Innovations in PLA Compounding for Enhanced Flexibility

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PLA Flexibility Evolution

The evolution of PLA flexibility has been a significant focus in the field of bioplastics, driven by the need to expand its applications beyond rigid packaging and disposable items. Initially, PLA was known for its high tensile strength and modulus but limited flexibility, which restricted its use in applications requiring elasticity or impact resistance.

In the early 2000s, researchers began exploring various compounding techniques to enhance PLA's flexibility. The first major breakthrough came with the introduction of plasticizers, such as citrate esters and polyethylene glycol (PEG). These additives increased the free volume between polymer chains, lowering the glass transition temperature and improving chain mobility, resulting in a more flexible material.

As the demand for sustainable and biodegradable plastics grew, the mid-2000s saw increased efforts to develop more advanced compounding methods. Blending PLA with other biodegradable polymers, such as polycaprolactone (PCL) and polybutylene succinate (PBS), emerged as a promising approach. These blends not only improved flexibility but also enhanced other properties like impact strength and thermal stability.

The late 2000s and early 2010s marked a shift towards more sophisticated compounding techniques. Reactive extrusion processes were developed, allowing for the in-situ formation of copolymers or grafted structures during processing. This approach led to improved compatibility between PLA and flexibility-enhancing additives, resulting in materials with better overall performance.

Nanotechnology began to play a crucial role in PLA flexibility enhancement around 2010. The incorporation of nanofillers, such as cellulose nanocrystals and organoclays, allowed for significant improvements in mechanical properties without compromising biodegradability. These nanocomposites offered a unique balance of strength and flexibility, opening up new application areas for PLA.

Recent years have seen a focus on developing bio-based plasticizers and impact modifiers specifically designed for PLA. These additives, derived from renewable resources, aim to maintain PLA's eco-friendly profile while significantly improving its flexibility and impact resistance. Innovations in this area have led to PLA compounds that can compete with traditional flexible plastics in various applications, including film packaging and automotive interiors.

The most recent trend in PLA flexibility evolution involves the development of multi-functional additives that simultaneously enhance flexibility, processability, and other key properties. This holistic approach to PLA compounding aims to create versatile materials that can meet the diverse requirements of different industries while maintaining the core benefits of biodegradability and sustainability.

In the early 2000s, researchers began exploring various compounding techniques to enhance PLA's flexibility. The first major breakthrough came with the introduction of plasticizers, such as citrate esters and polyethylene glycol (PEG). These additives increased the free volume between polymer chains, lowering the glass transition temperature and improving chain mobility, resulting in a more flexible material.

As the demand for sustainable and biodegradable plastics grew, the mid-2000s saw increased efforts to develop more advanced compounding methods. Blending PLA with other biodegradable polymers, such as polycaprolactone (PCL) and polybutylene succinate (PBS), emerged as a promising approach. These blends not only improved flexibility but also enhanced other properties like impact strength and thermal stability.

The late 2000s and early 2010s marked a shift towards more sophisticated compounding techniques. Reactive extrusion processes were developed, allowing for the in-situ formation of copolymers or grafted structures during processing. This approach led to improved compatibility between PLA and flexibility-enhancing additives, resulting in materials with better overall performance.

Nanotechnology began to play a crucial role in PLA flexibility enhancement around 2010. The incorporation of nanofillers, such as cellulose nanocrystals and organoclays, allowed for significant improvements in mechanical properties without compromising biodegradability. These nanocomposites offered a unique balance of strength and flexibility, opening up new application areas for PLA.

Recent years have seen a focus on developing bio-based plasticizers and impact modifiers specifically designed for PLA. These additives, derived from renewable resources, aim to maintain PLA's eco-friendly profile while significantly improving its flexibility and impact resistance. Innovations in this area have led to PLA compounds that can compete with traditional flexible plastics in various applications, including film packaging and automotive interiors.

The most recent trend in PLA flexibility evolution involves the development of multi-functional additives that simultaneously enhance flexibility, processability, and other key properties. This holistic approach to PLA compounding aims to create versatile materials that can meet the diverse requirements of different industries while maintaining the core benefits of biodegradability and sustainability.

Flexible PLA Market Demand

The market demand for flexible PLA (Polylactic Acid) has been steadily increasing in recent years, driven by the growing awareness of environmental issues and the need for sustainable alternatives to traditional plastics. This surge in demand is particularly evident in industries such as packaging, consumer goods, and medical devices, where the combination of biodegradability and flexibility is highly valued.

In the packaging sector, flexible PLA is gaining traction as a viable alternative to conventional petroleum-based plastics. Food packaging, in particular, has seen a significant uptake of flexible PLA materials due to their ability to maintain food freshness while offering a reduced environmental footprint. The global food packaging market's shift towards sustainable solutions has created a substantial opportunity for flexible PLA products.

Consumer goods manufacturers are also contributing to the rising demand for flexible PLA. As consumers become more environmentally conscious, there is a growing preference for products made from renewable and biodegradable materials. This trend has led to an increased adoption of flexible PLA in various applications, including disposable cutlery, bags, and textile products.

The medical device industry represents another key market for flexible PLA. The material's biocompatibility and ability to be engineered for specific mechanical properties make it an attractive option for applications such as sutures, implants, and drug delivery systems. The growing emphasis on personalized medicine and biodegradable medical devices is expected to further drive demand in this sector.

Geographically, North America and Europe are currently the leading markets for flexible PLA, owing to stringent environmental regulations and high consumer awareness. However, the Asia-Pacific region is anticipated to witness the fastest growth in demand, fueled by rapid industrialization, increasing disposable incomes, and government initiatives promoting sustainable materials.

Despite the positive market outlook, challenges remain in scaling up production and reducing costs to compete with traditional plastics. Innovations in PLA compounding for enhanced flexibility are crucial to address these challenges and meet the diverse requirements of different applications. As research and development efforts continue to improve the performance and cost-effectiveness of flexible PLA, the market is expected to expand further, potentially disrupting conventional plastic markets in the coming years.

In the packaging sector, flexible PLA is gaining traction as a viable alternative to conventional petroleum-based plastics. Food packaging, in particular, has seen a significant uptake of flexible PLA materials due to their ability to maintain food freshness while offering a reduced environmental footprint. The global food packaging market's shift towards sustainable solutions has created a substantial opportunity for flexible PLA products.

Consumer goods manufacturers are also contributing to the rising demand for flexible PLA. As consumers become more environmentally conscious, there is a growing preference for products made from renewable and biodegradable materials. This trend has led to an increased adoption of flexible PLA in various applications, including disposable cutlery, bags, and textile products.

The medical device industry represents another key market for flexible PLA. The material's biocompatibility and ability to be engineered for specific mechanical properties make it an attractive option for applications such as sutures, implants, and drug delivery systems. The growing emphasis on personalized medicine and biodegradable medical devices is expected to further drive demand in this sector.

Geographically, North America and Europe are currently the leading markets for flexible PLA, owing to stringent environmental regulations and high consumer awareness. However, the Asia-Pacific region is anticipated to witness the fastest growth in demand, fueled by rapid industrialization, increasing disposable incomes, and government initiatives promoting sustainable materials.

Despite the positive market outlook, challenges remain in scaling up production and reducing costs to compete with traditional plastics. Innovations in PLA compounding for enhanced flexibility are crucial to address these challenges and meet the diverse requirements of different applications. As research and development efforts continue to improve the performance and cost-effectiveness of flexible PLA, the market is expected to expand further, potentially disrupting conventional plastic markets in the coming years.

PLA Compounding Challenges

Polylactic acid (PLA) compounding faces several significant challenges that hinder its widespread adoption in applications requiring enhanced flexibility. One of the primary obstacles is PLA's inherent brittleness and low impact strength, which limit its use in products that demand high flexibility and durability. This characteristic stems from PLA's high glass transition temperature and low crystallization rate, resulting in a rigid polymer structure.

Another major challenge lies in maintaining PLA's biodegradability while improving its flexibility. Many traditional plasticizers and additives used to enhance flexibility can compromise PLA's eco-friendly nature, potentially negating one of its key advantages. Balancing the need for improved mechanical properties with the preservation of biodegradability remains a complex task for researchers and manufacturers.

The processing of PLA compounds also presents difficulties. PLA is sensitive to thermal degradation during melt processing, which can lead to a reduction in molecular weight and deterioration of mechanical properties. This sensitivity necessitates careful control of processing parameters, such as temperature and residence time, which can be challenging to maintain consistently in industrial-scale production.

Compatibility issues between PLA and other polymers or additives pose another significant hurdle. Many potential flexibility-enhancing agents do not mix well with PLA at the molecular level, leading to phase separation and inconsistent material properties. This incompatibility can result in products with poor mechanical performance or inconsistent quality across batches.

Cost considerations also play a role in PLA compounding challenges. Developing and implementing new compounding techniques or incorporating specialized additives can significantly increase production costs. This economic factor can make it difficult for PLA-based products to compete with traditional petroleum-based plastics in price-sensitive markets.

Achieving a balance between flexibility and other desirable properties, such as strength and barrier properties, remains a complex challenge. Enhancing flexibility often comes at the expense of tensile strength or gas barrier properties, which are crucial for certain applications like packaging. Finding the right formulation that optimizes all these properties simultaneously requires extensive research and development efforts.

Lastly, the scalability of laboratory-developed solutions to industrial production presents its own set of challenges. Techniques that work well in small-scale experiments may encounter unforeseen issues when scaled up, necessitating further refinement and adaptation of compounding processes for large-scale manufacturing environments.

Another major challenge lies in maintaining PLA's biodegradability while improving its flexibility. Many traditional plasticizers and additives used to enhance flexibility can compromise PLA's eco-friendly nature, potentially negating one of its key advantages. Balancing the need for improved mechanical properties with the preservation of biodegradability remains a complex task for researchers and manufacturers.

The processing of PLA compounds also presents difficulties. PLA is sensitive to thermal degradation during melt processing, which can lead to a reduction in molecular weight and deterioration of mechanical properties. This sensitivity necessitates careful control of processing parameters, such as temperature and residence time, which can be challenging to maintain consistently in industrial-scale production.

Compatibility issues between PLA and other polymers or additives pose another significant hurdle. Many potential flexibility-enhancing agents do not mix well with PLA at the molecular level, leading to phase separation and inconsistent material properties. This incompatibility can result in products with poor mechanical performance or inconsistent quality across batches.

Cost considerations also play a role in PLA compounding challenges. Developing and implementing new compounding techniques or incorporating specialized additives can significantly increase production costs. This economic factor can make it difficult for PLA-based products to compete with traditional petroleum-based plastics in price-sensitive markets.

Achieving a balance between flexibility and other desirable properties, such as strength and barrier properties, remains a complex challenge. Enhancing flexibility often comes at the expense of tensile strength or gas barrier properties, which are crucial for certain applications like packaging. Finding the right formulation that optimizes all these properties simultaneously requires extensive research and development efforts.

Lastly, the scalability of laboratory-developed solutions to industrial production presents its own set of challenges. Techniques that work well in small-scale experiments may encounter unforeseen issues when scaled up, necessitating further refinement and adaptation of compounding processes for large-scale manufacturing environments.

Current PLA Flexibilization

01 PLA blending with other polymers

Compounding PLA with other polymers can enhance its flexibility and improve overall properties. This approach allows for tailoring the material characteristics to specific applications, potentially increasing the range of uses for PLA-based products.- Polymer blending and modification: PLA compounding flexibility can be enhanced through polymer blending and modification techniques. This involves mixing PLA with other polymers or additives to improve its properties such as toughness, thermal stability, and processability. Various methods like reactive extrusion or grafting can be used to create customized PLA compounds with desired characteristics.

- Plasticizer incorporation: Incorporating plasticizers into PLA formulations can significantly improve its flexibility and processability. Plasticizers reduce the glass transition temperature of PLA, making it more pliable and easier to mold. This approach allows for the production of more flexible PLA-based products while maintaining biodegradability.

- Nanocomposite formulation: Developing PLA nanocomposites by incorporating nanomaterials such as nanoclay, carbon nanotubes, or nanocellulose can enhance the material's properties. These nanocomposites often exhibit improved mechanical strength, barrier properties, and thermal stability, expanding the range of applications for PLA-based materials.

- Copolymerization and chain extension: Copolymerization of PLA with other monomers or the use of chain extenders can modify its molecular structure, leading to improved flexibility and processability. This approach allows for fine-tuning of PLA properties to meet specific application requirements, such as increased elongation at break or improved melt strength.

- Processing parameter optimization: Optimizing processing parameters such as temperature, pressure, and cooling rates during PLA compounding and molding can significantly affect the final product's flexibility and performance. Advanced process control and monitoring systems can be employed to achieve precise control over these parameters, resulting in more consistent and tailored PLA compounds.

02 Use of plasticizers in PLA formulations

Incorporating plasticizers into PLA compounds can significantly improve flexibility and processability. These additives reduce the glass transition temperature and increase chain mobility, resulting in a more pliable material suitable for various applications.Expand Specific Solutions03 Nanocomposite technology for PLA

Developing PLA nanocomposites by incorporating nanoscale fillers can enhance flexibility while maintaining or improving other mechanical properties. This approach allows for the creation of lightweight, flexible materials with potential applications in packaging and consumer goods.Expand Specific Solutions04 Reactive extrusion techniques for PLA

Utilizing reactive extrusion techniques during PLA compounding can modify the polymer structure, leading to improved flexibility and processability. This method allows for in-situ modifications and can be used to create tailored PLA compounds with enhanced properties.Expand Specific Solutions05 Biobased additives for PLA flexibility

Incorporating biobased additives into PLA formulations can enhance flexibility while maintaining the material's biodegradability and sustainability profile. These additives can be derived from renewable resources and offer a green solution to improving PLA's mechanical properties.Expand Specific Solutions

Key PLA Compound Players

The field of PLA compounding for enhanced flexibility is in a growth phase, with increasing market size driven by demand for sustainable plastics. The global market for flexible PLA compounds is expanding rapidly, fueled by environmental concerns and regulatory pressures. Technologically, the sector is advancing but still maturing, with ongoing research to improve PLA's inherent brittleness. Key players like Sichuan University, Arkema France SA, and LG Chem Ltd. are at the forefront, developing innovative compounding techniques and additives. Universities such as Tongji University and Beijing University of Chemical Technology are contributing significant research, while companies like Northern Technologies International Corp. and SK Chemicals Co. Ltd. are commercializing advanced PLA compounds, indicating a competitive and dynamic landscape in this emerging field.

Arkema France SA

Technical Solution: Arkema has developed a proprietary technology for PLA compounding that enhances flexibility through the incorporation of bio-based plasticizers and impact modifiers. Their process involves a carefully controlled reactive extrusion technique that allows for the precise integration of these additives into the PLA matrix. This results in a significant improvement in elongation at break and impact strength without compromising the material's biodegradability. Additionally, Arkema's technology includes the use of chain extenders to maintain molecular weight during processing, ensuring that the enhanced flexibility does not come at the cost of reduced mechanical properties.

Strengths: Bio-based additives maintain overall sustainability; Improved flexibility without sacrificing biodegradability; Maintained mechanical properties. Weaknesses: Potential increase in production costs; May require specialized processing equipment.

LG Chem Ltd.

Technical Solution: LG Chem has innovated in PLA compounding by developing a unique blend of PLA with their proprietary elastomeric copolymers. This technology involves the creation of a multi-phase system where the elastomeric components are finely dispersed within the PLA matrix. The process utilizes compatibilizers to ensure good interfacial adhesion between the phases, resulting in a material with significantly enhanced flexibility and impact resistance. LG Chem's approach also incorporates nanotechnology, using nanofillers to further reinforce the material and provide additional property enhancements such as improved barrier properties and heat resistance.

Strengths: Significant improvement in flexibility and impact resistance; Enhanced barrier properties and heat resistance. Weaknesses: Complex multi-phase system may be challenging to process consistently; Potential for increased cost due to specialized copolymers and nanofillers.

Core PLA Compounding Tech

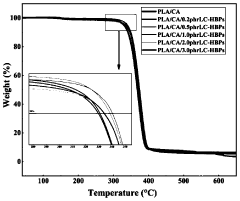

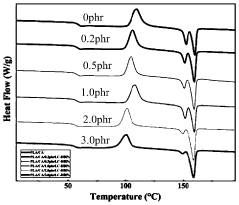

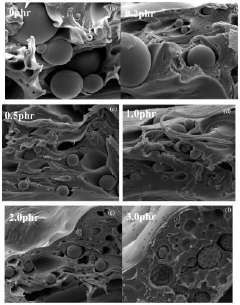

PLA/CA/LCHBPs blend and preparation method thereof

PatentActiveCN111454549A

Innovation

- Long-chain hyperbranched polymers (LCHBPs) are used for solution blending of PLA and CA. The highly branched structure of LCHBPs entangles with PLA and CA molecular chains to improve compatibility and mechanical properties.

Novel high-softness polylactic acid fiber composite material and preparation method thereof

PatentActiveCN104695047A

Innovation

- Multifunctional polycarbodiimide (PCDI) and tetrabutyl titanate are used as reactive compatibilizers, and the modified PLA/PPA material is blended to improve its high-temperature stability and compatibility, and through melt spinning Technology to prepare fibers with high softness.

Biodegradability Factors

Biodegradability is a crucial factor in the development of PLA compounds with enhanced flexibility. The ability of these materials to break down naturally in the environment is a key advantage over traditional petroleum-based plastics. However, the biodegradation process of PLA compounds can be influenced by various factors, which must be carefully considered in the innovation process.

The chemical structure of PLA plays a significant role in its biodegradability. The ester bonds in PLA are susceptible to hydrolysis, which is the primary mechanism for its degradation. Innovations in PLA compounding that aim to enhance flexibility must ensure that these ester bonds remain accessible to water and microorganisms. This can be challenging, as some flexibility-enhancing additives may create barriers that slow down the degradation process.

Environmental conditions also greatly affect the biodegradability of PLA compounds. Temperature, humidity, and the presence of specific microorganisms are critical factors. In industrial composting facilities, where conditions are optimized, PLA can degrade relatively quickly. However, in natural environments, the process can be significantly slower. Innovations in PLA compounding must consider how to maintain or improve biodegradability across a range of environmental conditions.

The molecular weight of PLA is another important factor influencing its biodegradability. Generally, lower molecular weight PLA degrades faster than higher molecular weight variants. However, lower molecular weight can also lead to reduced mechanical properties. Balancing the molecular weight to achieve both enhanced flexibility and acceptable biodegradation rates is a key challenge for researchers and developers.

Additives used to enhance flexibility can have complex effects on biodegradability. Some plasticizers, for example, may leach out of the material over time, potentially altering the degradation rate and environmental impact. Innovative approaches are needed to develop additives that not only improve flexibility but also maintain or enhance biodegradability.

The crystallinity of PLA also affects its biodegradation rate, with more amorphous regions generally degrading faster than crystalline ones. Flexibility-enhancing innovations often involve reducing crystallinity, which can potentially improve biodegradability. However, this must be balanced against other performance requirements, as reduced crystallinity can also affect thermal and barrier properties.

In conclusion, innovations in PLA compounding for enhanced flexibility must carefully consider the complex interplay of factors affecting biodegradability. Successful developments will require a holistic approach that balances flexibility improvements with maintained or enhanced biodegradation properties, ensuring that the resulting materials meet both performance and environmental sustainability goals.

The chemical structure of PLA plays a significant role in its biodegradability. The ester bonds in PLA are susceptible to hydrolysis, which is the primary mechanism for its degradation. Innovations in PLA compounding that aim to enhance flexibility must ensure that these ester bonds remain accessible to water and microorganisms. This can be challenging, as some flexibility-enhancing additives may create barriers that slow down the degradation process.

Environmental conditions also greatly affect the biodegradability of PLA compounds. Temperature, humidity, and the presence of specific microorganisms are critical factors. In industrial composting facilities, where conditions are optimized, PLA can degrade relatively quickly. However, in natural environments, the process can be significantly slower. Innovations in PLA compounding must consider how to maintain or improve biodegradability across a range of environmental conditions.

The molecular weight of PLA is another important factor influencing its biodegradability. Generally, lower molecular weight PLA degrades faster than higher molecular weight variants. However, lower molecular weight can also lead to reduced mechanical properties. Balancing the molecular weight to achieve both enhanced flexibility and acceptable biodegradation rates is a key challenge for researchers and developers.

Additives used to enhance flexibility can have complex effects on biodegradability. Some plasticizers, for example, may leach out of the material over time, potentially altering the degradation rate and environmental impact. Innovative approaches are needed to develop additives that not only improve flexibility but also maintain or enhance biodegradability.

The crystallinity of PLA also affects its biodegradation rate, with more amorphous regions generally degrading faster than crystalline ones. Flexibility-enhancing innovations often involve reducing crystallinity, which can potentially improve biodegradability. However, this must be balanced against other performance requirements, as reduced crystallinity can also affect thermal and barrier properties.

In conclusion, innovations in PLA compounding for enhanced flexibility must carefully consider the complex interplay of factors affecting biodegradability. Successful developments will require a holistic approach that balances flexibility improvements with maintained or enhanced biodegradation properties, ensuring that the resulting materials meet both performance and environmental sustainability goals.

Regulatory Considerations

The regulatory landscape surrounding PLA compounding for enhanced flexibility is complex and evolving. As bioplastics gain prominence in various industries, regulatory bodies are adapting their frameworks to address the unique characteristics and potential impacts of these materials. In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating PLA compounds intended for food contact applications. Manufacturers must ensure compliance with FDA regulations, particularly 21 CFR 177.1630, which outlines the requirements for polyester resins in food packaging.

In the European Union, the European Food Safety Authority (EFSA) oversees the safety assessment of PLA compounds used in food contact materials. The EU Plastics Regulation (EU) No 10/2011 provides specific migration limits and other requirements for PLA and its additives. Manufacturers must obtain proper authorization and conduct necessary testing to demonstrate compliance with these regulations.

Environmental regulations also significantly impact PLA compounding innovations. The EU's Single-Use Plastics Directive, which aims to reduce plastic waste, has implications for PLA-based products. While PLA is biodegradable under certain conditions, manufacturers must carefully consider end-of-life scenarios and provide clear disposal instructions to consumers. In the United States, the Federal Trade Commission (FTC) regulates environmental marketing claims, including those related to biodegradability and compostability of PLA compounds.

Safety regulations, such as REACH in the EU and TSCA in the US, require manufacturers to assess and report on the potential risks associated with new chemical substances used in PLA compounding. This includes additives and plasticizers employed to enhance flexibility. Compliance with these regulations often necessitates extensive toxicological testing and documentation.

As PLA compounds find applications in medical devices, regulatory considerations become even more stringent. In the US, the FDA's Center for Devices and Radiological Health (CDRH) oversees the approval process for medical devices, including those incorporating PLA compounds. Similarly, in the EU, the Medical Device Regulation (MDR) imposes strict requirements on materials used in medical applications.

Standardization efforts are ongoing to establish consistent methods for assessing the performance and environmental impact of PLA compounds. Organizations such as ASTM International and ISO are developing standards specific to bioplastics, which will likely influence future regulatory frameworks. Manufacturers engaged in PLA compounding innovations must stay abreast of these developments to ensure long-term compliance and market acceptance.

In the European Union, the European Food Safety Authority (EFSA) oversees the safety assessment of PLA compounds used in food contact materials. The EU Plastics Regulation (EU) No 10/2011 provides specific migration limits and other requirements for PLA and its additives. Manufacturers must obtain proper authorization and conduct necessary testing to demonstrate compliance with these regulations.

Environmental regulations also significantly impact PLA compounding innovations. The EU's Single-Use Plastics Directive, which aims to reduce plastic waste, has implications for PLA-based products. While PLA is biodegradable under certain conditions, manufacturers must carefully consider end-of-life scenarios and provide clear disposal instructions to consumers. In the United States, the Federal Trade Commission (FTC) regulates environmental marketing claims, including those related to biodegradability and compostability of PLA compounds.

Safety regulations, such as REACH in the EU and TSCA in the US, require manufacturers to assess and report on the potential risks associated with new chemical substances used in PLA compounding. This includes additives and plasticizers employed to enhance flexibility. Compliance with these regulations often necessitates extensive toxicological testing and documentation.

As PLA compounds find applications in medical devices, regulatory considerations become even more stringent. In the US, the FDA's Center for Devices and Radiological Health (CDRH) oversees the approval process for medical devices, including those incorporating PLA compounds. Similarly, in the EU, the Medical Device Regulation (MDR) imposes strict requirements on materials used in medical applications.

Standardization efforts are ongoing to establish consistent methods for assessing the performance and environmental impact of PLA compounds. Organizations such as ASTM International and ISO are developing standards specific to bioplastics, which will likely influence future regulatory frameworks. Manufacturers engaged in PLA compounding innovations must stay abreast of these developments to ensure long-term compliance and market acceptance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!