Advances in PLA Chemical Structure for Enhanced Properties

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PLA Evolution and Objectives

Polylactic acid (PLA) has emerged as a promising biodegradable polymer with a wide range of applications, from packaging to biomedical devices. The evolution of PLA technology has been driven by the growing demand for sustainable materials and the need to address environmental concerns associated with conventional plastics.

The journey of PLA began in the 1930s when it was first synthesized by Wallace Carothers at DuPont. However, it wasn't until the 1960s that PLA gained attention for its potential as a biodegradable material. The initial focus was on medical applications due to its biocompatibility and ability to degrade in the human body.

In the 1990s, advancements in fermentation technology and lactic acid production from renewable resources paved the way for large-scale PLA production. This marked a significant milestone in PLA's evolution, as it became economically viable for broader applications beyond the medical field.

The early 2000s saw a surge in research aimed at improving PLA's properties to compete with traditional petroleum-based plastics. Efforts were directed towards enhancing its thermal stability, mechanical strength, and processability. These advancements led to the commercialization of PLA for packaging and consumer goods.

Recent years have witnessed a shift towards tailoring PLA's chemical structure to achieve specific property enhancements. This includes the development of copolymers, blends, and composites to overcome limitations such as brittleness and low heat resistance. Researchers are exploring various strategies, including stereocomplexation, chain extension, and incorporation of nanofillers, to fine-tune PLA's performance.

The current objectives in PLA research and development are multifaceted. One primary goal is to further improve PLA's mechanical properties, particularly its impact strength and flexibility, to expand its use in durable applications. Another crucial objective is to enhance PLA's thermal stability and heat resistance, which would enable its use in high-temperature applications and improve its processability.

Additionally, there is a growing focus on developing PLA grades with improved barrier properties for food packaging applications. Researchers are also working on accelerating PLA's biodegradation rate in various environments while maintaining its stability during use. This balance is critical for ensuring PLA's effectiveness as a sustainable material across different applications.

Looking ahead, the evolution of PLA is expected to continue with a focus on circular economy principles. This includes developing more efficient recycling methods for PLA and exploring the potential of chemical recycling to recover lactic acid monomers. The ultimate goal is to create a closed-loop system for PLA production and use, further enhancing its sustainability credentials.

The journey of PLA began in the 1930s when it was first synthesized by Wallace Carothers at DuPont. However, it wasn't until the 1960s that PLA gained attention for its potential as a biodegradable material. The initial focus was on medical applications due to its biocompatibility and ability to degrade in the human body.

In the 1990s, advancements in fermentation technology and lactic acid production from renewable resources paved the way for large-scale PLA production. This marked a significant milestone in PLA's evolution, as it became economically viable for broader applications beyond the medical field.

The early 2000s saw a surge in research aimed at improving PLA's properties to compete with traditional petroleum-based plastics. Efforts were directed towards enhancing its thermal stability, mechanical strength, and processability. These advancements led to the commercialization of PLA for packaging and consumer goods.

Recent years have witnessed a shift towards tailoring PLA's chemical structure to achieve specific property enhancements. This includes the development of copolymers, blends, and composites to overcome limitations such as brittleness and low heat resistance. Researchers are exploring various strategies, including stereocomplexation, chain extension, and incorporation of nanofillers, to fine-tune PLA's performance.

The current objectives in PLA research and development are multifaceted. One primary goal is to further improve PLA's mechanical properties, particularly its impact strength and flexibility, to expand its use in durable applications. Another crucial objective is to enhance PLA's thermal stability and heat resistance, which would enable its use in high-temperature applications and improve its processability.

Additionally, there is a growing focus on developing PLA grades with improved barrier properties for food packaging applications. Researchers are also working on accelerating PLA's biodegradation rate in various environments while maintaining its stability during use. This balance is critical for ensuring PLA's effectiveness as a sustainable material across different applications.

Looking ahead, the evolution of PLA is expected to continue with a focus on circular economy principles. This includes developing more efficient recycling methods for PLA and exploring the potential of chemical recycling to recover lactic acid monomers. The ultimate goal is to create a closed-loop system for PLA production and use, further enhancing its sustainability credentials.

Market Demand Analysis

The market demand for advanced PLA (Polylactic Acid) with enhanced properties has been steadily increasing, driven by the growing awareness of environmental issues and the push for sustainable materials across various industries. PLA, a biodegradable and biocompatible polymer derived from renewable resources, has gained significant attention as an eco-friendly alternative to traditional petroleum-based plastics.

In the packaging industry, there is a strong demand for PLA with improved barrier properties and heat resistance. As consumers and regulators push for more sustainable packaging solutions, food and beverage companies are actively seeking PLA materials that can match the performance of conventional plastics while offering biodegradability. This has created a substantial market opportunity for PLA with enhanced chemical structures that can withstand higher temperatures and provide better protection against moisture and oxygen permeation.

The medical and pharmaceutical sectors have also shown increasing interest in advanced PLA materials. The biocompatibility and controlled degradation properties of PLA make it an attractive option for drug delivery systems, implants, and tissue engineering scaffolds. However, there is a need for PLA with tailored degradation rates and mechanical properties to suit specific medical applications, driving research into chemical structure modifications.

In the automotive and electronics industries, there is a growing demand for bio-based materials with improved mechanical properties and flame retardancy. As these sectors strive to reduce their environmental footprint, PLA with enhanced chemical structures that can meet stringent performance requirements is becoming increasingly sought after. This includes PLA composites and blends that offer higher strength, impact resistance, and thermal stability.

The textile industry has also shown significant interest in advanced PLA fibers. There is a demand for PLA-based textiles with improved moisture management, durability, and dyeability. This has led to research into chemical modifications of PLA to enhance its properties for use in sportswear, fashion, and technical textiles.

The global market for bioplastics, including PLA, is projected to grow substantially in the coming years. While exact figures vary depending on the source, industry reports consistently indicate double-digit growth rates for the PLA market. This growth is driven not only by consumer preferences for sustainable products but also by regulatory pressures and corporate sustainability initiatives.

However, to fully capitalize on these market opportunities, advancements in PLA's chemical structure are crucial. The industry needs to overcome current limitations in terms of thermal stability, mechanical properties, and processability to expand PLA's application range and market penetration. As such, there is a clear market pull for research and development efforts focused on enhancing PLA's properties through chemical structure modifications.

In the packaging industry, there is a strong demand for PLA with improved barrier properties and heat resistance. As consumers and regulators push for more sustainable packaging solutions, food and beverage companies are actively seeking PLA materials that can match the performance of conventional plastics while offering biodegradability. This has created a substantial market opportunity for PLA with enhanced chemical structures that can withstand higher temperatures and provide better protection against moisture and oxygen permeation.

The medical and pharmaceutical sectors have also shown increasing interest in advanced PLA materials. The biocompatibility and controlled degradation properties of PLA make it an attractive option for drug delivery systems, implants, and tissue engineering scaffolds. However, there is a need for PLA with tailored degradation rates and mechanical properties to suit specific medical applications, driving research into chemical structure modifications.

In the automotive and electronics industries, there is a growing demand for bio-based materials with improved mechanical properties and flame retardancy. As these sectors strive to reduce their environmental footprint, PLA with enhanced chemical structures that can meet stringent performance requirements is becoming increasingly sought after. This includes PLA composites and blends that offer higher strength, impact resistance, and thermal stability.

The textile industry has also shown significant interest in advanced PLA fibers. There is a demand for PLA-based textiles with improved moisture management, durability, and dyeability. This has led to research into chemical modifications of PLA to enhance its properties for use in sportswear, fashion, and technical textiles.

The global market for bioplastics, including PLA, is projected to grow substantially in the coming years. While exact figures vary depending on the source, industry reports consistently indicate double-digit growth rates for the PLA market. This growth is driven not only by consumer preferences for sustainable products but also by regulatory pressures and corporate sustainability initiatives.

However, to fully capitalize on these market opportunities, advancements in PLA's chemical structure are crucial. The industry needs to overcome current limitations in terms of thermal stability, mechanical properties, and processability to expand PLA's application range and market penetration. As such, there is a clear market pull for research and development efforts focused on enhancing PLA's properties through chemical structure modifications.

PLA Challenges and Limitations

Polylactic acid (PLA) has gained significant attention as a biodegradable and renewable alternative to conventional plastics. However, despite its promising attributes, PLA faces several challenges and limitations that hinder its widespread adoption across various industries.

One of the primary challenges associated with PLA is its inherent brittleness and low impact resistance. This mechanical weakness limits its application in products that require high toughness and durability. The low glass transition temperature of PLA also restricts its use in high-temperature applications, as it softens and deforms at relatively low temperatures compared to traditional thermoplastics.

PLA's slow crystallization rate poses another significant limitation. This characteristic affects its processability and thermal stability, making it challenging to achieve optimal mechanical properties in certain manufacturing processes. The slow crystallization also impacts the material's heat resistance and dimensional stability, further constraining its potential applications.

The hydrolytic instability of PLA presents a double-edged sword. While it contributes to the material's biodegradability, it also leads to rapid degradation in high-humidity environments. This sensitivity to moisture can result in premature deterioration of PLA-based products, limiting their shelf life and performance in certain conditions.

Another notable limitation is PLA's poor barrier properties, particularly its high gas permeability. This characteristic restricts its use in packaging applications that require extended shelf life or protection against oxygen and moisture. The material's inadequate barrier performance necessitates additional treatments or coatings, increasing production costs and complexity.

PLA's limited thermal stability during processing poses challenges in manufacturing. The material is prone to thermal degradation at elevated temperatures, which can lead to a reduction in molecular weight and deterioration of mechanical properties. This sensitivity narrows the processing window and requires careful control of processing parameters.

The relatively high production cost of PLA compared to conventional plastics remains a significant barrier to its widespread adoption. The complex synthesis process and the need for high-purity feedstocks contribute to the elevated costs, making it less competitive in price-sensitive markets.

Lastly, the end-of-life management of PLA presents challenges. While biodegradable, PLA requires specific conditions for efficient decomposition, which are not always available in standard waste management facilities. This limitation can lead to misconceptions about its environmental benefits and hinder proper disposal and recycling efforts.

One of the primary challenges associated with PLA is its inherent brittleness and low impact resistance. This mechanical weakness limits its application in products that require high toughness and durability. The low glass transition temperature of PLA also restricts its use in high-temperature applications, as it softens and deforms at relatively low temperatures compared to traditional thermoplastics.

PLA's slow crystallization rate poses another significant limitation. This characteristic affects its processability and thermal stability, making it challenging to achieve optimal mechanical properties in certain manufacturing processes. The slow crystallization also impacts the material's heat resistance and dimensional stability, further constraining its potential applications.

The hydrolytic instability of PLA presents a double-edged sword. While it contributes to the material's biodegradability, it also leads to rapid degradation in high-humidity environments. This sensitivity to moisture can result in premature deterioration of PLA-based products, limiting their shelf life and performance in certain conditions.

Another notable limitation is PLA's poor barrier properties, particularly its high gas permeability. This characteristic restricts its use in packaging applications that require extended shelf life or protection against oxygen and moisture. The material's inadequate barrier performance necessitates additional treatments or coatings, increasing production costs and complexity.

PLA's limited thermal stability during processing poses challenges in manufacturing. The material is prone to thermal degradation at elevated temperatures, which can lead to a reduction in molecular weight and deterioration of mechanical properties. This sensitivity narrows the processing window and requires careful control of processing parameters.

The relatively high production cost of PLA compared to conventional plastics remains a significant barrier to its widespread adoption. The complex synthesis process and the need for high-purity feedstocks contribute to the elevated costs, making it less competitive in price-sensitive markets.

Lastly, the end-of-life management of PLA presents challenges. While biodegradable, PLA requires specific conditions for efficient decomposition, which are not always available in standard waste management facilities. This limitation can lead to misconceptions about its environmental benefits and hinder proper disposal and recycling efforts.

Current PLA Enhancement Solutions

01 Basic chemical structure of PLA

Polylactic Acid (PLA) is a biodegradable thermoplastic aliphatic polyester derived from renewable resources. Its basic structure consists of repeating lactic acid units linked together by ester bonds. The chemical formula of the repeating unit is (C3H4O2)n, where n represents the degree of polymerization.- Basic chemical structure of PLA: Polylactic Acid (PLA) is a biodegradable thermoplastic aliphatic polyester derived from renewable resources. Its basic chemical structure consists of repeating units of lactic acid monomers linked together by ester bonds. The molecular formula of the repeating unit is (C3H4O2)n, where n represents the degree of polymerization.

- Stereochemistry of PLA: PLA can exist in different stereochemical forms due to the chiral nature of lactic acid. The most common forms are L-PLA, D-PLA, and the racemic mixture DL-PLA. The stereochemistry affects the crystallinity, mechanical properties, and biodegradation rate of the polymer.

- Synthesis methods for PLA: PLA can be synthesized through various methods, including direct condensation polymerization of lactic acid and ring-opening polymerization of lactide. The choice of synthesis method affects the molecular weight, purity, and properties of the resulting polymer.

- Modifications to PLA structure: The chemical structure of PLA can be modified to enhance its properties or create new functionalities. Common modifications include copolymerization with other monomers, grafting, and blending with other polymers. These modifications can alter the polymer's mechanical properties, thermal stability, and degradation rate.

- End-group modifications of PLA: The end groups of PLA chains can be modified to introduce specific functionalities or improve certain properties. Common end-group modifications include hydroxyl, carboxyl, or amine terminations. These modifications can affect the polymer's reactivity, compatibility with other materials, and processing characteristics.

02 Stereochemistry of PLA

PLA can exist in different stereochemical forms due to the chiral nature of lactic acid. The most common forms are L-PLA, D-PLA, and the racemic mixture DL-PLA. These stereochemical variations affect the properties of the polymer, such as crystallinity and melting point.Expand Specific Solutions03 Synthesis methods for PLA

PLA can be synthesized through various methods, including direct condensation polymerization of lactic acid and ring-opening polymerization of lactide. The choice of synthesis method affects the molecular weight, purity, and properties of the resulting polymer.Expand Specific Solutions04 Modifications to PLA structure

The chemical structure of PLA can be modified to enhance its properties or create copolymers. Common modifications include blending with other polymers, grafting, and the incorporation of functional groups. These modifications can improve mechanical properties, thermal stability, or introduce new functionalities.Expand Specific Solutions05 Degradation and recycling of PLA

The ester bonds in PLA's chemical structure make it susceptible to hydrolysis, leading to its biodegradability. Understanding the degradation mechanism is crucial for developing recycling strategies and controlling the polymer's lifecycle. Various methods for chemical recycling of PLA back to its monomers or other useful chemicals have been developed.Expand Specific Solutions

Key PLA Industry Players

The field of PLA chemical structure enhancement is in a growth phase, with increasing market size driven by demand for sustainable materials. The technology maturity varies, with some established players like NatureWorks LLC and Total Research Corp leading commercial applications, while academic institutions such as Sichuan University and Tongji University contribute to fundamental research. Companies like Toray Plastics and BYD Co., Ltd. are advancing industrial applications, while research centers like Michigan Molecular Institute and Beijing University of Chemical Technology focus on innovative structural modifications. The competitive landscape is diverse, with collaborations between industry and academia pushing the boundaries of PLA properties, indicating a dynamic and evolving market with significant potential for further technological advancements.

NatureWorks LLC

Technical Solution: NatureWorks LLC has developed a proprietary process for producing high-performance polylactic acid (PLA) polymers from renewable resources. Their Ingeo biopolymer technology involves fermenting plant sugars to produce lactic acid, which is then polymerized into PLA. They have focused on enhancing PLA's thermal stability and mechanical properties through various modifications, including the use of stereocomplex crystallites and the incorporation of chain extenders to increase molecular weight and melt strength.

Strengths: Renewable feedstock, biodegradability, and versatility in applications. Weaknesses: Higher production costs compared to traditional plastics and limited high-temperature performance.

Toray Plastics (America), Inc.

Technical Solution: Toray Plastics has been working on improving PLA film properties through their proprietary technology. They have developed a method to enhance PLA's heat resistance and durability by introducing a unique crystal structure. This involves a controlled biaxial orientation process that aligns PLA molecules, resulting in films with improved barrier properties, heat resistance, and mechanical strength. Additionally, they have explored blending PLA with other biodegradable polymers to create composite materials with enhanced characteristics.

Strengths: Improved heat resistance and barrier properties for PLA films. Weaknesses: Potentially higher production costs and limited to film applications.

Innovative PLA Modifications

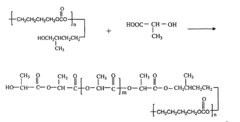

Producing method for polylactic acid-based copolymer

PatentActiveEP2184307A1

Innovation

- A method for preparing poly (lactic acid)-based copolymers by introducing flexible chain segments through copolymerization with polycaprolactone and aliphatic polycarbonate diols, enhancing molecular weight and mechanical properties, and incorporating chain extension processes to improve toughness, elasticity, and biodegradability.

Renewable, biodegradable poly(lactic acid) composites with improved thermal properties

PatentWO2015048589A1

Innovation

- A composite comprising PLA and microground cellulosic filler, with the microground cellulosic size ranging from 10 to 250 μm, is used to achieve an HDT greater than or equal to 85°C, which is 100% compostable and biosourced, eliminating the need for expensive additives and ensuring cost-effectiveness.

Environmental Impact of PLA

The environmental impact of PLA (Polylactic Acid) is a crucial consideration in the development and application of this biodegradable polymer. As advances in PLA chemical structure continue to enhance its properties, it is essential to evaluate the ecological implications throughout its lifecycle.

PLA production primarily relies on renewable resources, such as corn starch or sugarcane, which significantly reduces its carbon footprint compared to petroleum-based plastics. The cultivation of these feedstocks, however, raises concerns about land use and potential competition with food crops. Efforts to utilize agricultural waste and non-food biomass as PLA feedstock are ongoing to mitigate these issues.

The manufacturing process of PLA generally consumes less energy than traditional plastic production, contributing to lower greenhouse gas emissions. However, the use of chemical catalysts and solvents in PLA synthesis can have environmental implications if not properly managed. Recent advancements in green chemistry approaches aim to minimize the use of harmful substances and improve the overall sustainability of PLA production.

One of the most significant environmental benefits of PLA is its biodegradability. Under industrial composting conditions, PLA can break down into water, carbon dioxide, and biomass within a few months. This characteristic reduces the burden on landfills and helps address plastic pollution concerns. However, it is important to note that PLA requires specific conditions for optimal degradation, which are not always available in natural environments or home composting systems.

The end-of-life management of PLA products plays a crucial role in realizing its environmental benefits. Proper sorting and disposal in industrial composting facilities are necessary to ensure effective biodegradation. Challenges arise when PLA products contaminate conventional plastic recycling streams, potentially disrupting established recycling processes. Efforts to improve the identification and separation of PLA from other plastics are ongoing to address this issue.

As PLA applications expand into various sectors, including packaging, textiles, and medical devices, the environmental impact of these products throughout their lifecycle must be carefully assessed. Life Cycle Assessment (LCA) studies comparing PLA to conventional plastics have shown mixed results, depending on the specific application and disposal scenario. While PLA generally performs well in terms of fossil fuel consumption and greenhouse gas emissions, factors such as water usage and eutrophication potential require further optimization.

The development of PLA blends and composites with enhanced properties may introduce new environmental considerations. While these advancements aim to improve PLA's performance, the addition of non-biodegradable components or additives could compromise its environmental benefits. Striking a balance between enhanced properties and maintaining biodegradability remains a key challenge for researchers and manufacturers.

PLA production primarily relies on renewable resources, such as corn starch or sugarcane, which significantly reduces its carbon footprint compared to petroleum-based plastics. The cultivation of these feedstocks, however, raises concerns about land use and potential competition with food crops. Efforts to utilize agricultural waste and non-food biomass as PLA feedstock are ongoing to mitigate these issues.

The manufacturing process of PLA generally consumes less energy than traditional plastic production, contributing to lower greenhouse gas emissions. However, the use of chemical catalysts and solvents in PLA synthesis can have environmental implications if not properly managed. Recent advancements in green chemistry approaches aim to minimize the use of harmful substances and improve the overall sustainability of PLA production.

One of the most significant environmental benefits of PLA is its biodegradability. Under industrial composting conditions, PLA can break down into water, carbon dioxide, and biomass within a few months. This characteristic reduces the burden on landfills and helps address plastic pollution concerns. However, it is important to note that PLA requires specific conditions for optimal degradation, which are not always available in natural environments or home composting systems.

The end-of-life management of PLA products plays a crucial role in realizing its environmental benefits. Proper sorting and disposal in industrial composting facilities are necessary to ensure effective biodegradation. Challenges arise when PLA products contaminate conventional plastic recycling streams, potentially disrupting established recycling processes. Efforts to improve the identification and separation of PLA from other plastics are ongoing to address this issue.

As PLA applications expand into various sectors, including packaging, textiles, and medical devices, the environmental impact of these products throughout their lifecycle must be carefully assessed. Life Cycle Assessment (LCA) studies comparing PLA to conventional plastics have shown mixed results, depending on the specific application and disposal scenario. While PLA generally performs well in terms of fossil fuel consumption and greenhouse gas emissions, factors such as water usage and eutrophication potential require further optimization.

The development of PLA blends and composites with enhanced properties may introduce new environmental considerations. While these advancements aim to improve PLA's performance, the addition of non-biodegradable components or additives could compromise its environmental benefits. Striking a balance between enhanced properties and maintaining biodegradability remains a key challenge for researchers and manufacturers.

PLA Regulatory Framework

The regulatory framework surrounding Polylactic Acid (PLA) plays a crucial role in shaping its development, production, and application across various industries. As a biodegradable and biocompatible polymer, PLA has gained significant attention from regulatory bodies worldwide due to its potential to address environmental concerns associated with conventional plastics.

In the United States, the Food and Drug Administration (FDA) has approved PLA for use in food contact applications, medical devices, and drug delivery systems. The FDA's regulatory oversight ensures that PLA-based products meet stringent safety and quality standards. Similarly, the European Food Safety Authority (EFSA) has evaluated PLA and deemed it safe for food contact materials, subject to specific migration limits and usage conditions.

Environmental regulations have also been instrumental in promoting the adoption of PLA. The European Union's Packaging and Packaging Waste Directive, which sets targets for recycling and recovery of packaging materials, has indirectly boosted the demand for biodegradable alternatives like PLA. In the United States, several states have implemented regulations encouraging the use of compostable plastics, further driving the market for PLA-based products.

The regulatory landscape for PLA extends beyond food and packaging applications. In the medical field, regulatory bodies such as the FDA and the European Medicines Agency (EMA) have established guidelines for the use of PLA in implantable medical devices and drug delivery systems. These regulations ensure that PLA-based medical products meet rigorous safety and efficacy standards.

As the chemical structure of PLA continues to evolve for enhanced properties, regulatory frameworks are adapting to keep pace with these advancements. Regulatory bodies are increasingly focusing on the evaluation of modified PLA structures, assessing their safety profiles and potential environmental impacts. This ongoing regulatory scrutiny is essential to ensure that innovations in PLA chemistry align with public health and environmental protection goals.

The global nature of PLA production and trade necessitates harmonization of regulatory standards across different regions. Efforts are underway to develop international standards for PLA, addressing aspects such as biodegradability, compostability, and lifecycle assessment. These initiatives aim to facilitate global trade and ensure consistent quality and safety standards for PLA-based products worldwide.

In the United States, the Food and Drug Administration (FDA) has approved PLA for use in food contact applications, medical devices, and drug delivery systems. The FDA's regulatory oversight ensures that PLA-based products meet stringent safety and quality standards. Similarly, the European Food Safety Authority (EFSA) has evaluated PLA and deemed it safe for food contact materials, subject to specific migration limits and usage conditions.

Environmental regulations have also been instrumental in promoting the adoption of PLA. The European Union's Packaging and Packaging Waste Directive, which sets targets for recycling and recovery of packaging materials, has indirectly boosted the demand for biodegradable alternatives like PLA. In the United States, several states have implemented regulations encouraging the use of compostable plastics, further driving the market for PLA-based products.

The regulatory landscape for PLA extends beyond food and packaging applications. In the medical field, regulatory bodies such as the FDA and the European Medicines Agency (EMA) have established guidelines for the use of PLA in implantable medical devices and drug delivery systems. These regulations ensure that PLA-based medical products meet rigorous safety and efficacy standards.

As the chemical structure of PLA continues to evolve for enhanced properties, regulatory frameworks are adapting to keep pace with these advancements. Regulatory bodies are increasingly focusing on the evaluation of modified PLA structures, assessing their safety profiles and potential environmental impacts. This ongoing regulatory scrutiny is essential to ensure that innovations in PLA chemistry align with public health and environmental protection goals.

The global nature of PLA production and trade necessitates harmonization of regulatory standards across different regions. Efforts are underway to develop international standards for PLA, addressing aspects such as biodegradability, compostability, and lifecycle assessment. These initiatives aim to facilitate global trade and ensure consistent quality and safety standards for PLA-based products worldwide.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!