and improve yield.

Another significant research objective is to expand the range of feedstocks used for PLA production. This includes exploring the use of agricultural waste, algae, and other non-food biomass sources to address concerns about competition with food resources and to further reduce the carbon footprint of PLA production.

As the field progresses, researchers are also focusing on end-of-life solutions for PLA products. This includes developing more efficient composting and recycling processes, as well as exploring chemical recycling methods to break down PLA into its monomer components for reuse in new polymer production.

The primary objective of cutting-edge research on PLA polymer enhancements is to address the material's inherent limitations while capitalizing on its eco-friendly attributes. Researchers aim to improve PLA's mechanical properties, thermal stability, and barrier characteristics to expand its applicability across various industries. This involves exploring novel synthesis methods, developing innovative copolymerization techniques, and investigating the potential of nanocomposites.

One key focus area is enhancing PLA's toughness and flexibility without compromising its biodegradability. This is crucial for broadening its use in packaging applications, where it competes with more flexible petroleum-based plastics. Another critical research objective is to increase PLA's heat resistance, enabling its use in high-temperature applications such as automotive parts and electronics.

Improving PLA's barrier properties against oxygen and water vapor is also a priority, particularly for food packaging applications. Researchers are exploring various approaches, including the incorporation of nanoparticles and the development of multi-layer structures, to enhance these properties while maintaining the material's biodegradability.

The evolution of PLA technology is closely tied to advancements in biotechnology and green chemistry. Efforts are underway to optimize the fermentation processes used to produce lactic acid, the precursor to PLA, from renewable resources such as corn starch or sugarcane. This includes developing more efficient bacterial strains and refining separation techniques to reduce production costs and improve yield.

Another significant research objective is to expand the range of feedstocks used for PLA production. This includes exploring the use of agricultural waste, algae, and other non-food biomass sources to address concerns about competition with food resources and to further reduce the carbon footprint of PLA production.

As the field progresses, researchers are also focusing on end-of-life solutions for PLA products. This includes developing more efficient composting and recycling processes, as well as exploring chemical recycling methods to break down PLA into its monomer components for reuse in new polymer production.

Market Demand Analysis for Enhanced PLA

The market demand for enhanced PLA (Polylactic Acid) polymers has been steadily increasing due to the growing emphasis on sustainable and eco-friendly materials across various industries. As consumers become more environmentally conscious, there is a significant shift towards biodegradable and renewable alternatives to traditional petroleum-based plastics. This trend has created a substantial opportunity for enhanced PLA polymers, which offer improved performance characteristics while maintaining their biodegradability.

In the packaging industry, there is a strong demand for enhanced PLA materials that can provide better barrier properties, increased heat resistance, and improved mechanical strength. Food packaging, in particular, requires materials that can maintain product freshness and extend shelf life while being environmentally friendly. Enhanced PLA polymers that address these needs are experiencing rapid market growth, with major food and beverage companies actively seeking sustainable packaging solutions.

The automotive sector is another key driver of market demand for enhanced PLA polymers. As automakers strive to reduce vehicle weight and improve fuel efficiency, there is a growing interest in lightweight, bio-based materials for interior components and non-structural parts. Enhanced PLA polymers that offer improved impact resistance and thermal stability are particularly sought after in this industry.

In the medical and healthcare sectors, there is an increasing demand for biocompatible and biodegradable materials for applications such as implants, drug delivery systems, and tissue engineering scaffolds. Enhanced PLA polymers that provide better mechanical properties and controlled degradation rates are highly valued in these fields, driving research and development efforts.

The textile industry is also showing significant interest in enhanced PLA fibers. As sustainable fashion gains traction, there is a growing demand for bio-based textiles that offer comparable performance to synthetic fibers. Enhanced PLA polymers that provide better moisture management, improved durability, and enhanced dyeability are attracting attention from major apparel and sportswear brands.

Market analysis indicates that the global demand for enhanced PLA polymers is expected to grow at a compound annual growth rate (CAGR) of over 15% in the next five years. This growth is driven by stringent environmental regulations, increasing consumer awareness, and the push for circular economy principles across industries. The Asia-Pacific region, particularly China and Japan, is anticipated to be a major market for enhanced PLA polymers, followed by North America and Europe.

However, challenges such as higher production costs compared to conventional plastics and limitations in certain performance characteristics still need to be addressed to fully realize the market potential of enhanced PLA polymers. Ongoing research and development efforts are focused on overcoming these barriers and expanding the application range of these materials.

In the packaging industry, there is a strong demand for enhanced PLA materials that can provide better barrier properties, increased heat resistance, and improved mechanical strength. Food packaging, in particular, requires materials that can maintain product freshness and extend shelf life while being environmentally friendly. Enhanced PLA polymers that address these needs are experiencing rapid market growth, with major food and beverage companies actively seeking sustainable packaging solutions.

The automotive sector is another key driver of market demand for enhanced PLA polymers. As automakers strive to reduce vehicle weight and improve fuel efficiency, there is a growing interest in lightweight, bio-based materials for interior components and non-structural parts. Enhanced PLA polymers that offer improved impact resistance and thermal stability are particularly sought after in this industry.

In the medical and healthcare sectors, there is an increasing demand for biocompatible and biodegradable materials for applications such as implants, drug delivery systems, and tissue engineering scaffolds. Enhanced PLA polymers that provide better mechanical properties and controlled degradation rates are highly valued in these fields, driving research and development efforts.

The textile industry is also showing significant interest in enhanced PLA fibers. As sustainable fashion gains traction, there is a growing demand for bio-based textiles that offer comparable performance to synthetic fibers. Enhanced PLA polymers that provide better moisture management, improved durability, and enhanced dyeability are attracting attention from major apparel and sportswear brands.

Market analysis indicates that the global demand for enhanced PLA polymers is expected to grow at a compound annual growth rate (CAGR) of over 15% in the next five years. This growth is driven by stringent environmental regulations, increasing consumer awareness, and the push for circular economy principles across industries. The Asia-Pacific region, particularly China and Japan, is anticipated to be a major market for enhanced PLA polymers, followed by North America and Europe.

However, challenges such as higher production costs compared to conventional plastics and limitations in certain performance characteristics still need to be addressed to fully realize the market potential of enhanced PLA polymers. Ongoing research and development efforts are focused on overcoming these barriers and expanding the application range of these materials.

Current PLA Limitations and Challenges

Polylactic acid (PLA) has gained significant attention as a biodegradable and renewable alternative to conventional plastics. However, despite its promising attributes, PLA faces several limitations and challenges that hinder its widespread adoption across various industries.

One of the primary limitations of PLA is its relatively low heat resistance compared to traditional petroleum-based plastics. The glass transition temperature of PLA typically ranges from 55°C to 65°C, which restricts its use in high-temperature applications such as hot-fill packaging or automotive components. This thermal instability also affects the material's dimensional stability and mechanical properties at elevated temperatures.

Another significant challenge is PLA's inherent brittleness and low impact strength. While PLA exhibits good tensile strength and modulus, its poor toughness and elongation at break limit its use in applications requiring high flexibility or impact resistance. This brittleness is particularly problematic in thin-walled products or those subjected to sudden impacts.

The moisture sensitivity of PLA poses additional challenges in processing and long-term stability. PLA is susceptible to hydrolysis, which can lead to degradation of mechanical properties and molecular weight reduction during processing or storage in humid environments. This sensitivity necessitates careful control of moisture content during manufacturing and packaging.

PLA's relatively slow crystallization rate compared to other thermoplastics presents difficulties in processing, particularly in injection molding applications. The slow crystallization kinetics can result in longer cycle times and reduced productivity, making it less economically viable for certain manufacturing processes.

The barrier properties of PLA, particularly its gas permeability, are inferior to those of conventional plastics like PET. This limitation restricts its use in food packaging applications where extended shelf life is crucial. The high oxygen and water vapor transmission rates of PLA can lead to premature spoilage of packaged goods.

Cost remains a significant challenge for PLA adoption. Despite improvements in production efficiency, PLA is generally more expensive than conventional plastics, which can deter manufacturers from switching to this sustainable alternative, especially in price-sensitive markets.

Lastly, the end-of-life management of PLA presents both opportunities and challenges. While PLA is compostable under industrial conditions, the lack of widespread industrial composting facilities and the potential contamination of recycling streams with PLA pose significant obstacles to its effective disposal and recycling.

Addressing these limitations and challenges is crucial for expanding the application range of PLA and realizing its full potential as a sustainable alternative to conventional plastics. Ongoing research efforts are focused on enhancing PLA's properties through various modification techniques and developing more efficient processing methods to overcome these hurdles.

One of the primary limitations of PLA is its relatively low heat resistance compared to traditional petroleum-based plastics. The glass transition temperature of PLA typically ranges from 55°C to 65°C, which restricts its use in high-temperature applications such as hot-fill packaging or automotive components. This thermal instability also affects the material's dimensional stability and mechanical properties at elevated temperatures.

Another significant challenge is PLA's inherent brittleness and low impact strength. While PLA exhibits good tensile strength and modulus, its poor toughness and elongation at break limit its use in applications requiring high flexibility or impact resistance. This brittleness is particularly problematic in thin-walled products or those subjected to sudden impacts.

The moisture sensitivity of PLA poses additional challenges in processing and long-term stability. PLA is susceptible to hydrolysis, which can lead to degradation of mechanical properties and molecular weight reduction during processing or storage in humid environments. This sensitivity necessitates careful control of moisture content during manufacturing and packaging.

PLA's relatively slow crystallization rate compared to other thermoplastics presents difficulties in processing, particularly in injection molding applications. The slow crystallization kinetics can result in longer cycle times and reduced productivity, making it less economically viable for certain manufacturing processes.

The barrier properties of PLA, particularly its gas permeability, are inferior to those of conventional plastics like PET. This limitation restricts its use in food packaging applications where extended shelf life is crucial. The high oxygen and water vapor transmission rates of PLA can lead to premature spoilage of packaged goods.

Cost remains a significant challenge for PLA adoption. Despite improvements in production efficiency, PLA is generally more expensive than conventional plastics, which can deter manufacturers from switching to this sustainable alternative, especially in price-sensitive markets.

Lastly, the end-of-life management of PLA presents both opportunities and challenges. While PLA is compostable under industrial conditions, the lack of widespread industrial composting facilities and the potential contamination of recycling streams with PLA pose significant obstacles to its effective disposal and recycling.

Addressing these limitations and challenges is crucial for expanding the application range of PLA and realizing its full potential as a sustainable alternative to conventional plastics. Ongoing research efforts are focused on enhancing PLA's properties through various modification techniques and developing more efficient processing methods to overcome these hurdles.

Existing PLA Enhancement Techniques

01 PLA polymer synthesis and modification

This category focuses on the synthesis and modification of PLA (Polylactic Acid) polymers. It includes methods for producing PLA with specific properties, such as improved molecular weight, crystallinity, or thermal stability. Various techniques for modifying PLA, such as copolymerization or blending with other materials, are also covered to enhance its performance for different applications.- PLA polymer synthesis and modification: This category focuses on the synthesis and modification of PLA (Polylactic Acid) polymers. It includes methods for producing PLA with specific properties, such as improved molecular weight, crystallinity, or thermal stability. Various techniques for modifying PLA, such as copolymerization or blending with other materials, are also covered to enhance its performance for different applications.

- PLA-based composites and blends: This area involves the development of PLA-based composites and blends. It includes combining PLA with other materials such as natural fibers, nanoparticles, or other polymers to create new materials with improved properties. These composites and blends often aim to enhance mechanical strength, biodegradability, or specific functional characteristics of PLA for various applications.

- PLA processing techniques: This category covers various processing techniques for PLA polymers. It includes methods for molding, extrusion, 3D printing, and other fabrication processes specific to PLA. The focus is on optimizing processing conditions to achieve desired product properties and overcoming challenges associated with PLA's thermal sensitivity and crystallization behavior.

- PLA applications in packaging and consumer products: This area focuses on the use of PLA in packaging materials and consumer products. It covers the development of PLA-based films, containers, and other packaging solutions that offer biodegradability and sustainability. Additionally, it includes applications in consumer goods such as disposable cutlery, textiles, and personal care products, emphasizing PLA's eco-friendly properties.

- PLA degradation and end-of-life management: This category addresses the degradation processes of PLA and strategies for its end-of-life management. It includes studies on the biodegradation mechanisms of PLA in various environments, methods to control or accelerate degradation, and recycling techniques. The focus is on understanding and improving the environmental impact of PLA throughout its lifecycle.

02 PLA-based composites and blends

This area involves the development of PLA-based composites and blends. It includes combining PLA with other materials such as natural fibers, nanoparticles, or other polymers to create new materials with enhanced properties. These composites and blends often aim to improve mechanical strength, barrier properties, or biodegradability of PLA for various applications in packaging, automotive, or biomedical fields.Expand Specific Solutions03 PLA processing techniques

This category covers various processing techniques for PLA polymers. It includes methods for extrusion, injection molding, film blowing, and 3D printing of PLA materials. The focus is on optimizing processing parameters to achieve desired product properties and overcoming challenges associated with PLA processing, such as thermal degradation or slow crystallization rates.Expand Specific Solutions04 PLA applications in packaging and consumer goods

This area focuses on the use of PLA in packaging and consumer goods. It includes the development of PLA-based materials for food packaging, disposable cutlery, and other single-use items. The emphasis is on creating biodegradable and compostable alternatives to traditional plastics, while maintaining necessary properties such as strength, flexibility, and barrier performance.Expand Specific Solutions05 PLA in biomedical applications

This category covers the use of PLA in biomedical applications. It includes the development of PLA-based materials for tissue engineering scaffolds, drug delivery systems, and biodegradable implants. The focus is on tailoring PLA properties to meet specific biomedical requirements, such as controlled degradation rates, biocompatibility, and mechanical properties suitable for various medical applications.Expand Specific Solutions

Key Players in PLA Research and Production

The research on PLA polymer enhancements is in a growth phase, with increasing market size and technological advancements. The global PLA market is expanding rapidly, driven by demand for sustainable materials. Technologically, PLA enhancements are progressing, with varying maturity levels across different applications. Key players like NatureWorks LLC, Sichuan University, and Changchun Institute of Applied Chemistry are at the forefront, developing innovative solutions. Academic institutions such as the University of Guelph and Zhejiang University contribute significantly to fundamental research. Companies like Arkema, Inc. and LG Chem Ltd. are advancing commercial applications, while research centers like CNRS and CAS are pushing boundaries in polymer science, creating a competitive and collaborative landscape.

NatureWorks LLC

Technical Solution: NatureWorks has developed a proprietary process for producing high-performance PLA (polylactic acid) polymers from renewable resources. Their Ingeo biopolymer technology involves fermenting plant sugars to produce lactic acid, which is then polymerized into PLA. They have also focused on enhancing PLA's properties through various modifications, including the development of heat-resistant PLA grades and PLA composites with improved mechanical properties.

Strengths: Renewable feedstock, established commercial production, wide range of applications. Weaknesses: Higher cost compared to traditional plastics, limited high-temperature performance.

Floreon Technology Ltd.

Technical Solution: Floreon has developed a patented PLA compound that significantly enhances the material's performance. Their technology involves blending PLA with specific additives to improve its strength, toughness, and heat resistance. Floreon's enhanced PLA can be processed using conventional plastic manufacturing equipment and offers improved mechanical properties and durability compared to standard PLA, making it suitable for a wider range of applications.

Strengths: Specialized focus on PLA enhancement, patented technology, improved material properties. Weaknesses: Smaller scale compared to major chemical companies, limited product range.

Breakthrough PLA Modification Strategies

Thermoformed articles made from reactive extrusion products of biobased materials

PatentWO2011071666A1

Innovation

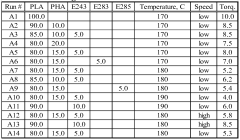

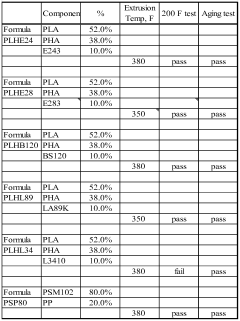

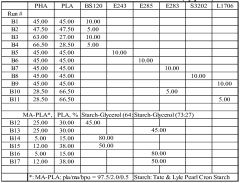

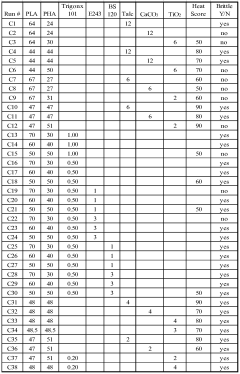

- Development of thermoformable composite materials through blending PHAs and PLA with additives, processed via extrusion, to enhance thermal and mechanical performance while maintaining sustainability, with specific formulations achieving higher heat distortion indices and Vicat softening points.

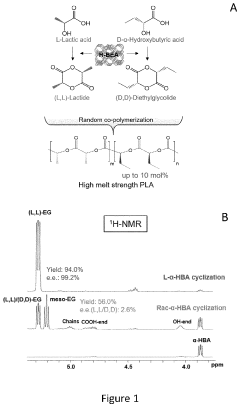

High melt strength polylactic acid polymers

PatentPendingUS20240026070A1

Innovation

- Random co-polymerization of lactide with small amounts (0.4-10 mol %) of diethylglycolide of opposite chiral nature, synthesized via a one-step zeolite-catalyzed process, significantly enhances melt shear viscosity and elasticity.

Environmental Impact of Advanced PLA

The environmental impact of advanced PLA (Polylactic Acid) polymers is a critical consideration in the development and application of these materials. As research in PLA enhancements progresses, it is essential to evaluate the ecological footprint throughout the entire lifecycle of these advanced polymers.

Advanced PLA formulations have shown promising improvements in biodegradability compared to conventional plastics. These enhanced polymers can decompose more efficiently in industrial composting facilities, reducing the accumulation of plastic waste in landfills and oceans. However, it is crucial to note that the biodegradation process still requires specific conditions, and improper disposal may lead to similar environmental issues as traditional plastics.

The production of advanced PLA polymers generally involves lower greenhouse gas emissions compared to petroleum-based plastics. The use of renewable resources, such as corn or sugarcane, as feedstock for PLA production contributes to a reduced carbon footprint. However, the environmental impact of agricultural practices used to grow these feedstocks must be carefully considered, including land use changes, water consumption, and potential competition with food crops.

Enhanced PLA polymers often exhibit improved mechanical properties and durability, potentially extending the lifespan of products made from these materials. This increased longevity can lead to a reduction in overall plastic consumption and waste generation. However, the addition of certain additives or reinforcing agents to achieve these enhanced properties may complicate the recycling process or introduce new environmental concerns.

The recyclability of advanced PLA polymers is an area of ongoing research and development. While PLA can be mechanically recycled, the process may be challenging due to the potential presence of additives or blends in enhanced formulations. Chemical recycling techniques, such as hydrolysis or thermal depolymerization, show promise for recovering raw materials from advanced PLA products, but these processes are still being optimized for large-scale implementation.

The end-of-life management of advanced PLA products remains a crucial aspect of their environmental impact. While these materials offer improved biodegradability, the lack of widespread industrial composting facilities in many regions may limit their potential benefits. Additionally, the mixing of PLA with conventional plastics in recycling streams can complicate existing recycling processes, highlighting the need for improved waste management infrastructure and consumer education.

In conclusion, while advanced PLA polymers offer several environmental advantages over traditional plastics, their overall ecological impact depends on various factors throughout their lifecycle. Continued research and development efforts are necessary to optimize production processes, enhance recyclability, and ensure proper end-of-life management to fully realize the environmental benefits of these advanced materials.

Advanced PLA formulations have shown promising improvements in biodegradability compared to conventional plastics. These enhanced polymers can decompose more efficiently in industrial composting facilities, reducing the accumulation of plastic waste in landfills and oceans. However, it is crucial to note that the biodegradation process still requires specific conditions, and improper disposal may lead to similar environmental issues as traditional plastics.

The production of advanced PLA polymers generally involves lower greenhouse gas emissions compared to petroleum-based plastics. The use of renewable resources, such as corn or sugarcane, as feedstock for PLA production contributes to a reduced carbon footprint. However, the environmental impact of agricultural practices used to grow these feedstocks must be carefully considered, including land use changes, water consumption, and potential competition with food crops.

Enhanced PLA polymers often exhibit improved mechanical properties and durability, potentially extending the lifespan of products made from these materials. This increased longevity can lead to a reduction in overall plastic consumption and waste generation. However, the addition of certain additives or reinforcing agents to achieve these enhanced properties may complicate the recycling process or introduce new environmental concerns.

The recyclability of advanced PLA polymers is an area of ongoing research and development. While PLA can be mechanically recycled, the process may be challenging due to the potential presence of additives or blends in enhanced formulations. Chemical recycling techniques, such as hydrolysis or thermal depolymerization, show promise for recovering raw materials from advanced PLA products, but these processes are still being optimized for large-scale implementation.

The end-of-life management of advanced PLA products remains a crucial aspect of their environmental impact. While these materials offer improved biodegradability, the lack of widespread industrial composting facilities in many regions may limit their potential benefits. Additionally, the mixing of PLA with conventional plastics in recycling streams can complicate existing recycling processes, highlighting the need for improved waste management infrastructure and consumer education.

In conclusion, while advanced PLA polymers offer several environmental advantages over traditional plastics, their overall ecological impact depends on various factors throughout their lifecycle. Continued research and development efforts are necessary to optimize production processes, enhance recyclability, and ensure proper end-of-life management to fully realize the environmental benefits of these advanced materials.

Regulatory Framework for Bioplastics

The regulatory framework for bioplastics, particularly in relation to PLA (Polylactic Acid) polymer enhancements, is a complex and evolving landscape. As the demand for sustainable alternatives to traditional plastics grows, governments and international bodies are developing and refining regulations to ensure the safety, efficacy, and environmental impact of these materials.

In the European Union, the regulatory approach to bioplastics is guided by the European Green Deal and the Circular Economy Action Plan. These initiatives aim to promote the use of bio-based, biodegradable, and compostable plastics while ensuring they do not harm the environment. The EU has established standards for biodegradability and compostability, such as EN 13432, which PLA-based products must meet to be certified as compostable.

The United States has a different regulatory structure, with the Food and Drug Administration (FDA) overseeing the use of bioplastics in food contact applications. The FDA has approved PLA for food contact under certain conditions, but ongoing research into PLA enhancements may require additional regulatory scrutiny. The Environmental Protection Agency (EPA) also plays a role in regulating the environmental impact of bioplastics, including their disposal and potential effects on ecosystems.

In Asia, countries like Japan and China are developing their own regulatory frameworks for bioplastics. Japan's Biomass Plastics Mark certification system promotes the use of plant-derived materials in plastic products, while China has introduced standards for biodegradable plastics to address pollution concerns.

International standards organizations, such as ISO and ASTM International, have developed guidelines and testing methods for bioplastics. These standards help ensure consistency in product performance and environmental claims across different jurisdictions. For instance, ASTM D6400 and D6868 set specifications for compostable plastics.

As research on PLA polymer enhancements progresses, regulatory bodies are likely to adapt their frameworks to address new developments. This may include regulations on novel additives, processing techniques, or end-of-life management strategies for enhanced PLA materials. Researchers and manufacturers must stay informed about these evolving regulations to ensure compliance and market acceptance of their innovations.

The regulatory landscape also intersects with waste management policies. As enhanced PLA polymers may have different degradation properties compared to standard PLA, regulations regarding their disposal, recycling, and composting may need to be updated. This could involve changes to labeling requirements, waste sorting guidelines, and industrial composting standards.

In the European Union, the regulatory approach to bioplastics is guided by the European Green Deal and the Circular Economy Action Plan. These initiatives aim to promote the use of bio-based, biodegradable, and compostable plastics while ensuring they do not harm the environment. The EU has established standards for biodegradability and compostability, such as EN 13432, which PLA-based products must meet to be certified as compostable.

The United States has a different regulatory structure, with the Food and Drug Administration (FDA) overseeing the use of bioplastics in food contact applications. The FDA has approved PLA for food contact under certain conditions, but ongoing research into PLA enhancements may require additional regulatory scrutiny. The Environmental Protection Agency (EPA) also plays a role in regulating the environmental impact of bioplastics, including their disposal and potential effects on ecosystems.

In Asia, countries like Japan and China are developing their own regulatory frameworks for bioplastics. Japan's Biomass Plastics Mark certification system promotes the use of plant-derived materials in plastic products, while China has introduced standards for biodegradable plastics to address pollution concerns.

International standards organizations, such as ISO and ASTM International, have developed guidelines and testing methods for bioplastics. These standards help ensure consistency in product performance and environmental claims across different jurisdictions. For instance, ASTM D6400 and D6868 set specifications for compostable plastics.

As research on PLA polymer enhancements progresses, regulatory bodies are likely to adapt their frameworks to address new developments. This may include regulations on novel additives, processing techniques, or end-of-life management strategies for enhanced PLA materials. Researchers and manufacturers must stay informed about these evolving regulations to ensure compliance and market acceptance of their innovations.

The regulatory landscape also intersects with waste management policies. As enhanced PLA polymers may have different degradation properties compared to standard PLA, regulations regarding their disposal, recycling, and composting may need to be updated. This could involve changes to labeling requirements, waste sorting guidelines, and industrial composting standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!