How to Expand Commercial Use of PLA for Packaging?

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PLA Packaging Evolution

Polylactic acid (PLA) packaging has undergone significant evolution since its introduction in the 1990s. Initially developed as a biodegradable alternative to traditional petroleum-based plastics, PLA has steadily gained traction in the packaging industry due to its environmental benefits and versatile properties.

In the early stages, PLA packaging was primarily used for niche applications, such as disposable cutlery and food containers. The material's limited heat resistance and moisture barrier properties restricted its widespread adoption. However, continuous research and development efforts led to improvements in PLA formulations and processing techniques.

The mid-2000s saw a surge in PLA packaging applications, driven by growing environmental concerns and stricter regulations on single-use plastics. Manufacturers began incorporating PLA into a wider range of packaging products, including bottles, films, and trays. This period also witnessed advancements in PLA blending techniques, which enhanced the material's mechanical properties and expanded its potential uses.

A significant milestone in PLA packaging evolution occurred with the development of high-heat resistant PLA grades in the early 2010s. This breakthrough allowed PLA to compete more effectively with conventional plastics in hot-fill applications and microwave-safe containers. Concurrently, improvements in barrier properties through the use of additives and multi-layer structures broadened PLA's applicability in food packaging.

Recent years have seen a focus on enhancing PLA's end-of-life options. Innovations in composting infrastructure and recycling technologies have improved the material's circularity, addressing concerns about its disposal and environmental impact. Additionally, the integration of nanotechnology and smart packaging concepts has opened up new possibilities for PLA in active and intelligent packaging systems.

The evolution of PLA packaging has also been marked by advancements in production efficiency and cost-effectiveness. Improved polymerization processes and the scaling up of manufacturing capabilities have gradually reduced the price gap between PLA and conventional plastics, making it a more economically viable option for businesses.

As the packaging industry continues to prioritize sustainability, PLA's role is expected to expand further. Ongoing research into bio-based additives, enhanced barrier properties, and advanced processing techniques promises to unlock new applications and markets for PLA packaging, solidifying its position as a key player in the transition towards more environmentally friendly packaging solutions.

In the early stages, PLA packaging was primarily used for niche applications, such as disposable cutlery and food containers. The material's limited heat resistance and moisture barrier properties restricted its widespread adoption. However, continuous research and development efforts led to improvements in PLA formulations and processing techniques.

The mid-2000s saw a surge in PLA packaging applications, driven by growing environmental concerns and stricter regulations on single-use plastics. Manufacturers began incorporating PLA into a wider range of packaging products, including bottles, films, and trays. This period also witnessed advancements in PLA blending techniques, which enhanced the material's mechanical properties and expanded its potential uses.

A significant milestone in PLA packaging evolution occurred with the development of high-heat resistant PLA grades in the early 2010s. This breakthrough allowed PLA to compete more effectively with conventional plastics in hot-fill applications and microwave-safe containers. Concurrently, improvements in barrier properties through the use of additives and multi-layer structures broadened PLA's applicability in food packaging.

Recent years have seen a focus on enhancing PLA's end-of-life options. Innovations in composting infrastructure and recycling technologies have improved the material's circularity, addressing concerns about its disposal and environmental impact. Additionally, the integration of nanotechnology and smart packaging concepts has opened up new possibilities for PLA in active and intelligent packaging systems.

The evolution of PLA packaging has also been marked by advancements in production efficiency and cost-effectiveness. Improved polymerization processes and the scaling up of manufacturing capabilities have gradually reduced the price gap between PLA and conventional plastics, making it a more economically viable option for businesses.

As the packaging industry continues to prioritize sustainability, PLA's role is expected to expand further. Ongoing research into bio-based additives, enhanced barrier properties, and advanced processing techniques promises to unlock new applications and markets for PLA packaging, solidifying its position as a key player in the transition towards more environmentally friendly packaging solutions.

Market Demand Analysis

The market demand for PLA (Polylactic Acid) in packaging applications has been steadily increasing due to growing environmental concerns and regulatory pressures to reduce plastic waste. As consumers become more environmentally conscious, there is a significant shift towards sustainable packaging solutions, driving the demand for biodegradable materials like PLA.

The global PLA market for packaging is experiencing robust growth, with the food and beverage industry being the primary driver. This sector accounts for a substantial portion of the market share, as PLA offers excellent barrier properties and is suitable for food contact applications. The retail and consumer goods sectors are also contributing to the increased demand, particularly in disposable packaging and single-use items.

One of the key factors fueling market growth is the stringent regulations imposed by various governments worldwide to curb plastic pollution. Many countries have implemented bans or restrictions on single-use plastics, creating a favorable environment for PLA adoption. This regulatory landscape is expected to continue driving the market expansion in the coming years.

The packaging industry is witnessing a paradigm shift towards circular economy principles, which aligns well with PLA's biodegradable and compostable properties. This trend is further boosting the demand for PLA in packaging applications, as companies seek to improve their sustainability credentials and meet consumer expectations for eco-friendly products.

Despite the positive market outlook, there are challenges that need to be addressed to fully realize PLA's potential in the packaging sector. The relatively higher cost of PLA compared to conventional plastics remains a barrier to widespread adoption, particularly in price-sensitive markets. Additionally, the limited availability of industrial composting facilities in many regions poses a challenge to the proper disposal and recycling of PLA products.

To overcome these challenges and expand the commercial use of PLA for packaging, several strategies can be employed. Investing in research and development to improve PLA's performance characteristics and reduce production costs is crucial. Collaborations between PLA manufacturers, packaging companies, and end-users can help drive innovation and create tailored solutions for specific packaging needs.

Furthermore, educating consumers about the benefits of PLA and proper disposal methods is essential to create demand and ensure effective end-of-life management. Developing infrastructure for industrial composting and establishing efficient collection systems will also play a vital role in supporting the growth of PLA in the packaging market.

In conclusion, the market demand for PLA in packaging applications is poised for significant growth, driven by environmental concerns, regulatory pressures, and changing consumer preferences. Addressing cost and infrastructure challenges while capitalizing on the material's sustainability benefits will be key to expanding its commercial use in the packaging industry.

The global PLA market for packaging is experiencing robust growth, with the food and beverage industry being the primary driver. This sector accounts for a substantial portion of the market share, as PLA offers excellent barrier properties and is suitable for food contact applications. The retail and consumer goods sectors are also contributing to the increased demand, particularly in disposable packaging and single-use items.

One of the key factors fueling market growth is the stringent regulations imposed by various governments worldwide to curb plastic pollution. Many countries have implemented bans or restrictions on single-use plastics, creating a favorable environment for PLA adoption. This regulatory landscape is expected to continue driving the market expansion in the coming years.

The packaging industry is witnessing a paradigm shift towards circular economy principles, which aligns well with PLA's biodegradable and compostable properties. This trend is further boosting the demand for PLA in packaging applications, as companies seek to improve their sustainability credentials and meet consumer expectations for eco-friendly products.

Despite the positive market outlook, there are challenges that need to be addressed to fully realize PLA's potential in the packaging sector. The relatively higher cost of PLA compared to conventional plastics remains a barrier to widespread adoption, particularly in price-sensitive markets. Additionally, the limited availability of industrial composting facilities in many regions poses a challenge to the proper disposal and recycling of PLA products.

To overcome these challenges and expand the commercial use of PLA for packaging, several strategies can be employed. Investing in research and development to improve PLA's performance characteristics and reduce production costs is crucial. Collaborations between PLA manufacturers, packaging companies, and end-users can help drive innovation and create tailored solutions for specific packaging needs.

Furthermore, educating consumers about the benefits of PLA and proper disposal methods is essential to create demand and ensure effective end-of-life management. Developing infrastructure for industrial composting and establishing efficient collection systems will also play a vital role in supporting the growth of PLA in the packaging market.

In conclusion, the market demand for PLA in packaging applications is poised for significant growth, driven by environmental concerns, regulatory pressures, and changing consumer preferences. Addressing cost and infrastructure challenges while capitalizing on the material's sustainability benefits will be key to expanding its commercial use in the packaging industry.

Technical Challenges

Despite the growing interest in PLA (Polylactic Acid) as a sustainable packaging material, several technical challenges hinder its widespread commercial adoption. One of the primary obstacles is PLA's inherent brittleness, which limits its application in flexible packaging and products requiring high impact resistance. This characteristic makes PLA less suitable for certain types of packaging that need to withstand rough handling or protect delicate contents.

Another significant challenge is PLA's relatively low heat resistance compared to conventional plastics. The material begins to soften at temperatures around 60°C (140°F), which restricts its use in hot-fill applications or products that may be exposed to high temperatures during transportation or storage. This limitation is particularly problematic for food packaging, where heat sterilization is often required.

PLA's moisture sensitivity poses additional challenges for packaging applications. The material tends to absorb moisture from the environment, which can lead to hydrolysis and degradation of its mechanical properties over time. This characteristic affects the shelf life of packaged products and limits PLA's use in high-humidity environments or for moisture-sensitive goods.

The processing of PLA for packaging applications also presents technical hurdles. The material has a narrow processing window, which makes it more challenging to manufacture than traditional plastics. Achieving consistent quality and performance in large-scale production can be difficult, leading to increased production costs and potential quality control issues.

Furthermore, PLA's barrier properties are inferior to those of many conventional packaging plastics. It has relatively high permeability to gases such as oxygen and carbon dioxide, which can affect the shelf life of packaged foods and beverages. This limitation necessitates the development of additional barrier layers or coatings, adding complexity and cost to the packaging production process.

The end-of-life management of PLA packaging also presents technical challenges. While PLA is biodegradable under specific industrial composting conditions, these facilities are not widely available in many regions. Additionally, PLA can contaminate recycling streams for conventional plastics if not properly sorted, potentially compromising the quality of recycled materials.

Addressing these technical challenges requires ongoing research and development efforts. Scientists and engineers are working on improving PLA's properties through various approaches, including blending with other materials, developing new copolymers, and exploring novel processing techniques. Overcoming these hurdles is crucial for expanding the commercial use of PLA in packaging and realizing its potential as a sustainable alternative to conventional plastics.

Another significant challenge is PLA's relatively low heat resistance compared to conventional plastics. The material begins to soften at temperatures around 60°C (140°F), which restricts its use in hot-fill applications or products that may be exposed to high temperatures during transportation or storage. This limitation is particularly problematic for food packaging, where heat sterilization is often required.

PLA's moisture sensitivity poses additional challenges for packaging applications. The material tends to absorb moisture from the environment, which can lead to hydrolysis and degradation of its mechanical properties over time. This characteristic affects the shelf life of packaged products and limits PLA's use in high-humidity environments or for moisture-sensitive goods.

The processing of PLA for packaging applications also presents technical hurdles. The material has a narrow processing window, which makes it more challenging to manufacture than traditional plastics. Achieving consistent quality and performance in large-scale production can be difficult, leading to increased production costs and potential quality control issues.

Furthermore, PLA's barrier properties are inferior to those of many conventional packaging plastics. It has relatively high permeability to gases such as oxygen and carbon dioxide, which can affect the shelf life of packaged foods and beverages. This limitation necessitates the development of additional barrier layers or coatings, adding complexity and cost to the packaging production process.

The end-of-life management of PLA packaging also presents technical challenges. While PLA is biodegradable under specific industrial composting conditions, these facilities are not widely available in many regions. Additionally, PLA can contaminate recycling streams for conventional plastics if not properly sorted, potentially compromising the quality of recycled materials.

Addressing these technical challenges requires ongoing research and development efforts. Scientists and engineers are working on improving PLA's properties through various approaches, including blending with other materials, developing new copolymers, and exploring novel processing techniques. Overcoming these hurdles is crucial for expanding the commercial use of PLA in packaging and realizing its potential as a sustainable alternative to conventional plastics.

Current PLA Solutions

01 Biodegradable packaging applications

PLA is widely used in biodegradable packaging applications due to its environmentally friendly properties. It can be used to produce various packaging materials such as food containers, bottles, and films. The biodegradability of PLA makes it an attractive alternative to traditional petroleum-based plastics in the packaging industry.- Biodegradable packaging materials: PLA is widely used in the production of biodegradable packaging materials, including food containers, bags, and films. Its eco-friendly properties make it an attractive alternative to traditional petroleum-based plastics in various packaging applications.

- 3D printing filaments: PLA is a popular material for 3D printing filaments due to its ease of use, low warping, and ability to produce detailed prints. It is used in both consumer and industrial 3D printing applications for rapid prototyping and small-scale manufacturing.

- Medical and pharmaceutical applications: PLA's biocompatibility and biodegradability make it suitable for various medical applications, including surgical sutures, implants, drug delivery systems, and tissue engineering scaffolds. It is also used in pharmaceutical coatings and controlled-release formulations.

- Textile and fiber production: PLA is used in the production of biodegradable fibers and textiles. It can be spun into fibers for use in clothing, upholstery, and other textile applications, offering an eco-friendly alternative to traditional synthetic fibers.

- Composite materials: PLA is utilized in the development of biocomposites and hybrid materials. It can be combined with natural fibers or other biodegradable materials to create composite materials with enhanced properties for various applications, including automotive parts and construction materials.

02 Medical and pharmaceutical applications

PLA finds extensive use in medical and pharmaceutical applications due to its biocompatibility and biodegradability. It is used in the production of medical implants, drug delivery systems, and tissue engineering scaffolds. PLA-based materials can be designed to degrade at controlled rates, making them suitable for various medical applications.Expand Specific Solutions03 Textile and fiber applications

PLA is used in the textile industry to produce biodegradable fibers and fabrics. These fibers can be used in clothing, upholstery, and other textile applications. PLA fibers offer advantages such as moisture-wicking properties and resistance to UV radiation, making them suitable for various textile products.Expand Specific Solutions04 3D printing and additive manufacturing

PLA is one of the most popular materials used in 3D printing and additive manufacturing. Its low melting point, ease of processing, and dimensional stability make it ideal for creating prototypes, models, and functional parts. PLA filaments are widely used in desktop 3D printers for both hobbyist and industrial applications.Expand Specific Solutions05 Composite materials and blends

PLA is used in the development of composite materials and blends to enhance its properties or create new materials with unique characteristics. It can be combined with other polymers, natural fibers, or inorganic materials to improve mechanical properties, thermal stability, or introduce new functionalities. These composites and blends find applications in various industries, including automotive and construction.Expand Specific Solutions

Key Industry Players

The commercial expansion of PLA for packaging is in a growth phase, with increasing market size driven by sustainability trends. The technology's maturity is advancing, as evidenced by research from institutions like Tongji University, Sichuan University, and the University of Coimbra. Companies such as Stora Enso Oyj, International Paper Co., and Wanhua Chemical Group Co., Ltd. are actively developing PLA applications. The competitive landscape is diverse, with both established players and innovative startups like Floreon Technology Ltd. and Sulapac Oy entering the market. Key challenges include improving PLA's performance characteristics and cost-effectiveness to compete with traditional plastics, areas where companies like Avantium Knowledge Centre BV and Henkel AG & Co. KGaA are focusing their efforts.

International Paper Co.

Technical Solution: International Paper has developed a PLA-coated paperboard technology for sustainable packaging solutions. Their approach combines the renewability of paper with the barrier properties of PLA. The company uses a thin PLA coating on their paperboard products, creating a compostable and recyclable packaging material. This technology is particularly suitable for food packaging, providing grease and moisture resistance while maintaining the biodegradability of the overall product. International Paper has also invested in optimizing the PLA coating process to ensure strong adhesion and uniform coverage.

Strengths: Combines benefits of paper and PLA, compostable and recyclable, suitable for food packaging. Weaknesses: Limited to specific applications, potential for delamination, higher cost compared to traditional coated papers.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical has developed a range of biodegradable PLA-based packaging solutions. Their technology focuses on improving PLA's thermal stability and mechanical properties through copolymerization and blending techniques. They have successfully created PLA compounds with enhanced heat resistance and flexibility, making them suitable for various packaging applications, including food containers, disposable cutlery, and agricultural films. Wanhua's PLA products also incorporate additives to improve processability and extend shelf life.

Strengths: Advanced polymer technology, wide range of applications, improved thermal and mechanical properties. Weaknesses: Higher production costs compared to traditional plastics, limited biodegradability in certain environments.

PLA Innovations

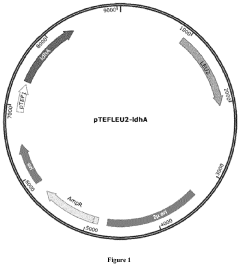

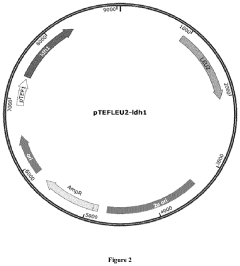

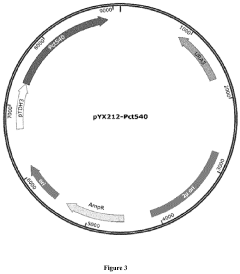

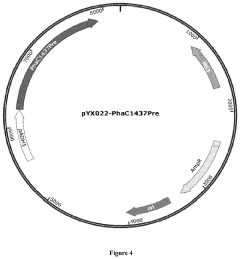

Process for cellular biosynthesis of poly d-lactic acid and poly l-lactic acid

PatentActiveUS20210324429A1

Innovation

- Engineering eukaryotic cells, such as yeast strains, to redirect metabolic pathways for the direct biological synthesis of PLLA and PDLA from carbon sources like glucose, using enzymes like D-lactate dehydrogenase, propionyl-CoA transferase, and polyhydroxyalkanoate synthase to convert pyruvate into lactyl-CoA and subsequently polymerize it into the desired polymers.

A biodegradable biocomposite and a process for its preparation

PatentWO2021028816A1

Innovation

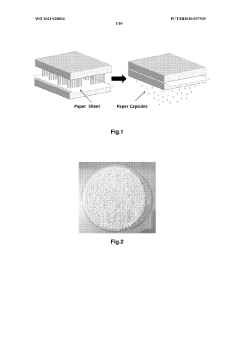

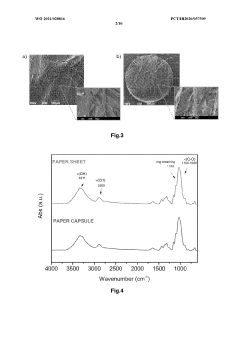

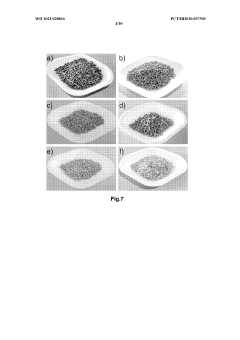

- A continuous and automatable process for producing biodegradable biocomposites using high loadings of compressed or treated paper with biodegradable thermoplastics like PLA, where paper is processed into compact capsules for uniform dispersion and stabilization against thermal and oxidative degradation using eco-friendly additives, allowing for extrusion at temperatures below 180°C to prevent degradation and produce materials with improved mechanical and oxygen-barrier properties.

Environmental Impact

The environmental impact of expanding the commercial use of PLA (Polylactic Acid) for packaging is a critical consideration in the sustainable development of this biodegradable polymer. PLA offers significant advantages over traditional petroleum-based plastics in terms of its environmental footprint. As a bio-based material derived from renewable resources such as corn starch or sugarcane, PLA production consumes less fossil fuel and generates fewer greenhouse gas emissions compared to conventional plastics.

One of the key environmental benefits of PLA is its biodegradability. Under proper composting conditions, PLA can break down into water, carbon dioxide, and biomass within a few months, significantly reducing the long-term environmental impact associated with plastic waste. This characteristic makes PLA an attractive option for single-use packaging applications, potentially mitigating the growing problem of plastic pollution in landfills and oceans.

However, the environmental impact of PLA is not without complexities. The production of PLA requires agricultural inputs, which can lead to land use changes, water consumption, and the use of fertilizers and pesticides. These factors must be carefully managed to ensure that the overall environmental benefit of PLA outweighs its production costs. Additionally, the energy-intensive processes involved in PLA manufacturing currently limit its carbon footprint reduction potential compared to some conventional plastics.

The end-of-life management of PLA packaging also presents challenges. While biodegradable, PLA requires specific industrial composting conditions to break down efficiently. Many regions lack the necessary infrastructure for proper PLA disposal, which can lead to these materials ending up in landfills where they may not degrade as intended. Improving waste management systems and educating consumers about proper disposal methods are crucial steps in maximizing the environmental benefits of PLA packaging.

Expanding the commercial use of PLA for packaging could have positive implications for reducing microplastic pollution. Unlike traditional plastics that persist in the environment and break down into harmful microplastics, PLA's biodegradability offers a potential solution to this growing environmental concern. However, more research is needed to fully understand the long-term impacts of PLA degradation in various environmental conditions.

As the production scale of PLA increases, there is potential for improved efficiency and reduced environmental impact through technological advancements. Innovations in feedstock sourcing, production processes, and end-of-life management could further enhance PLA's environmental profile, making it an increasingly viable alternative to conventional plastics in the packaging industry.

One of the key environmental benefits of PLA is its biodegradability. Under proper composting conditions, PLA can break down into water, carbon dioxide, and biomass within a few months, significantly reducing the long-term environmental impact associated with plastic waste. This characteristic makes PLA an attractive option for single-use packaging applications, potentially mitigating the growing problem of plastic pollution in landfills and oceans.

However, the environmental impact of PLA is not without complexities. The production of PLA requires agricultural inputs, which can lead to land use changes, water consumption, and the use of fertilizers and pesticides. These factors must be carefully managed to ensure that the overall environmental benefit of PLA outweighs its production costs. Additionally, the energy-intensive processes involved in PLA manufacturing currently limit its carbon footprint reduction potential compared to some conventional plastics.

The end-of-life management of PLA packaging also presents challenges. While biodegradable, PLA requires specific industrial composting conditions to break down efficiently. Many regions lack the necessary infrastructure for proper PLA disposal, which can lead to these materials ending up in landfills where they may not degrade as intended. Improving waste management systems and educating consumers about proper disposal methods are crucial steps in maximizing the environmental benefits of PLA packaging.

Expanding the commercial use of PLA for packaging could have positive implications for reducing microplastic pollution. Unlike traditional plastics that persist in the environment and break down into harmful microplastics, PLA's biodegradability offers a potential solution to this growing environmental concern. However, more research is needed to fully understand the long-term impacts of PLA degradation in various environmental conditions.

As the production scale of PLA increases, there is potential for improved efficiency and reduced environmental impact through technological advancements. Innovations in feedstock sourcing, production processes, and end-of-life management could further enhance PLA's environmental profile, making it an increasingly viable alternative to conventional plastics in the packaging industry.

Regulatory Framework

The regulatory framework surrounding the commercial use of PLA (Polylactic Acid) for packaging is a critical factor in its expansion. Governments worldwide are increasingly implementing policies to promote sustainable packaging solutions, which has created a favorable environment for PLA adoption. In the European Union, the Single-Use Plastics Directive has set ambitious targets for reducing plastic waste, indirectly boosting the demand for biodegradable alternatives like PLA.

The United States Food and Drug Administration (FDA) has approved PLA for food contact applications, providing a significant boost to its use in food packaging. This approval has paved the way for wider adoption in the food and beverage industry, a major sector for packaging materials. Similarly, regulatory bodies in other countries, such as Japan's Ministry of Health, Labour and Welfare, have also granted approvals for PLA in food contact materials.

However, the regulatory landscape is not uniform across all regions. Some countries have more stringent requirements for biodegradable plastics, which can pose challenges for PLA manufacturers. For instance, the European Committee for Standardization (CEN) has established specific standards for compostable and biodegradable packaging, which PLA products must meet to be marketed as such in the EU.

Labeling regulations also play a crucial role in PLA's commercial expansion. Clear guidelines on how to label PLA products as biodegradable or compostable are essential to prevent greenwashing and build consumer trust. The Federal Trade Commission in the US has issued Green Guides to help companies make accurate environmental claims, which impacts how PLA packaging can be marketed.

Waste management regulations are another important aspect of the regulatory framework. As PLA requires specific conditions for optimal biodegradation, some jurisdictions are developing regulations to ensure proper disposal and processing of PLA waste. This includes guidelines for industrial composting facilities and the integration of PLA into existing recycling streams.

Tax incentives and subsidies for eco-friendly packaging materials are being implemented in various countries, providing financial motivation for businesses to switch to PLA. These economic policies are crucial in making PLA more competitive with traditional plastics, especially in price-sensitive markets.

As the regulatory landscape continues to evolve, it is likely to further support the expansion of PLA in commercial packaging applications. However, manufacturers and businesses must stay informed about regional variations in regulations and adapt their strategies accordingly to fully capitalize on the growing opportunities in the sustainable packaging market.

The United States Food and Drug Administration (FDA) has approved PLA for food contact applications, providing a significant boost to its use in food packaging. This approval has paved the way for wider adoption in the food and beverage industry, a major sector for packaging materials. Similarly, regulatory bodies in other countries, such as Japan's Ministry of Health, Labour and Welfare, have also granted approvals for PLA in food contact materials.

However, the regulatory landscape is not uniform across all regions. Some countries have more stringent requirements for biodegradable plastics, which can pose challenges for PLA manufacturers. For instance, the European Committee for Standardization (CEN) has established specific standards for compostable and biodegradable packaging, which PLA products must meet to be marketed as such in the EU.

Labeling regulations also play a crucial role in PLA's commercial expansion. Clear guidelines on how to label PLA products as biodegradable or compostable are essential to prevent greenwashing and build consumer trust. The Federal Trade Commission in the US has issued Green Guides to help companies make accurate environmental claims, which impacts how PLA packaging can be marketed.

Waste management regulations are another important aspect of the regulatory framework. As PLA requires specific conditions for optimal biodegradation, some jurisdictions are developing regulations to ensure proper disposal and processing of PLA waste. This includes guidelines for industrial composting facilities and the integration of PLA into existing recycling streams.

Tax incentives and subsidies for eco-friendly packaging materials are being implemented in various countries, providing financial motivation for businesses to switch to PLA. These economic policies are crucial in making PLA more competitive with traditional plastics, especially in price-sensitive markets.

As the regulatory landscape continues to evolve, it is likely to further support the expansion of PLA in commercial packaging applications. However, manufacturers and businesses must stay informed about regional variations in regulations and adapt their strategies accordingly to fully capitalize on the growing opportunities in the sustainable packaging market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!